Water control fracturing method for switchable cementing sliding sleeve of horizontal well

A horizontal well and water fracturing technology, which is applied in the direction of wellbore/well components, wellbore/well valve devices, production fluids, etc., can solve the problem of water plugging technology that is difficult to accurately control the water production section, single well production and design Anticipate low problems, achieve the effect of controlling the risk of water breakthrough, improving the recovery degree of mature oilfields, and high resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

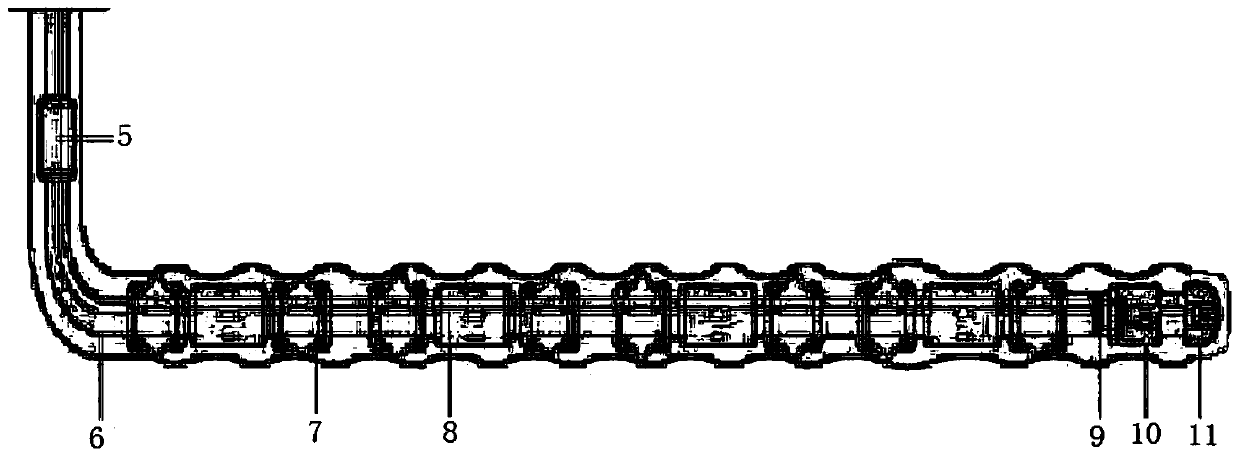

[0051] The invention provides a water-controlled fracturing method for a horizontal well with switchable cementing sliding sleeve, which comprises the following steps:

[0052] Step 1. According to the interpretation results of reservoir logging, select the positions with high acoustic transit time, low natural gamma ray and high resistivity in each fracturing stage as the fracturing sweet spots of each fracturing stage;

[0053] Step 2. Carry out preparatory work such as well drilling and reaming;

[0054] Step 3. Connect the switchable cementing sleeve to 5 1 / 2 "Casing predetermined fracturing position, can switch cementing sliding sleeve and 5 1 / 2 ″Thread and screw connection of the casing; run into the 5 1 / 2 ″casing, and cement the horizontal well;

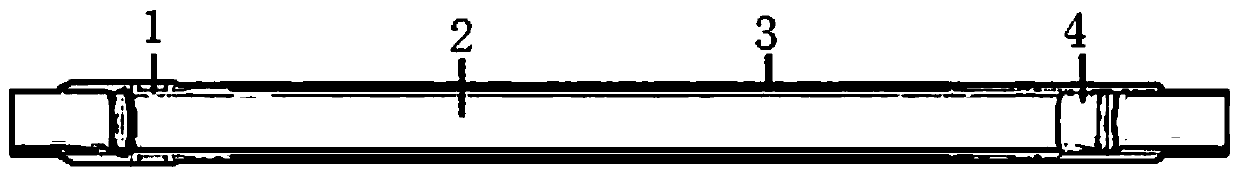

[0055] The switchable cementing sleeve meets pressure ≥70MPa, high temperature resistance ≥120°C, low temperature resistance ≤-30°C, maximum outer diameter ≤178mm, minimum inner diameter ≥124.26mm, tool assembly le...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com