Low-temperature resistant and soil phase-free shielding environment-friendly killing fluid for oil and gas well workover

A low-temperature-resistant, soil-free technology, used in drilling compositions, chemical instruments and methods, etc., can solve the problems of large filtration loss, no suspension, and high price.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

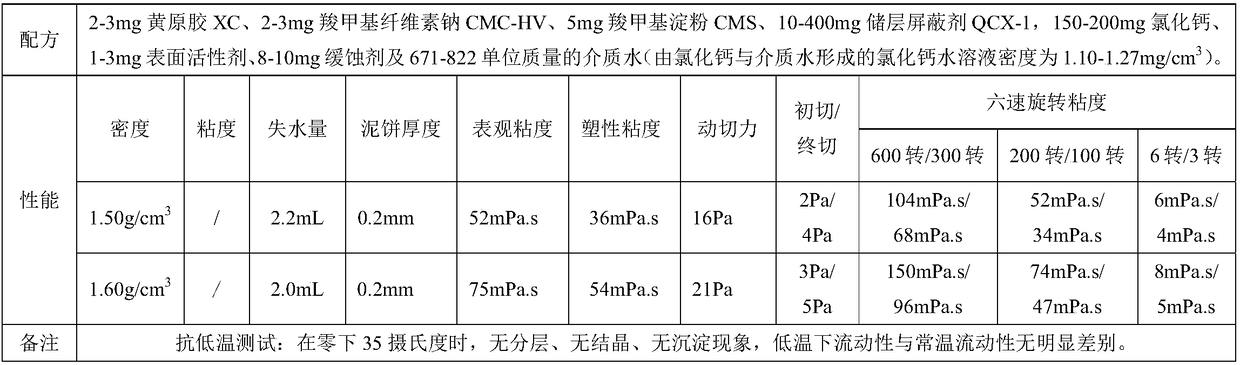

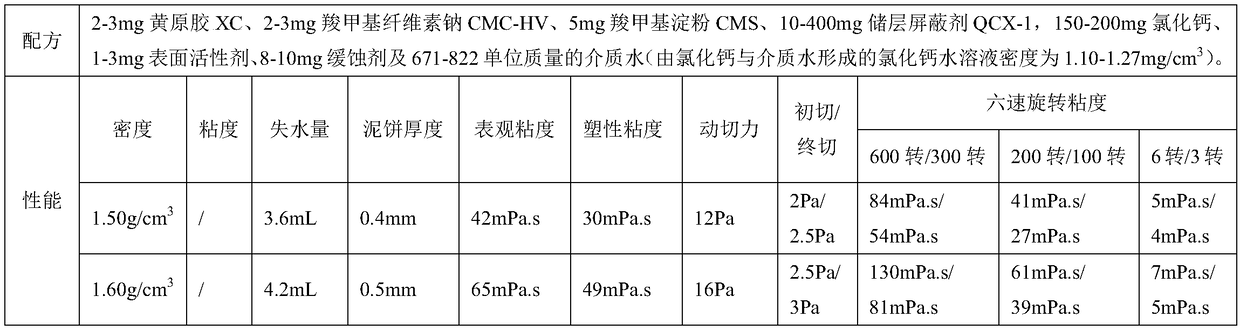

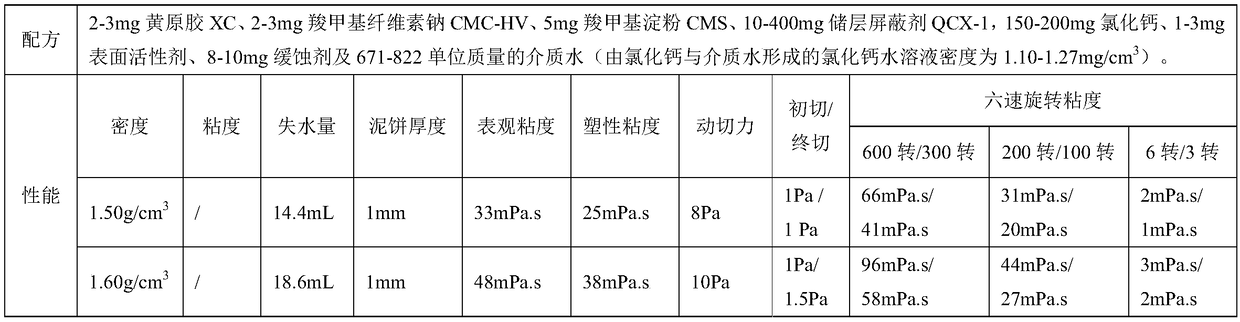

[0007] A kind of anti-low temperature and non-earth shielding environment-friendly well killing fluid for oil and gas well workover, including 2-3 units of suspending agent xanthan gum XC, 2-3 units of viscosity enhancer sodium carboxymethyl cellulose CMC- HV, 5-10 units of fluid loss reducer carboxymethyl starch CMS, 10-400 units of reservoir shielding agent QCX-1, 150-200 units of inorganic salt weighting agent calcium chloride, 1-3 units Quality of surfactant, 8-10 units of corrosion inhibitor and 371-822 units of medium water; calcium chloride is less than or equal to the maximum mass that is completely dissolved by medium water in a physical environment at normal temperature, and the calcium chloride and medium The density of the calcium chloride aqueous solution formed by water is 1.10-1.27g / cm in the normal temperature physical environment 3 .

[0008] When the newly made carboxymethyl starch CMS content of the present invention is 5mg and is maintained in a normal tem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com