Dispersing and grinding device for paint production

A grinding device and dispersing technology, applied in the field of paint production, can solve problems such as uneven grinding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical solution of the present invention will be further described in detail below in conjunction with specific examples, but the protection scope of the present invention is not limited to the following description.

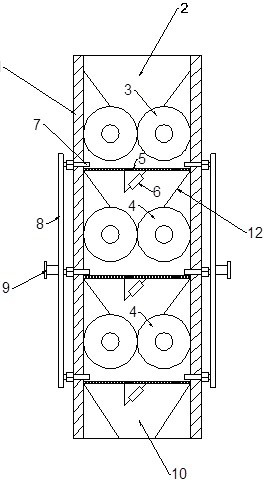

[0024] refer to figure 1 As shown, a dispersing and grinding device for paint production includes a grinding channel 1, the grinding channel 1 is vertically or obliquely arranged, and the upper and lower ports of the grinding channel 1 are respectively a feed port 2 and a discharge port 10. Wherein, the grinding channel 1 is a pipe made of metal material, preferably, the end face of the grinding channel 1 is designed as a rectangle, which is composed of figure 1 It can be seen that both the feed port 2 and the discharge port 10 are designed in a funnel shape.

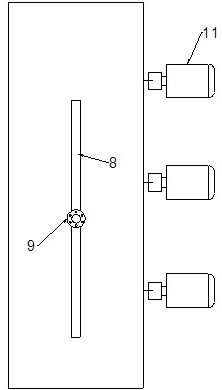

[0025] Furthermore, a first grinding roller 3 and at least one second grinding roller 4 are sequentially arranged in the grinding channel 1 from top to bottom, and its structure can be refe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com