Preparation method of high molecular polyethylene polyamine polyether used for preparing water-based functional liquids

A technology of ethylene polyamine polyether and polyethylene polyamine, which is applied in the field of improvement of polymer polyethylene polyamine polyether prepared by polymerization reaction, and can solve the problems of increasing polyether molecular weight, increasing polyether viscosity, narrow molecular weight distribution, etc. , to achieve the effects of improved shear resistance and viscosity-temperature performance, product cost saving, and short production cycle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

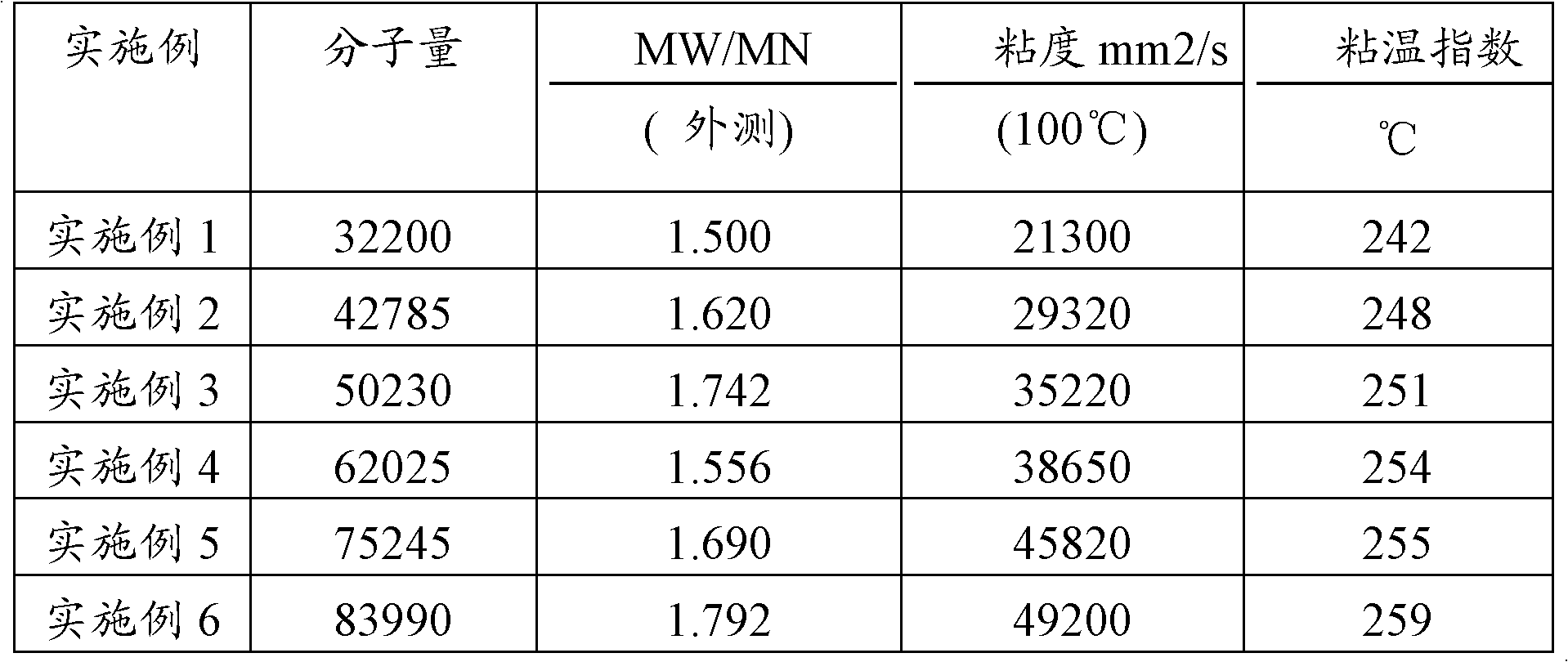

Examples

Embodiment 1

[0020] Aggregate in two steps:

[0021] (1) Add 10Kg of polyethylene polyamine into the reaction kettle, heat up to 120°C, vacuum dehydrate for 1 hour, slowly add 120Kg of a mixture of propylene oxide and ethylene oxide dropwise, the weight ratio between the two is: epoxy Propane: ethylene oxide = 1:3.5, control the reaction temperature at 90-100°C, after the dropwise addition, keep the temperature for 1 hour, cool down to 80°C and discharge.

[0022] (2) Polyether 0.8Kg from the previous step, add 50g of catalyst metal hydride, add 7Kg of propylene oxide and ethylene oxide mixture at one time, the ratio is 1:3.5, heat up to 140°C, after the reaction is completed, slowly add ring The mixture of oxypropylene and ethylene oxide is 130Kg, and the reaction temperature is controlled at 90-100°C. After the dropwise addition is completed, the temperature is kept for 1 hour, and the temperature is lowered to discharge.

Embodiment 2

[0024] Take 0.6Kg of polyether in the first step in Example 1, add 50g of catalyst metal hydride, add 7Kg of propylene oxide and ethylene oxide mixture at one time, the ratio is 1:3.5, heat up to 140°C, after the reaction is completed, slowly drop Add 130Kg of a mixture of propylene oxide and ethylene oxide, and control the reaction temperature at 90-100°C. After the dropwise addition, keep the temperature for 1 hour, then cool down and discharge.

Embodiment 3

[0026] Take 0.4Kg of polyether in the first step in Example 1, add 50g of catalyst metal hydride, add 7Kg of propylene oxide and ethylene oxide mixture at one time, the ratio is 1:3.5, heat up to 140°C, after the reaction is completed, slowly drop Add 130Kg of a mixture of propylene oxide and ethylene oxide, and control the reaction temperature at 90-100°C. After the dropwise addition, keep the temperature for 1 hour, then cool down and discharge.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Molecular weight distribution coefficient | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com