Patents

Literature

146 results about "Potassium hydride" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Potassium hydride, KH, is the inorganic compound of potassium and hydrogen. It is an alkali metal hydride. It is a white solid, although commercial samples appear gray. A powerful base that is useful in organic synthesis, it is also a dangerously reactive compound. For this reason it is sold commercially as a slurry (~35%) in mineral oil or sometimes paraffin wax to facilitate dispensing.

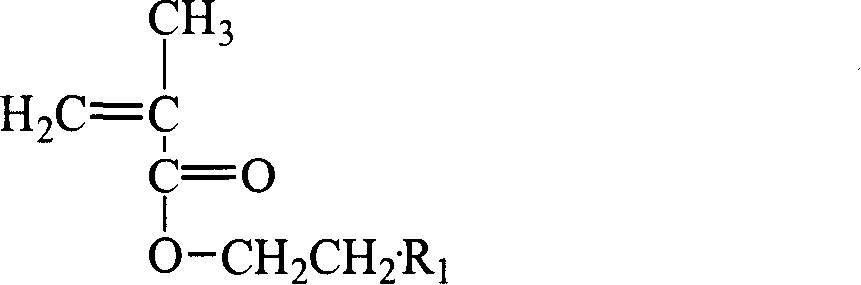

Amphipathic three block copolymer and its preparation method and application

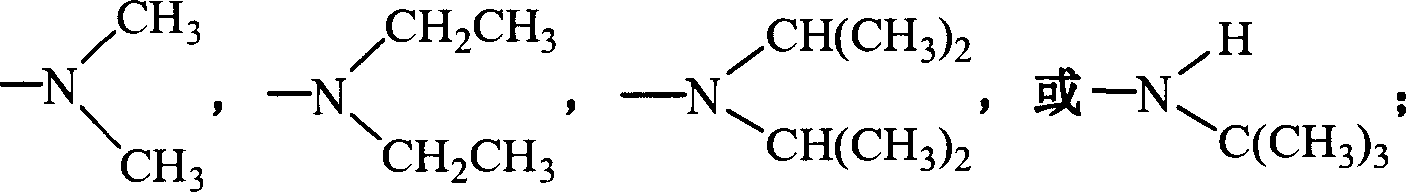

InactiveCN101265312AEvade captureAvoid the effect of adsorptionPharmaceutical non-active ingredientsPolyesterPolymer science

The invention relates to a polyethylene glycol / aliphatic polyester / cationic polymer amphiphilic triblock copolymer. The copolymer contains a hydrophilic non-ionic polymer block, a hydrophobic block and a pH-sensitive cationic polymer block. Potassium hydride is taken as an initiator, the polyethylene glycol and the aliphatic polyester monomers and the cationic monomer are sequentially added in a polymerization reactor for respective reaction, methanol is added for terminating the reaction; n-hexane is used for the precipitation and the purification of the triblock copolymer in tetrahydrofuran, the precipitation is repeated for 3 times, and a product undergoes the vacuum drying. The copolymer can form a micelle or a nanoparticle by self-assembly in a water medium, wherein, a core of a loading hydrophobic drug is formed by clustering the hydrophobic cationic polyester block, the polyethylene glycol block is assembled into a hydrophilic shell, thus having the functions of stabilizing the micelle and effectively avoiding the capture and protein absorption of a reticuloendothelial system of an organism; the cationic polymer block can be further acted with DNA, protein, peptide and other biological macromolecules, thus forming the biodegradable and pH-sensitive drug-loading polymer micelle or the nanoparticle which can be further dispersed,.

Owner:TIANJIN UNIV

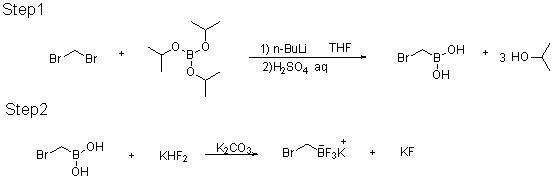

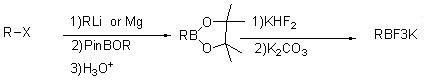

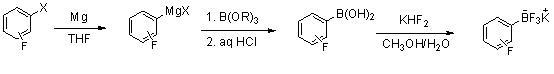

Method for preparing potassium trifluoroborate series compounds

InactiveCN102060867ASolve corrosiveAvoid affecting yieldGroup 3/13 element organic compoundsOrganic baseBoronic acid

The invention relates to synthesis of organic compounds, and provides a method for preparing potassium trifluoroborate series compounds. The method comprises the following steps of: adding organic boric acid or organic borate and solvent (THF (tetrahydrofuran), or MTBE (Methyl Tertiary Butyl Ether), or ethyl acetate, or methanol) into a reaction kettle lined with tetrafluoroethylene plastic at room temperature; adding potassium bifluoride and water at normal temperature, stirring for 1 to 12 hours, and reacting to prepare a solid-liquid mixture; adding solid potassium ion containing inorganic or organic alkali into the solid-liquid mixture after the reaction is completed, neutralizing until the pH is between 7 and 9, and continuously stirring for 1 to 5 hours; directly filtering to obtain a solid coarse product after stirring is completed; dissolving the coarse product with solvent, filtering and concentrating, adding nonpolar solvent, and pulping to obtain high-quality RBF3K series compounds. The method is easy to operate, has mild reaction conditions, and can realize scale-up production; and the product prepared by the method has high yield and excellent purity, and the cost is greatly reduced.

Owner:大连联化医药技术有限公司

P-aramid nanofiber solution and preparation method thereof

The invention relates to a novel method for preparing a p-aramid nanofiber solution, belongs to the field of macromolecules and also belongs to the field of nano-materials. According to the solution, p-aramid nanofibers have the diameter of 20-50nm and the length of about 10 microns. The method comprises the steps: purging a dry three-mouthed bottle with nitrogen gas for 10 minutes under the protection of nitrogen gas, adding a deprotonation reagent (sodium hydride or potassium hydride or lithium hydride) and anhydrous dimethyl sulfoxide under the protection of nitrogen gas, mechanically stirring, heating to the temperature of 70 DEG C within 20 minutes, continuously reacting for 40 minutes, and then, cooling to the temperature of 30 DEG C; and then, slowly adding poly-p-phenylene terephthalamide staple fibers, and reacting for 6-72 hours at the temperature of 30 DEG C, thereby obtaining an orange-red solution containing the p-aramid nanofibers, wherein the weight percent of the p-aramid nanofibers is 0.05-3.6%. The method disclosed by the invention is simple and is strong in operability, and a feasible method is provided for the low-cost and large-scale preparation of p-aramid nanofiber materials.

Owner:LUDONG UNIVERSITY

Aqueous phase preparation method of ZnSe/ZnS core-shell structure quantum dots

The invention discloses an aqueous phase preparation method of ZnSe / ZnS core-shell structure quantum dots. The aqueous phase preparation method comprises the following steps of: A, preparing KH4Te solution, namely preparing by reducing tellurium powder with sodium borohydride; B, respectively weighing potassium borohydride and selenium powder and adding into a test tube with a stopper, adding high purity water into the test tube, and plugging the stopper to obtain colorless and transparent liquid, namely selenium potassium hydride; C, weighing zinc acetate crystals and reduced glutathione respectively, and dissolving in anaerobic high purity water; D, adding the selenium potassium hydride under the condition of stirring at the speed of 150 to 300 revolutions / min and continuously introducing high purity argon, adjusting a pH value of the solution by using sodium hydroxide solution, and mixing; and E, packaging in a polytetrafluoroethylene digestion tank, and performing microwave heating, wherein a molar ratio of KH4Se to Zn(Ac)2.2H2O to the reduced glutathione is (1 / 15-1 / 10):1:(1.6-1.8). The preparation process of the quantum dots is easy, and is high in biocompatibility and fluorescent quantum yield, heavy metal ion toxicity is avoided, fluorescence labeling can be performed on organisms without the aftertreatment process, and process parameters are easy to control.

Owner:WUHAN UNIV

Preparation method of ZnSe/ZnS core-shell quantum dots

InactiveCN102517025AOvercoming complexityOvercome operabilityLuminescent compositionsPotassium borohydrideUltraviolet lights

The invention discloses a preparation method of ZnSe / ZnS core-shell quantum dots through illumination assisted room-temperature synthesis. The method comprises the steps of: A. preparing a potassium hydrogen selenide solution by reducing selenium powder with potassium borohydride; B. weighing zinc acetate crystals, which is then dissolved in deionized water to a constant volume, thus obtaining a zinc acetate solution; C. adding quantitative thioglycolic acid into the zinc acetate solution; D. adjusting the solution to a specific pH value with a sodium hydroxide solution; E. after introducing an inert gas for deoxygenation, adding the potassium hydrogen selenide solution; F. placing the stock solution or a diluted solution of the mixed solution under an ultraviolet light for radiation for a certain period of time, and conducting detection with fluorescence spectrum analysis; and G. adding isopropyl alcohol for purification, then carrying out drying by a freeze drier so as to obtain ZnSe / ZnS core-shell quantum dot solid powder, which is dissolved in a PBS solution or deionized water before using, thus obtaining a ZnSe / ZnS core-shell quantum dot solution. The method of the invention has the advantages of simple process, easily controllable technological parameters, as well as cheap raw materials. The synthesized ZnSe / ZnS core-shell quantum dots are free of heavy metal ions, and can be used for biological labeling and imaging.

Owner:WUHAN UNIV

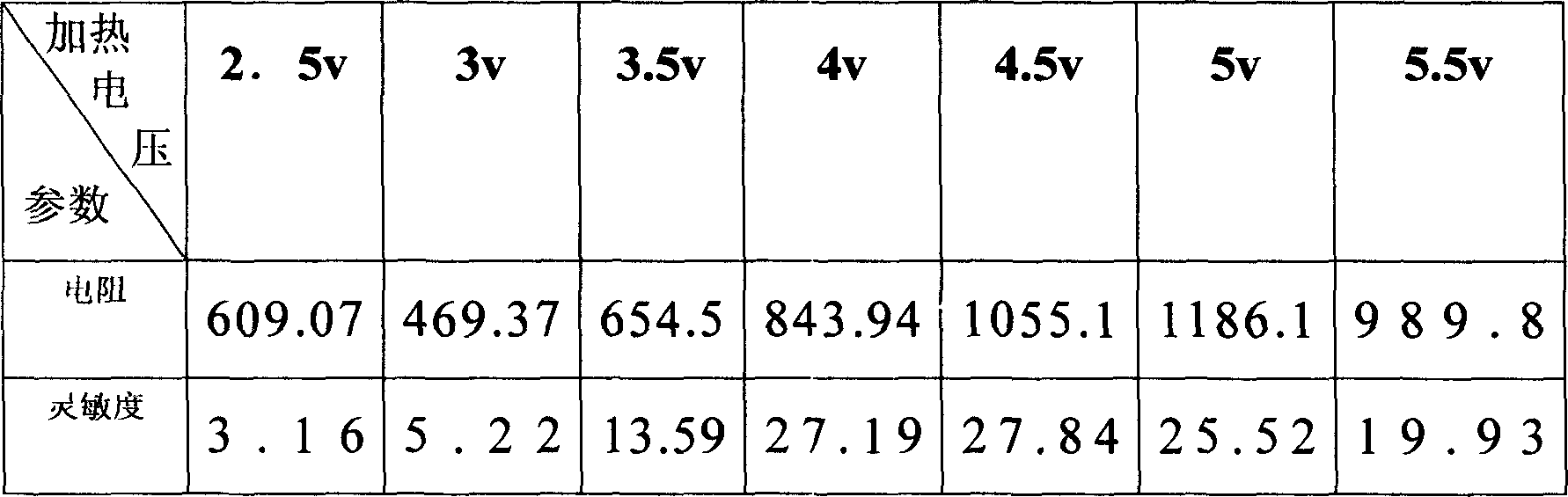

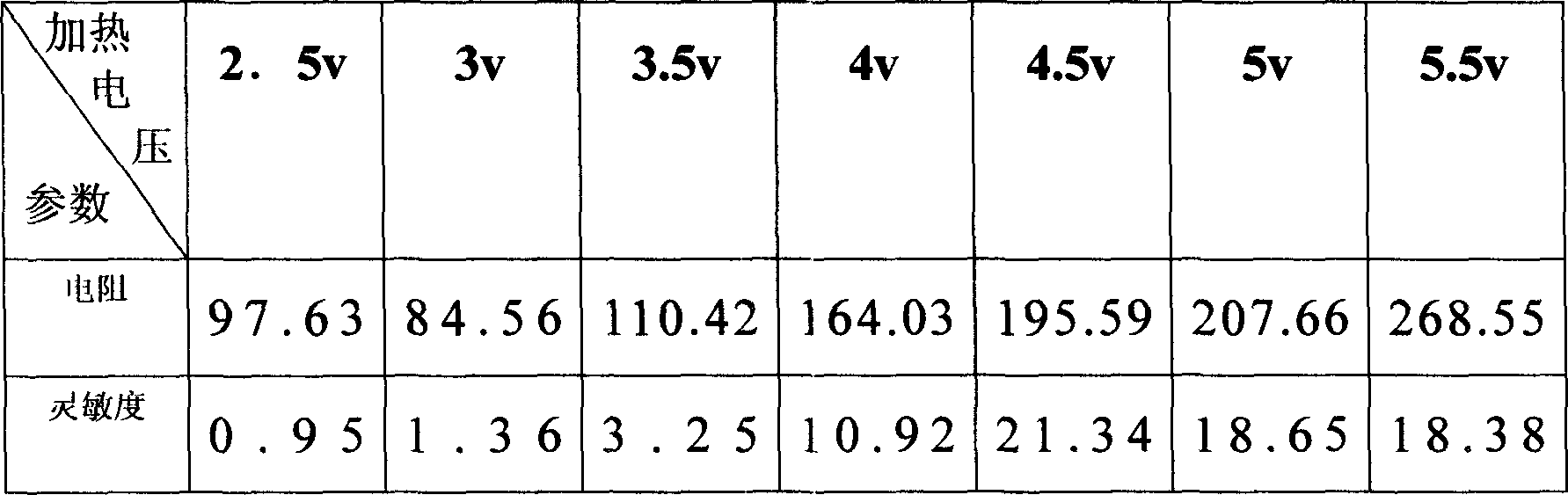

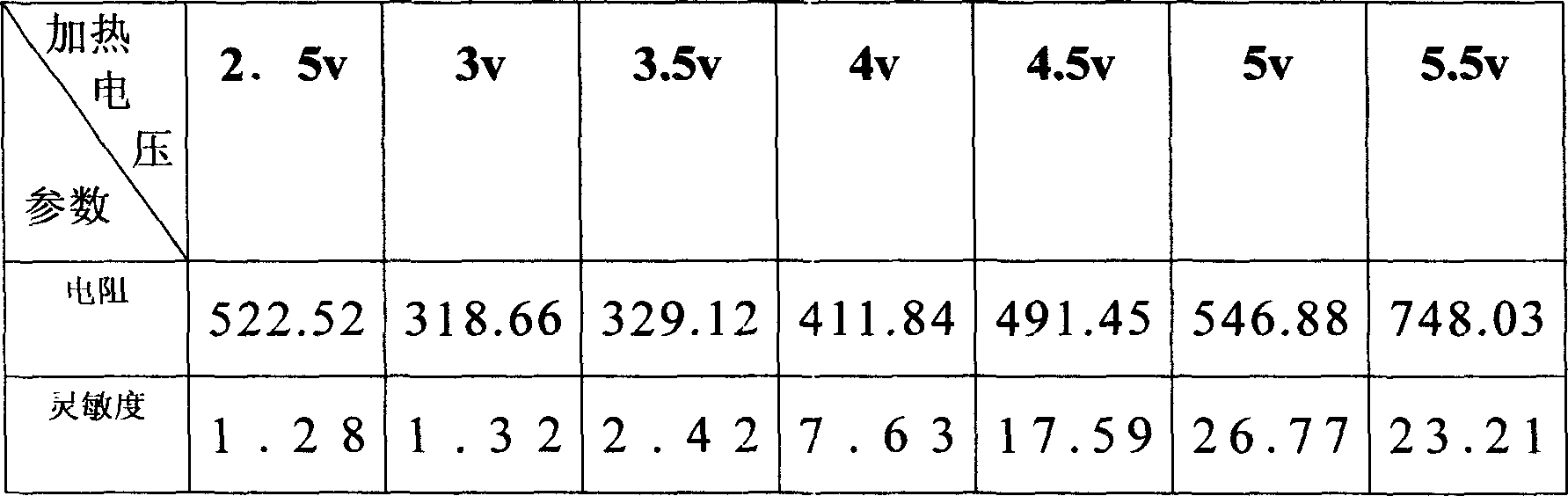

Tin dioxide based nano gas sensitive material and preparation method thereof

InactiveCN1769881AImprove adsorption capacityHigh sensitivityMaterial electrochemical variablesElemental selenium/telluriumTin dioxidePotassium borohydride

The invention relates to a stannic oxide (SnO2) base nano air-sensitive material and method for making the same which comprises steps of: calculating and getting stannous chloride as mole ratio, proportioning with sodium dodecylbenzene sulfonate, potassium borohydride, antimony oxide and ethyl silicate; grinding, drying, prefiring to get stannic oxide nano powder; according to the mole proportion, doping carbon nano tube with the produced stannic oxide nano powder. The inventive method has the advantages of being lower cost than doping noble metallic elements in the stannic oxide (SnO2) base nano air-sensitive material, and of having high sensitivity.

Owner:GUANGZHOU UNIVERSITY

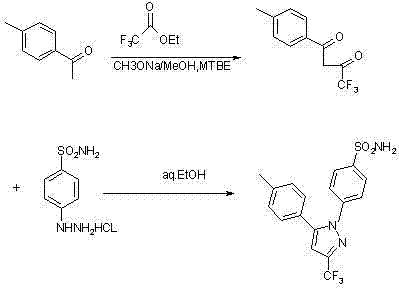

Synthesis method of celecoxib

InactiveCN102391184AHigh purityHigh yieldOrganic chemistryPhenylhydrazine hydrochlorideClaisen condensation

The invention relates to a synthesis method of celecoxib, which comprises the following specific steps of: 1, carrying out claisen condensation on p-methylacetophenone and trifluoroacetic acid ethyl esters in an aprotic organic solvent under the catalysis of alkali to obtain 1-(4-methylphenyl)-4,4,4-trifluoro-1,3-butanedione; and 2, reacting the obtained 1-(4-methylphenyl)-4,4,4-trifluoro-1,3-butanedione with sulfonamide-phenylhydrazine hydrochloride to obtain celecoxib, wherein in the step 1, the alkali for catalysis is selected from one or more of sodium hydride, potassium hydride, lithium hydride and calcium hydride. The synthesis method of celecoxib provided by the invention is easy to operate, high in yield, high in product purity and easy for industrial production.

Owner:JIANGXI SYNERGY PHARMA

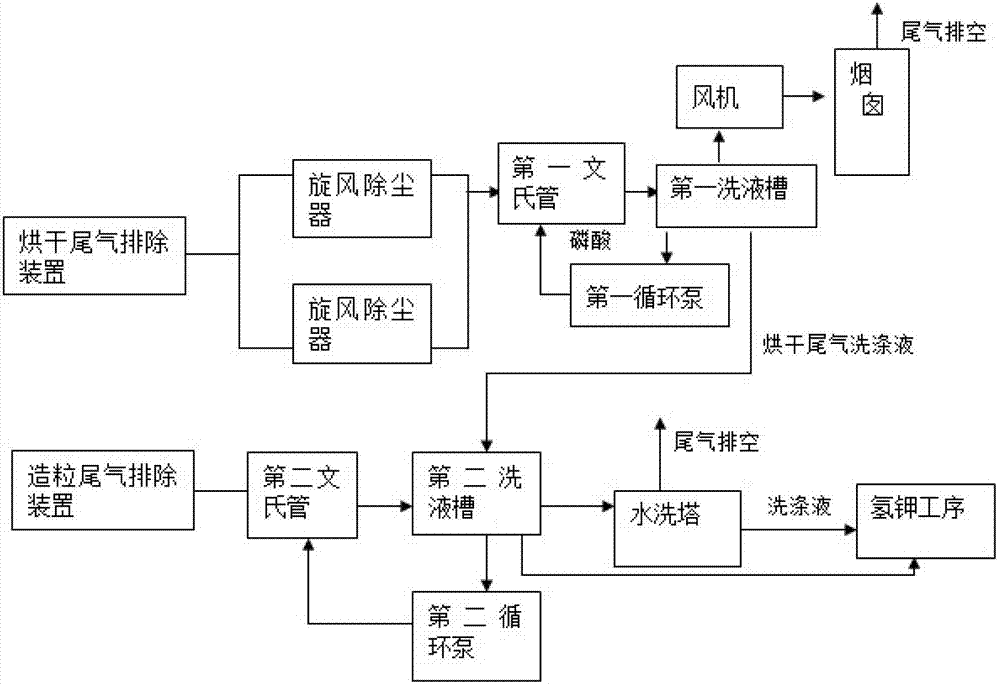

Treatment method and treatment system for ammoniated pelleting compound fertilizer tail gas

InactiveCN102886196AGuaranteed washing effectReduce complaintsDispersed particle separationAir quality improvementSocial benefitsHydrogen

The invention discloses a treatment method and a treatment system for ammoniated pelleting compound fertilizer tail gas. The tail gas treatment method provided by the invention comprises the following steps of: simultaneously adding phosphoric acid and tail gas in a drying working section to a venturi tube; using phosphoric acid to wash ammonia in the tail gas; emptying the tail gas, and punching washing liquid into a pelleting working section, so as to react with pelleting tail gas in a pelleting working section venturi tube; performing secondary water washing due to high ammonia content in the pelleting tail gas; emptying the tail gas after ammonia content of the tail gas is qualified; and punching the washing liquid into a potassium hydride process to reuse. The tail gas treatment system provided by the invention comprises a drying tail gas working section and a pelleting tail gas working section. Ammonia discharge amount of the tail gas is reduced to be 20 kg per hour from 50-60 kg per hour, thereby being greatly lower than a national emission standard; the ammoniated pelleting compound fertilizer tail gas is discharged after reaching the standard, thereby reducing complaints from surrounding residents and creating a good social benefit; absorbed ammonia can be recycled, so that ammonia consumption is reduced, and production is more stable; the washing liquid is recycled without waste liquid, and is economical and practicable.

Owner:山东聊城鲁西化工第五化肥有限公司

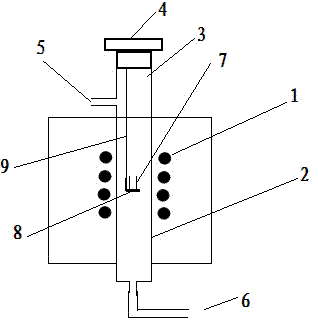

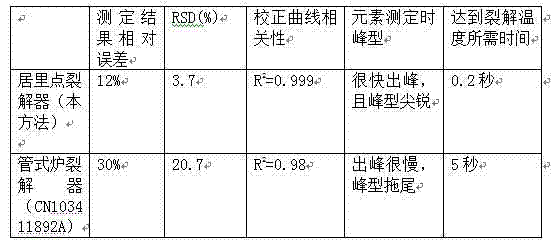

Elemental analysis determination method and device

InactiveCN103792223AReduce distractionsSlow heating ratePreparing sample for investigationAnalysis by thermal excitationSodium hydrosulfideElemental analysis

The invention discloses an elemental analysis determination method and device. The elemental analysis determination method comprises the following steps: adding an inorganic compound capable of releasing hydrogen in pyrolysis into a to-be-detected sample and mixing the inorganic compound with the sample uniformly; carrying out pyrolysis on the mixture at a certain temperature, enabling an element to form a volatile matter, and determining the volatile matter by an atom spectrogram, wherein the inorganic compound for releasing hydrogen in pyrolysis is sodium bisulfide, potassium hydrogen sulfide, ammonium sulfide, ammonia hydrogen sulfide, ammonium iodide, hydrogen sulfide or hydrogen iodide, and the weight of the added inorganic compound is 0.2-100 times the weight of the sample. According to the invention, an inorganic hydrogen release reagent and a curie point pyrolyser are used, and the advantages of low analysis cost, less interference, high element volatile matter formation speed, high sampling efficiency of to-be-detected elements and the like are realized, and the method is a rapid and accurate analysis method.

Owner:TIANJIN NORMAL UNIVERSITY

Water-retaining agent improving alfalfa drought tolerance and preparation method thereof

ActiveCN105036965AImprove breathabilityIncrease productionFertilizer mixturesPotassium borohydrideSludge

The invention discloses a water-retaining agent improving alfalfa drought tolerance and a preparation method thereof. The water-retaining agent comprises, by weight, 60-80 parts of starch-grafting acrylate particles, 20-30 parts of organic fertilizer particles, 5-10 parts of soil ameliorant particles and 15-20 parts of ceramsite. The organic fertilizer particles comprise 100-150 parts of livestock excrement, 30-50 parts of humic acid, 20-40 parts of straw, 40-60 parts of bagasse, 10-20 parts of peanut meal, 5-10 parts of sawdust and 5-10 parts of fishbone powder. The soil ameliorant particles comprise 0.25-0.3 part of ammonium molybdate, 0.1-0.2 part of potassium borohydride, 0.05-0.08 part of boronic acid, 0.05-0.08 part of borax, 0.1-0.2 part of ferrous sulfate, 0.3-0.4 part of ammonium ferrous sulfate, 1-2 parts of zinc sulfate, 0.05-0.1 part of manganese sulfate, 0.2-0.3 part of monopotassium phosphate, 0.2-0.4 part of sodium selenate and 5-8 parts of photosynthetic bacterium inoculants. The ceramsite is obtained by mixing and forging attapulgite, biological sludge, vermiculite powder and river bottom mud.

Owner:INST OF ANIMAL SCI OF CHINESE ACAD OF AGRI SCI

Method for microwave-assisted preparation of CdTeSeS/ZnTe core-shell quantum dot in water

InactiveCN104974742ARich sourcesLower synthesis costLuminescent compositionsQuantum yieldPotassium borohydride

The invention relates to a method for microwave-assisted preparation of a CdTeSeS / ZnTe core-shell quantum dot in water. The method comprises the following steps: 1) preparing a sodium elenosulfate solution; 2) preparing a cadmium chloride solution; 3) adding mercaptopropionic acid into the cadmium chloride solution; 4) adjusting the pH value of the solution; 5) dissolving a sodium tellurite crystal in the solution and simultaneously adding potassium borohydride and the sodium elenosulfate solution; 6) subjecting a mixture obtained in the step 6) to heating reaction in a microwave digestion furnace; 7) carrying out cooling to room temperature and adding isopropanol for purification so as to obtain CdTeSeS quantum dot gel; and 8) preparing a mixed solution of the cadmium chloride solution, the mercaptopropionic acid and the sodium tellurite crystal, dissolving the CdTeSeS quantum dot gel in the mixed solution anew, adding potassium borohydride and successively carrying out heating reaction in the microwave digestion furnace, cooling to room temperature, addition of isopropanol for purification and drying with a lyophilizer so as to obtain solid powder of the CdTeSeS / ZnTe core-shell quantum dot. The method is fast and simple and has easily controllable technological parameters and a low price; and the synthesized quantum dot has uniform particle size distribution, high stability, high fluorescence quantum yield and wide emission spectrum.

Owner:天门市天宝化工科技有限公司

Packing Material for a Micro-Adsorption Column for Drying and/or Purification of Dissolved Organic or Biological Analytes and Micro-Adsorption Column and use thereof

InactiveUS20100258494A1Rapid and efficient separationQuick analysisComponent separationOther chemical processesSodium BentonitePack material

The invention relates to a packing material for a micro-adsorption column for drying and / or purification of dissolved organic or biological analytes, such as toxins, antibiotics, vitamins, hormones, pesticides and similar, containing at least one drying agent which contains magnesium sulphate and at least one further drying agent selected from the group comprising aluminium oxide, calcium chloride, calcium hydride, calcium oxide, calcium sulphate, potassium hydride, silica gel, copper sulphate, magnesium oxide, magnesium perchlorate, molecular sieves, sodium hydroxide, phosphorus pentoxide, sulphuric acid on silica, phosphorus pentoxide on silica and 0.5 to 90 wt. % of a naturally-occurring or synthetic support with large internal surface such as zeolite, diatomic earths, bentonite, silicon dioxide or similar. The invention further relates to a micro-adsorption column packed with the above and use thereof.

Owner:ERBER AG

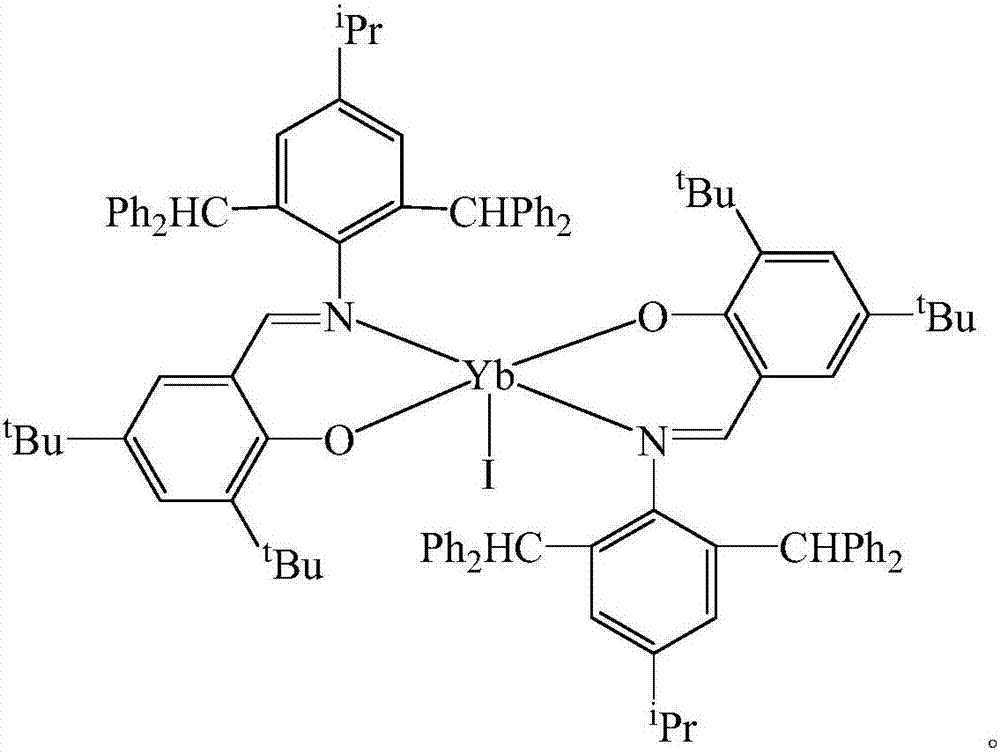

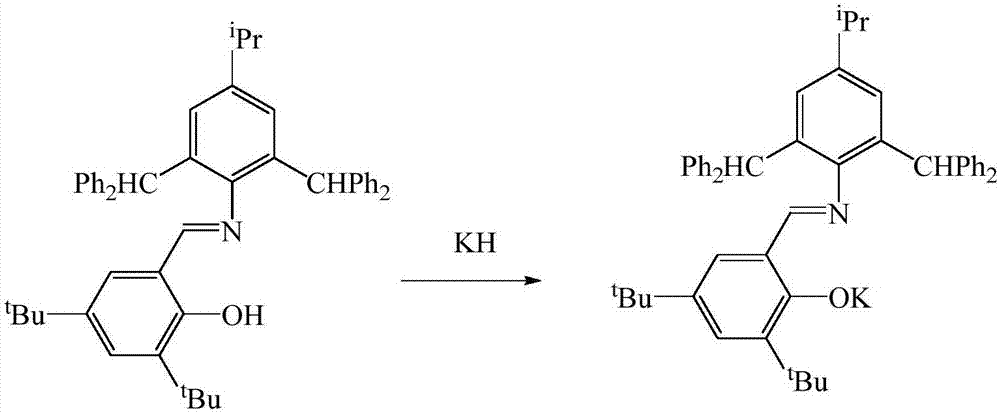

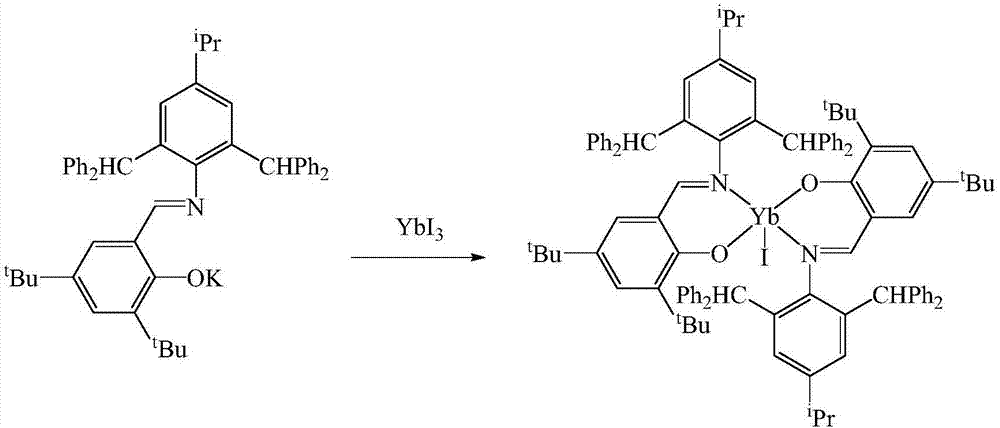

Schiff base rare earth ytterbium iodide, and preparation method and application thereof

InactiveCN107501309AEasy to purifyLow toxicityCarboxylic acid nitrile preparationOrganic compound preparationIodideRare earth

The invention discloses Schiff base rare earth ytterbium iodide, and a preparation method and the application thereof. The Schiff base rare earth ytterbium iodide is N-(4-isopropyl-2,6-di(diphenylmethyl)phenyl)-3,5-ditert-butyl-2-oxygen Schiff base rare earth ytterbium iodide. The preparation method comprises the following steps: performing reaction on N-(4-isopropyl-2,6-di(diphenylmethyl)phenyl)-3,5-ditert-butyl-2-hydroxybenzaldimine and potassium hydride to obtain corresponding potassium salt under the conditions of no water and no oxygen, and performing reaction on the potassium salt and ytterbium iodide to obtain a yellow crystal, namely the N-(4-isopropyl-2,6-di(diphenylmethyl)phenyl)-3,5-ditert-butyl-2-oxygen Schiff base rare earth ytterbium iodide. The Schiff base rare earth ytterbium iodide is simple in synthesis, convenient in separation and purification, definite in structure and high in yield; the Schiff base rare earth ytterbium iodide serving as a catalyst has high activity of catalyzing reaction of aldehyde or ketone and pinacolborane and wide substrate universality.

Owner:NANJING FORESTRY UNIV +1

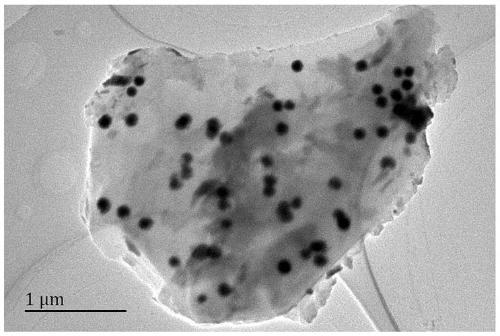

Fluorine-containing superbranching-grafting block polymer and its preparation

InactiveCN1911978AIncrease temperatureImproved pH Dual Response PerformanceMethacrylatePolymer science

The present invention relates to one kind of fluoric super branched-grafted block polymer, and features that the polymer has core-arm structure comprising core of super branched poly(3-ethyl-3-methyol trimethylene oxide) and arm of alkyl substituted amino methacrylate and fluoric methacrylate block polymerized structure. The fluoric super branched-grafted block polymer is prepared through an oxygen ion initiated polymerization process. The fluoric amphiphilic super branched copolymer of the present invention has double temperature and pH responding performance and lowered surface energy, and the preparation process has fast reaction speed, high conversion rate and high product purity.

Owner:SUZHOU UNIV

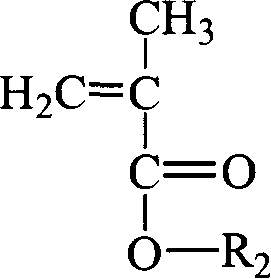

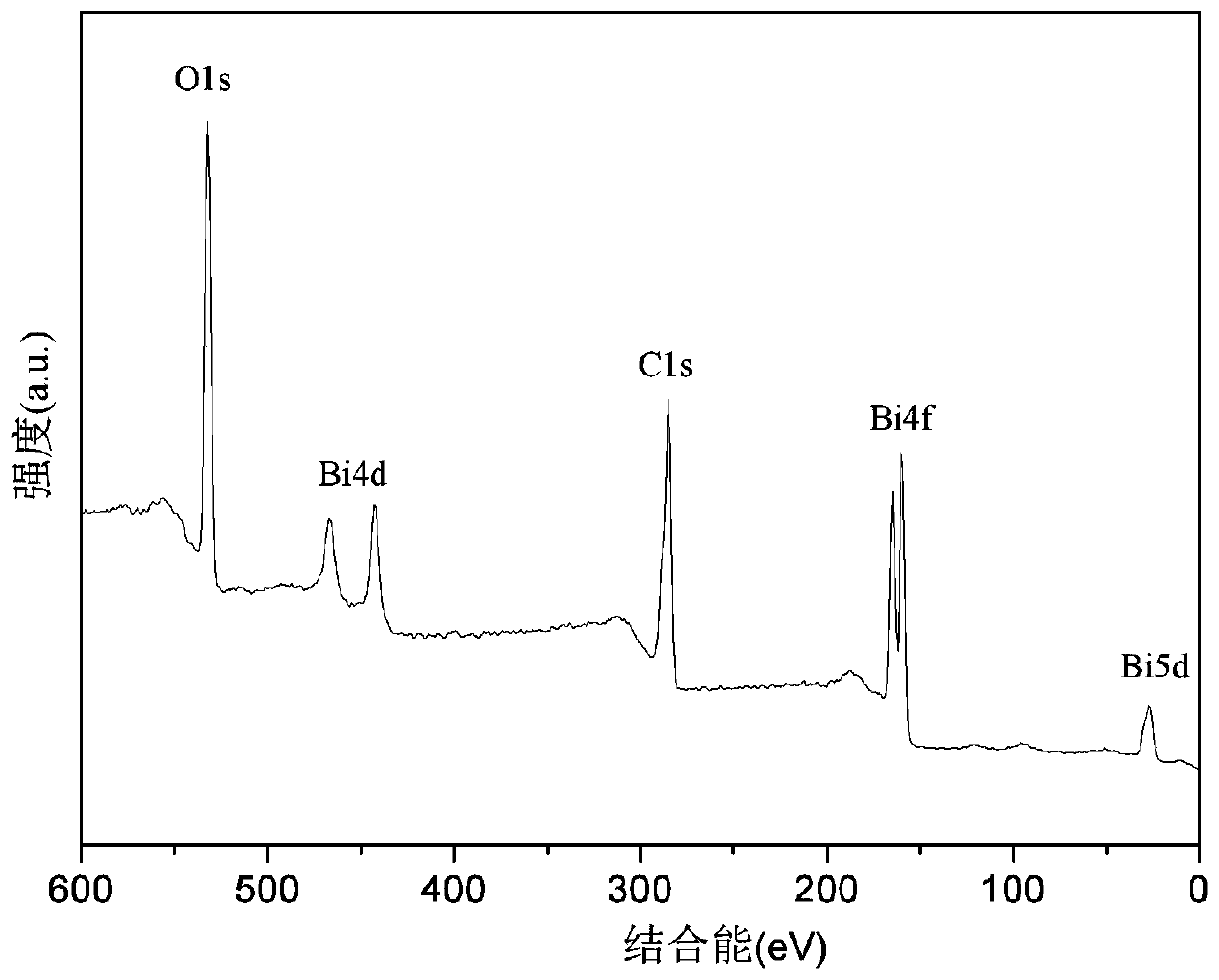

Carbon-loaded nano bismuth composite material, preparation method and application thereof

ActiveCN111330565AGood dispersionHigh catalytic activityOrganic compound preparationCatalyst activation/preparationPotassium borohydrideNitrobenzene

The invention discloses a carbon-loaded nano bismuth composite material, a preparation method and application thereof. The method comprises the following steps: mixing metered citric acid, bismuth nitrate pentahydrate, tartaric acid and water, uniformly stirring, transferring the obtained mixed solution into a hydrothermal kettle, putting the hydrothermal kettle into a drying oven, controlling thereaction temperature to be 150-220 DEG C and the reaction time to be 4-12 hours, naturally cooling the hydrothermal kettle, taking out the content in the hydrothermal kettle, washing with water, anddrying to obtain the carbon-loaded nano bismuth material, wherein the mass ratio of the citric acid to the bismuth nitrate pentahydrate to the tartaric acid to the water is 1:(0.02-0.1):(0.1-1):(2-10). According to the method, the technological process is simplified, the production cost is reduced, the nano bismuth particles in the prepared composite material are uniformly dispersed, potassium borohydride can be effectively catalyzed to reduce p-nitrophenol, and the composite material has high catalytic activity and good repeatability and has potential utilization value in the aspect of sewagetreatment.

Owner:XUZHOU UNIV OF TECH

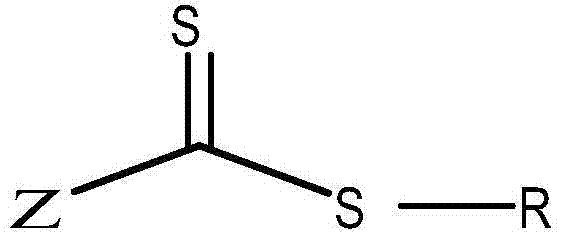

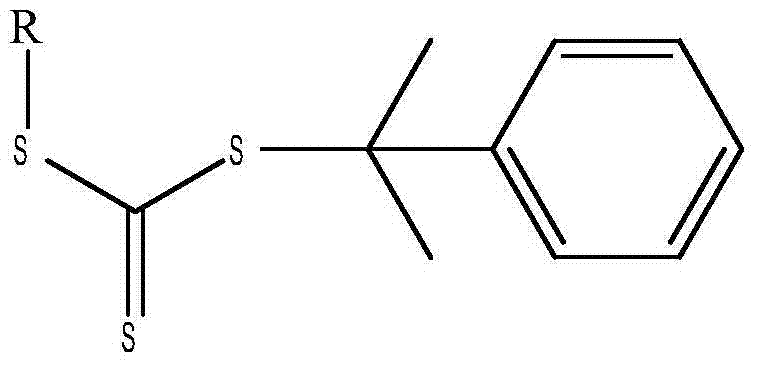

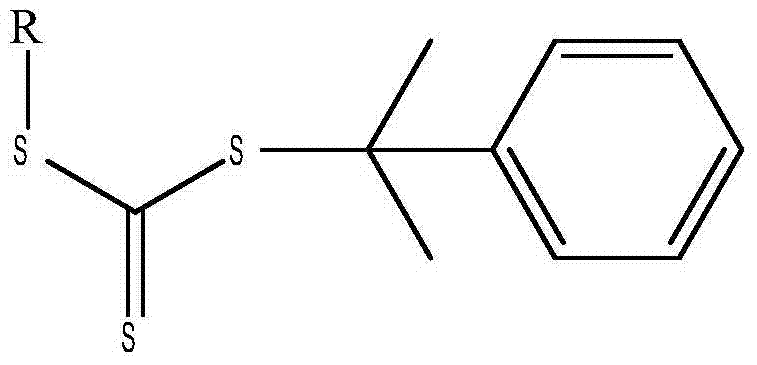

A reversible addition-fragmentation chain transfer agent, and preparation and applications thereof

ActiveCN104513326AImprove activation abilityStrong ability to leaveOrganic chemistry2-phenylpropaneTrithiocarbonic acid

The invention relates to preparation of a reversible addition-fragmentation chain transfer agent, and applications of the agent. The agent is cumyl alkyltrithiocarbonate having the following structure shown in the specification, wherein R is C2-12 n-alkyl. A preparation process of the agent includes: reacting n-alkyl thiol, sodium hydride or potassium hydride, and carbon disulfide to produce sodium alkyltrithiocarbonate or potassium alkyltrithiocarbonate; and reacting 2-chloro-2-phenylpropane or 2-bromo-2-phenylpropane with the sodium alkyltrithiocarbonate or the potassium alkyltrithiocarbonate to produce the cumyl alkyltrithiocarbonate that is the agent. The agent is simple in after-treatment and easy in purification, and has high addition-fragmentation capability in RAFT polymerization, and high reaction activity in RAFT polymerization. The agent can effectively control polymerization of a large scale of monomers, particularly monomers with high steric hindrance, and is rich in raw material source, low in cost, simple in process, short in period, free of special equipment, and easy in after-treatment.

Owner:PETROCHINA CO LTD

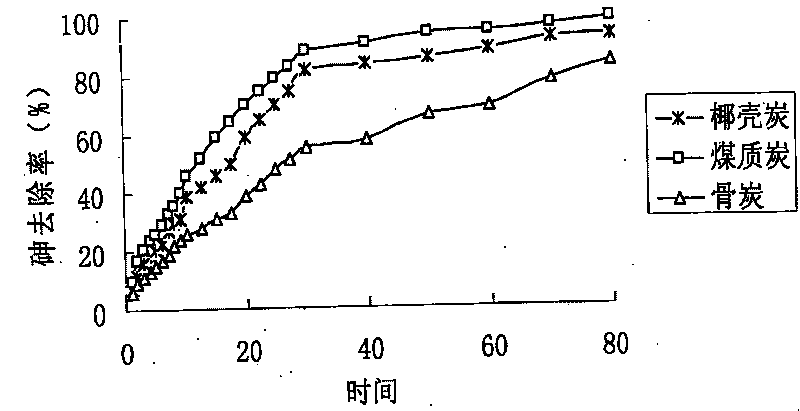

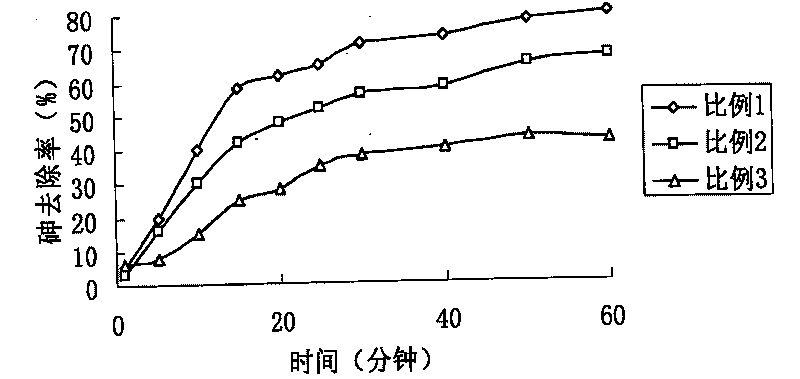

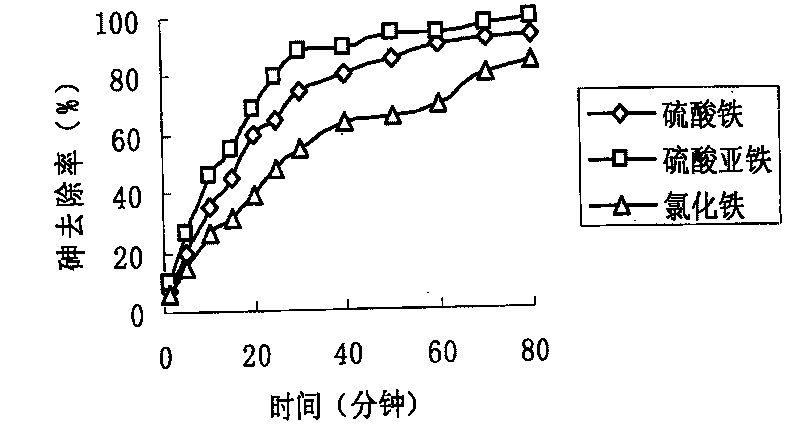

Method for preparing load type nano arsenic-removing sorbent for drinking water

InactiveCN101347717BLarge adsorption capacityImprove adsorption capacityOther chemical processesWater/sewage treatment by sorptionPotassium borohydrideSorbent

The invention relates to the elimination of the arsenic in drinking water, in particular to a preparation method of a supported type nano-adsorbent for removing arsenic from drinking water; the methodincludes the following steps: (1) activated carbon material with pore volume of 0.100-0.500cm<3> / g is selected for pretreatment; (2) soluble ferric salt solution is firstly used for soaking the activated carbon for 10-120 min; (3) alcoholic solution is taken as a dispersant to be added into the ferric salt solution; (4) under the protection of inert gases at room temperature, a strong reductant,potassium borohydride or sodium borohydride, is used for titrating the ferric salt, and agitation is carried out under the protection of inert gases; after the titration of potassium borohydride or sodium borohydride solution, agitation lasts for 10-120 min; (5) after agitation, centrifugation is carried out; oxygen-free water is firstly used for washing for 1-3 times, then organic solvent is adopted for washing for 1-3 times, and vacuum drying is done at 40-100 DEG C for 12-48h to obtain the product. The adsorbent of the invention has large adsorption capacity and small volume and is safe, stable and easy to store and transport.

Owner:SHENYANG INST OF APPL ECOLOGY CHINESE ACAD OF SCI

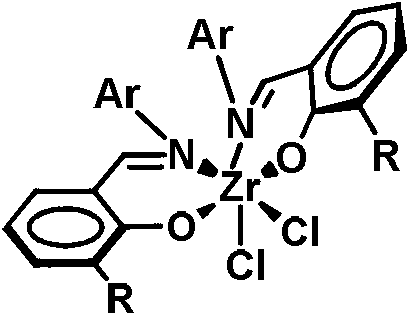

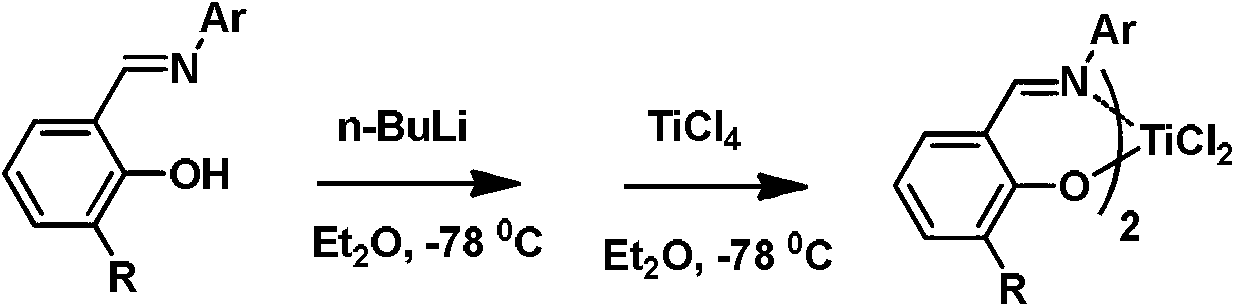

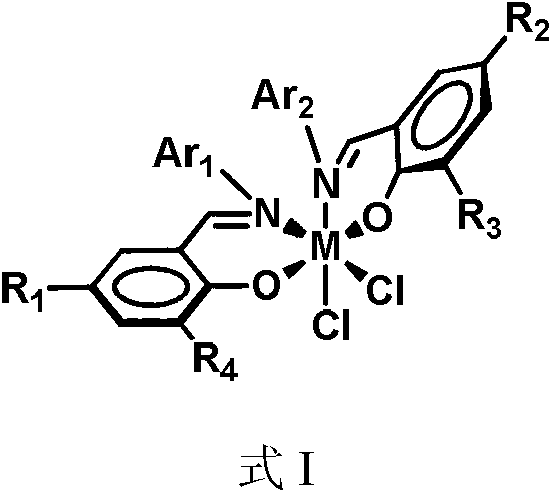

Metal miscellaneous ligand catalyst precursor based on salicylaldehyde imine ligand, as well as preparation and application thereof

The invention discloses a metal miscellaneous ligand catalyst precursor based on a salicylaldehyde imine ligand, as well as a synthesis method of the catalyst precursor and an application of the catalyst precursor in olefin polymerization. The catalyst precursor comprises two different salicylaldehyde imine ligands and transition metal of the IV group and can be rapidly synthesized by raw materials including the salicylaldehyde imine ligands, titanium tetrachloride and potassium hydride at normal temperature, the operation is simple and time-saving, and the yield is doubled compared with that of a conventional method. When a catalyst formed of the precursor and alkylaluminoxane catalyzes olefin homopolymerization or copolymerization, the activity is in the magnitude order of 106g.mol<-1>(Ti).h<-1>, the molecular weight of the obtained copolymer is about 150,000, and the dispersity is between 1.2 and 3.5. Compared with a single ligand metal catalyst, a miscellaneous ligand catalyst shows the advantages of both parent bodies or even exceeds a parent catalyst.

Owner:PEKING UNIV

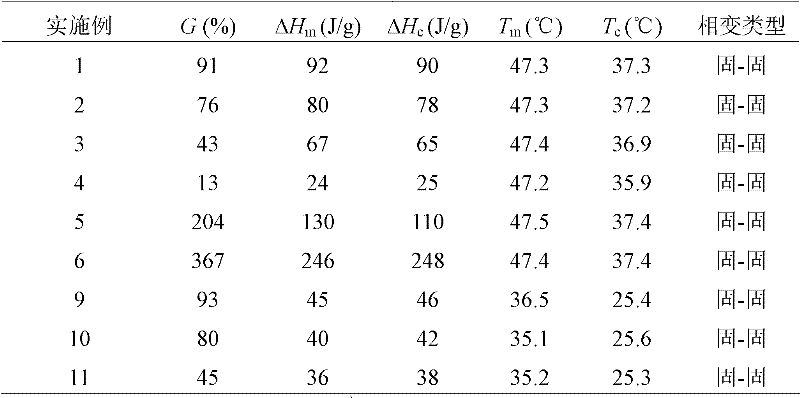

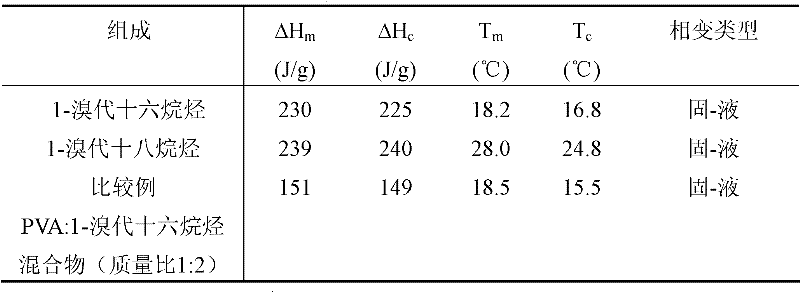

Preparation method of comb-type polymer phase change energy storage material

InactiveCN102199231AQuick responseImprove thermal stabilityHeat-exchange elementsAlkanePolymer dissolution

The invention discloses a preparation method of a comb-type polymer phase change energy storage material. The preparation method comprises the following steps: firstly, dissolving polymers such as dried poval and the like in a solvent the amount of which is 2-4 times that of the polymers, and then carrying out metallization reaction on the mixture and one of calcium hydride, sodium hydride, potassium hydride, sodium methoxide, sodium ethoxide, potassium methoxide or potassium ethoxide; stirring and reacting for 1-4 hours in the solvent at the temperature of 30-60 DEG C so as to obtain a polymer metalized product with an active group; adding at leas one of 1-halognated n-alkanes, wherein the molar ratio of the 1-halognated n-alkane to the polymers such as poval and the like is (0.1:1)-(6:1), and the adding speed is controlled at 1-10mL / min; adding a catalyst the weight of which is 0.01-1% of that of the polymers such as poval and the like; and stirring and carrying out grafting reaction for 4-12 hours in the solvent at the temperature of 30-90 DEG C; and washing the obtained product for impurity removal and drying, so as to obtain the comb-type polymer phase change energy storage material.

Owner:TIANJIN POLYTECHNIC UNIV

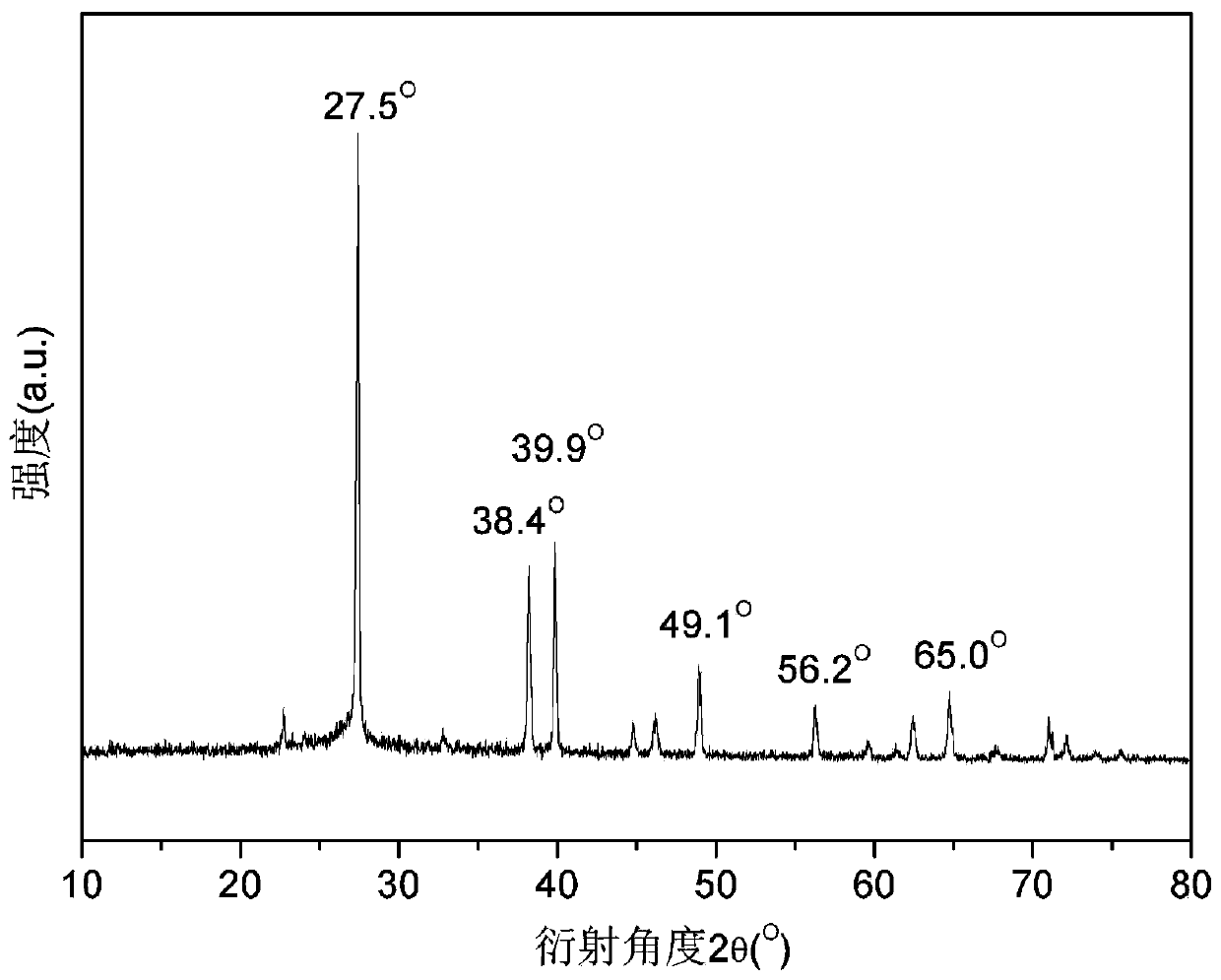

Preparation method of nano titanic acid tablets

InactiveCN102094243ALess varietyStable chemical and physical propertiesPolycrystalline material growthSingle crystal growth detailsCleansing AgentsTitanic acid

The invention relates to a preparation method of nano titanic acid tablets. In the preparation method, sodium hydroxide and potassium hydride are used as alkali melting agents, titanium dioxide is used as a titanic acid raw material, de-ionized water is used as a cleaning agent, a washing agent and an extracting agent, and absolute ethyl alcohol is used as a washing agent and a dry support to synthesize nano titanic acid tablet monocrystal under atmospheric pressure of 0.1MPa at low temperature of 200 DEG C. A dispersing agent is not used in synthesis, the used raw materials are fewer, the process flow is short and the product is in a monocrystal structure. The titanic acid tablets are 2-4nm thick and 120-150nm long and have stable chemical and physical properties, and the purity is as high as 99.5%. The preparation method has the characteristics of low synthesis temperature, accurate combination, low cost and the like, is simple to operate and is an ideal method for quickly preparing the nano titanic acid tablets.

Owner:ZHEJIANG NORMAL UNIVERSITY

Preparation method for CdHgTe/CdS core-shell quantum dot

ActiveCN104927868ARich sourcesLow priceNanoopticsLuminescent compositionsQuantum yieldPotassium borohydride

The invention provides a preparation method for a CdHgTe / CdS core-shell quantum dot. The preparation method comprises the following steps: A, preparing a potassium tellurium hydride solution which is prepared by reducing tellurium powder through potassium borohydrate; B, weighing a certain proportion of cadmium chloride and mercuric chloride crystal, dissolving the mixture with deionized water, and performing metered volume to obtain a mixed solution of cadmium chloride and mercuric chloride; C, adding quantified thioglycolic acid into the mixed solution; D, adjusting the solution with a potassium hydroxide solution to enable the solution to have a specific pH value; E, after inert gas is introduced for oxygen removal, adding the new prepared potassium tellurium hydride solution; F, irradiating through a UV light, and detecting through fluorescence spectrum analysis; G, adding isopropanol for purification, and drying through a freezer dryer to obtain CdHgTe / CdS core-shell quantum dot solid powder. According to the preparation method, the process is relatively simple; process parameters are easy to control; raw materials are inexpensive, the synthesized quantum dot is small in particle size and relatively uniform in particle size distribution, and the fluorescence quantum yield is relatively high.

Owner:湖北荆楚理工资产经营管理有限公司

Preparation method of high molecular polyethylene polyamine polyether used for preparing water-based functional liquids

InactiveCN102731769AMild reaction conditionsEasy to controlLubricant compositionWater basedPolymer science

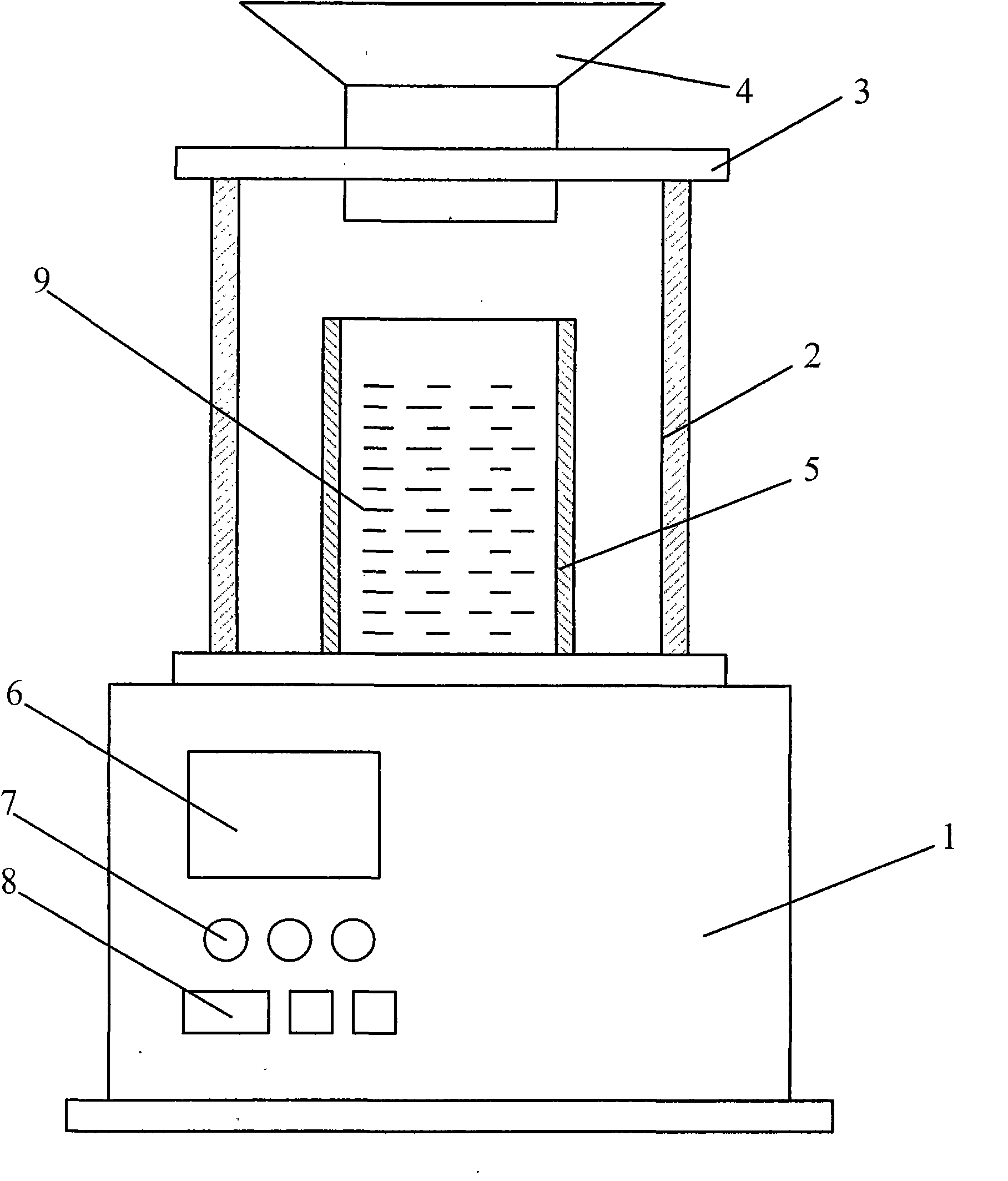

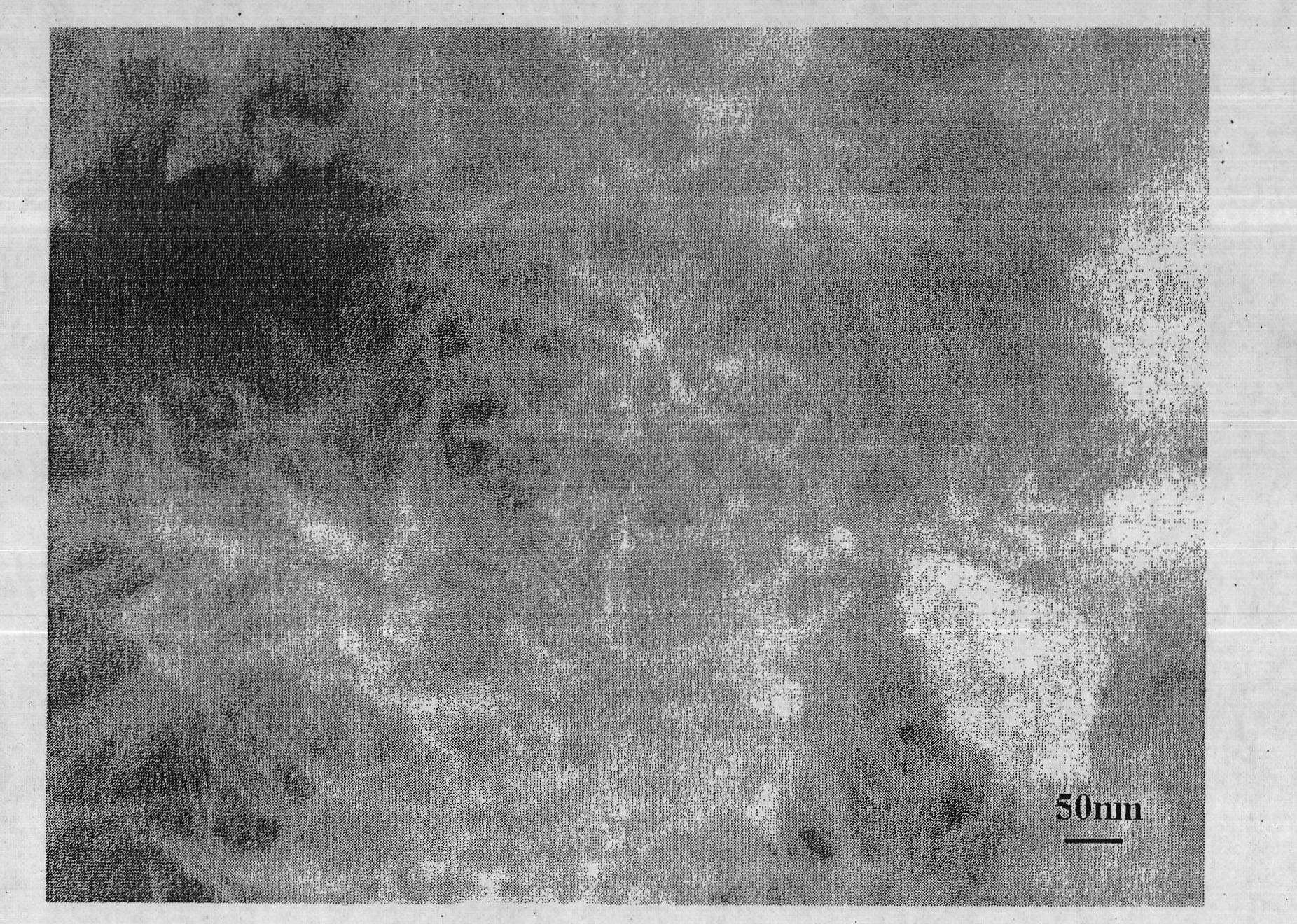

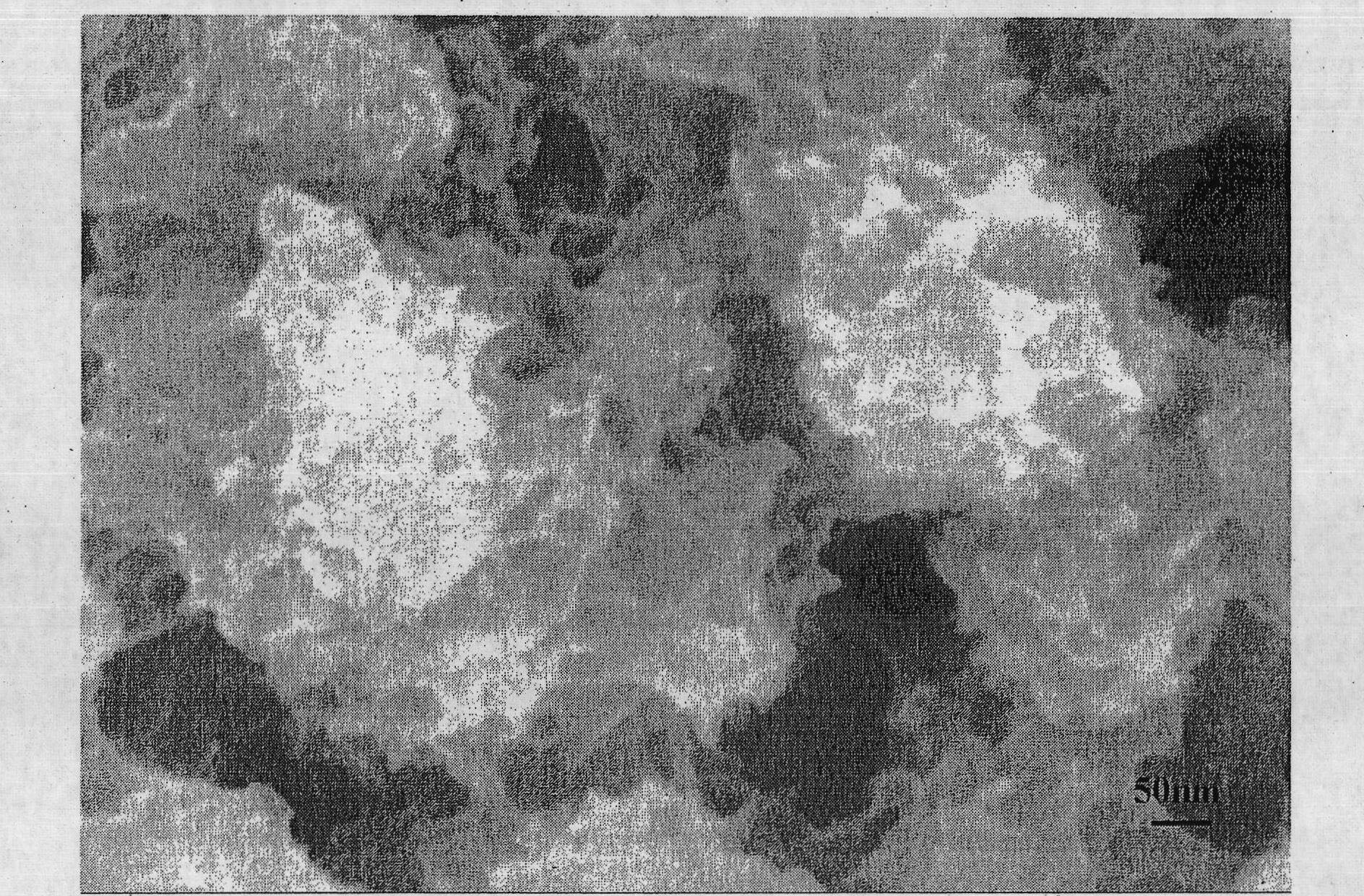

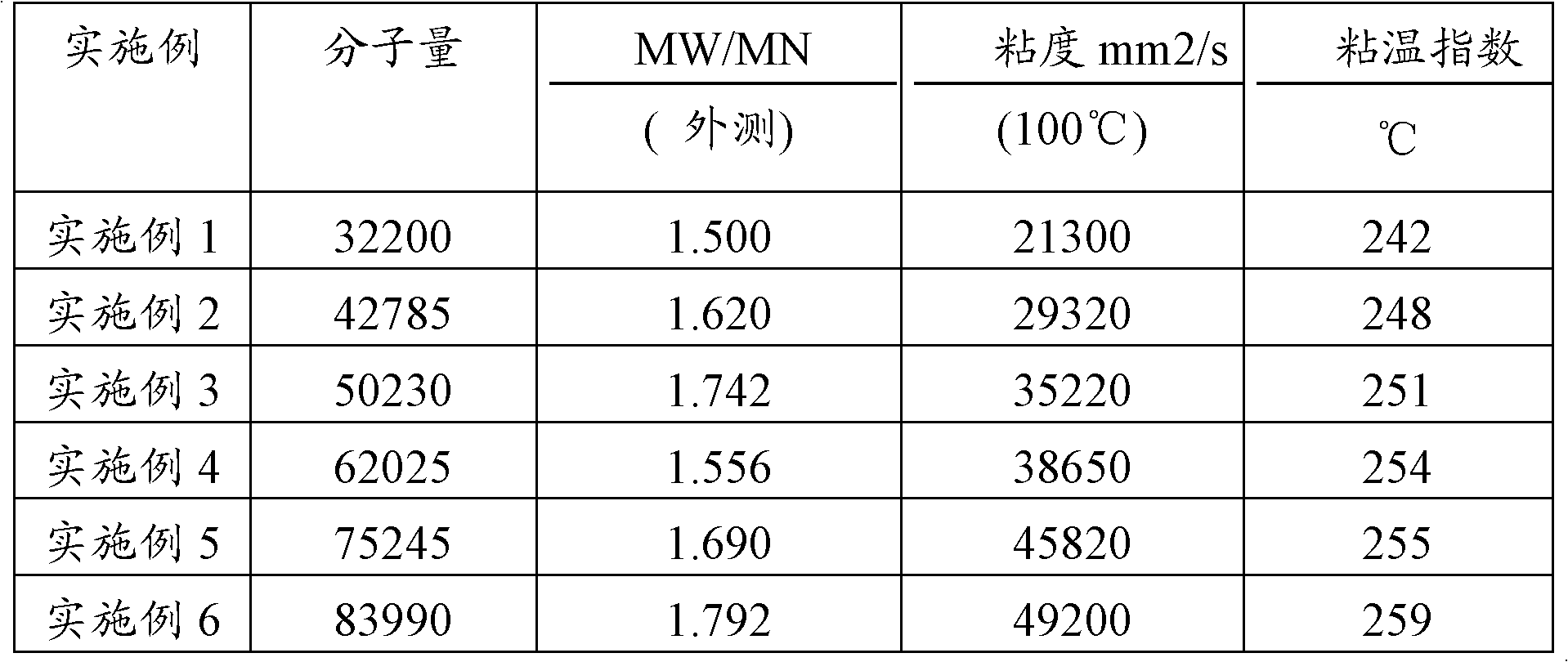

The invention discloses a preparation method of high molecular polyethylene polyamine polyether used for preparing water-based functional liquids. The method adopts polyethylene polyamine and a mixture of propylene oxide and ethylene oxide as raw materials, and employs sodium hydride or potassium hydride as a catalyst to conduct a polymerization reaction so as to obtain the high molecular polyethylene polyamine polyether used for preparing water-based functional liquids. The invention preferably selects a two-step polymerization method as the preparation process. And the prepared high molecular polyether has the characteristics of high molecular weight, narrow distribution and high viscosity, etc., thus being suitable to be used for preparing hydraulic liquids, quenching liquids, and cutting fluids, etc. And the prepared water-based functional liquids have especially outstanding thickening property, viscosity-temperature property and shearing resistance, thus having prolonged service life. The average molecular weight of the high molecular polyether prepared by the method of the invention can reach 30000-35000, 40000-45000, 50000-55000, 60000-65000, 70000-75000, and 80000-90000, the molecular weight distribution coefficient MW / MN is 1.4-1.9, the viscosity range at 100DEG C can be 20000-50000mm<2> / s, and the viscosity-temperature index can be up to 240-260DEG C.

Owner:大连广会科技有限公司

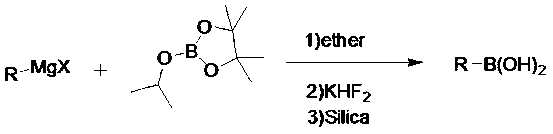

Method for preparing fatty boric acid by utilizing isopropoxyboric acid pinacol ester

InactiveCN103183695AAvoid generatingAchieve securityGroup 3/13 element organic compoundsHydrocarbon solventsOrganic solvent

The invention discloses a method for preparing fatty boric acid by utilizing isopropoxyboric acid pinacol ester. The method comprises the steps of adding a Grignard reagent dropwise in isopropoxyboric acid pinacol ester under the temperature condition of subzero 5 DEG C to 0 DEG C, stirring for 1-2 hours at the room temperature, adding a potassium bifluoride aqueous solution dropwise into a reaction liquid, stirring for 2-3 hours at the room temperature, adding silica gel, stirring for 2-3 hours at the room temperature, filtering, and extracting a water layer by an organic solvent A; adding an organic solvent B into an organic layer, filtering again, adding a nonpolar hydrocarbon solvent into the filtrate for pulping, and filtering to obtain organic boric acid. The method has the advantages of simplicity and convenience in operation, safety, environmental protection, lower cost and higher yield, is an appropriate method for preparing fatty boric acid, and is suitable for the industrial production; and further, the raw materials are easy to obtain.

Owner:DALIAN NETCHEM CHIRAL TECH

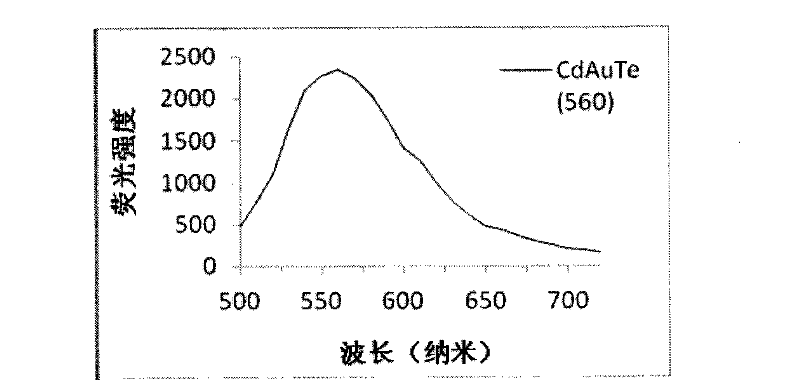

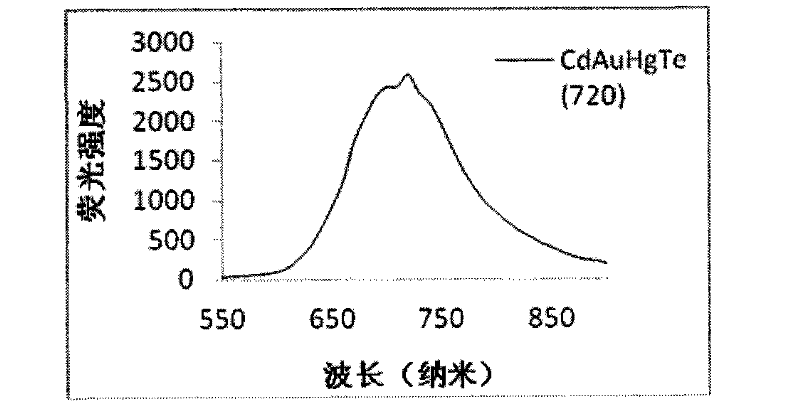

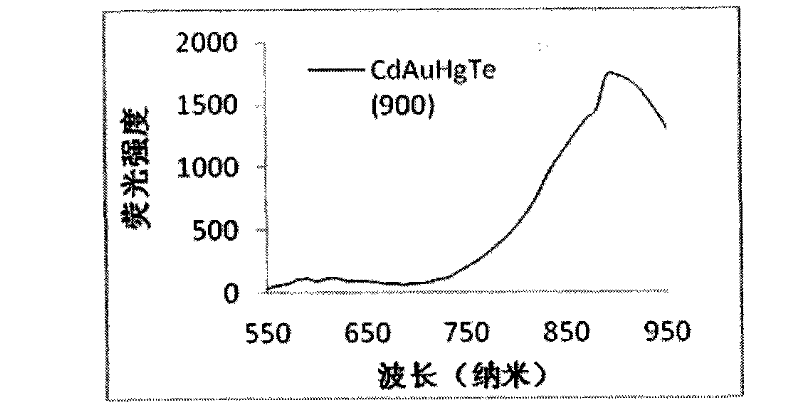

Method for synthesizing gold-doped fluorescent quantum dots

InactiveCN101747899ALow toxicityStrong fluorescent signalLuminescent compositionsFluorescenceSemiconductor quantum dots

The invention provides a method for synthesizing gold-doped fluorescent quantum dots, which performs water phase synthesis on a cadmium salt, a compound of gold, a mercury salt, a sulfhydryl compound and newly-prepared tellurium potassium hydride under an anaerobic condition at the temperature of between 90 and 130 DEG C to obtain CdnAuxTez and near infrared CdnAuxHgyTez gold-doped fluorescent quantum dots. The gold-doped fluorescent quantum dots synthesized by the method are slightly poisonous, have strong fluorescence signals, have an emission spectrum positioned at visible and near infrared light, contain the gold element, and can be used for performing analytical studies correlative with a gold nano material; and the wavelength can be adjusted according to the proportion of componentsand the reaction time. The method dopes gold which has no bio-toxicity into semiconductor quantum dots to improve the biological compatibility of the quantum dots and reduce the nano-toxicity. The method can be applied in the fields of biological analytic detections, biomedical imaging and the like.

Owner:ZHEJIANG UNIV

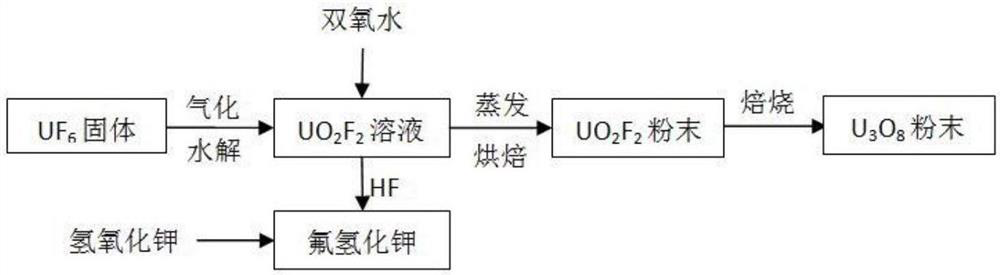

Method for preparing triuranium octaoxide from uranium hexafluoride

PendingCN112607780AAvoid joiningReduce generationAlkali metal fluoridesUranium oxides/hydroxidesHydrolysatePotassium hydroxide

The invention belonging to the technical field of nuclear fuel circulation, and particularly relates to a method for preparing triuranium octaoxide from uranium hexafluoride. The method comprises the following three steps: step 1, preparation of a UO2F2 hydrolysate; step 2, preparation of UO2F2 powder; step 3, roasting for preparation of U3O8. According to the method, the process of preparing U3O8 through conventional UF6 reduction is shortened, and the addition of ammonia water in the process is avoided, so ammonia nitrogen wastewater generated in the process is reduced, a preparation process is simple, cost is low, and industrialization is easy to realize. According to the method, a large amount of fluorine in UF6 is converted into HF acid through water, the HF acid reacts with potassium hydroxide to finally prepare a byproduct potassium hydrogen fluoride, and the byproduct potassium hydrogen fluoride can be returned to an electrolytic fluorine production unit in a uranium conversion system so as to realize recycling. The U3O8 prepared by the method is more uniform in granularity, good in powder flowability, low in radioactivity, low in fluorine content and convenient for long-term stable storage.

Owner:中核二七二铀业有限责任公司

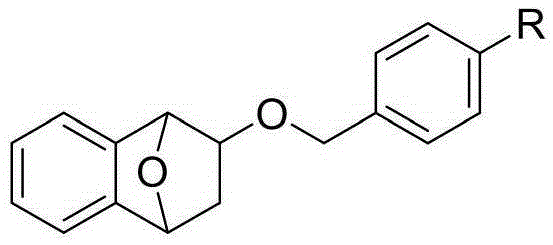

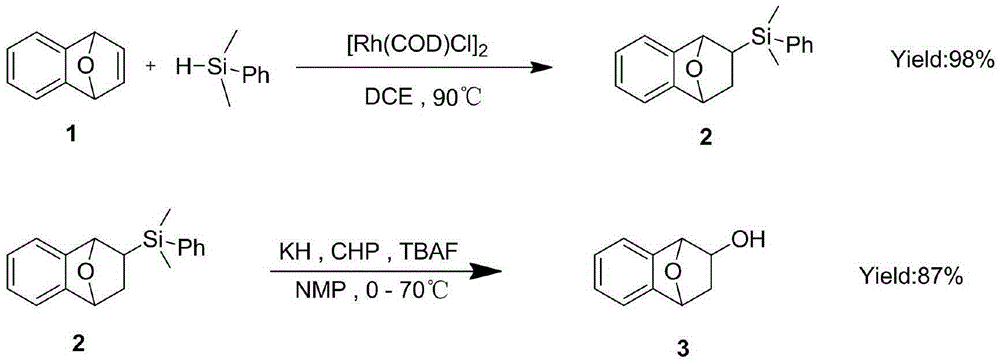

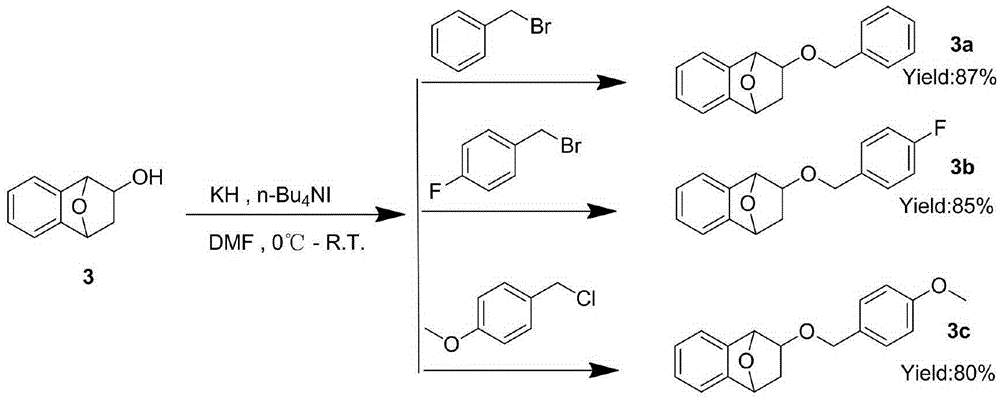

Novel compound as well as preparation method and application thereof

InactiveCN105399752AEnhanced inhibitory effectGrowth inhibitionBiocideOrganic chemistryBenzoyl bromideBenzyl chloride

The invention discloses a novel compound with a structure shown in the specification, wherein R is H, F or methoxyl. The novel compound is prepared by a method comprising the following steps: performing hydrosilylation by taking oxabenzonorbornadiene and dimethylphenylsilane as standard substrates and [Rh(COD)Cl]2 as a metal catalyst to obtain a product A; reacting the product A with tetrabutyl ammonium fluoride, cumyl hydroperoxide and potassium hydride to remove a silicon substrate so as to generate alcohol B; and reacting the alcohol B with benzyl bromide or benzyl chloride with different substituent groups under the action of alkali to obtain a target product. The invention further relates to a weeding composition comprising the novel compound, and also relates to an application of the novel compound particularly used for controlling weeds in useful plant crops.

Owner:YUNNAN MINZU UNIV

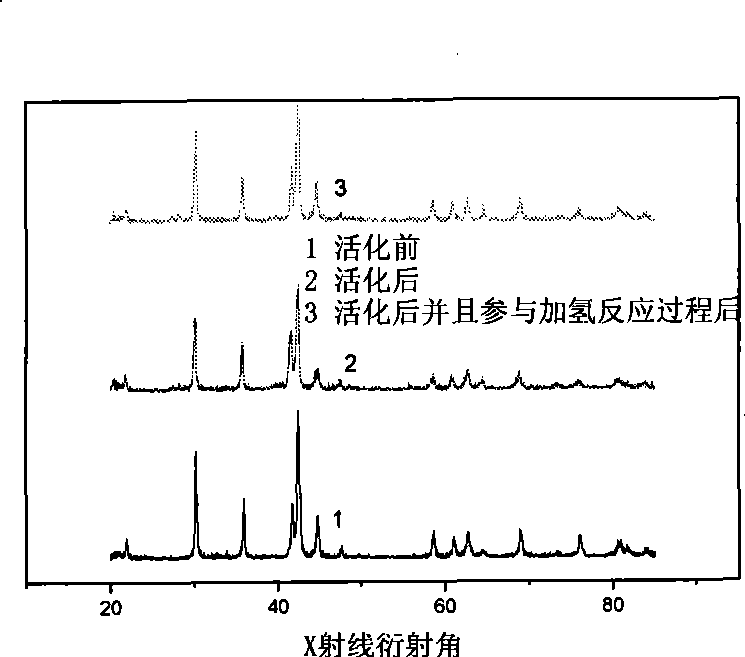

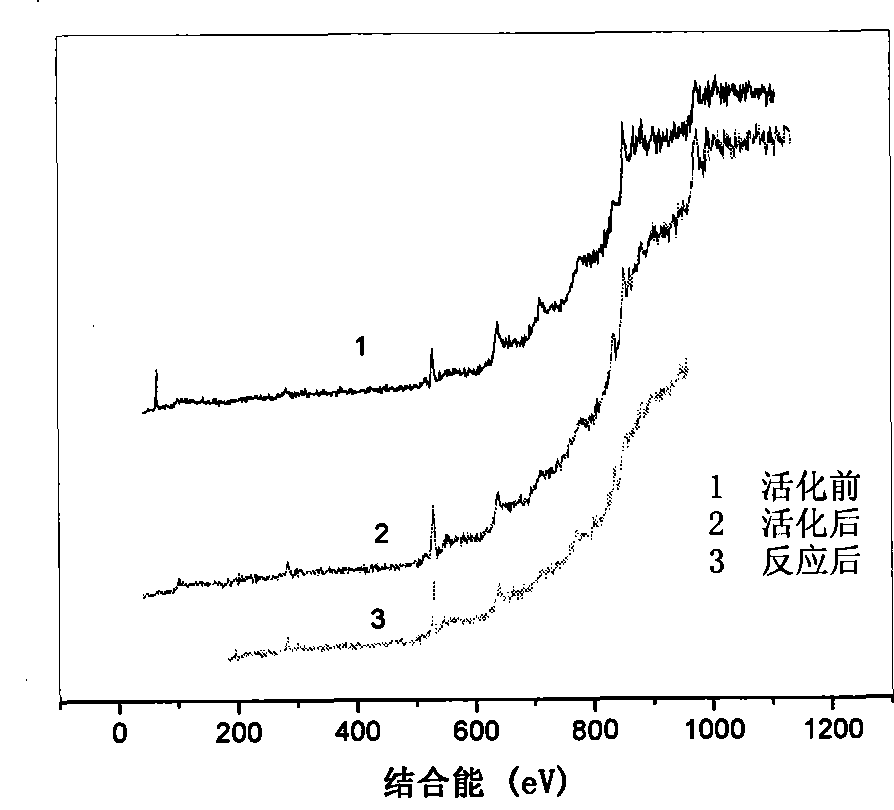

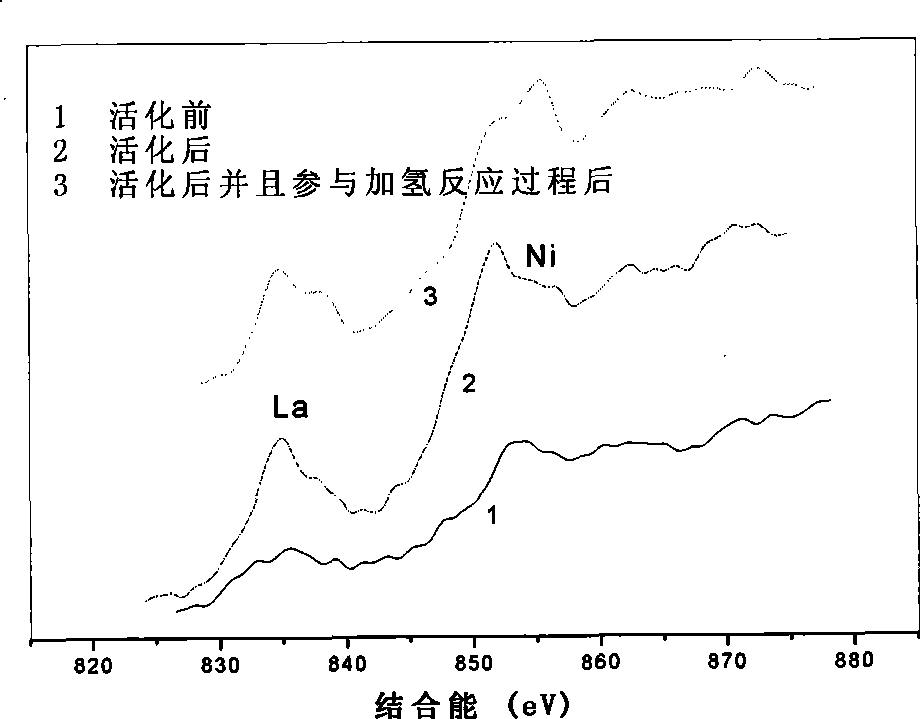

Hydrogen storage alloy type hydrogenation catalyst and preparation method thereof

ActiveCN101450314AHighlight substantive featuresSignificant progressMetal/metal-oxides/metal-hydroxide catalystsPotassium borohydrideFiltration

The invention provides a hydrogen storage alloy type hydrogenation catalyst and a preparation method thereof. The hydrogen storage alloy type hydrogenation catalyst product is M1Ni3.7Co0.6Mn0.3Al0.4 (M is mixed rare earth). The method comprises the processes of prefabrication and activation of the hydrogen storage alloy type hydrogenation catalyst, wherein the prefabrication process is to smelt alloy raw materials for designing the counterweight of compositions under the protection of argon gas atmosphere, and to perform heat treatment, quenching and milling on the alloy raw materials; and the activation process is to add an alkaline solution of potassium borohydride or sodium borohydride into prefabricated hydrogen storage alloy type hydrogenation catalyst powder, to heat the mixture to obtain a treatment liquid, to add solid potassium borohydride or solid sodium borohydride into the treatment liquid, and to perform temperature rise, filtration and drying to obtain the activated hydrogen storage alloy type hydrogenation catalyst product. The yield of a reaction product obtained from the hydrogen storage alloy type hydrogenation catalyst during hydrogenation reaction at a temperature of 200 DEG C is improved from 2.6 percent to 65.6 percent.

Owner:兴化市正阳水泥有限公司

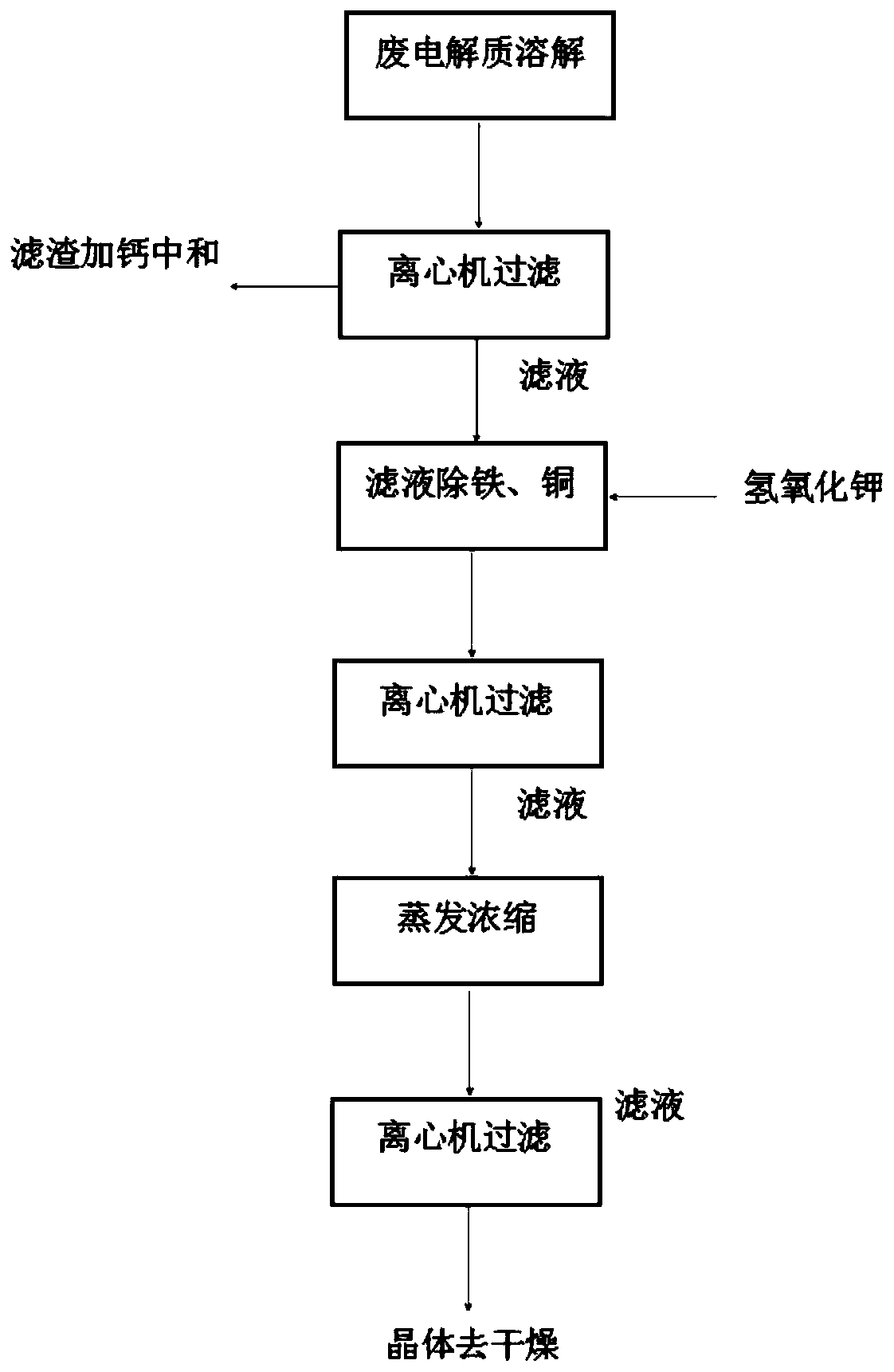

Electrolytic fluorine waste electrolyte recovery method

ActiveCN111020632AIncrease ion productPolycrystalline material growthElectrolysis componentsElectrolysisPotassium hydrogenfluoride

The invention belongs to the technical field of uranium conversion electrolysis fluorine production, and particularly relates to an electrolysis fluorine production waste electrolyte recovery method.The method comprises the following steps: (1) dissolving a waste electrolyte; (2) carrying out pH adjustment; and (3) carrying out crystallization of potassium bifluoride. Dissolving and filtering canbe adopted to obtain a clear electrolyte dissolved solution, copper is removed, the pH value is controlled to be 10 to 12, and is adjusted to be 3 to 4 before crystallization, the recovered electrolyte with indexes similar to those of newly purchased electrolyte can be prepared. Through research, alkaline wastewater and acidic wastewater treated by an electrolytic cathode can be used for dissolving the waste electrolyte, and the ion product of potassium bifluoride during electrolyte crystallization can be increased by adjusting the pH value.

Owner:中核二七二铀业有限责任公司

Method for aqueous phase synthesizing stable GSH-CdTeSe alloy quantum dots

InactiveCN101280190ASimple and safe operationMild conditionsLuminescent compositionsQuantum yieldPotassium borohydride

Disclosed is the method of synthesizing stable GSH-CdTeSe alloy quantum dot in water phase. Biological small molecular glutathione (GSH) is used as stabilizer and complexing agent in water solution; inorganic salt CdCl2 is added to the solution; tellurium potassium hydride (sodium) solution and selenium potassium hydride (sodium) solution prepared by the reaction of potassium borohydride (sodium) and tellurium powder or selenium powder are injected to the solution under the protection of inert gas; and then the heating reflux is processed to generate the soluble GSH-CdTeSe alloy quantum dot; the GSH-CdTeSe alloy quantum dots with different particle diameter and adjustable spectrum through the control of the reflux time and the composition. The preparation method has the advantages of convenient operation, low cost and strong operability. The obtained soluble GSH-CdTeSe alloy quantum dot is purified and dried, and then is dissolved in Tris-HCl buffer solution (pH=7.4); the synthesizing method of the GSH-CdTeSe alloy quantum dot has high dot production rate and high stability.

Owner:NANKAI UNIV

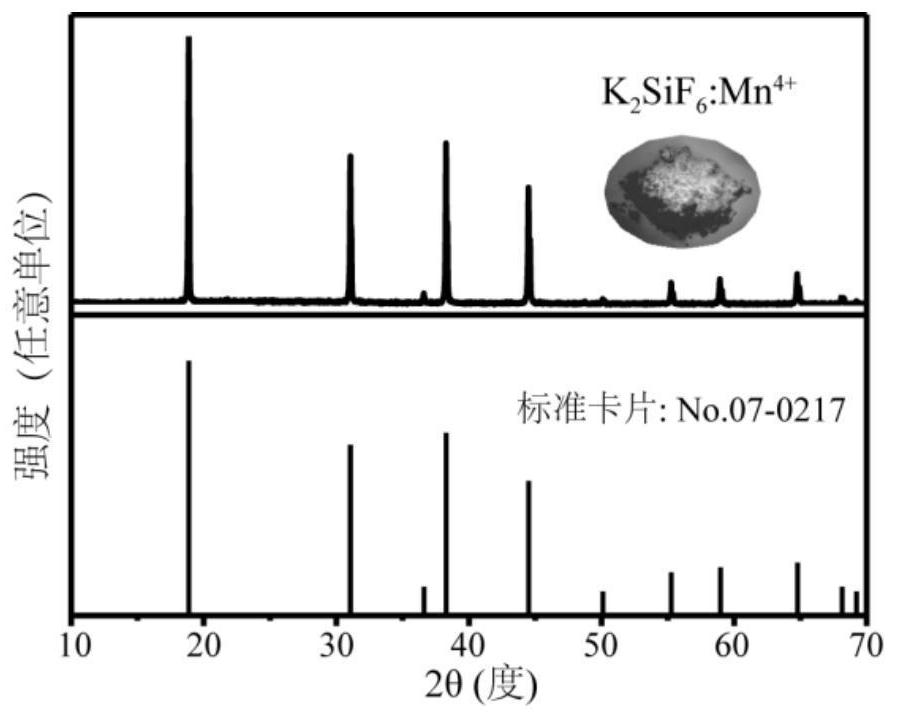

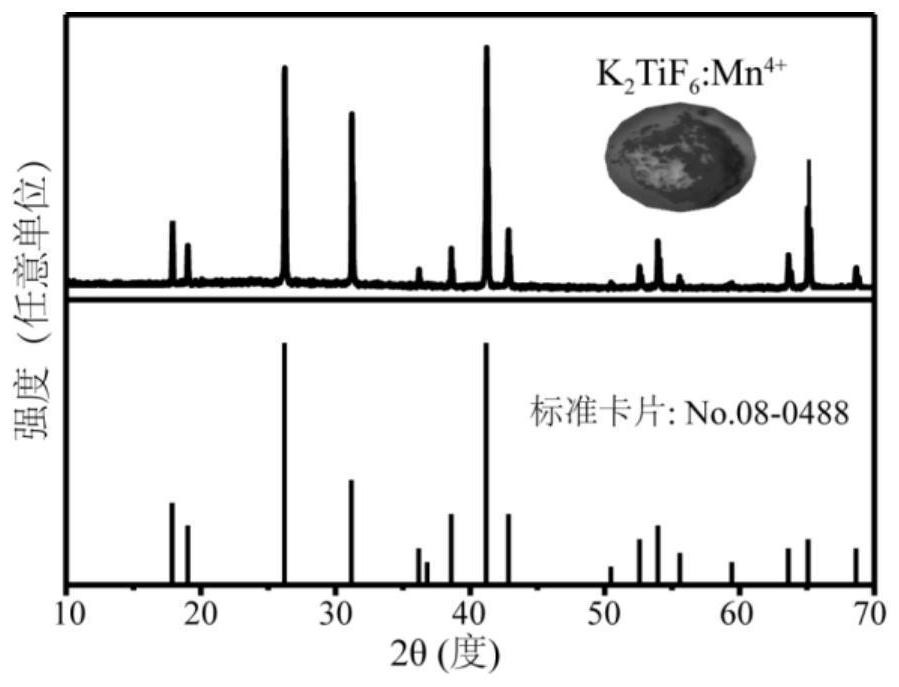

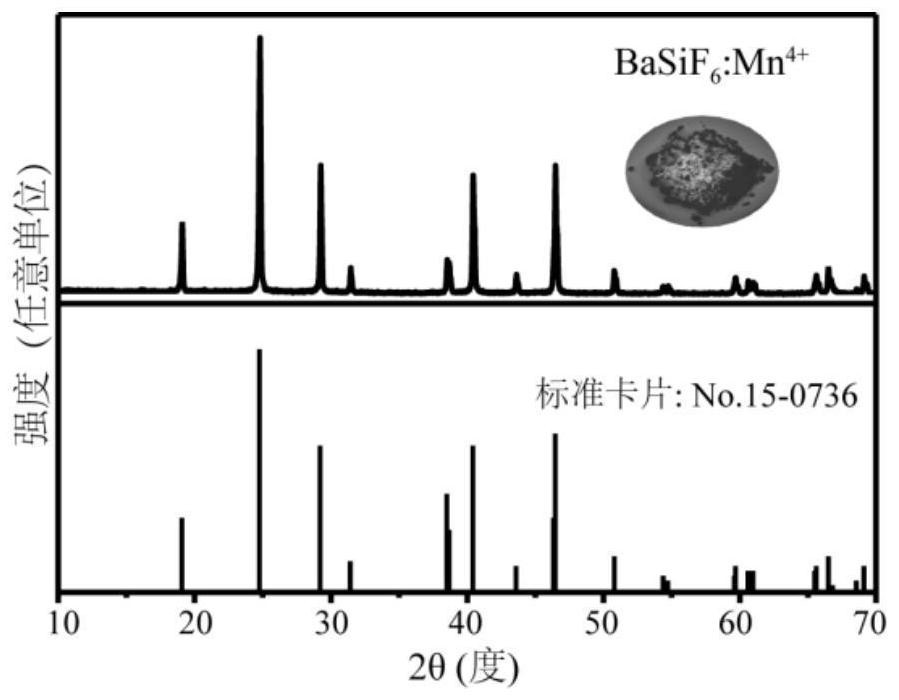

Green synthesis method of tetravalent manganese ion activated fluoride red luminescent material

PendingCN114381260AMild conditionsSynthesis speedLuminescent compositionsSemiconductor devicesBarium dichloridePotassium fluoride

The invention discloses a green synthesis method of a tetravalent manganese ion activated fluoride red luminescent material. The synthesis method comprises the following steps: adding potassium hexafluoromanganate into a fluosilicic acid solution or a fluotitanic acid solution until the potassium hexafluoromanganate is completely dissolved to obtain a solution 1, adding potassium fluoride, potassium bifluoride or barium chloride into water until the potassium fluoride, potassium bifluoride or barium chloride is completely dissolved to obtain a solution 2, the molar concentration of the potassium fluoride, potassium bifluoride or barium chloride in the solution 2 is 0.25-3.00 mol / L, and stirring to obtain a solution 3; mixing and stirring the solution 1 and the solution 2 to obtain a solution 3, centrifuging the solution 3 to obtain a precipitate, and washing and drying the precipitate to obtain a final product, namely the tetravalent manganese ion activated fluoride red luminescent material. The synthesis method provided by the invention has the advantages of greenness, environmental protection (no hydrofluoric acid), mild conditions (normal temperature, normal pressure and aqueous solution reaction), high synthesis speed (several minutes) and the like, and is convenient for large-scale industrial preparation.

Owner:INST OF RESOURCES UTILIZATION & RARE EARTH DEV GUANGDONG ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com