Silicon carbide micro-powder drying and grading integrated device

A silicon carbide micropowder, all-in-one technology, used in silicon carbide, drying solid materials, heating to dry solid materials, etc., can solve the problems of troublesome process, equipment occupied space, and high purchase cost, and achieve high drying efficiency and classification efficiency. The structure is simple and reasonable, and the effect of improving the processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

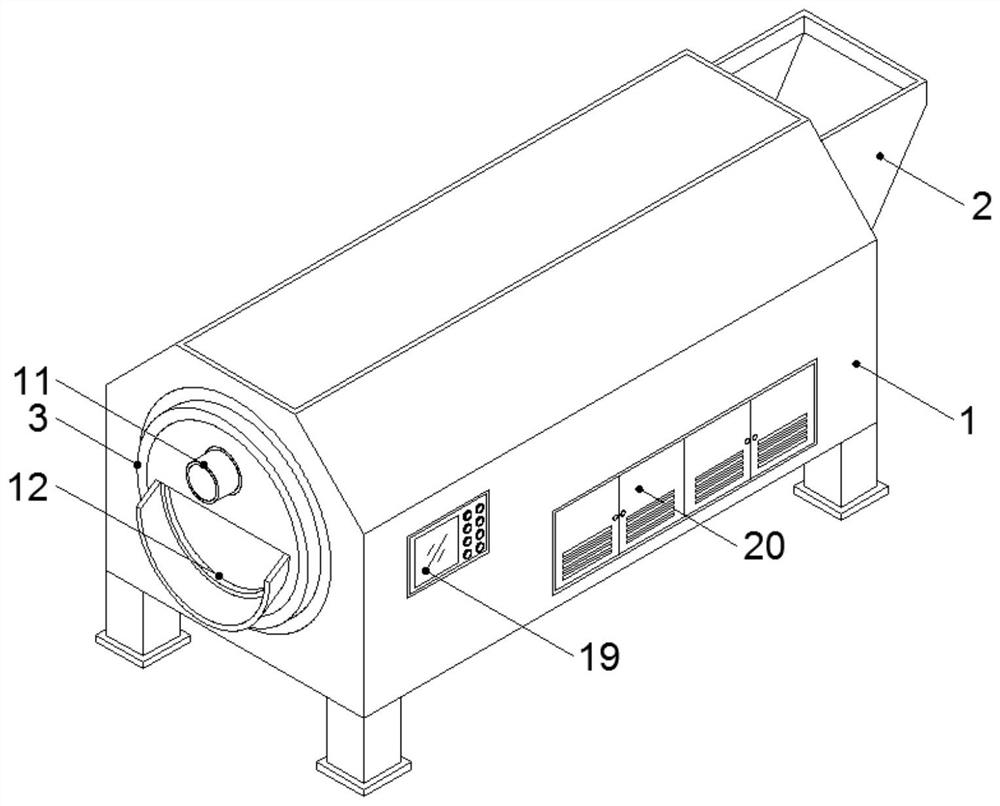

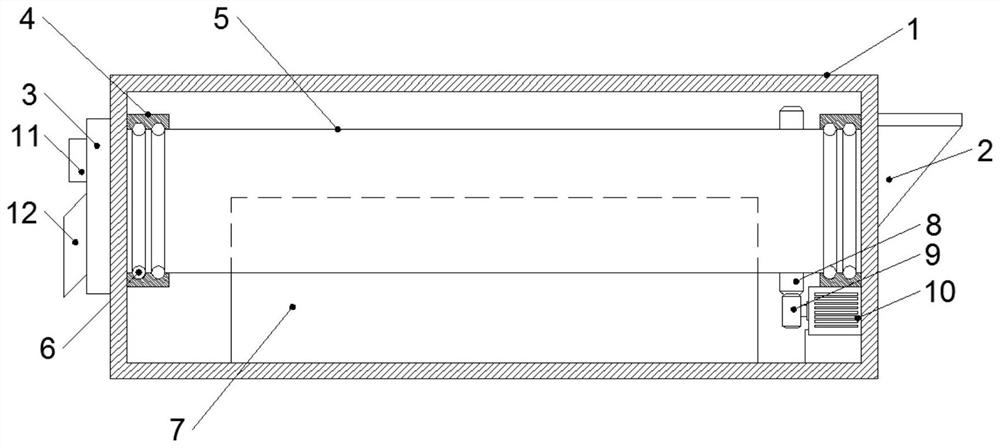

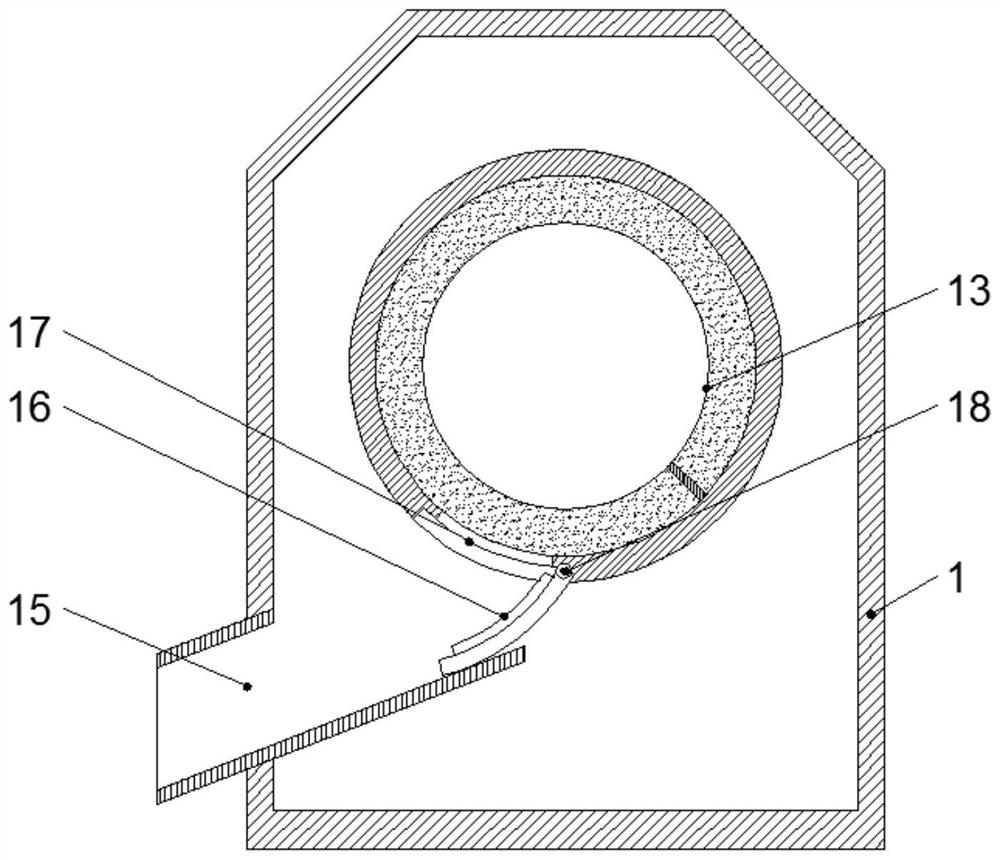

[0026] Example: such as Figure 1-5 As shown, an integrated device for drying and grading silicon carbide micropowder according to the present invention includes a main body 1, openings are arranged on the left and right sides of the main body 1, and a feeding hopper 2 and a sealing cover are respectively connected to the openings. 3. The inside of the main body 1 is fixedly installed with a fixed seat 4 on the inner side close to the opening, and a drying cylinder 5 is fixedly installed through the fixed seat 4, and a plurality of sets of fixing rings are fixedly installed inside the drying cylinder 5, and the A filter screen 14 is fixedly installed on the inner ring of the fixed ring, and the inner wall of the drying cylinder 5 is fixedly equipped with spiral blades 13 on both sides close to the filter screen 14, and the main body 1 is fixed on the bottom of the drying cylinder 5. The heating seat 7 is installed, and the heating seat 7 is an electromagnetic heating seat, a g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com