Electrolytic fluorine waste electrolyte recovery method

A technology of waste electrolyte and recovery method, applied in the direction of electrolysis process, electrolysis components, chemical instruments and methods, etc., can solve problems such as iron and copper, and achieve the effect of increasing ion product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

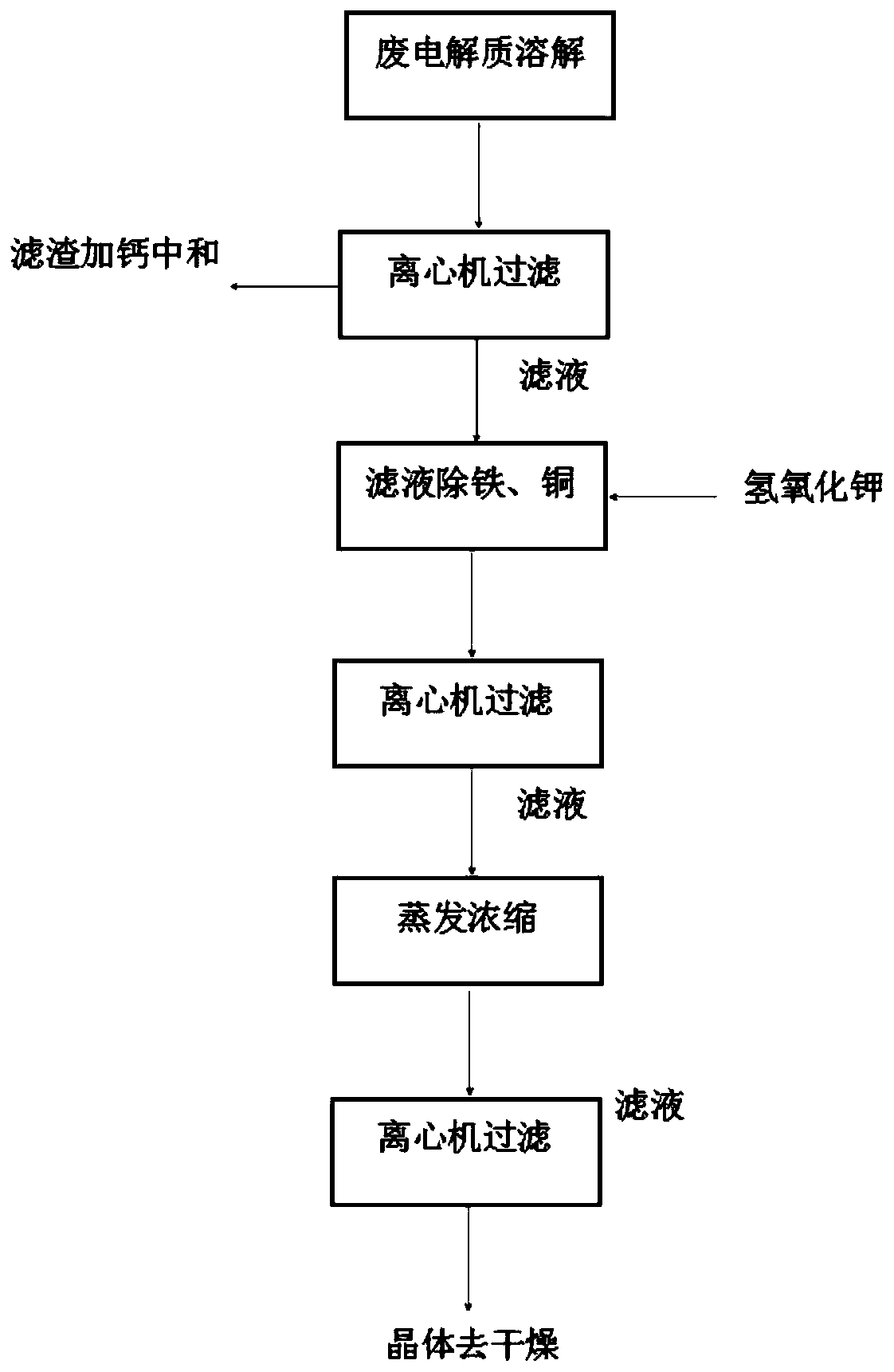

[0035] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0036] Such as figure 1 Shown, a kind of electrolytic fluorine waste electrolyte recovery method of the present invention comprises the following steps:

[0037] (1) Dissolution of waste electrolyte

[0038] By dissolving the solid waste electrolyte in the electrolytic cathode alkali washing wastewater;

[0039] In the solid waste electrolyte, the main component is potassium bifluoride, and the mass content of potassium bifluoride is 80-90%, specifically 88% in this embodiment; other impurities are carbon powder, iron, and copper;

[0040] The composition of electrolytic cathode alkaline washing wastewater is potassium fluoride solution with a concentration of 100-150g / L; the temperature of electrolytic cathode alkaline washing wastewater is 60-80°C;

[0041] The liquid is filtered and separated by a centrifuge; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com