Method for preparing fatty boric acid by utilizing isopropoxyboric acid pinacol ester

A technology of isopropoxyboric acid and propoxyboronic acid, which is applied in the field of preparing aliphatic boric acid from isopropoxyboronic acid pinacol ester, can solve the problems of restricting industrial production, potential safety hazards, harsh temperature conditions, etc. Flammable by-products, easy operation, avoiding the effect of cryogenic low temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

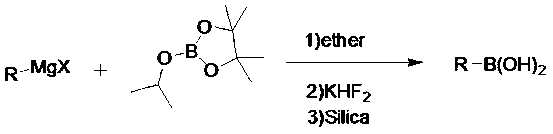

Method used

Image

Examples

Embodiment 1

[0019] Into a mechanically stirred 1L four-neck flask, under the protection of argon, add 74.4g of isopropoxy borate pinacol ester (0.40mol, 1eq), and put 200g of methylmagnesium chloride in tetrahydrofuran solution (2.0mmol / g, 0.40mol, 1eq), temperature controlled at -5 ~ 0 ℃ drop Grignard reagent, 3h after the drop, the temperature was raised to 20 ~ 25 ℃ for 2h reaction. After the reaction is completed, the temperature is controlled at 20-30°C, and 312g (1mol, 2.5eq) of 25% potassium bifluoride aqueous solution is added dropwise, and stirred at 20-30°C for 2-3 hours after dropping. Add 20 g of silica gel, and continue stirring at 20-30°C for 2-3 hours. After filtration, the filtrate was separated into layers, the aqueous layer was extracted with MTBE (200g×6), and the organic layers were combined. Concentrate the organic layer to obtain a crude product, add 40g ethyl acetate to redissolve, filter out insolubles, concentrate the filtrate, beat with 30g n-hexane, filter, an...

Embodiment 2

[0021] Into a mechanically stirred 1L four-neck flask, under argon protection, add 70.7g of isopropoxy borate pinacol ester (0.38mol, 1eq), and put 200g of ethylmagnesium chloride in tetrahydrofuran solution (1.9mmol / g, 0.38mol, 1eq), temperature controlled at -5 ~ 0 ℃ drop Grignard reagent, 2h after the drop, the temperature was raised to 20 ~ 25 ℃ for 2h reaction. After the reaction is completed, 296.4 g (0.95 mol, 2.5 eq) of 25% potassium bifluoride aqueous solution is added dropwise at a temperature of 20-30°C, and stirred at 20-30°C for 2-3 hours after dropping. Add 20 g of silica gel, and continue stirring at 20-30°C for 2-3 hours. After filtration, the filtrate was separated into layers, the aqueous layer was extracted with MTBE (180g×4), and the organic layers were combined. Concentrate the organic layer to obtain a crude product, add 35g of ethyl acetate to redissolve, filter out insolubles, concentrate the filtrate, beat with 28g of n-hexane, filter, and dry to obt...

Embodiment 3

[0023] In a mechanically stirred 1L four-neck flask, under argon protection, add 89.3g of isopropoxy borate pinacol ester (0.48mol, 1eq), and put 240g of isobutylmagnesium chloride in tetrahydrofuran solution (2.0mmol / g, 0.48mol, 1eq), temperature controlled at -5 ~ 0 ℃ drop Grignard reagent, 2h after the drop, the temperature was raised to 20 ~ 25 ℃ for 2h. After the reaction is completed, control the temperature at 20-30°C, add dropwise 374.4g (1.2mol, 2.5eq) of 25% potassium bifluoride aqueous solution, and stir at 20-30°C for 2-3 hours after dropping. Add 20 g of silica gel, and continue stirring at 20-30°C for 2-3 hours. After filtration, the filtrate was separated into layers, the aqueous layer was extracted with MTBE (200g×4), and the organic layers were combined. Concentrate the organic layer to obtain crude product, add 40g ethyl acetate to redissolve, filter out insoluble matter, concentrate the filtrate, 31g n-hexane beating, filter, dry to obtain 29.0g of white p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com