Fruit screening and conveying production line and technological process thereof

A production line and fruit technology, applied in solid separation, grading, food processing, etc., can solve the problems of fruit surface bumping, inability to achieve fruit grading and screening, and poor fruit screening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

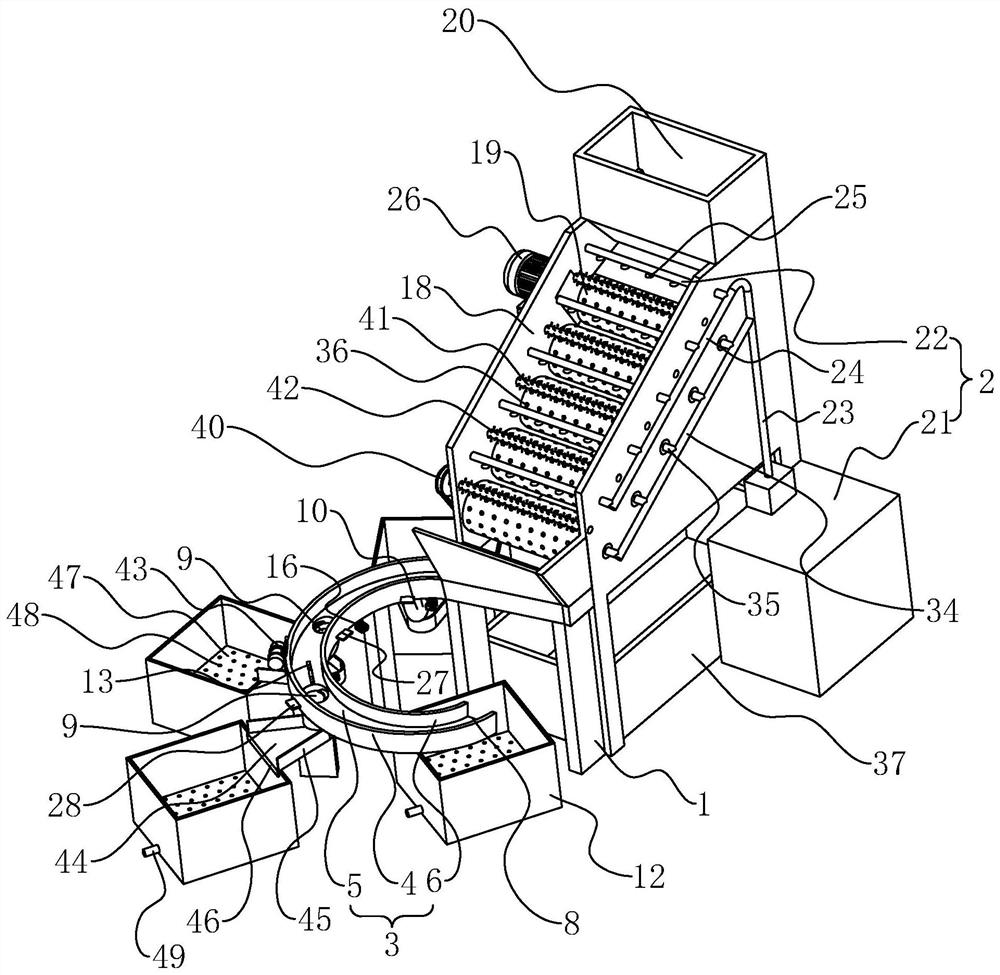

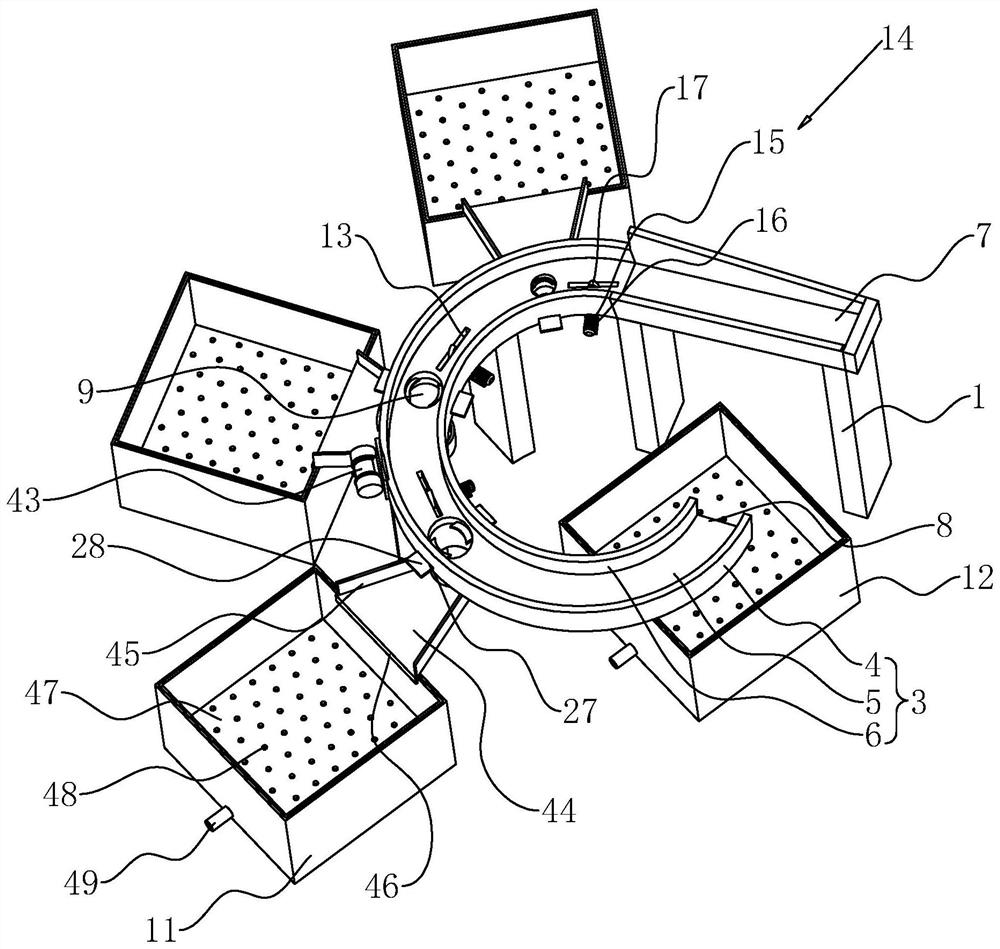

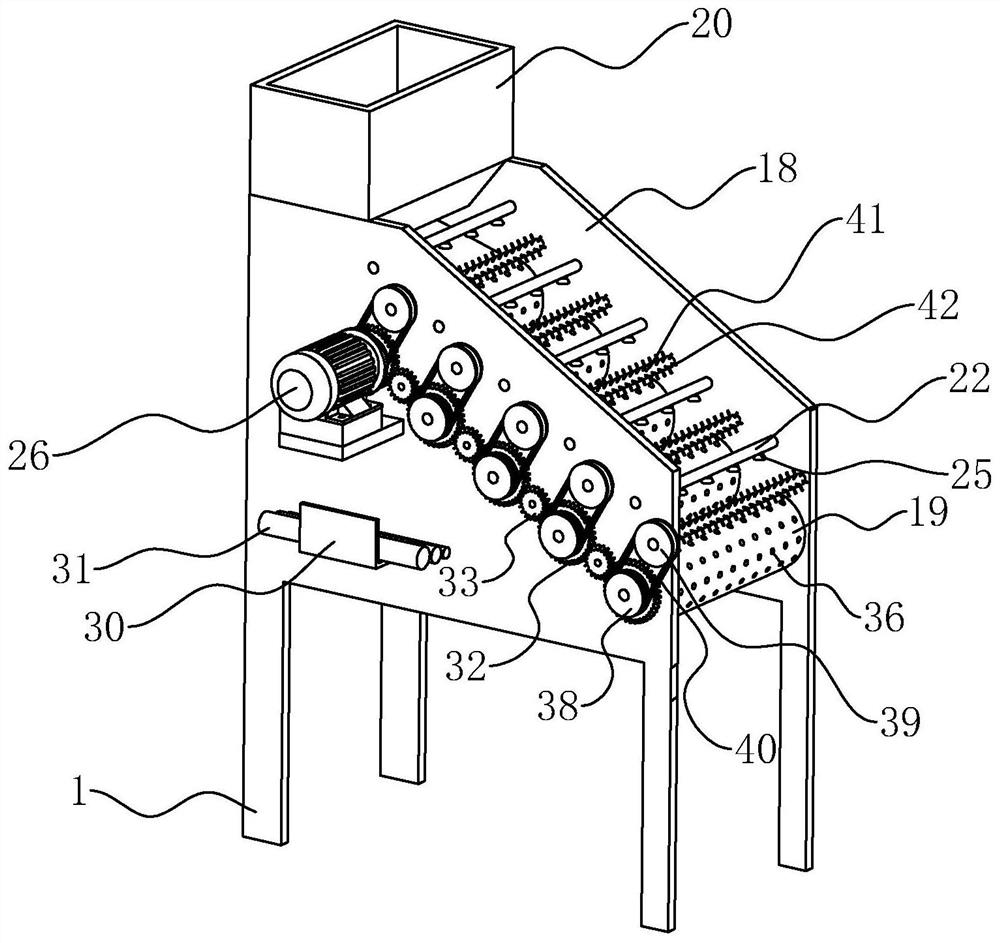

[0041] refer to figure 1 with figure 2 , a fruit screening and conveying production line, comprising a frame 1, the frame 1 is provided with a cleaning component 2 and a screw conveying tray 3, the frame 1 is fixedly connected with the spiral conveying tray 3, and the spiral conveying tray 3 is made of stainless steel and has good load-bearing capacity and corrosion resistance. The screw conveying tray 3 is provided with a feed inlet 7 and a discharge outlet 8. The feed inlet 7 is located at the higher end of the spiral conveying tray 3, and the discharge outlet 8 is located at the lower end of the spiral conveying tray 3. When screening and conveying, the fruits are first cleaned by the cleaning assembly 2, and then the cleaned fruits are added to the bottom plate 5 of the screw conveyor plate 3 from the feed port 7, and the diameter of the screw conveyor plate 3 is gradually increased from top to bottom along the height direction. become larger, under the action of the th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com