P-aramid nanofiber solution and preparation method thereof

A nanofiber, para-aramid fiber technology, applied in the fields of nanomaterials and polymers, can solve the problems of long time and achieve the effects of low cost, simple process and high processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

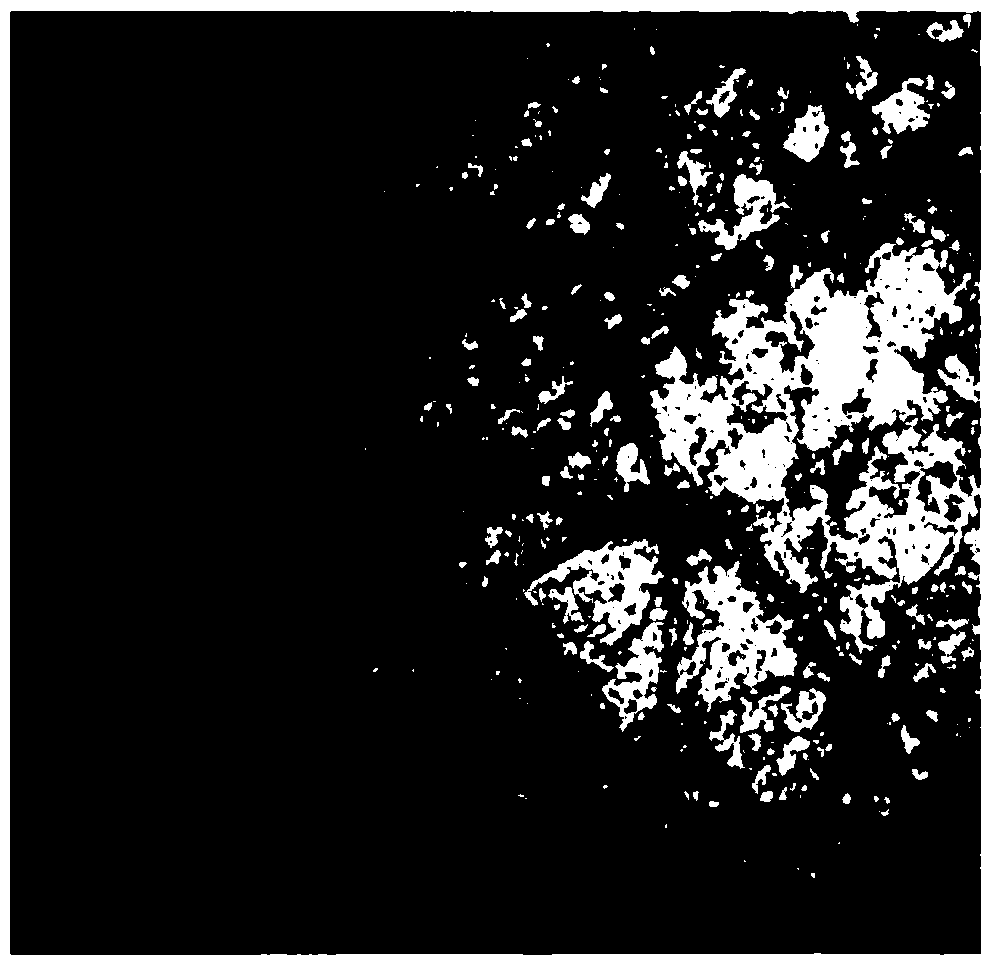

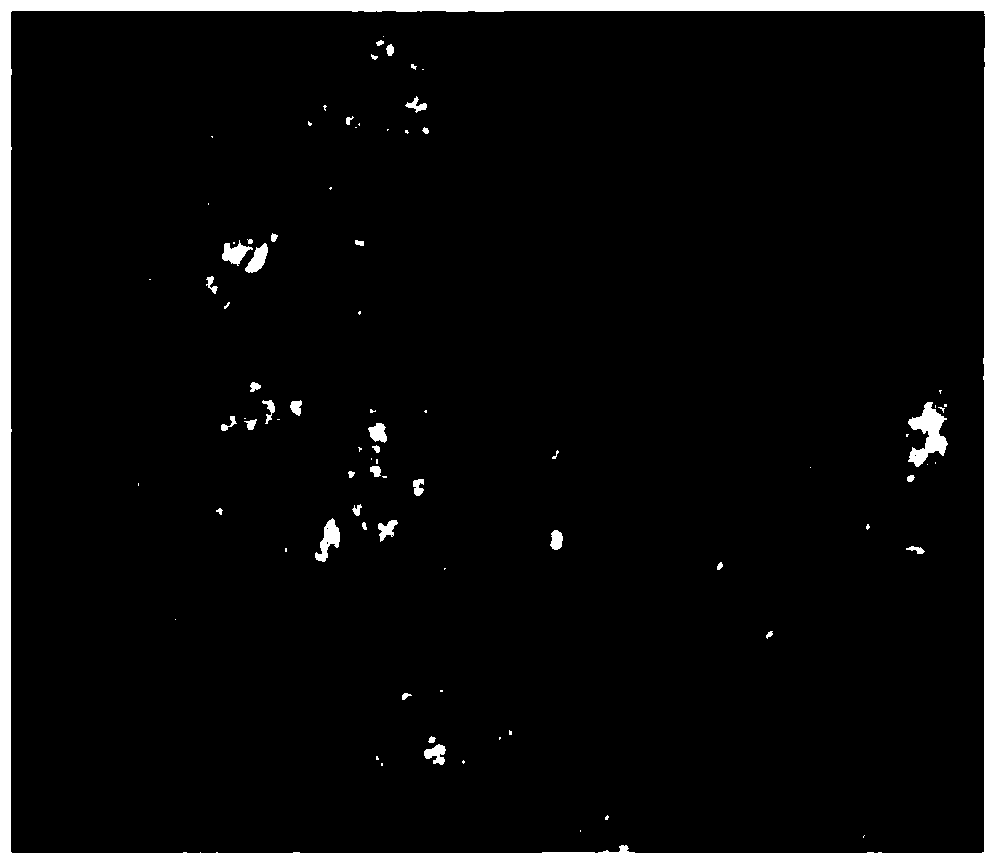

Image

Examples

Embodiment 1

[0019] The short poly(p-phenylene terephthalamide) fibers were washed with acetone, toluene, and deionized water for 3 hours, and then vacuum-dried at 60°C.

[0020] After purging the dry 150ml three-neck flask with nitrogen for 10 minutes, add 0.01 g of sodium hydride and 100 ml of anhydrous dimethyl sulfoxide at 30°C, raise the temperature to 70°C within 20 minutes, keep the temperature for 40 minutes, and then cool down to 30°C. Slowly add 0.05 g of pretreated aramid short fibers, and mechanically stir at 30° C. for 36 hours to obtain an orange-red solution containing aramid nanofibers. Bottled and sealed, it can be used as coating material or reinforcing material. (mass fraction about 0.05%)

Embodiment 2

[0022] The short poly(p-phenylene terephthalamide) fibers were washed with acetone, toluene, and deionized water for 3 hours, and then vacuum-dried at 60°C.

[0023] After purging the dry 150ml three-neck flask with nitrogen for 10 minutes, add 0.0204 g of sodium hydride and 100 ml of anhydrous dimethyl sulfoxide at 30°C, heat up to 70°C within 20 minutes, keep the temperature for 40 minutes, and then cool down to 30°C. Slowly add 0.1 g of pretreated aramid short fibers, and mechanically stir at 30° C. for 36 hours to obtain an orange-red solution containing aramid nanofibers. Bottled and sealed, it can be used as coating material or reinforcing material. (mass fraction about 0.1%)

Embodiment 3

[0025] The short poly(p-phenylene terephthalamide) fibers were washed with acetone, toluene, and deionized water for 3 hours, and then vacuum-dried at 60°C.

[0026] After purging the dry 150ml three-necked flask with nitrogen for 10 minutes, add 0.1 g of sodium hydride and 100 ml of anhydrous dimethyl sulfoxide at 30°C, raise the temperature to 70°C within 20 minutes, keep the temperature for 40 minutes, and then cool down to 30°C. Slowly add 0.5 g of pretreated aramid short fibers, and mechanically stir at 30° C. for 36 hours to obtain an orange-red solution containing aramid nanofibers. Bottled and sealed, it can be used as coating material or reinforcing material. (mass fraction about 0.5%)

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com