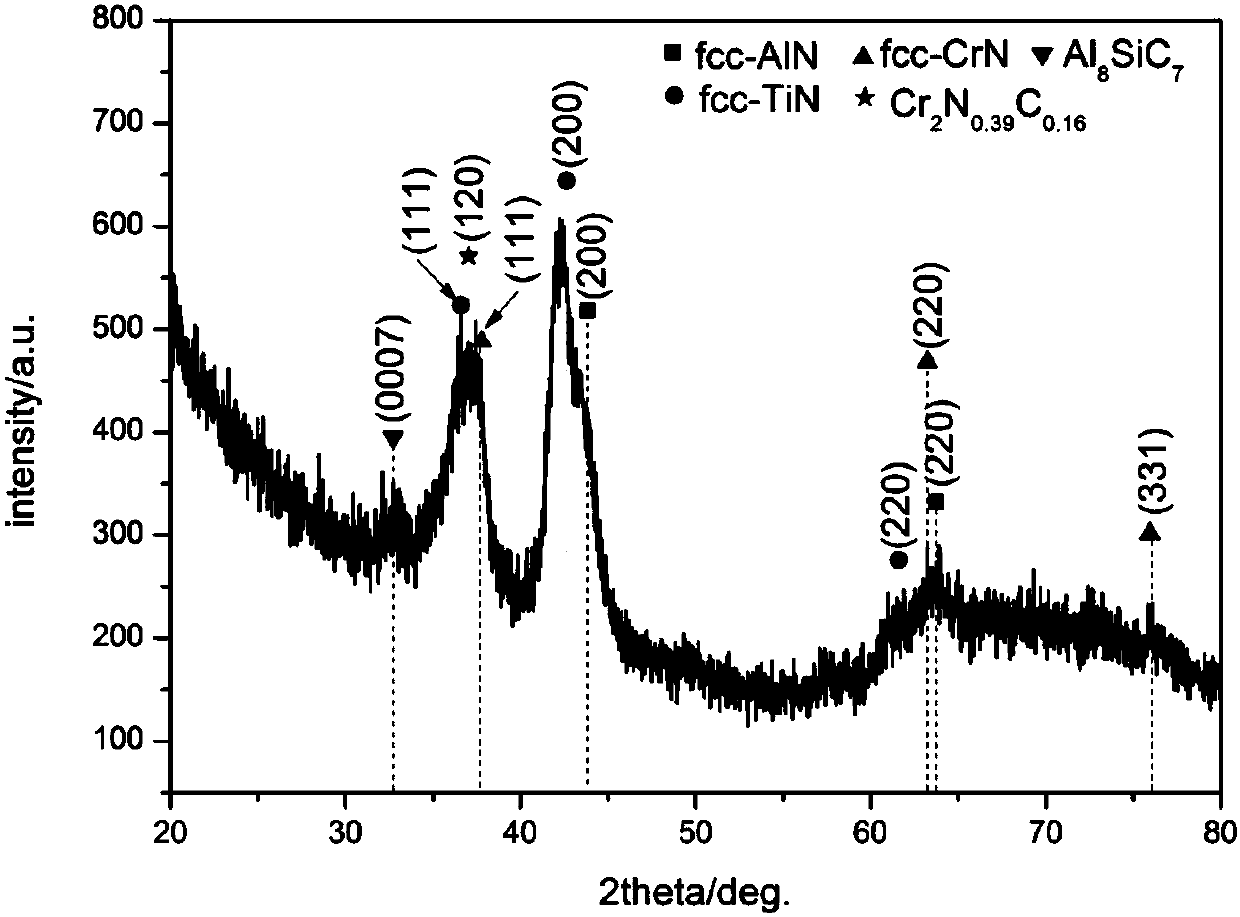

AlCrTiSiCN coating structure and preparing method thereof

A technology of coating and transition layer, which is applied in the direction of coating, metal material coating process, ion implantation plating, etc., can solve the problems of limiting the application of cutting tools, low hardness of TiN coating, and inability to meet cutting conditions, etc., to achieve high Hardness and strength, good wear resistance, high hardness and toughness effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solutions of the present invention will be further described below in conjunction with specific embodiments.

[0024] First, the background vacuum of the vacuum chamber is evacuated to 4.0×10 -3 Pa, and preheated to 500°C, then apply -800V DC bias voltage, flow argon gas into the vacuum chamber with a flow rate of 150 sccm, and perform glow discharge cleaning on the surface of the substrate, keep the working pressure at 2.4Pa, and discharge cleaning for 10 minutes;

[0025] Then lower the argon flow rate to 70sccm, and the working pressure drops to 0.8Pa (because the too high pressure in the transition layer will cause the ions to sputter back, and the ions are not easy to deposit, 0.8pa is the best deposition pressure when depositing the transition layer) , turn on the power of AlCr target and AlTi target at the same time, the target composition Ti30Al70, Cr30Al70 (atomic ratio, that is, the Cr atoms in the AlCr target account for 30%, the Al atoms accoun...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com