Oil recovery method for casing leaked well and dual-tubing oil recovery string adopted therein

A technology for lost wells and oil production pipes, applied in the field of downhole oil production pipe strings, can solve problems such as difficult repairs, high costs, and sand production at leak points, and achieve good promotion and application value, simple treatment methods, and the effect of solving casing leakage problems

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

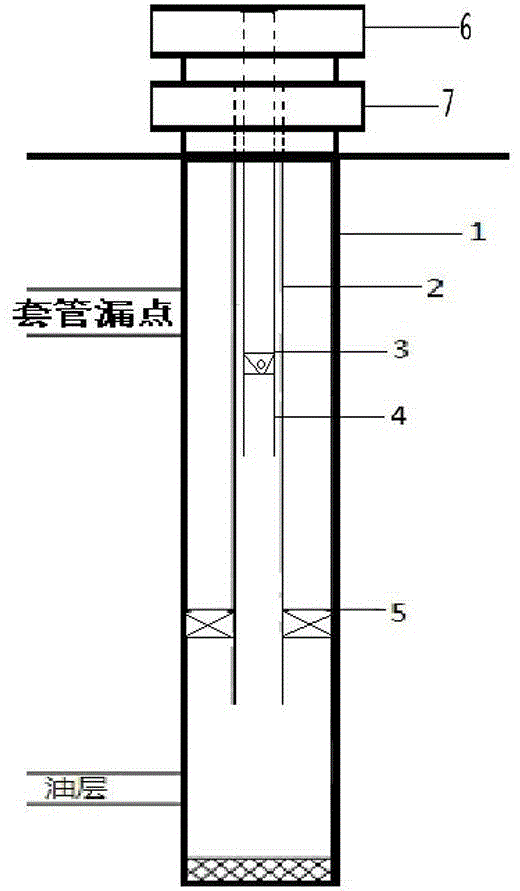

[0020] see figure 1 , the double-pipe production string used for the oil production method of a casing leakage well includes a tubing 2, a packer 5 is seated between the tubing 2 and the casing 1, and is located above the oil layer below the casing leakage point, and the tubing 2 The small-diameter oil pipe 4 and the small-diameter tubular pump 3 are lowered in the middle, and the oil pipe 2 is suspended at the wellhead through the lower oil pipe head 7 , The small-diameter tubing 4 is connected to the pump barrel of the small-diameter tubular pump 3 and is suspended at the wellhead through the upper tubing head 6, which can realize the operations of well flushing and liquid level measurement, and the packer 5 will no longer be affected by alternating loads and fail , the sealing effect is good and the validity period is long. The inner diameter of the lower oil pipe head 7 is greater than the inner diameter of the upper oil pipe head 6, and the upper oil pipe head 6 is threa...

Embodiment 2

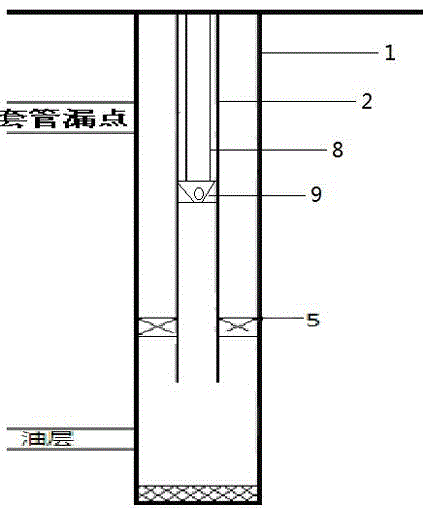

[0022] see figure 2 , the double-pipe production string used for the oil production method of a casing leakage well includes a tubing 2, a packer 5 is seated between the tubing 2 and the casing 1, and is located above the oil layer below the casing leakage point, and the tubing 2 Insert the hollow sucker rod 8 and the rod type oil well pump 9 in the middle, and the support sleeve of the rod type oil well pump 9 is fixed on the oil pipe 2 . The support sleeve of the rod well pump 9 can also be fixed on the tubing 2 below the packer 5. If the support sleeve is fixed below the packer 5, the validity period will be longer and the ferrule leakage effect will be better. The oil pipe 2 above the device 5 leaks, and oil recovery is also possible. The diameter of the hollow sucker rod 8 is 36mm; the diameter of the oil pipe 2 is 89mm, and the hollow sucker rod 8 serves as a liquid flow channel.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com