Hydrogen storage alloy type hydrogenation catalyst and preparation method thereof

A technology for hydrogenation catalysts and hydrogen storage alloys, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, physical/chemical process catalysts, etc., can solve the problem of large wastewater discharge, complicated treatment methods, Unfavorable environmental protection and other issues, to achieve the effect of simple operation, excellent effect, and few types

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

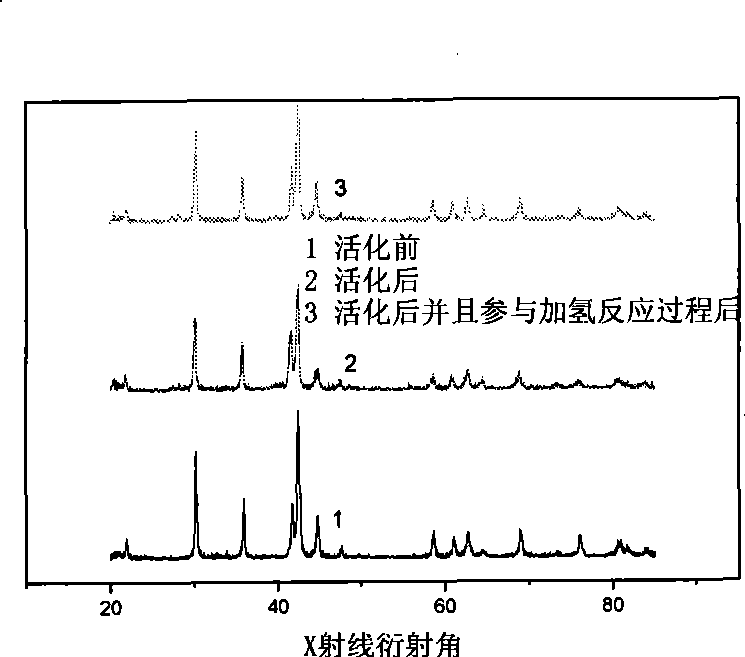

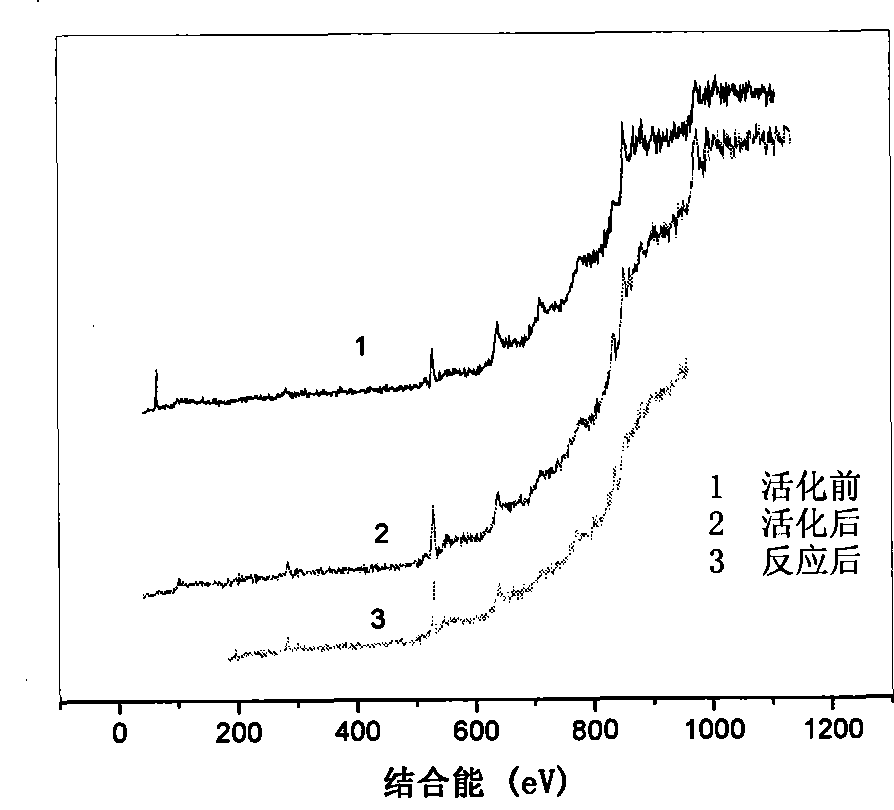

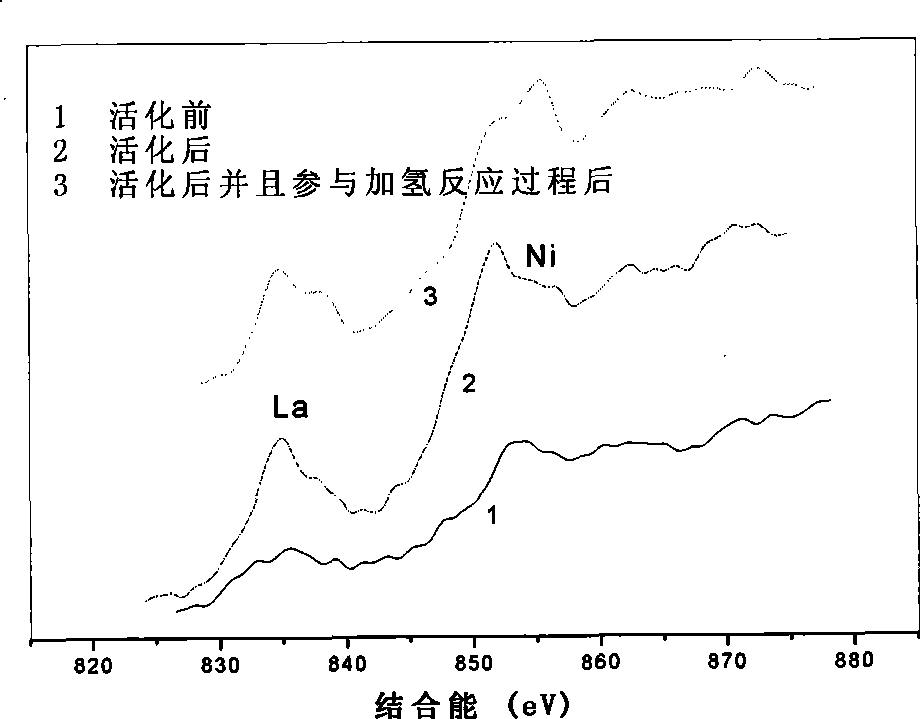

[0045] Preparation of Hydrogen Storage Alloy Type Hydrogenation Catalyst MlNi 3.7 co 0.6 mn 0.3 Al 0.4 The alloy ingot is configured according to the design composition, and the metals used are Ni90at%, Co90at%, Mn90at%, Al90at%, M is mixed rare earth, which contains 40at%La, 3at%Ce, 10at%Pr, 35at%Nd. Clean the above-mentioned raw materials with an ultrasonic oscillator, then distribute the weight according to the design composition, put the prepared material in a water-cooled copper mold, and melt it in an electric arc furnace under the protection of an argon atmosphere. During the melting process, the alloy is turned over and weighed. Melt five times while carrying out electromagnetic stirring to ensure the uniformity of the alloy. After smelting, seal the alloy ingot in a vacuum quartz tube, put it into a heat treatment furnace, heat it up to 1000-1200°C for 6-10 hours and then quench it. Then the sample was ball milled to obtain a powder with a particle size below 100↘...

Embodiment 2

[0047] Preparation of Hydrogen Storage Alloy Type Hydrogenation Catalyst MlNi 3.7 co 0.6 mn 0.3 Al 0.4 The alloy ingot is configured according to the design composition. The metals used are Ni95at%, Co95at%, Mn95at%, Al95at%, M is mixed rare earth, which contains 45at%La, 5at%Ce, 12at%Pr, 38at%Nd. Clean the above-mentioned raw materials with an ultrasonic oscillator, then distribute the weight according to the design composition, put the prepared material in a water-cooled copper mold, and melt it in an electric arc furnace under the protection of an argon atmosphere. During the melting process, the alloy is turned over and weighed. Melt five times while carrying out electromagnetic stirring to ensure the uniformity of the alloy. After smelting, seal the alloy ingot in a vacuum quartz tube, put it into a heat treatment furnace, heat it up to 1000-1200°C for 6-10 hours and then quench it. Then the sample was ball milled to obtain a powder with a particle size below 100↘m. ...

Embodiment 3

[0049] Preparation of Hydrogen Storage Alloy Type Hydrogenation Catalyst MlNi 3.7 co 0.6 mn 0.3 Al 0.4 The alloy ingot is configured according to the design composition, and the metals used are Ni97at%, Co97at%, Mn97at%, Al97at%, M is mixed rare earth, which contains 48at%La, 6at%Ce, 13at%Pr, 40at%Nd. Clean the above-mentioned raw materials with an ultrasonic oscillator, then distribute the weight according to the design composition, put the prepared material in a water-cooled copper mold, and melt it in an electric arc furnace under the protection of an argon atmosphere. During the melting process, the alloy is turned over and weighed. Melt five times while carrying out electromagnetic stirring to ensure the uniformity of the alloy. After smelting, seal the alloy ingot in a vacuum quartz tube, put it into a heat treatment furnace, heat it up to 1000-1200°C for 6-10 hours and then quench it. Then the sample was ball milled to obtain a powder with a particle size below 100↘...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com