Well killing process using fuzzy ball well killing fluid for natural gas well without reduction of pressure

A technology of natural gas and well killing fluid, which is applied in the field of well killing operation technology in the workover process of natural gas wells. To solve the problem, achieve good effect of formation temporary plugging, avoid prolonging the construction period, and highlight the effect of formation applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

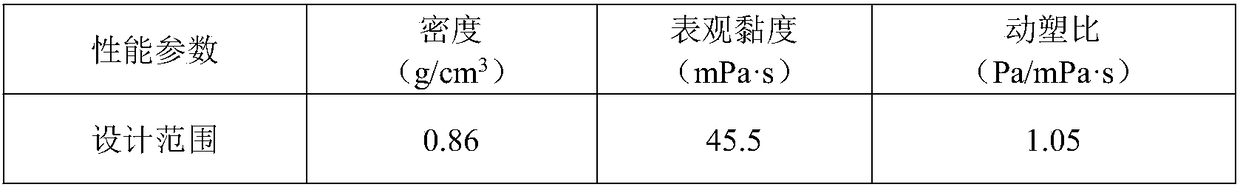

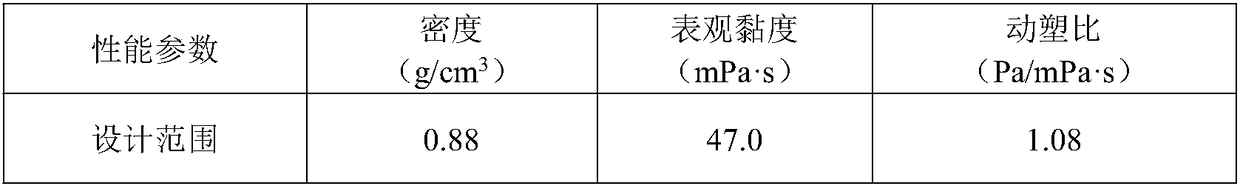

[0023] The process of killing a gas well without depressurization by the velvet well killing fluid of a natural gas well comprises the following steps:

[0024] A, the production of gas well workover with vesicle kill fluid, that is, in 1000 parts by weight of clear water, add 2.4-4.8 parts by weight of velvet agent, 7.2-14.4 parts by weight of cystic agent and 2.4-4.8 parts by weight of cholecystic agent;

[0025] The velvet agent consists of 4-6 parts by weight of petroleum grade sodium carboxymethylcellulose, 3-4 parts by weight of high molecular weight polyacrylamide, 1-2 parts by weight of cross-linked polyvinylpyrrolidone, 1-2 parts by weight Parts of industrial potassium chloride mixed;

[0026] The cystic agent is made by mixing 4-6 parts by weight of carboxymethyl starch, 1-2 parts by weight of hydroxyethyl starch, and 1-2 parts by weight of hydroxypropyl starch;

[0027] The gallbladder agent is made by mixing 1-3 parts by weight of sodium dodecylbenzenesulfonate, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com