Preparation method of gemini hybrid fluorine surfactant applied as shale fracturing fluid cleanup additive

A fluorosurfactant, fracturing fluid technology, applied in the fields of organic chemistry, fracturing and enhanced oil and gas recovery, interfacial chemistry, surface, can solve the problems of poor salt resistance, low surface, interfacial tension, high dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

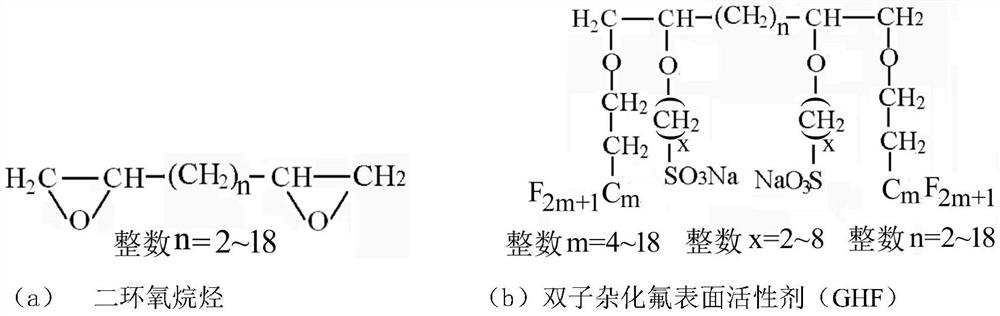

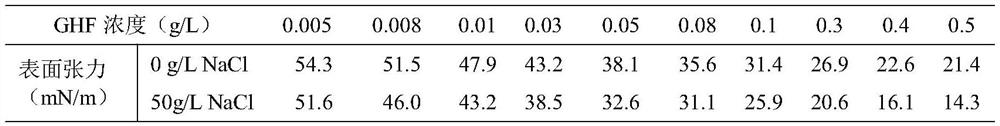

Method used

Image

Examples

Embodiment 1

[0029] Add 10 grams of tetrahydrofuran and 0.846 grams of catalyst sodium to a three-necked reaction flask equipped with a reflux condensing device. Under an ice bath and a nitrogen atmosphere, add a solution containing 30 grams of tetrahydrofuran and 10 grams of 2-perfluorohexyl ethanol drop by drop, and stir the reaction After 4 hours, the temperature was raised to 75°C, and a solution containing 20 grams of 1,4-dioxane and 2.360 grams of 1,2,7,8-dioxoctane was slowly added dropwise, reacted for 28 hours, and then the solution containing A solution of 25 grams of tetrahydrofuran and 4.452 grams of sodium 2-chloroethylsulfonate was gradually added dropwise into a three-necked reaction flask, and the reaction was continued for 60 hours, maintaining the reaction temperature within the range of 70°C. The solvent was distilled off from the reaction product under reduced pressure to obtain a crude product, which was then separated by silica gel column chromatography to obtain a gem...

Embodiment 2

[0031] Add 20 grams of tetrahydrofuran and 1.520 grams of catalyst sodium hydride into a three-necked reaction flask equipped with a reflux condensing device, and add 40 grams of N,N-dimethylformamide and 2-perfluoro A solution of 10 grams of dodecyl ethanol was stirred and reacted for 4 hours, then the temperature was raised to 75°C, and a solution containing 30 grams of tetrahydrofuran and 4.728 grams of 1,2,9,10-dioxidecane was slowly added dropwise, and the reaction was continued for 28 hours , and then gradually add a solution containing 40 grams of N,N-dimethylformamide and 6.904 grams of sodium 4-bromobutylsulfonate into the three-necked reaction flask, and continue to react for 60 hours, maintaining the reaction temperature in the range of 70 °C Inside. The solvent was distilled off from the reaction product under reduced pressure to obtain a crude product, which was then separated by silica gel column chromatography to obtain a gemini hybrid fluorosurfactant with a yi...

Embodiment 3

[0033] Add 20 grams of tetrahydrofuran, 20 grams of ethyl acetate, and 4.038 grams of catalyst potassium hydride into a three-necked reaction flask equipped with a reflux condensing device. gram, 20 grams of chloroform and 10 grams of 2-perfluorooctadecyl ethanol, stirred and reacted for 4 hours, then heated to 80 ° C, slowly added dropwise containing 50 grams of tetrahydrofuran and 6.830 grams of 1,2,15,16 -The solution of diepoxyhexadecane was reacted for 32 hours, and then the solution containing 80 grams of N,N-dimethylformamide and 10.629 grams of 6-iodohexylsulfonate was gradually added dropwise to the three-necked reaction flask, The reaction was continued for 64 hours, maintaining the reaction temperature within the range of 80°C. The solvent was distilled off from the reaction product under reduced pressure to obtain a crude product, which was then separated by silica gel column chromatography to obtain a gemini hybrid fluorosurfactant with a yield of 84%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| critical temperature | aaaaa | aaaaa |

| critical pressure | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com