Wetting reversal agent for pressure reduction and augmented injection of ultra-low permeability reservoir and preparation method thereof

A wetting reversal and oil penetration technology, which is applied in ether preparation, reductive alkylation preparation, chemical instruments and methods, etc., can solve the problems of short validity period, small action distance, poor effect, etc., to improve oil displacement efficiency, The effect of improving flow ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

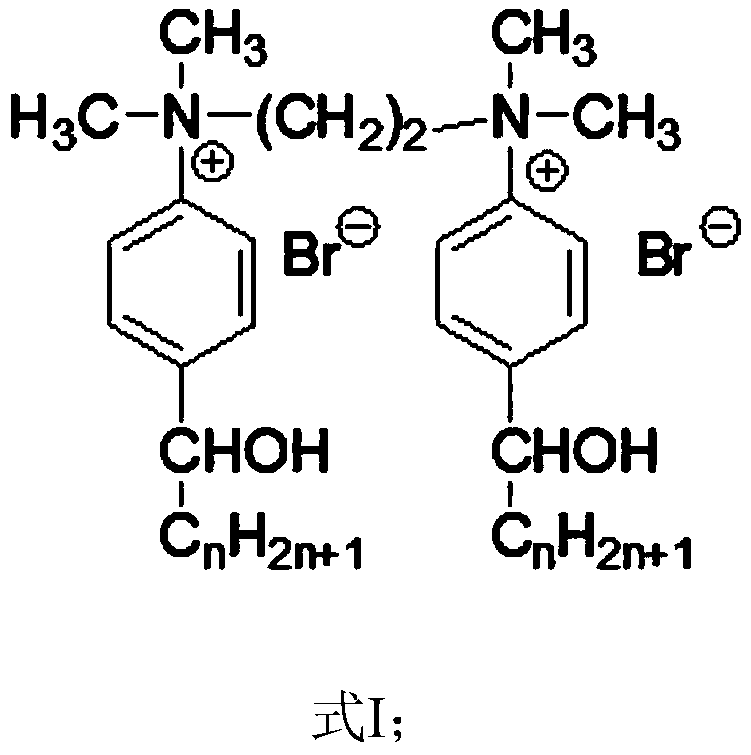

[0047] Cationic gemini type surfactant shown in embodiment 1 formula I

[0048] The preparation method is as follows:

[0049]

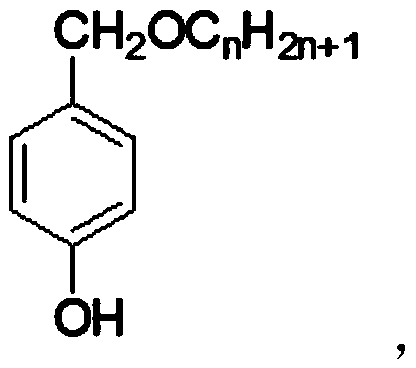

[0050] S1. Dissolve 1 mol of p-hydroxybenzaldehyde in 100 mL of dichloromethane, add 1 mol of thionyl chloride and 2 mol of triethylamine in sequence, react at room temperature for 2 hours, add 1 mol of alkyl alcohol (n=12), stir and react at room temperature for 2 hours, and obtain Intermediate I (A);

[0051]

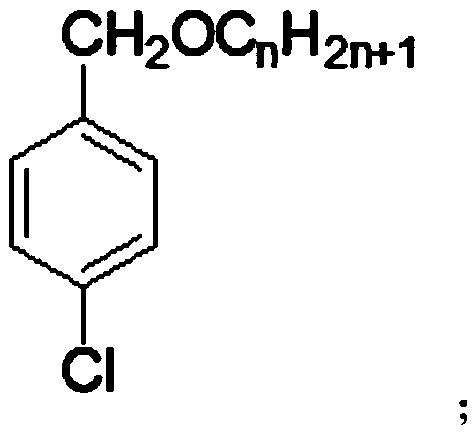

[0052] S2. Dissolve intermediate I (A) in 100 mL of acetonitrile, add 2 mol of triethylamine and 1 mol of p-toluenesulfonyl chloride, heat to 60°C, and react for 2 hours to obtain intermediate II (B);

[0053] S3. Dissolve the intermediate II (B) in 100 mL of acetone, add 2 mol of triethylamine and 1 mol of potassium bromide, and react at room temperature for 1 hour to obtain the intermediate III (C);

[0054]

[0055] S4. Mix 1mol N,N'-dimethylethylenediamine and 100mL 85wt% formic acid, heat up to 80°C, add 100mL 35wt% formaldehyd...

Embodiment 2

[0059] Embodiment 2 cationic gemini type surfactant shown in formula I

[0060] The preparation method is as follows:

[0061] S1. Dissolve 1.2 mol of p-hydroxybenzaldehyde in 100 mL of dichloromethane, add 1 mol of thionyl chloride and 2 mol of triethylamine in sequence, react at room temperature for 3 hours, add 1 mol of alkyl alcohol (n=10), and stir at room temperature for 2 hours. Intermediate I (A) is obtained;

[0062] S2. Dissolve intermediate I (A) in 100 mL of acetonitrile, add 2 mol of triethylamine and 1.2 mol of p-toluenesulfonyl chloride, heat to 80°C, and react for 4 hours to obtain intermediate II (B);

[0063] S3. Dissolving intermediate II (B) in 100 mL of acetone, adding 2 mol of triethylamine and 1.2 mol of potassium bromide, and reacting at room temperature for 2 hours to obtain intermediate III (C);

[0064] S4. Mix 1.2mol N,N'-dimethylethylenediamine and 100mL 85wt% formic acid, heat up to 85°C, add 100mL 40wt% formaldehyde solution, heat up to 120°C, ...

Embodiment 3

[0066] Example 3 Cationic Gemini Surfactants Shown in Formula I

[0067] The preparation method is as follows:

[0068] S1. Dissolve 1.1 mol of p-hydroxybenzaldehyde in 100 mL of dichloromethane, add 1 mol of thionyl chloride and 2 mol of triethylamine in sequence, react at room temperature for 2.5 hours, then add 1 mol of alkyl alcohol (n=18), and stir for 2 hours at room temperature , to obtain intermediate I (A);

[0069] S2. Dissolve intermediate I (A) in 100 mL of acetonitrile, add 2 mol of triethylamine and 1.1 mol of p-toluenesulfonyl chloride, heat to 70°C, and react for 3 hours to obtain intermediate II (B);

[0070] S3. Dissolving the intermediate II (B) in 100 mL of acetone, adding 2 mol of triethylamine and 1.1 mol of potassium bromide, and reacting at room temperature for 1.5 h to obtain the intermediate III (C);

[0071] S4. Mix 1.1mol N,N'-dimethylethylenediamine and 100mL 85wt% formic acid, heat up to 82°C, add 100mL 35-40wt% formaldehyde solution, heat up to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com