Soil-phase-free strong-inhibition shielding environment-friendly well killing fluid

A strong inhibitory and environmentally friendly technology, applied in the drilling composition, chemical instruments and methods, etc., can solve the problems of reservoir permeability damage, solid phase blockage of oil layer, change of rock channel and rock properties, etc. Restore the effect of reservoir permeability and easy backflow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

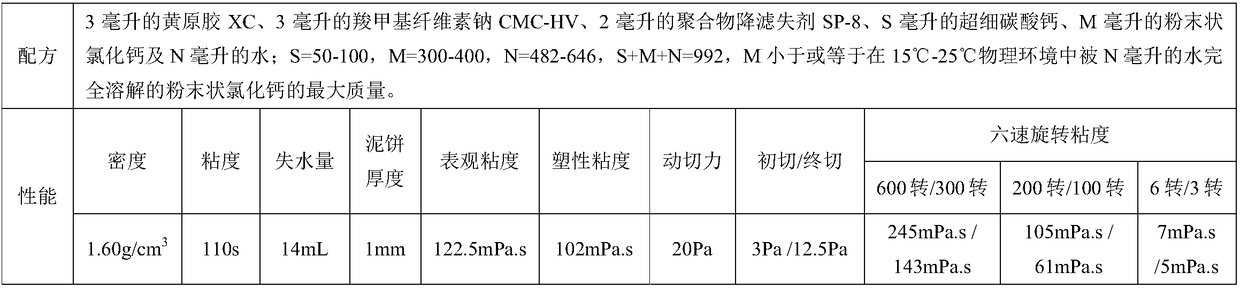

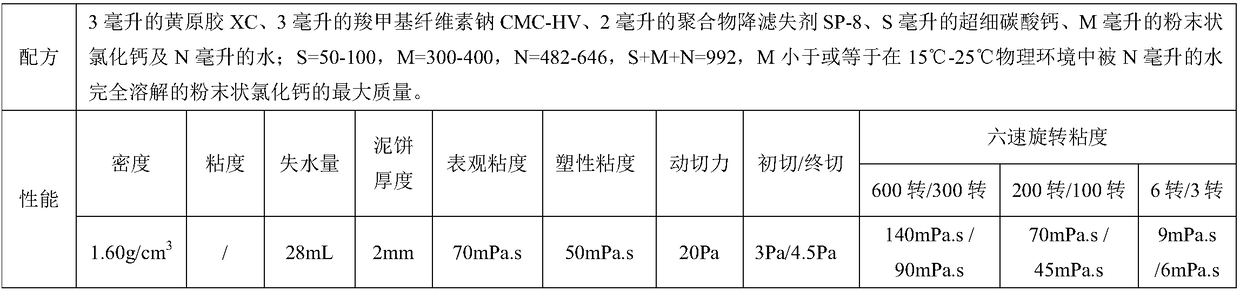

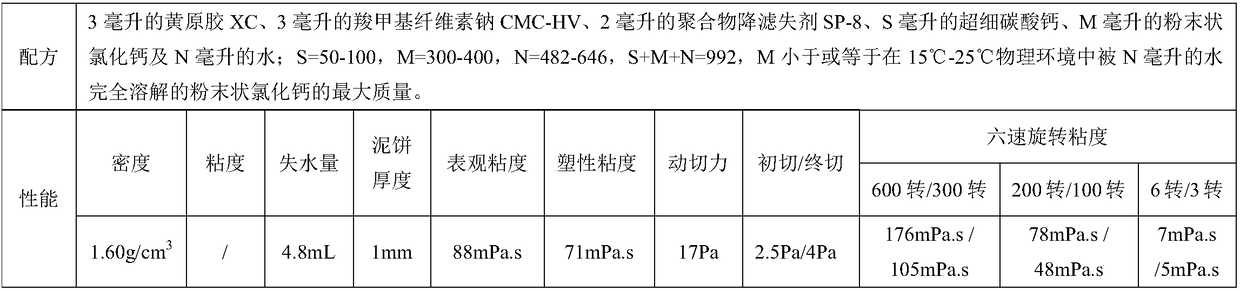

[0009] An environment-friendly well-killing fluid without soil phase strong inhibition shielding, including X unit volume of xanthan gum XC, Y unit volume of carboxymethyl cellulose sodium CMC-HV, Z unit volume of polymer fluid loss reducer SP- 8. Superfine calcium carbonate per unit volume of S, carboxymethyl starch CMS per unit volume of L, powdered calcium chloride per unit volume of M and water per unit volume of N; X=2-3, Y=2-3, Z =0-2, S=50-100, L=0-10, M=300-400, N=482-646, X+Y+Z+S+L+M+N=1000, M is less than or equal to The maximum mass of powdered calcium chloride completely dissolved by N unit volume of water in the physical environment of 15°C-25°C.

[0010] Excluding polymer fluid loss control agent SP-8, Z=0, X+Y+S+L+M+N=1000.

[0011] It also includes polymer fluid loss control agent SP-8, Z=2, X+Y+S+L+M+N=998.

[0012] Excluding carboxymethyl starch CMS, L=0, X+Y+S+M+N=998.

[0013] Also includes carboxymethyl starch CMS, L=10, X+Y+S+M+N=988.

[0014] When th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com