Treatment method and treatment system for ammoniated pelleting compound fertilizer tail gas

A treatment method and compound fertilizer technology, which are applied in chemical instruments and methods, separation methods, dispersed particle separation, etc., can solve the problems of not meeting the environmental protection objectives of production tasks, reducing environmental protection emission indicators, and low ammonia solubility, and achieving a good society. Benefit, Complaint Reduction, Effect of Reducing Ammonia Consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

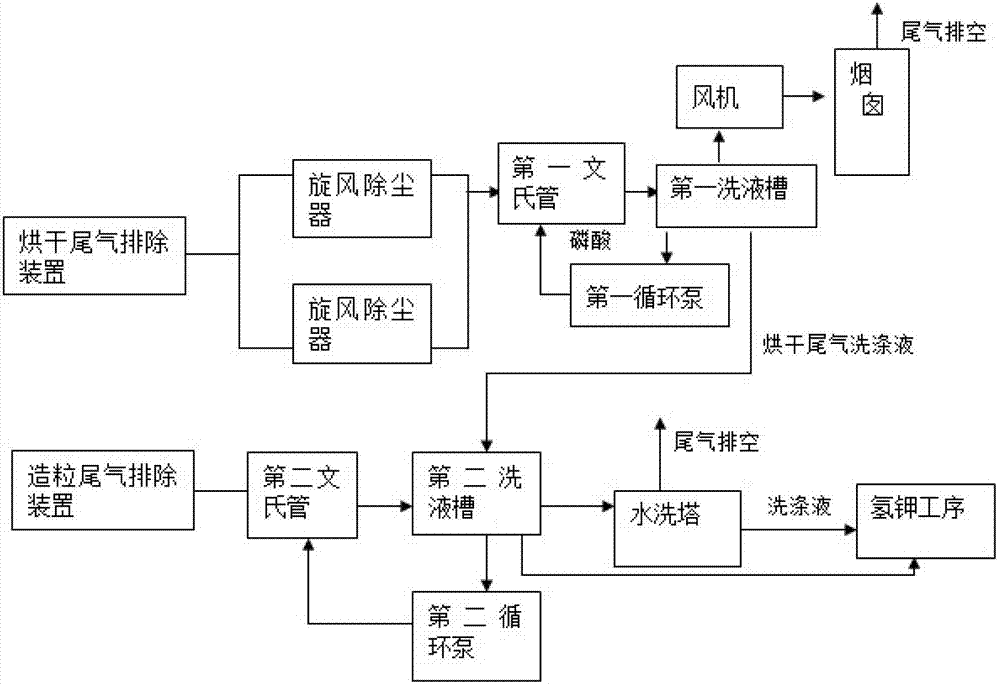

Image

Examples

Embodiment 1

[0034] A method for treating tail gas of ammoniated granulated compound fertilizer, comprising the following process steps:

[0035] (1) 50000m per hour 3 Containing NH at a temperature of 60°C 3 The amount of 80 kg of dry tail gas is transported to two parallel cyclone dust collectors for cyclone dust removal, and then enters the first venturi tube;

[0036] (2) put 20m 3 Phosphoric acid aqueous solution with a mass concentration of phosphorus pentoxide of 20% is pumped into the first venturi tube by the first circulation pump from the first washing liquid tank, and is sprayed out through the nozzle in the first venturi tube to dry the tail gas. Washing, using phosphoric acid to absorb ammonia in the tail gas so that the pH of the washing solution is ≤ 1;

[0037] (3) The exhaust gas and washing liquid after washing are recycled to the first washing liquid tank; the amount of ammonia discharged from the drying tail gas after absorption is 20 kg / hour, and the gas that meets...

Embodiment 2

[0046] A method for treating tail gas of ammoniated granulated compound fertilizer, comprising the following process steps:

[0047] (1) 70000m per hour 3 Containing NH at a temperature of 80°C 3 The amount of 90 kg of dry tail gas is transported to two parallel cyclone dust collectors for cyclone dust removal, and then enters the first venturi tube;

[0048] (2) put 20m 3 Phosphoric acid aqueous solution with a mass concentration of phosphorus pentoxide of 20% is pumped into the first venturi tube by the first circulation pump from the first washing liquid tank, and is sprayed out through the nozzle in the first venturi tube to dry the tail gas. Washing, using phosphoric acid to absorb ammonia in the tail gas so that the pH of the washing solution is ≤ 1;

[0049] (3) The exhaust gas and washing liquid after washing are recycled to the first washing liquid tank; the amount of ammonia discharged from the drying tail gas after absorption is 20 kg / hour, and the gas that meets t...

Embodiment 3

[0058] A method for treating tail gas of ammoniated granulated compound fertilizer, comprising the following process steps:

[0059] (1) 100000m per hour 3 Containing NH at a temperature of 90°C 3 The amount of 100 kg of dry tail gas is transported to two parallel cyclone dust collectors for cyclone dust removal, and then enters the first venturi tube;

[0060] (2) put 20m 3 Phosphoric acid aqueous solution with a mass concentration of phosphorus pentoxide of 20% is pumped into the first venturi tube by the first circulation pump from the first washing liquid tank, and is sprayed out through the nozzle in the first venturi tube to dry the tail gas. Washing, using phosphoric acid to absorb ammonia in the tail gas so that the pH of the washing solution is ≤ 1;

[0061] (3) The exhaust gas and washing liquid after washing are recycled to the first washing liquid tank; the amount of ammonia discharged from the drying tail gas after absorption is 20 kg / hour, and the gas that mee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com