Carbon-loaded nano bismuth composite material, preparation method and application thereof

A composite material and nano-bismuth technology, which is applied in the preparation of organic compounds, preparation of amino hydroxyl compounds, chemical instruments and methods, etc., can solve the problems of limited application range, poor dispersion of nano-bismuth, etc., so as to reduce production costs and simplify Production process, the effect of improving the dispersion performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] A preparation method of carbon-loaded nano-bismuth composite material, comprising the following steps: mixing 10g citric acid, 0.5g bismuth nitrate pentahydrate, 5g tartaric acid and 50g water, after stirring evenly, transferring the mixed solution obtained to a polytetrafluoroethylene Put the hydrothermal kettle in an ethylene-lined hydrothermal kettle, then put the hydrothermal kettle into an oven, control the reaction temperature at 180°C, and the reaction time for 8 hours. After the hydrothermal kettle is naturally cooled, take out the contents of the hydrothermal kettle, wash with water, Dry to obtain the carbon-loaded nano-bismuth material.

[0021] A carbon-loaded nano-bismuth composite material, which is prepared by the above-mentioned preparation method.

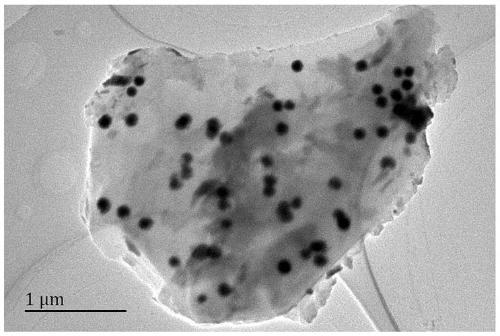

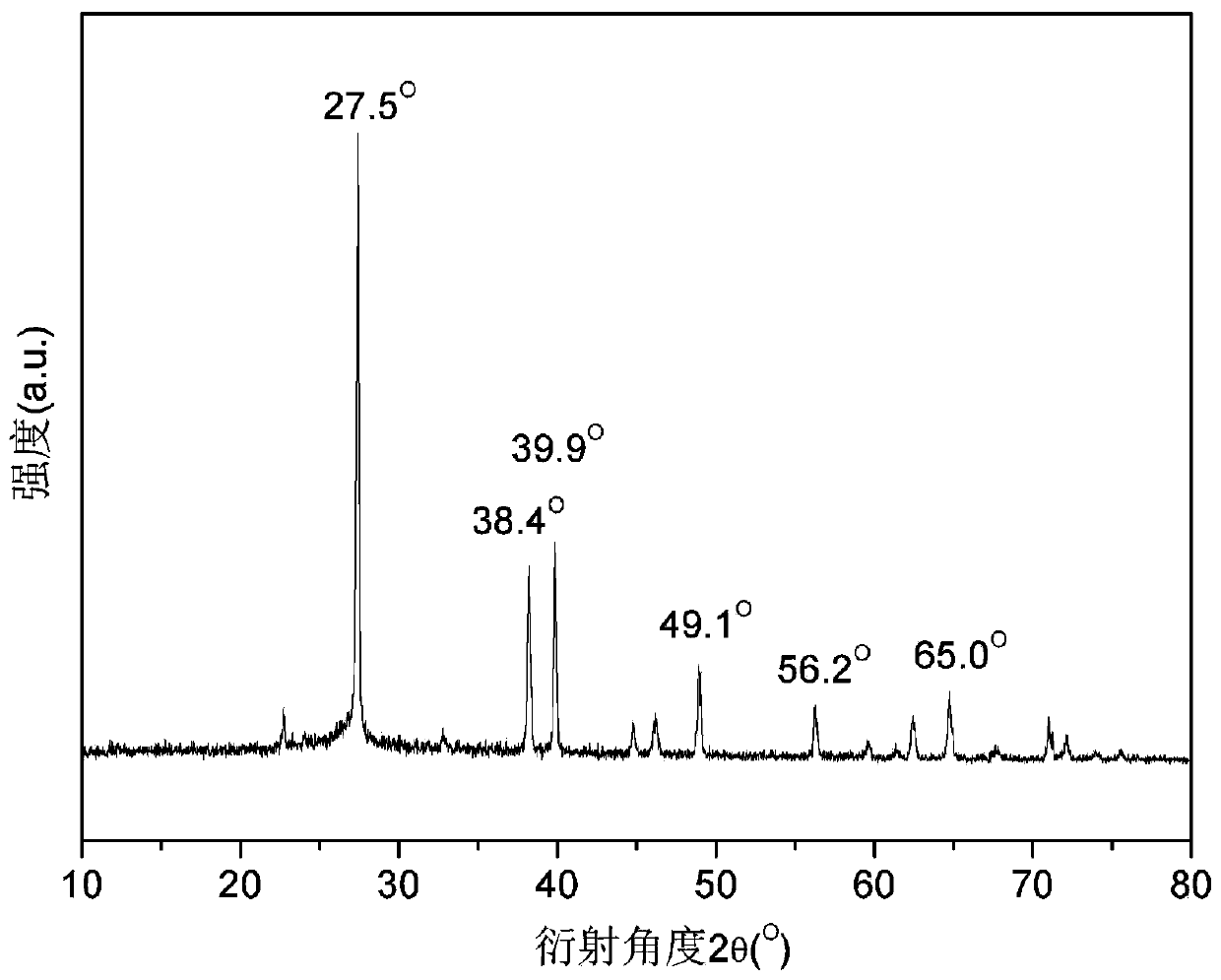

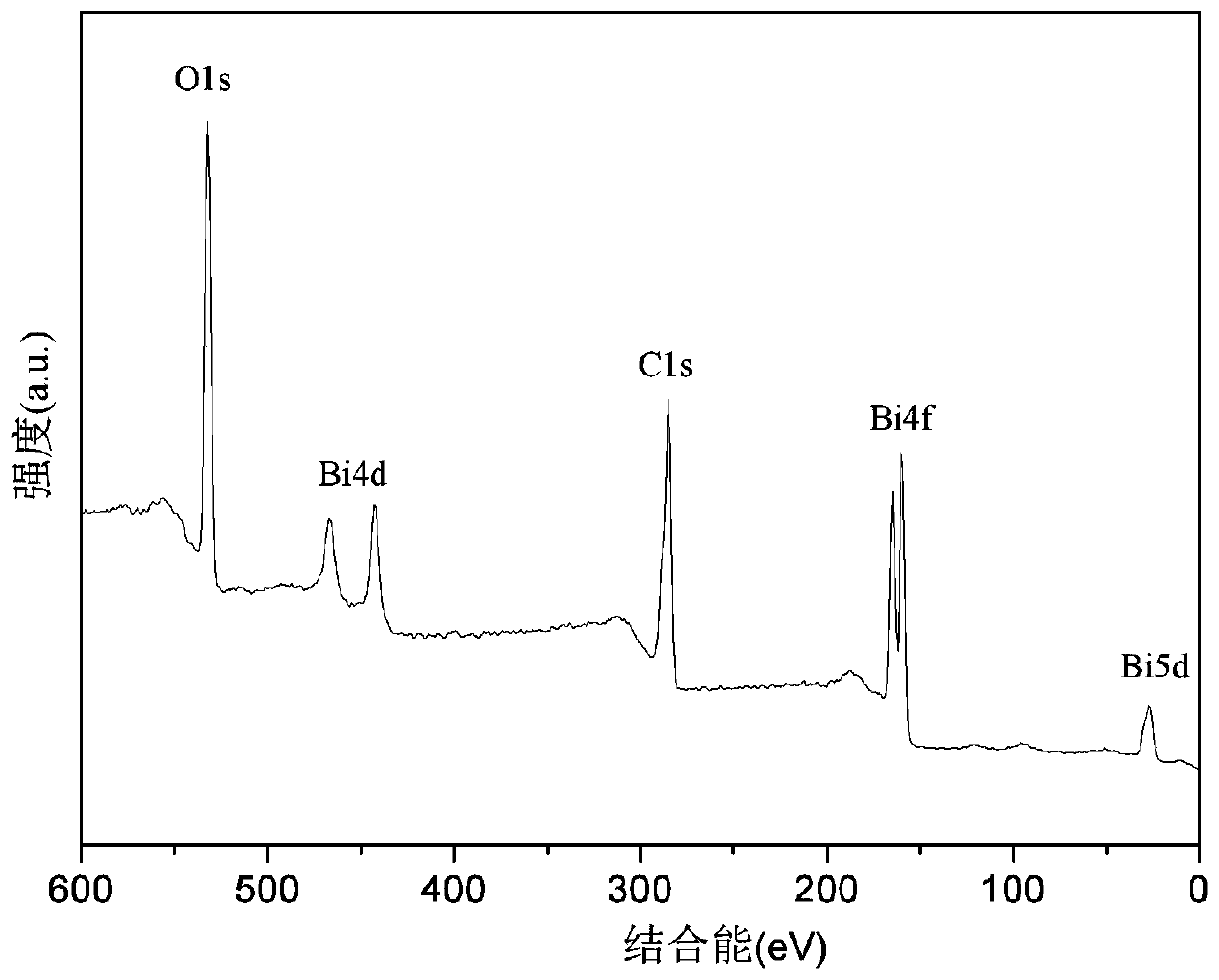

[0022] The prepared composites were characterized by transmission electron microscope, X-ray powder diffractometer and X-ray photoelectron spectrometer. figure 1 , figure 2 ,and image 3 They are the tran...

Embodiment 2

[0031] A preparation method of a carbon-loaded nano-bismuth composite material, comprising the steps of: mixing 10 g of citric acid, 0.2 g of bismuth nitrate pentahydrate, 1 g of tartaric acid and 20 g of water, and stirring evenly, transferring the resulting mixed solution to a hydrothermal kettle , and then put the hydrothermal kettle into an oven, control the reaction temperature to 150° C., and the reaction time to 12 hours. After the hydrothermal kettle is naturally cooled, take out the contents of the hydrothermal kettle, wash with water, and dry to obtain a carbon-loaded nanobismuth material.

[0032]A carbon-loaded nano-bismuth composite material, which is prepared by the above-mentioned preparation method.

[0033] The composite material was characterized by transmission electron microscopy, X-ray diffractometer and X-ray photoelectron spectroscopy. The results showed that nanobismuth was uniformly dispersed in the carbon material, and the atomic percentage of carbon i...

Embodiment 3

[0036] A preparation method of carbon-loaded nano-bismuth composite material, comprising the following steps: 10g citric acid, 1.0g bismuth nitrate pentahydrate, 10g tartaric acid and 100g water are mixed, after stirring evenly, the mixed solution obtained is transferred to a polytetrafluoroethylene Put the hydrothermal kettle into an oven, control the reaction temperature to 220°C, and the reaction time for 4 hours. After the hydrothermal kettle is naturally cooled, take out the contents of the hydrothermal kettle, wash with water, Dry to obtain the carbon-loaded nano-bismuth material.

[0037] A carbon-loaded nano-bismuth composite material, which is prepared by the above-mentioned preparation method.

[0038] The composite material was characterized by transmission electron microscope, X-ray diffractometer and X-ray photoelectron spectrometer, etc. The results showed that nano-bismuth was uniformly dispersed in the carbon material, and the atomic percentage of carbon in the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com