Preparation method of comb-type polymer phase change energy storage material

A technology of phase-change energy storage materials and comb-like polymers, applied in the direction of heat exchange materials, chemical instruments and methods, etc., can solve the problems of unstable heat storage performance, narrow application range, and low heat enthalpy of polyethylene glycol , to achieve the effects of good degradation resistance, good applicability and fast response speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

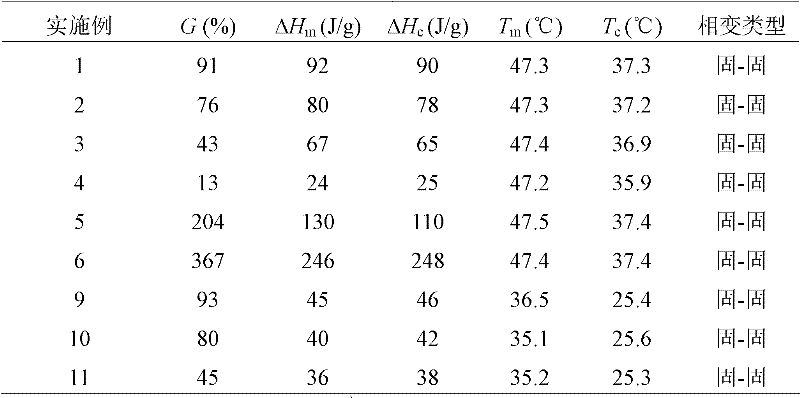

Embodiment 1

[0028] PVA (degree of polymerization 1780, degree of hydrolysis 98%) is placed in an oven and dried at 100°C for more than 6 hours until constant weight; 3% of its mass of CaH is added to the solvent DMF 2 , and then purified by distillation under reduced pressure to obtain dry DMF for later use; mix the dried PVA with DMF and NaH twice its mass, heat up to 50°C to dissolve, stir and mix evenly, and react for 4 hours to obtain a PVA metallization product; dry 1-Bromooctadecane is dissolved in DMF to form a solution with a mass fraction of 20%, and then the prepared solution is added dropwise at a speed of 1mL / min to control the ratio between 1-Bromooctadecane and PVA. Molar ratio is 1: 1, add the catalyst DBTDL of mass 0.01%, vigorously stir, and keep reaction temperature 75 ℃, react 10h, until complete reaction, obtain the primary product of the copolymer of 1-octadecane grafted PVA; The primary product was extracted with acetone for 4 hours to remove unreacted PVA, and the p...

Embodiment 2

[0035] The molar ratio between 1-bromooctadecane and PVA in Example 1 was adjusted to 0.8:1, and the rest were the same as in Example 1. The properties of the obtained phase change material are listed in Table 1.

Embodiment 3

[0037] The molar ratio between 1-bromooctadecane and PVA in Example 1 was adjusted to 0.4:1, and the rest were the same as in Example 1. The properties of the obtained phase change material are listed in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| endothermic temperature | aaaaa | aaaaa |

| exothermic temperature | aaaaa | aaaaa |

| thermal resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com