Tin dioxide based nano gas sensitive material and preparation method thereof

A technology of tin dioxide and gas-sensitive materials, which is applied to the analysis of materials, electrochemical variables of materials, and material analysis by electromagnetic means.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Weigh 1 part of stannous chloride according to the net molar (part) ratio; 1 part of sodium dodecylbenzenesulfonate; 2 parts of potassium borohydride; 0.03 part of antimony trioxide; 0.02 part of ethyl orthosilicate; After 0.3 parts of the tube were prepared according to the following steps:

[0017] A) Grind the reactant particles stannous chloride and half of sodium dodecylbenzenesulfonate in an agate mortar for 10 minutes respectively, then mix and grind for 10 minutes, then mix the reactant particles with potassium borohydride and the remaining half Sodium dodecylbenzene sulfonate was firstly ground separately in an agate mortar for 10 minutes, then mixed and ground for 10 minutes, and finally the final products of the above two steps were mixed, ground for 30 minutes, and placed in air for 12 hours;

[0018] B) dilute ethyl orthosilicate with an appropriate amount of ethanol, add dropwise deionized water to produce a milky precipitate, then dissolve antimony trioxi...

Embodiment 2

[0023] First weigh 1 part of stannous chloride according to the net molar (part) ratio; 2 parts of sodium dodecylbenzenesulfonate; 2 parts of potassium borohydride; 0.04 part of antimony trioxide; 0.02 part of ethyl orthosilicate, carbon After 0.4 parts of nanotubes, the novel tin dioxide-based nano gas-sensitive material of the present invention was prepared in the same steps and sequence as Example 1.

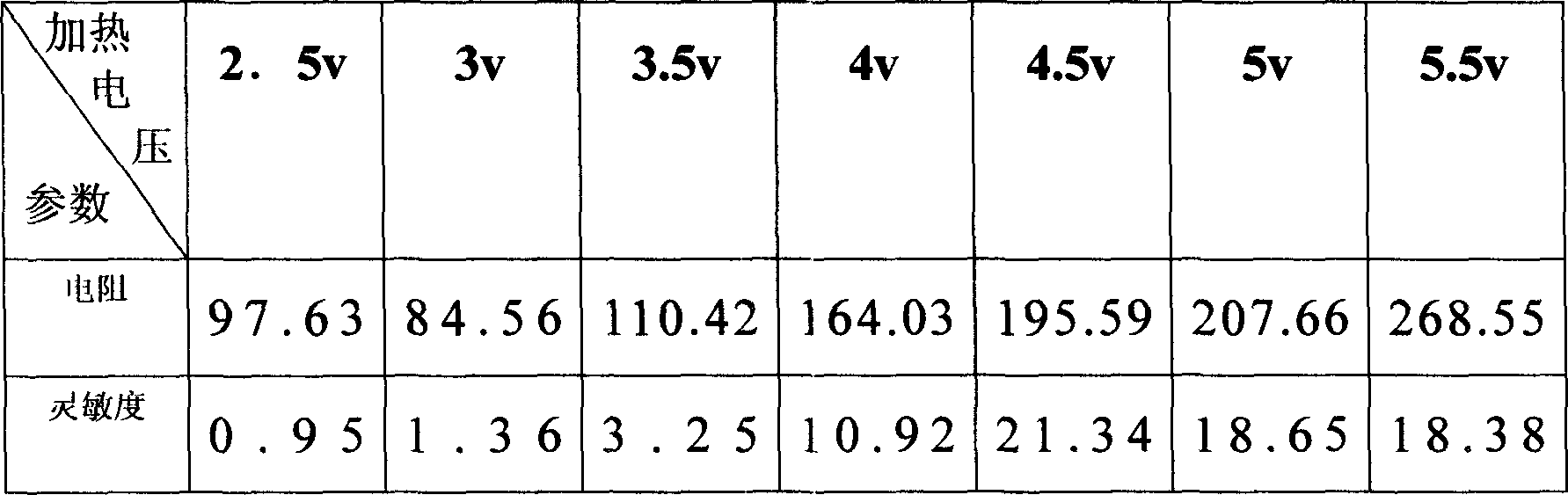

[0024] With the resistive gas sensor produced by the novel tin dioxide-based nano gas-sensitive material obtained in this example, the resistance (KΩ) value in the air and the sensitivity in 500ppm ethanol gas vary with the heating voltage parameters as shown in Table 2. Show.

Embodiment 3

[0026] First weigh 1 part of stannous chloride according to the net molar (part) ratio; 1 part of sodium dodecylbenzenesulfonate; 2 parts of potassium borohydride; 0.01 part of antimony trioxide; After 0.1 part of nanotubes, the novel tin dioxide-based nano gas-sensitive material of the present invention was prepared according to the same steps and sequence as Example 1.

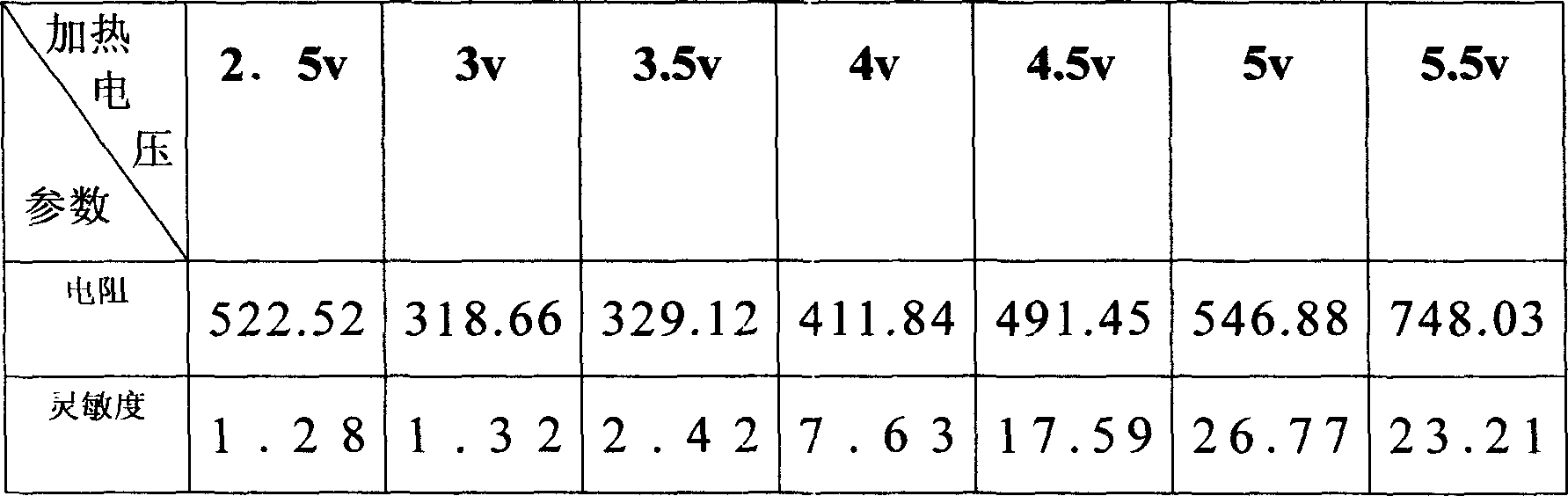

[0027] With the resistive gas sensor produced by the novel tin dioxide-based nano gas-sensitive material obtained in this example, the resistance (KΩ) value in the air and the sensitivity in 500ppm ethanol gas vary with the heating voltage parameters as shown in Table 3. Show.

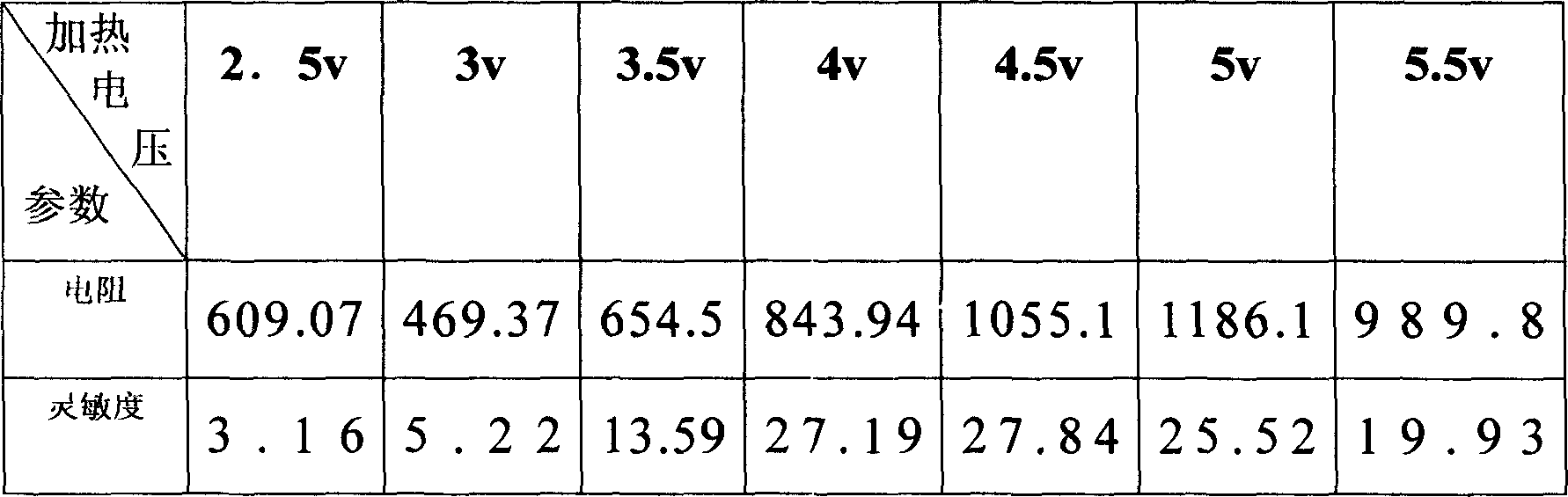

[0028] Table 1:

[0029]

[0030] Table 2:

[0031]

[0032] table 3:

[0033]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com