A high-efficiency circulation industrial desulfurization device based on ion exchange

A technology of ion exchange and desulfurization equipment, which is applied in the field of industrial desulfurization, can solve the problems of corrosion of desulfurization towers, waste of water resources, etc., and achieve the effect of increasing contact area, long contact time and increasing coverage area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

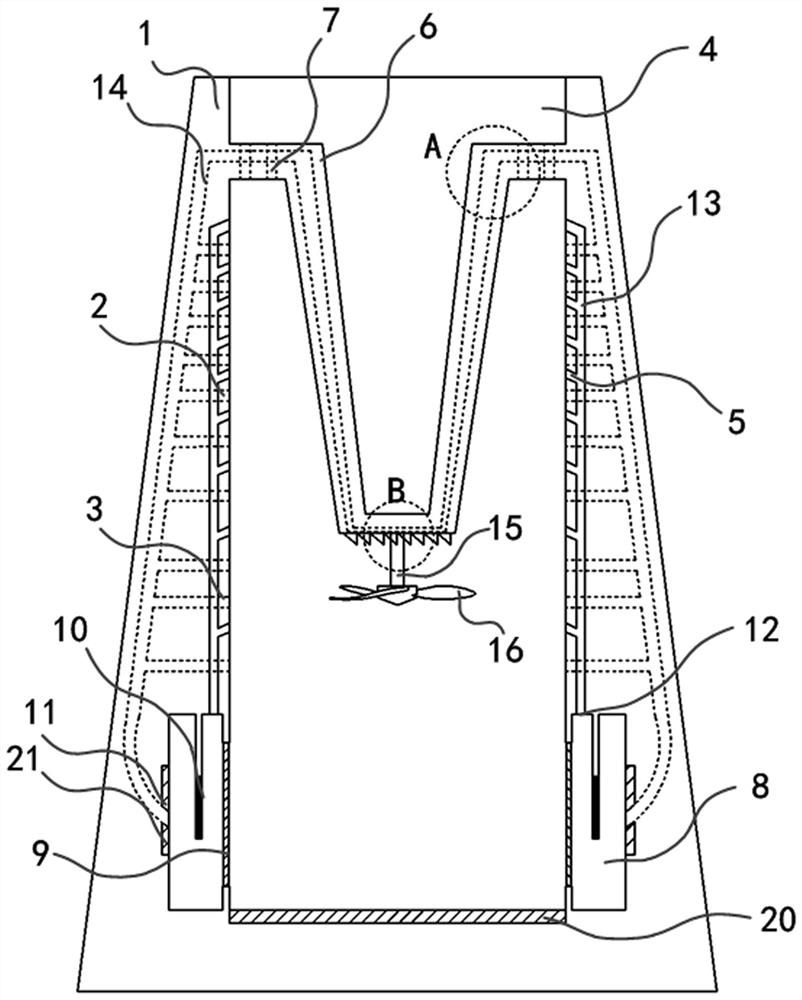

[0039] refer to Figure 1-6 . This embodiment provides a high-efficiency circulating industrial desulfurization device based on ion exchange, which includes a tower body 1 with a through interior and a vertical inner wall. The interior of the tower body 1 is divided into an upper zone and a lower zone.

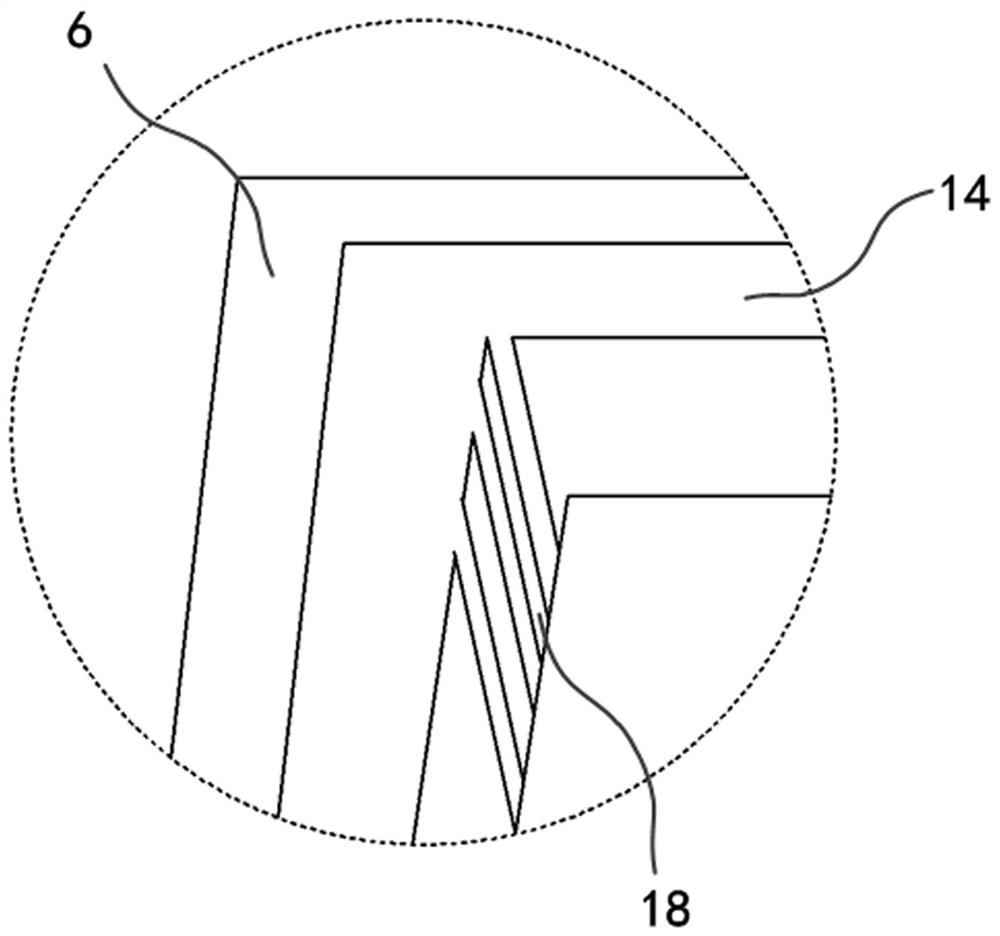

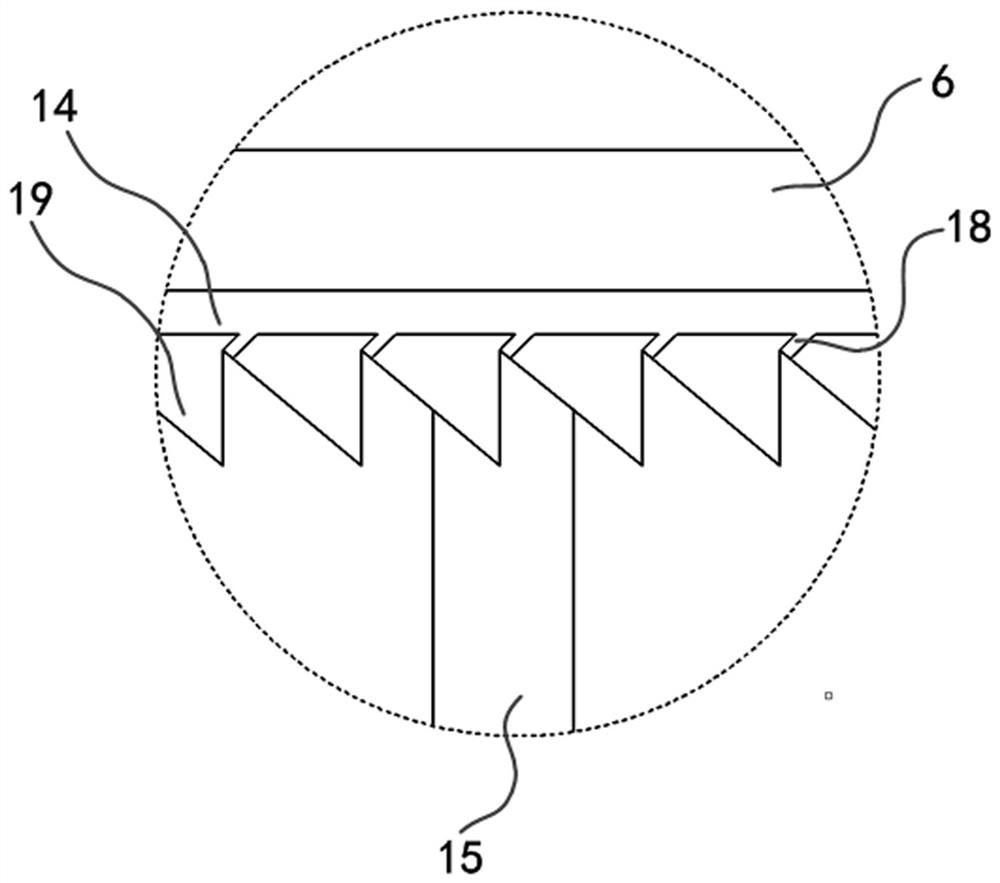

[0040] The upper zone includes a smoke inlet, a number of first spray ports 2, a number of second spray ports 3, a smoke outlet 4, a number of first gas outlets 5, and a concave well 6, and the smoke inlet is arranged in the upper zone In the connection position with the lower layer area, the flue gas outlet 4 is arranged on the top of the tower, and the tower body 1 is provided with a convex sill, and the convex sill is connected to the concave well 6, and the well wall of the concave well 6 is inclined and The bottom of the well is flat, the bottom of the concave well 6 is located at the half-height position of the upper zone, and the top of the convex sill is provided with...

Embodiment 2

[0064] refer to Figure 1-6 . This embodiment is basically the same as Embodiment 1, the difference is that in this embodiment:

[0065] As a preferred mode of the present invention, the bottom surface of the lower zone is provided with a first heating partition 20, and the first heating partition 20 is used to heat the working solution in the lower zone.

[0066] As a preferred mode of the present invention, a second heating partition 21 is provided on the side wall of the outer casing 8 facing the cation exchange membrane 9, and the second heating partition 21 is used to partially heat the lime water. heating.

[0067] As a preferred mode of the present invention, the water delivery pipeline 14 is provided with an insulating layer.

[0068] As a preferred mode of the present invention, the lower layer area also includes a pH detector, and an emergency water supply pipeline is also arranged between the lower layer area and the outer bag cavity 8, and an emergency water pum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com