Chemical material screening device facilitating rapid separation and impurity removal

A screening device and chemical technology, applied in the direction of solid separation, sieve, chemical instruments and methods, etc., can solve the problems of mixing some impurities, affecting product quality, and inconvenient discharge of impurities on the screen, and achieving the effect of increasing the rotation range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

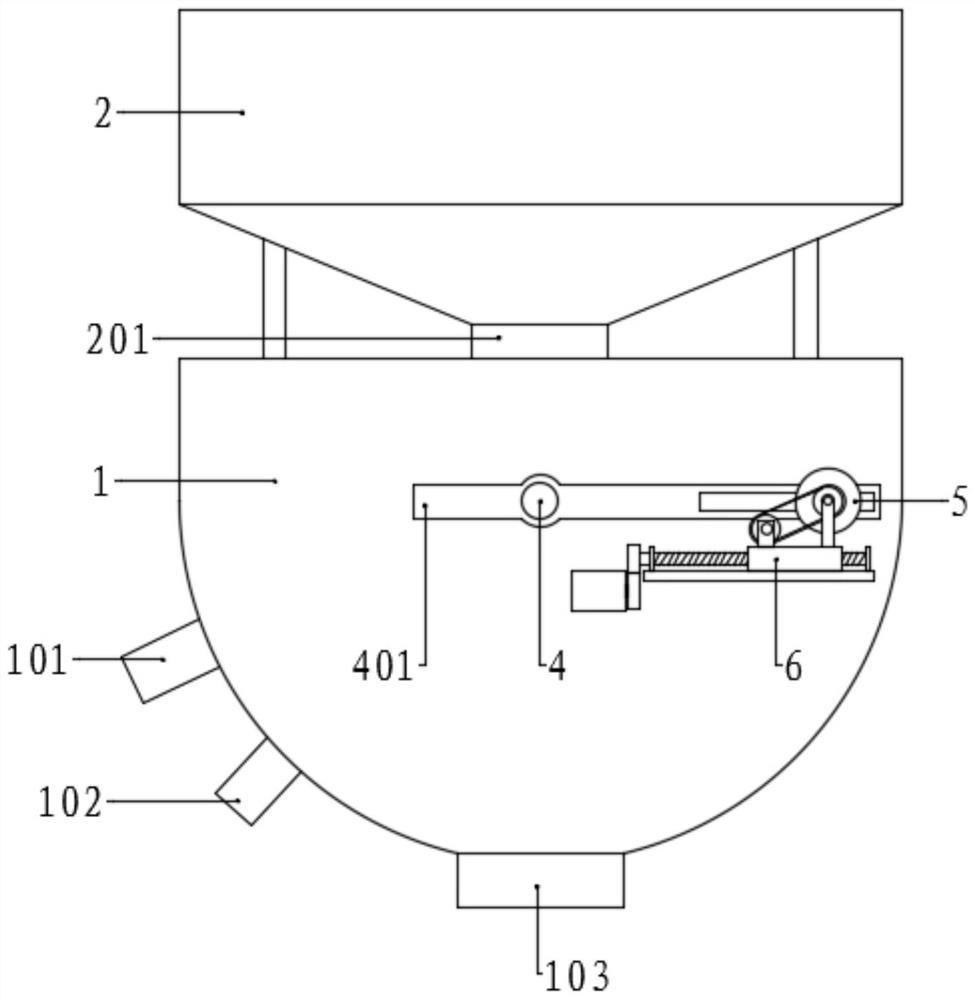

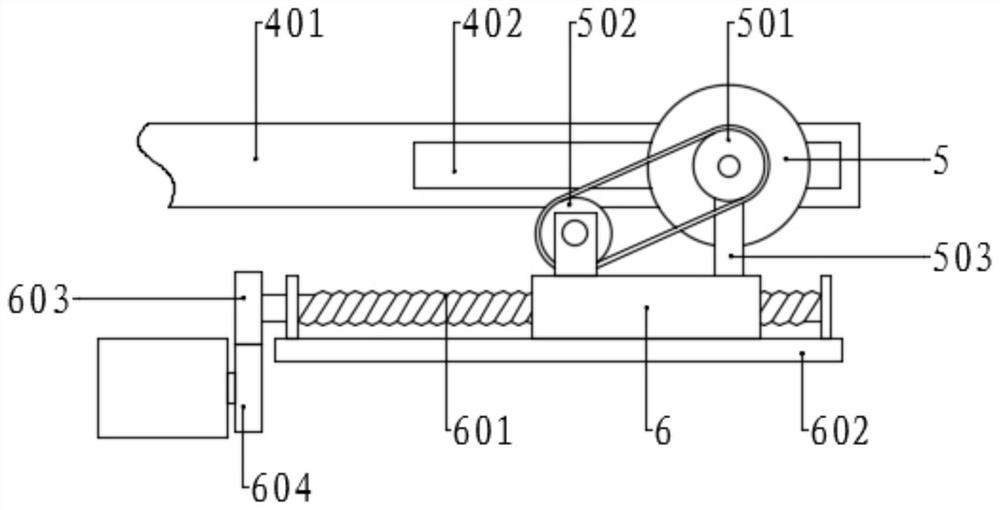

[0033] Please refer to the accompanying drawings, the present invention provides a technical solution: a chemical material screening device that facilitates rapid separation and removal of impurities, including a screening box 1 and a feed hopper 2, and a feed pipe 201 is fixed in the middle of the bottom of the feed hopper 2 , the bottom of the feed hopper 2 is inclined towards the feed pipe 201, and the bottom end of the feed pipe 201 extends into the upper part of the inner cavity of the screening box 1, and the bottom surface of the inner cavity of the screening box 1 is set as a circular arc surface, and the front and rear sides The center position of the wall corresponding to the arc surface of the screening box 1 is rotatably connected with a rotating shaft 4, and a screening assembly is fixed between the inner ends of the two rotating shafts 4, and the upper part of the left section of the arc-shaped bottom of the screening box 1 is provided with an inclined first The l...

Embodiment 2

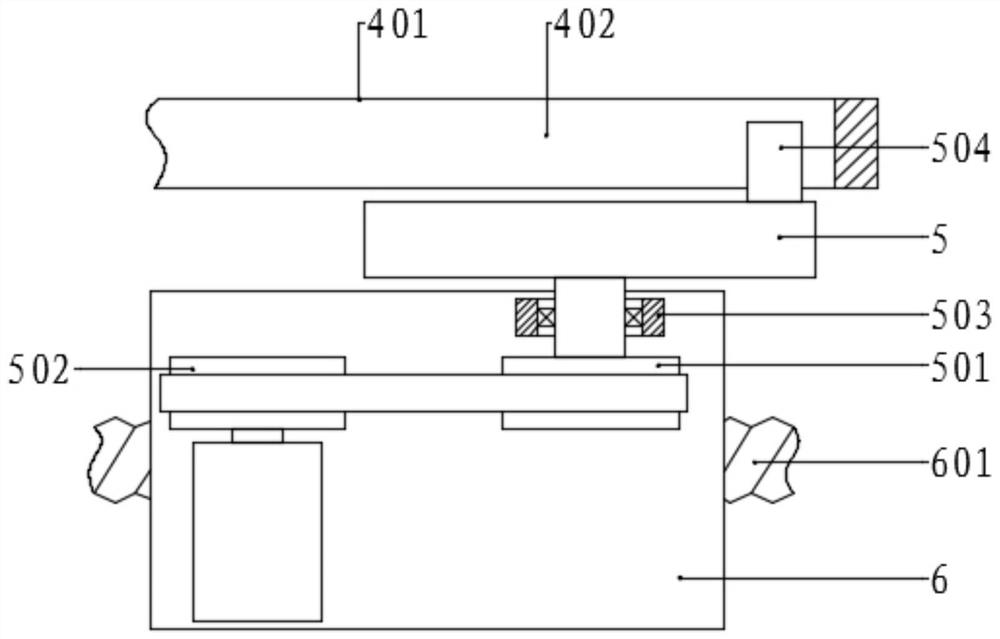

[0045] The structure of this embodiment is basically the same as that of Embodiment 1, except that an arc-shaped third sealing plate 305 is arranged above the screening assembly, and the center of circle of the third sealing plate 305 coincides with the center of the rotating shaft 4, and the right side The end extends downward along the arc direction, and is fixedly connected with the top right section of the rotating plate 3, a support rod 306 is fixed between the left end and the top left side of the rotating plate 3, and the bottom end of the feed pipe 201 is provided with arc-shaped, and the bottom end is slidingly connected with the top surface of the third sealing plate 305 .

[0046] The right side of the inner cavity of the feed pipe 201 is fixed with a material guide block 202, the top surface of the material guide block 202 is inclined, the left side is low and the right side is high, and the left side is located on the left side of the center of the rotating shaft 4...

Embodiment 3

[0049] The structure of this embodiment is basically the same as that of Embodiment 1. The difference is that an arc-shaped block 403 is fixed on the inside of the left section of the rotating rod 401, and the center of the arc-shaped block 403 coincides with the center of the rotating shaft 4. The wall is correspondingly provided with an arc groove 104, and the arc block 403 is slidably connected in the arc groove 104, and springs are respectively connected between the two ends of the arc block 403 and the inner two ends of the arc groove 104, when swinging When the component drives the screening component to rotate through the rotating shaft 4, the first screen 301 and the second screen 302 will tilt, and the material will move to the lower end, so that the screening component and the swinging component will be affected by the gravity of the material, and the impact of the gravity of the material will be slowed down by the spring. Effects of individual components of the scree...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com