Patents

Literature

125results about How to "Quick dump" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

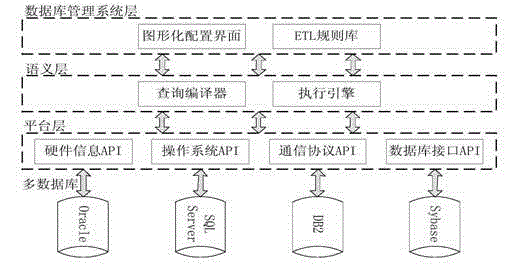

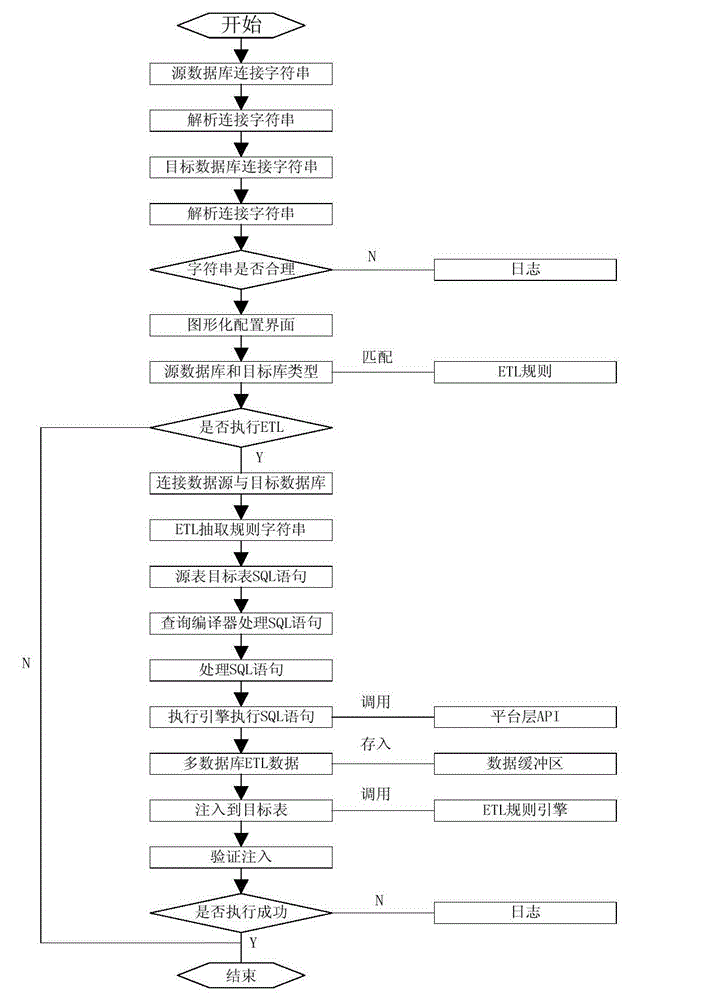

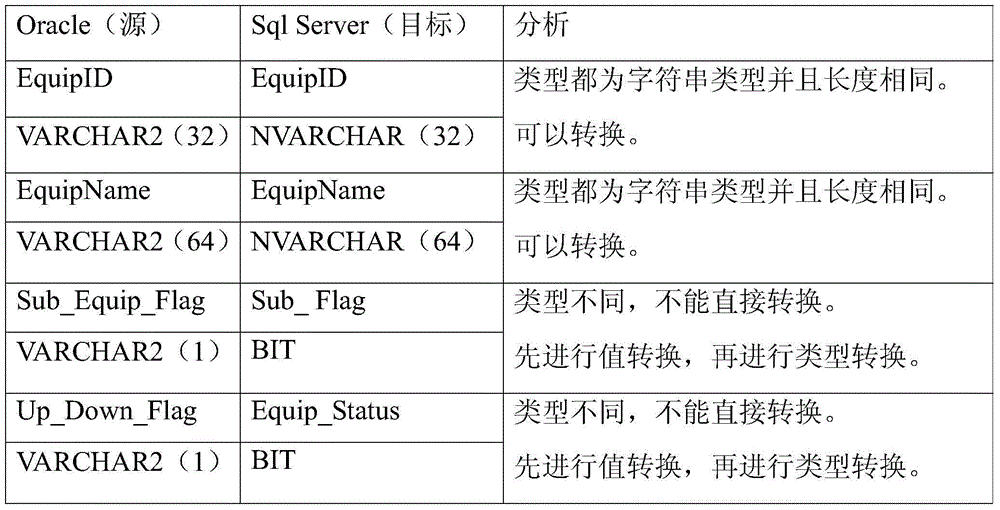

Visual multi-database ETL integration method and system

InactiveCN104915341AReduce complexityReduce risk of integrationSpecial data processing applicationsData miningTarget database

The invention provides a visual multi-database ETL integration method and system. The visual multi-database ETL integration method includes the following steps that source databases and target databases are connected; the SQL statements of source lists of the source databases are obtained through ETL matching of the source databases and the target databases; the SQL statements are optimized and executed, and the ETL data of the multiple source databases are obtained and introduced into target lists of the target databases. The visual multi-database ETL integration system comprises a database management system layer and a semantic layer, the database management system layer connects the source databases with the target databases, and the SQL statements of the source lists of the source databases are obtained through ETL matching of the source databases and the target databases; the semantic layer optimizes and executes the SQL statements, obtains the ETL data of the multiple source databases and introduces the ETL data to the target lists of the target databases. The visual multi-database ETL integration method and system reduce the complexity degree of integration of the multiple databases, improve the integration efficiency of the multiple databases, and reduce the risk of integration of the multiple databases.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

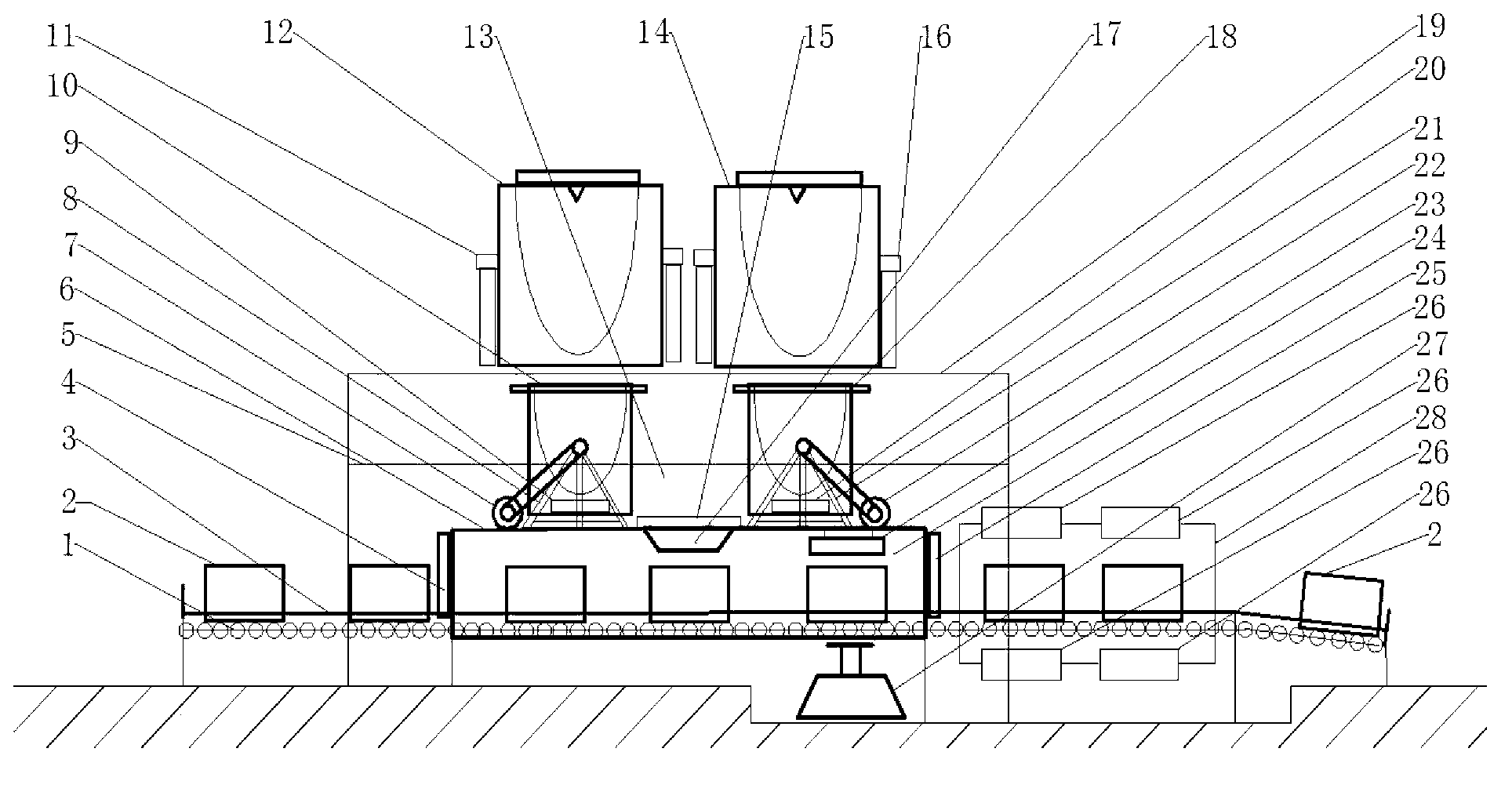

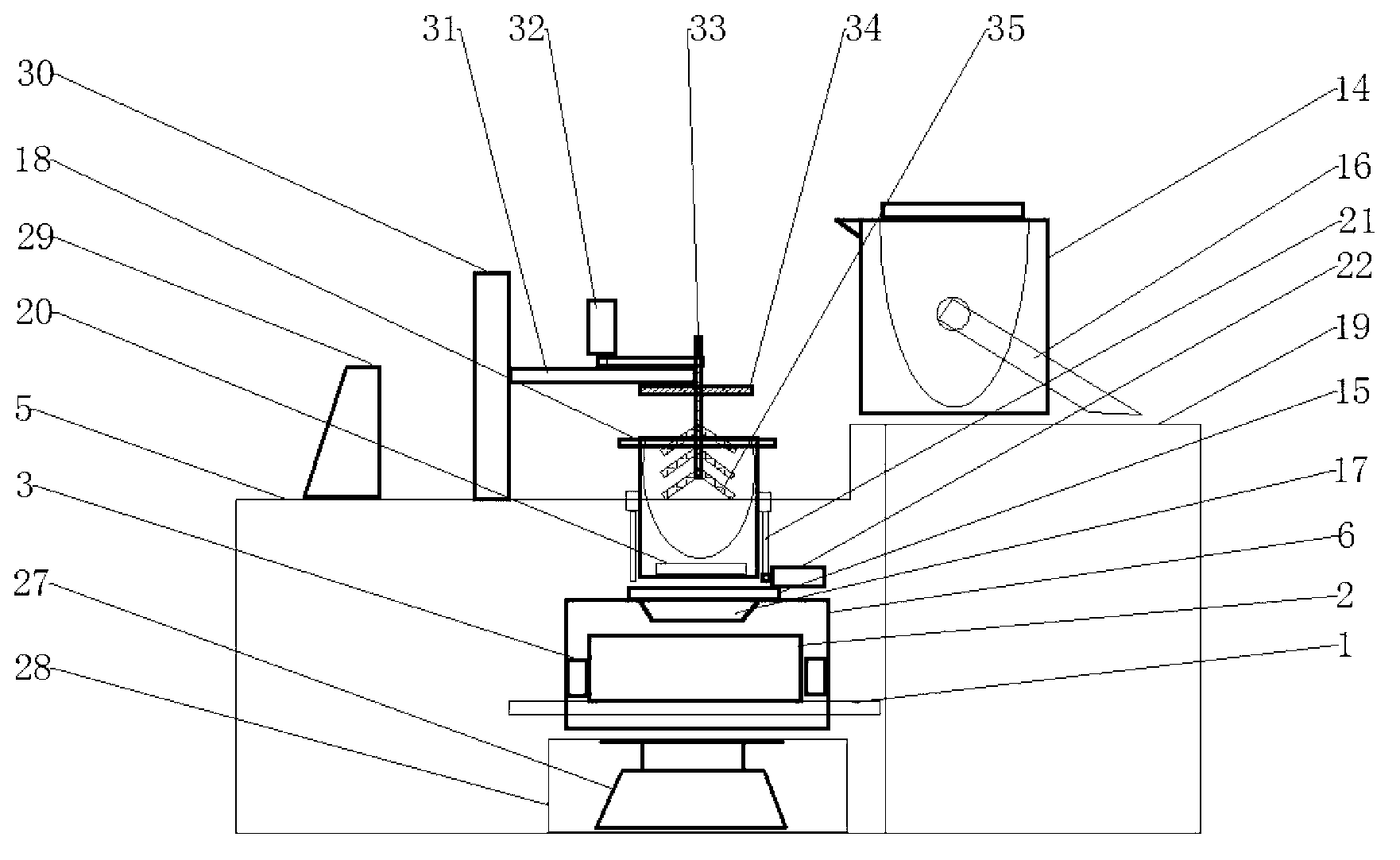

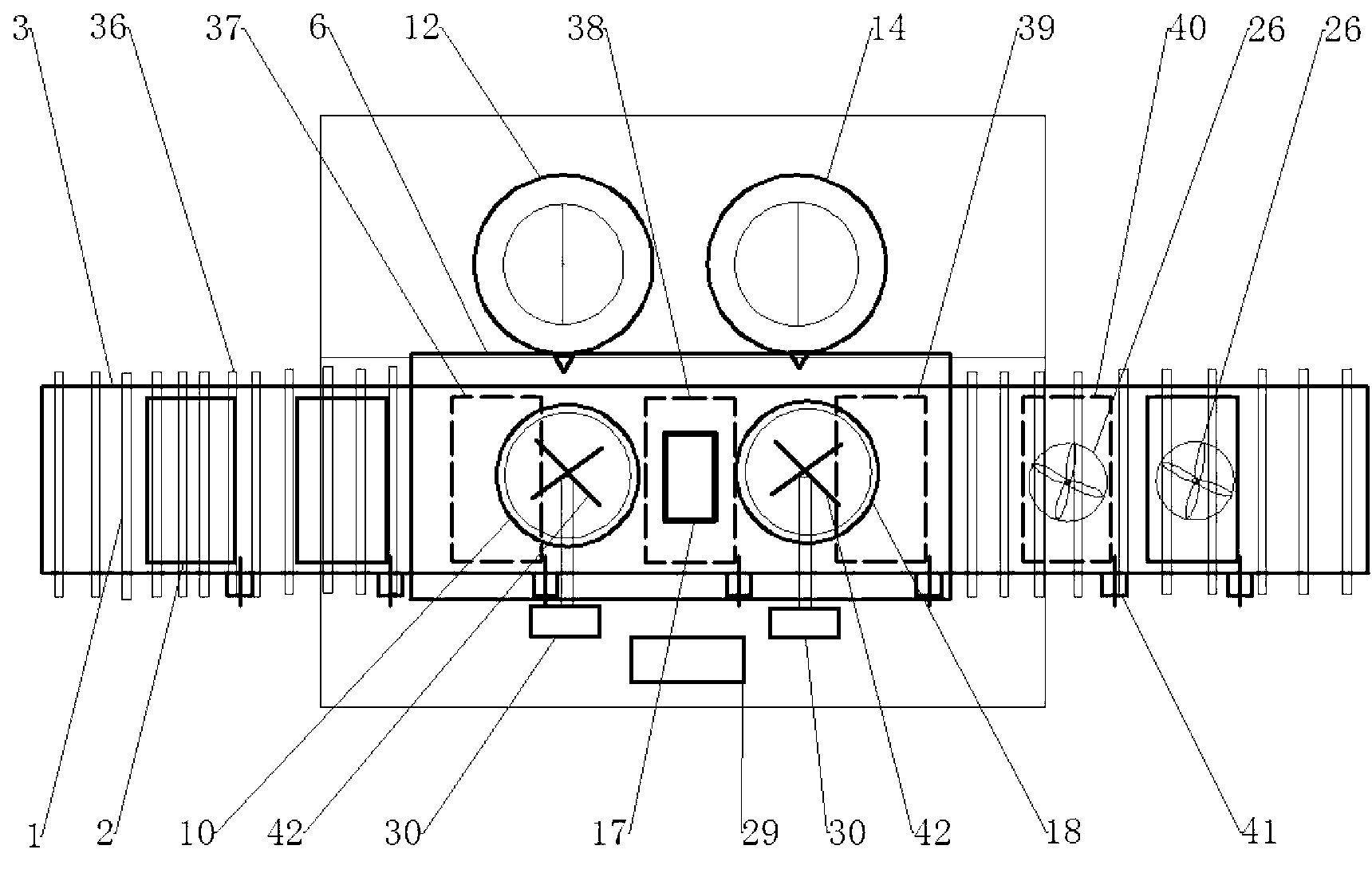

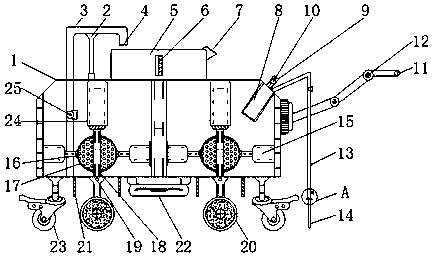

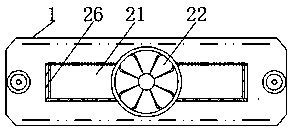

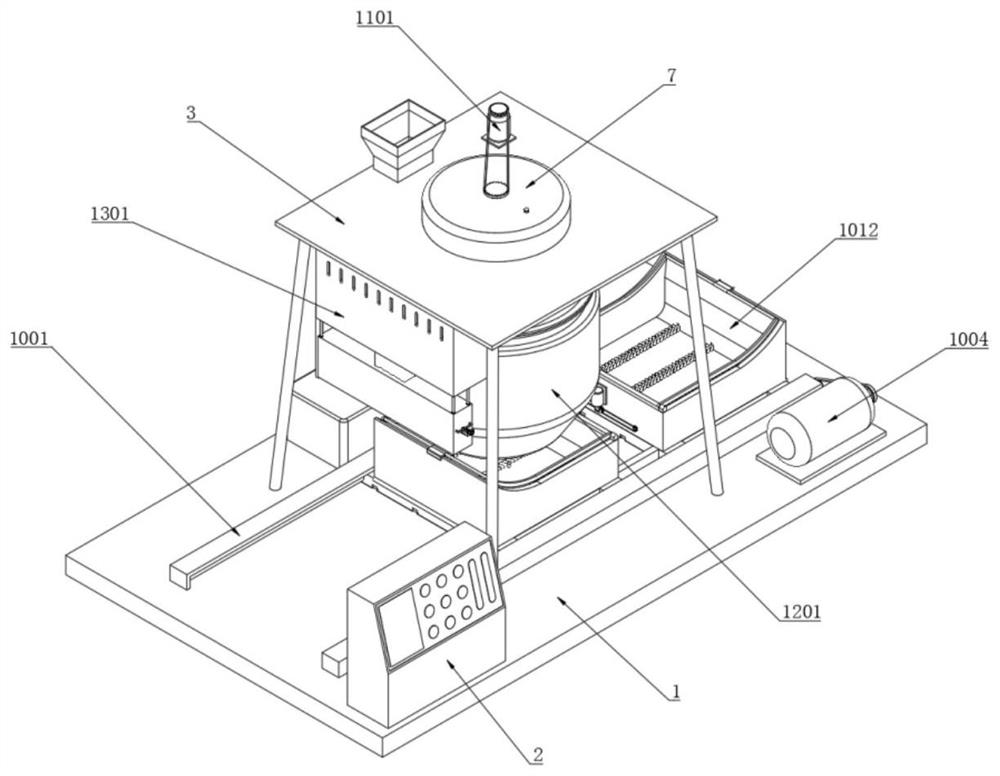

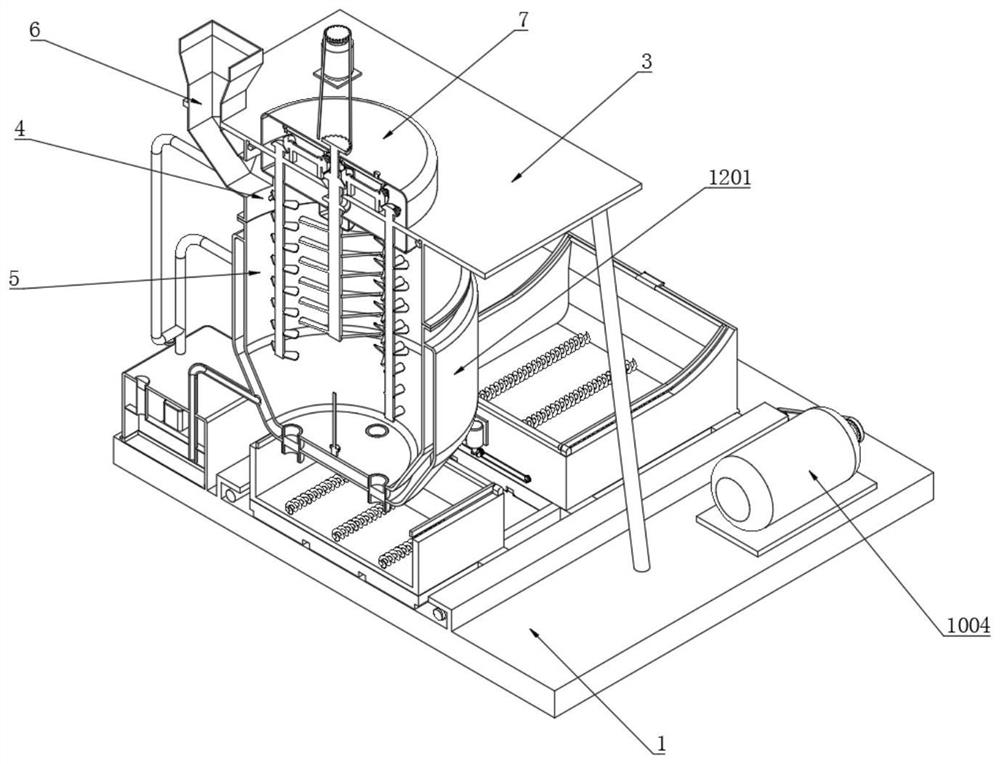

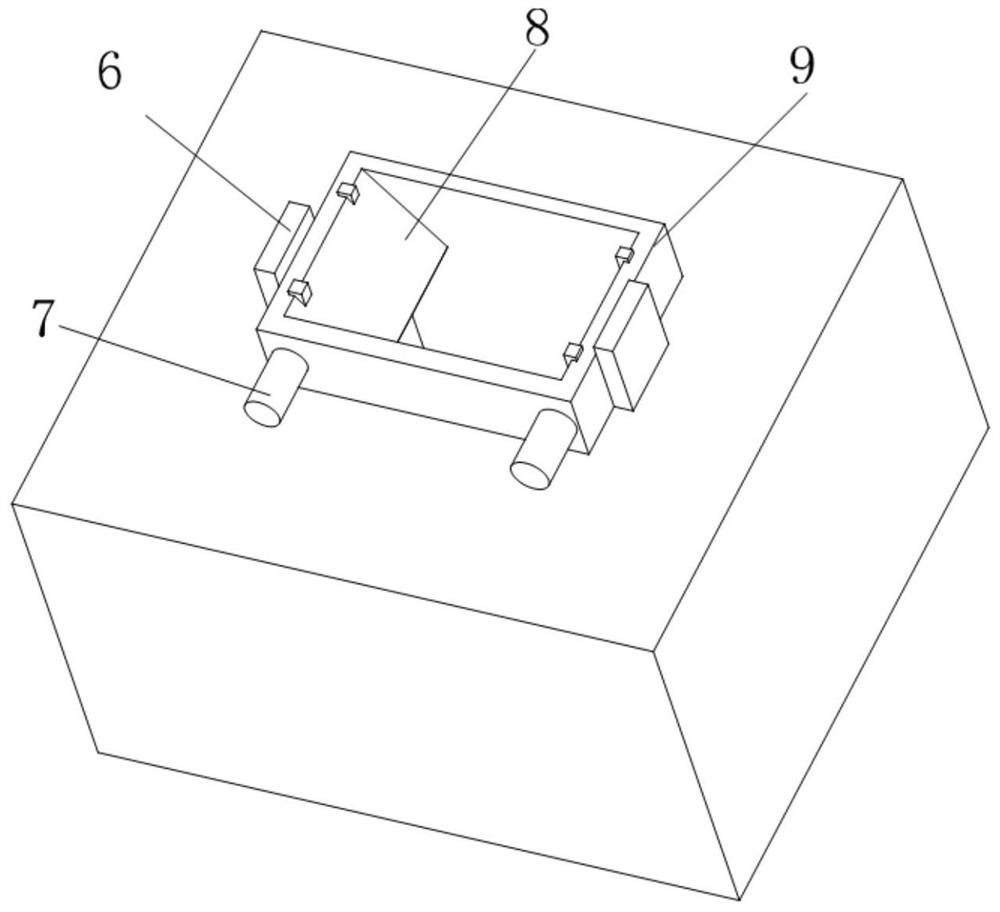

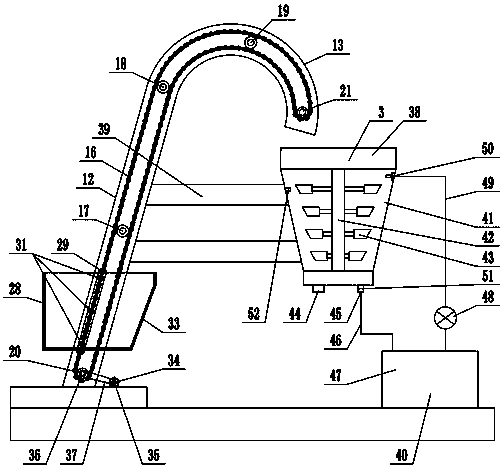

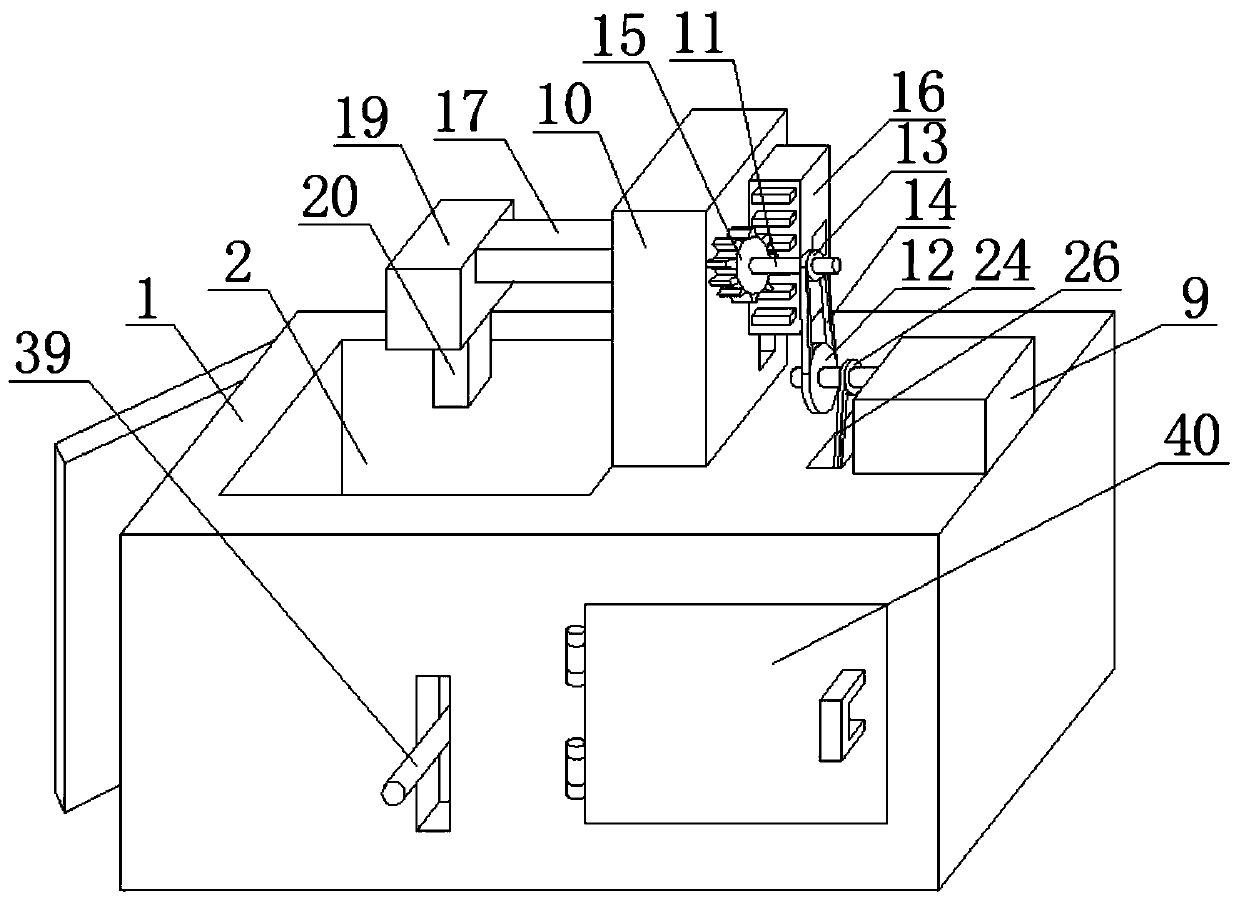

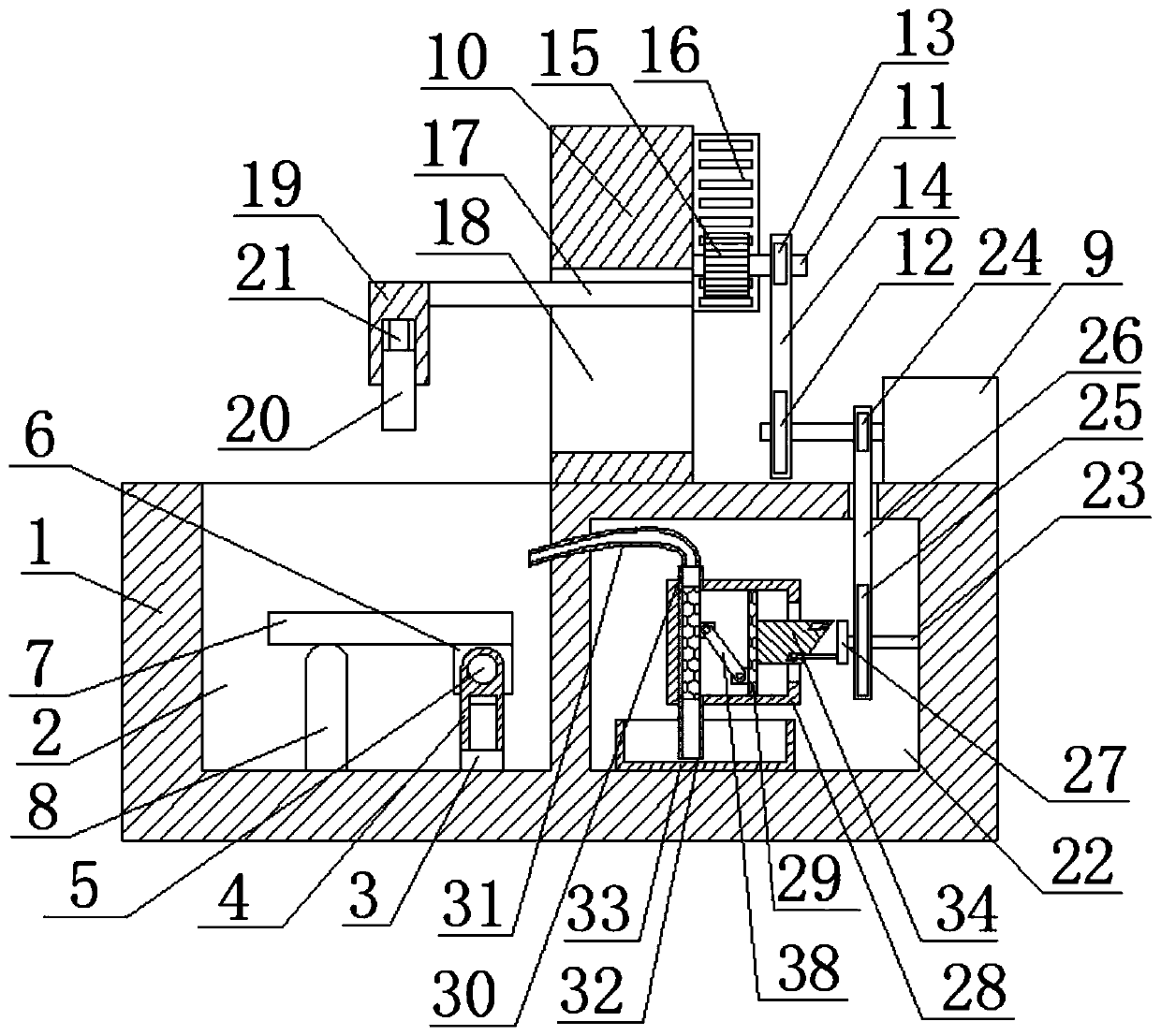

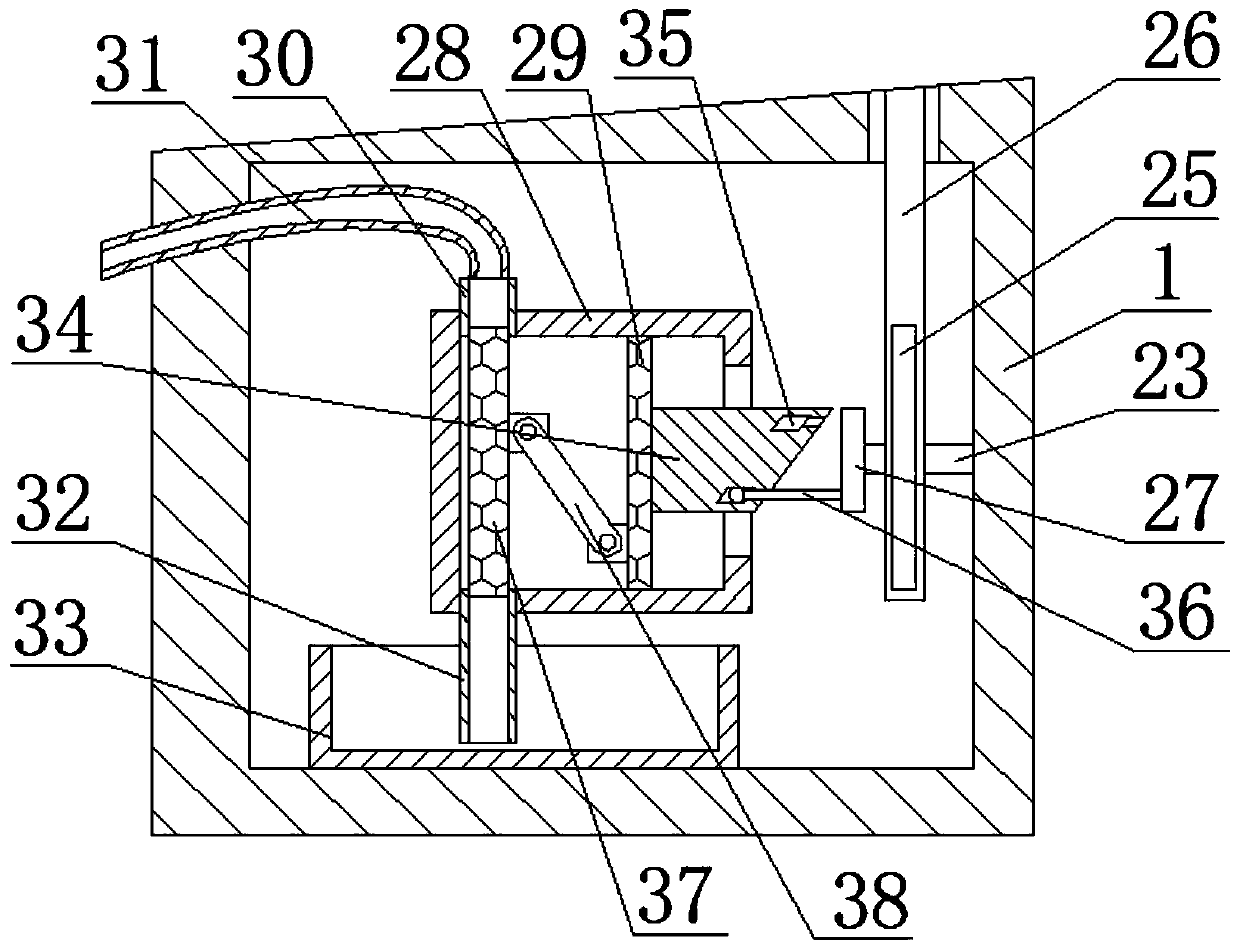

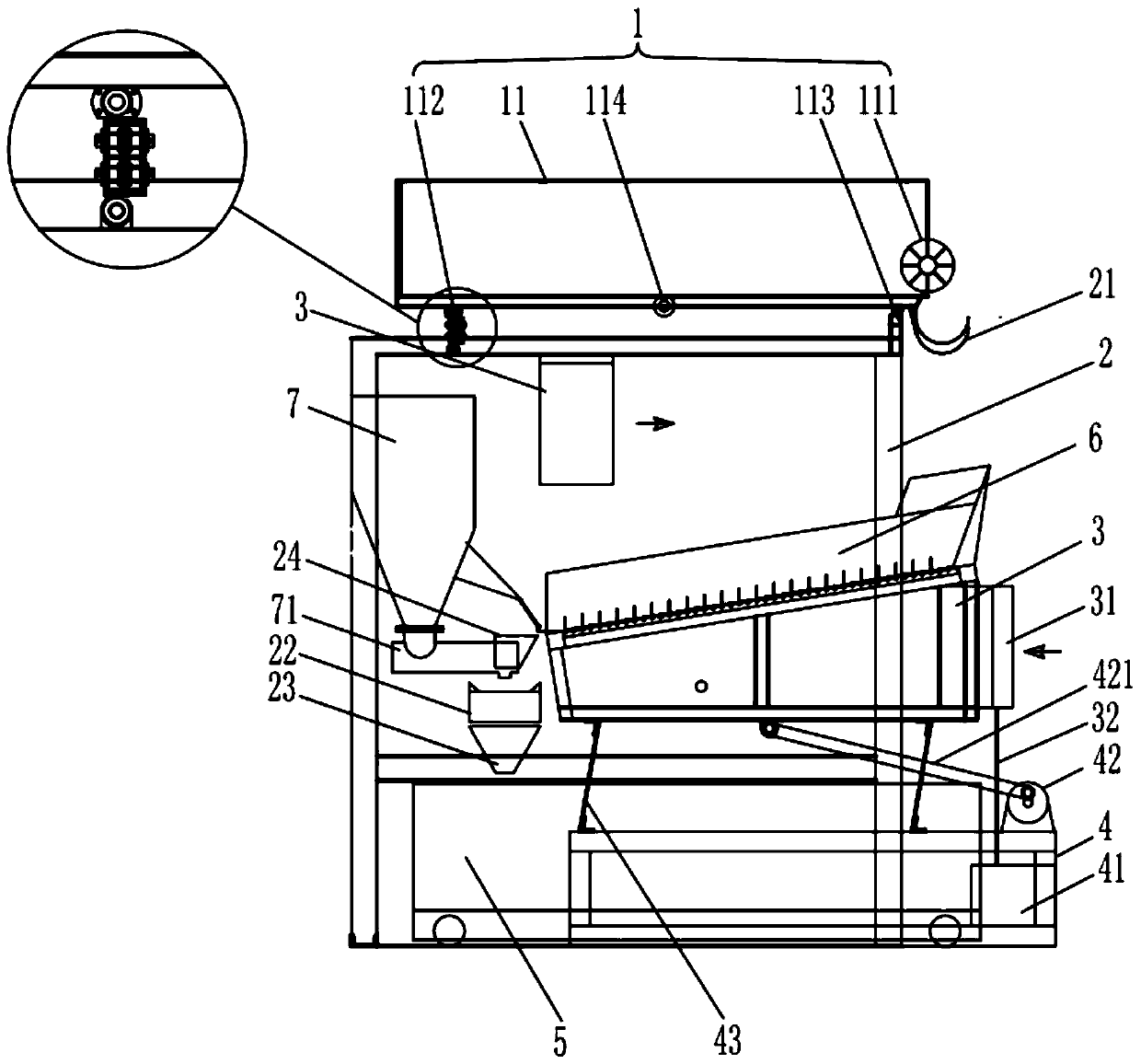

Complete equipment for producing foam aluminum

The invention relates to complete equipment for producing foam aluminum, and relates to manufacture of an alloy with an open or closed gap. The complete equipment mainly comprises a mould conveying device, a machining platform, a seal box type heat preserving furnace, two same stirring devices, two same smelting devices, a shaping device, a cooling device and a control platform, wherein the two same stirring devices can vertically lift. According to the invention, the operation of the integral equipment is controlled by the independently arranged control platform through a circuit, machining processes, namely metal smelting, pouring, mould preheating, tackifying, forming stirring, heat preservation foaming shaping and cooling, and equipment systematization are designed to the same machining platform so that the three dimensions, automation and continuity of smelting, stirring, pouring, foaming heat preservation and cooling procedures are realized, so that the defects that the full-automatic continuous production of a foam aluminum production procedure can not be realized, the automation degree is low, the production efficiency is lower, or large-size high-quality foam aluminum can not be manufactured, the process flow is complex and more procedures are needed in the prior art are overcome.

Owner:HEBEI UNIV OF TECH

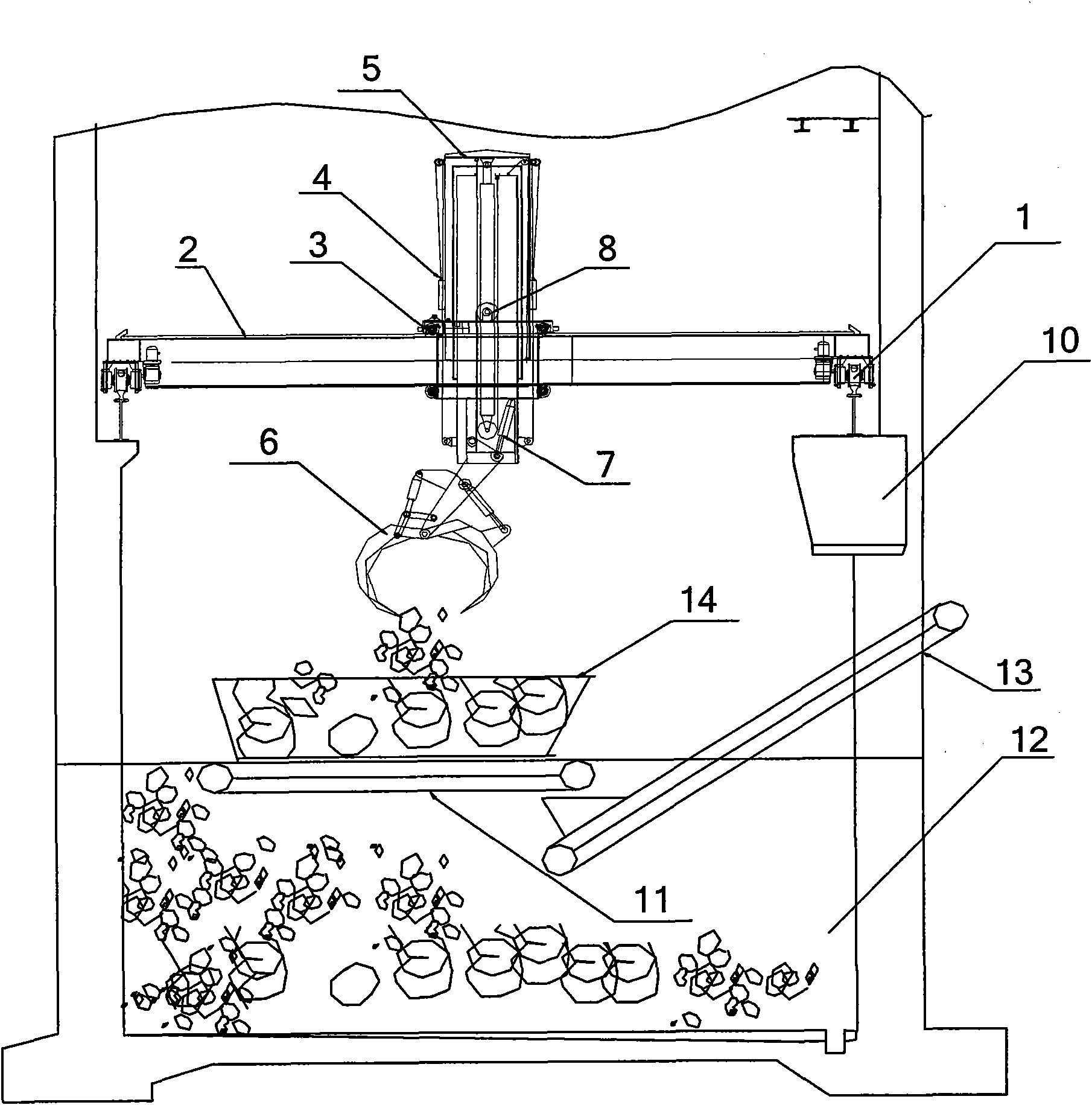

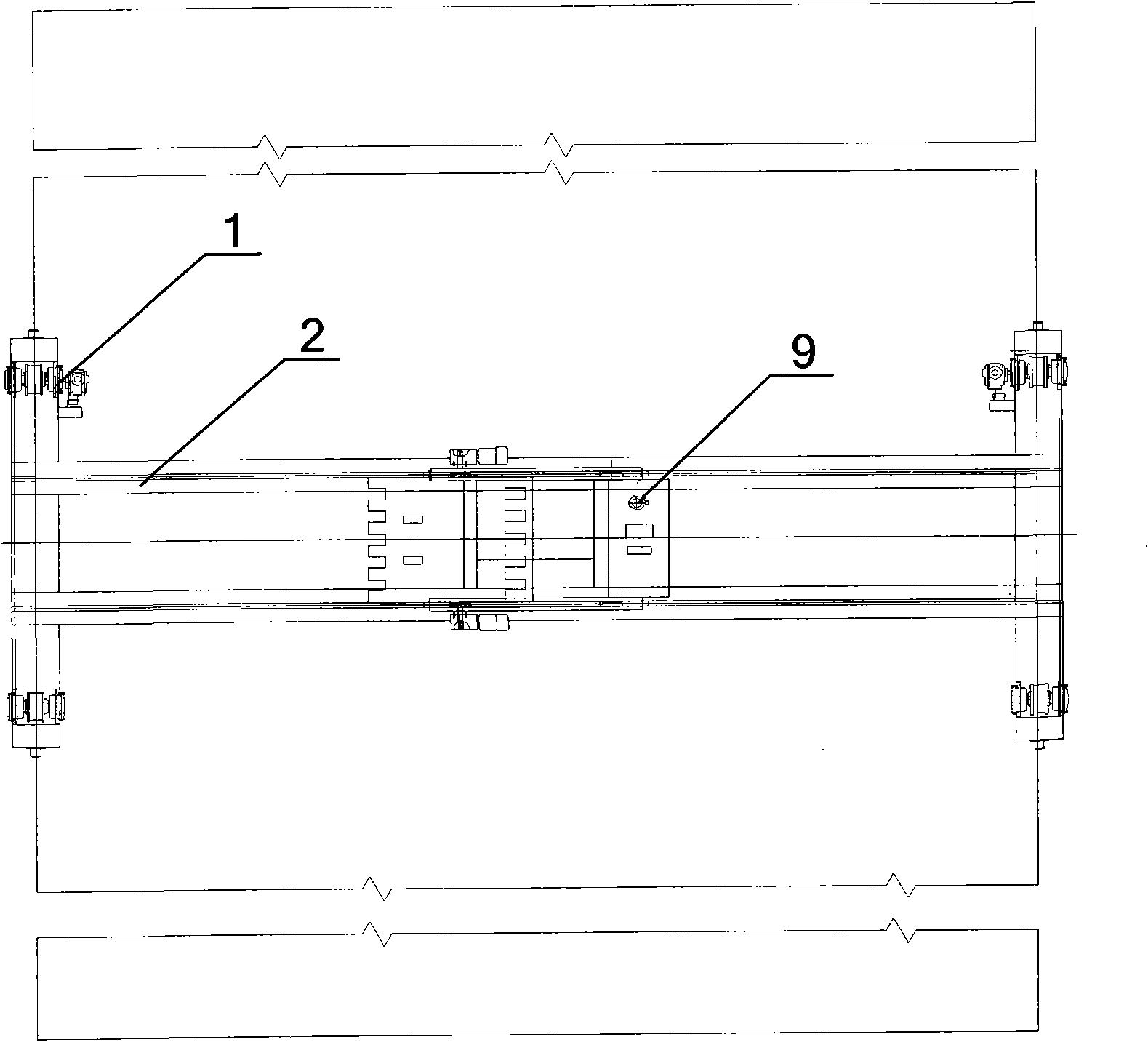

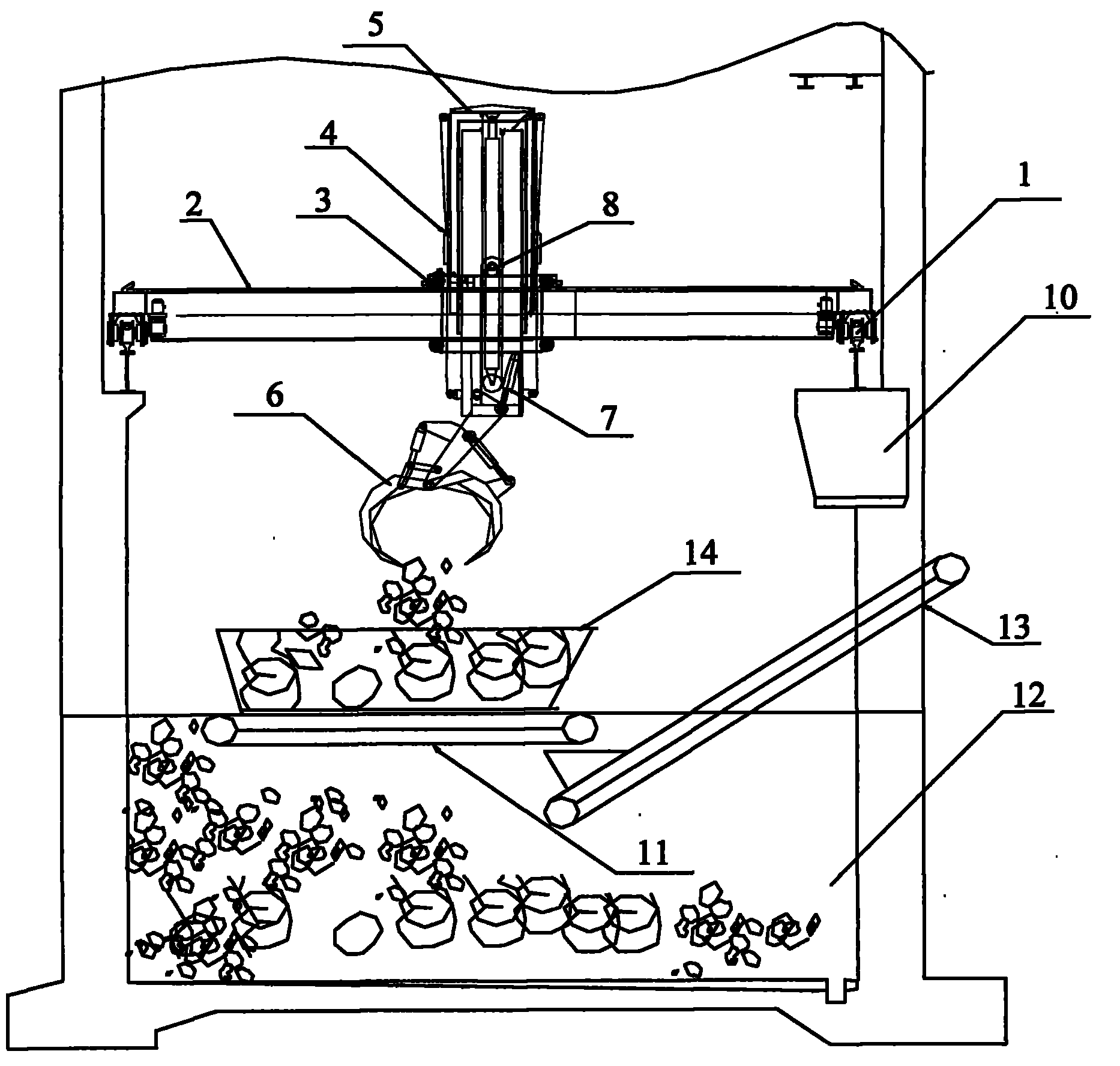

Manipulator device for feeding garbage

The invention discloses a manipulator device for feeding garbage and belongs to garbage processing equipment. The manipulator device comprises a beam, a cart traveling mechanism, a trolley running gear, an up and down moving mechanism, a manipulator swing device, a catching manipulator and a hydraulic device; the beam is arranged on the cart traveling mechanism; the trolley running gear is arranged on the beam and can freely move along the beam; the up and down moving mechanism is arranged on the trolley running gear; the lower end of the up and down moving mechanism is connected with the catching manipulator through the manipulator swing device; and the hydraulic device is arranged on the trolley running gear, and is respectively connected with the up and down moving mechanism, the manipulator swing device and the catching manipulator through hydraulic pipelines so as to drive the up and down moving mechanism to move the catching manipulator up and down, and the manipulator swing device to swing the catching manipulator. The manipulator device has simple structure and high catching speed, and can controllably swing the catching manipulator to quickly catch materials on a slope, thereby improving the catching efficiency.

Owner:EGUARD NEW ENERGY AUTOMOBILE CO LTD

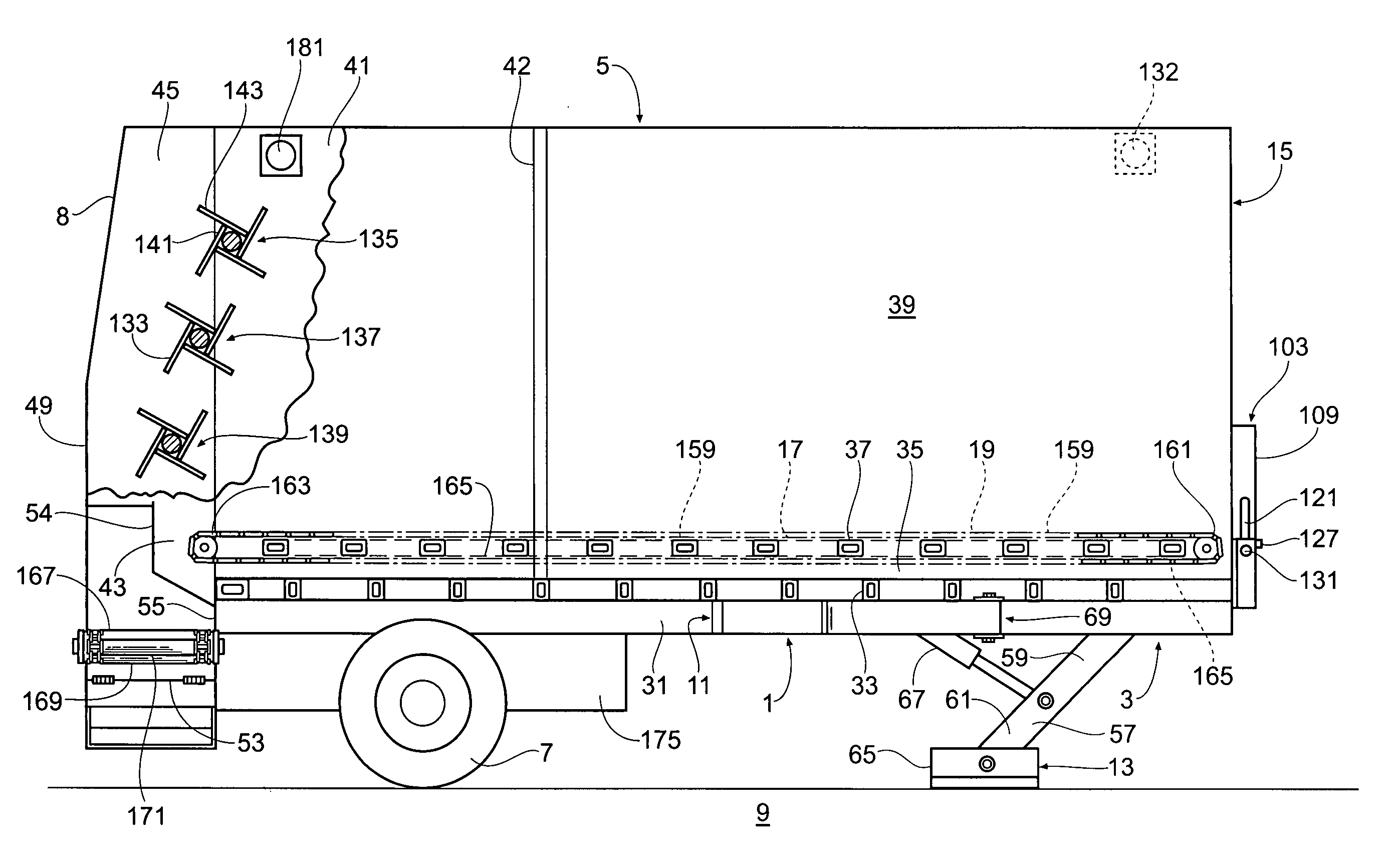

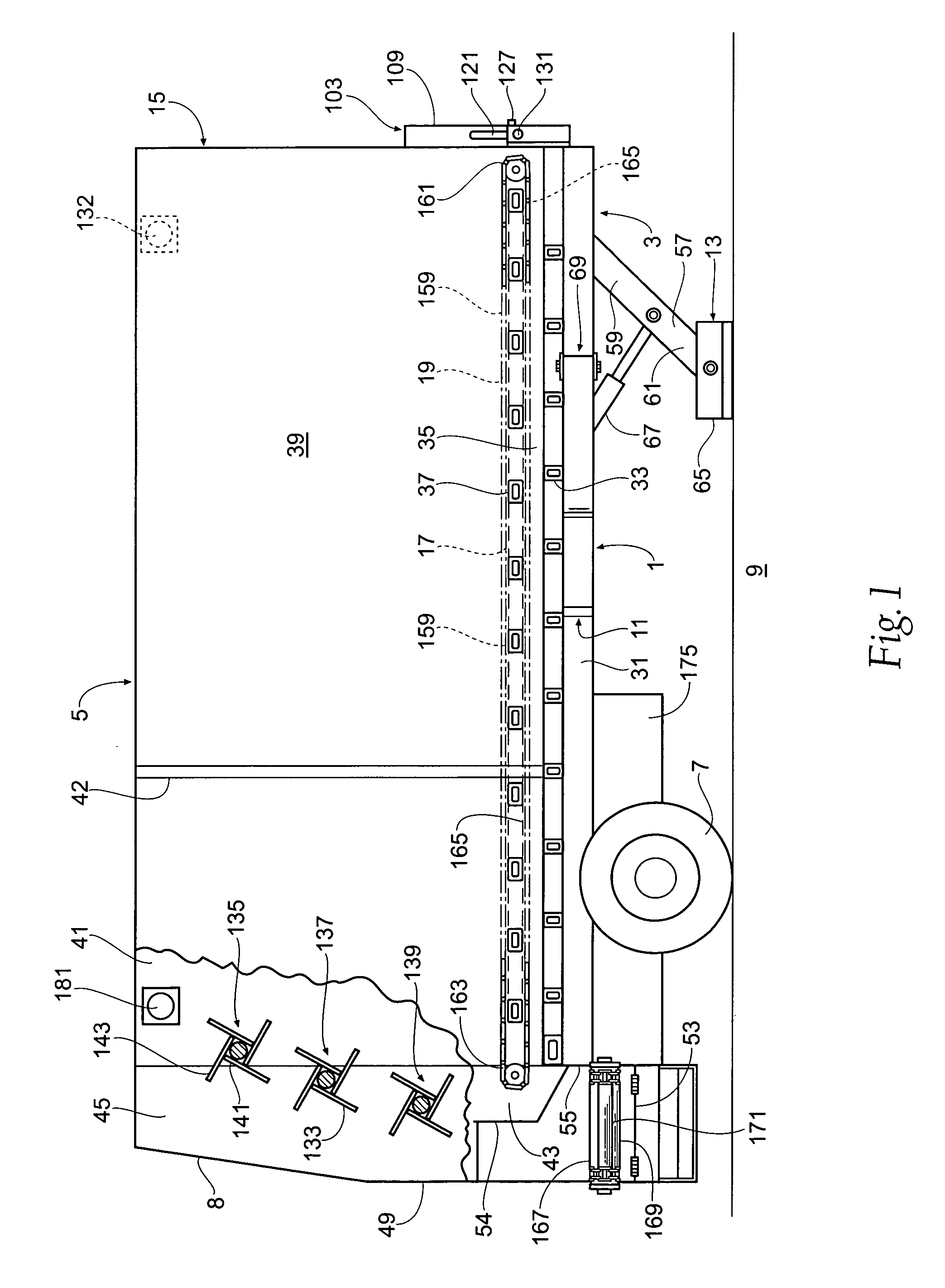

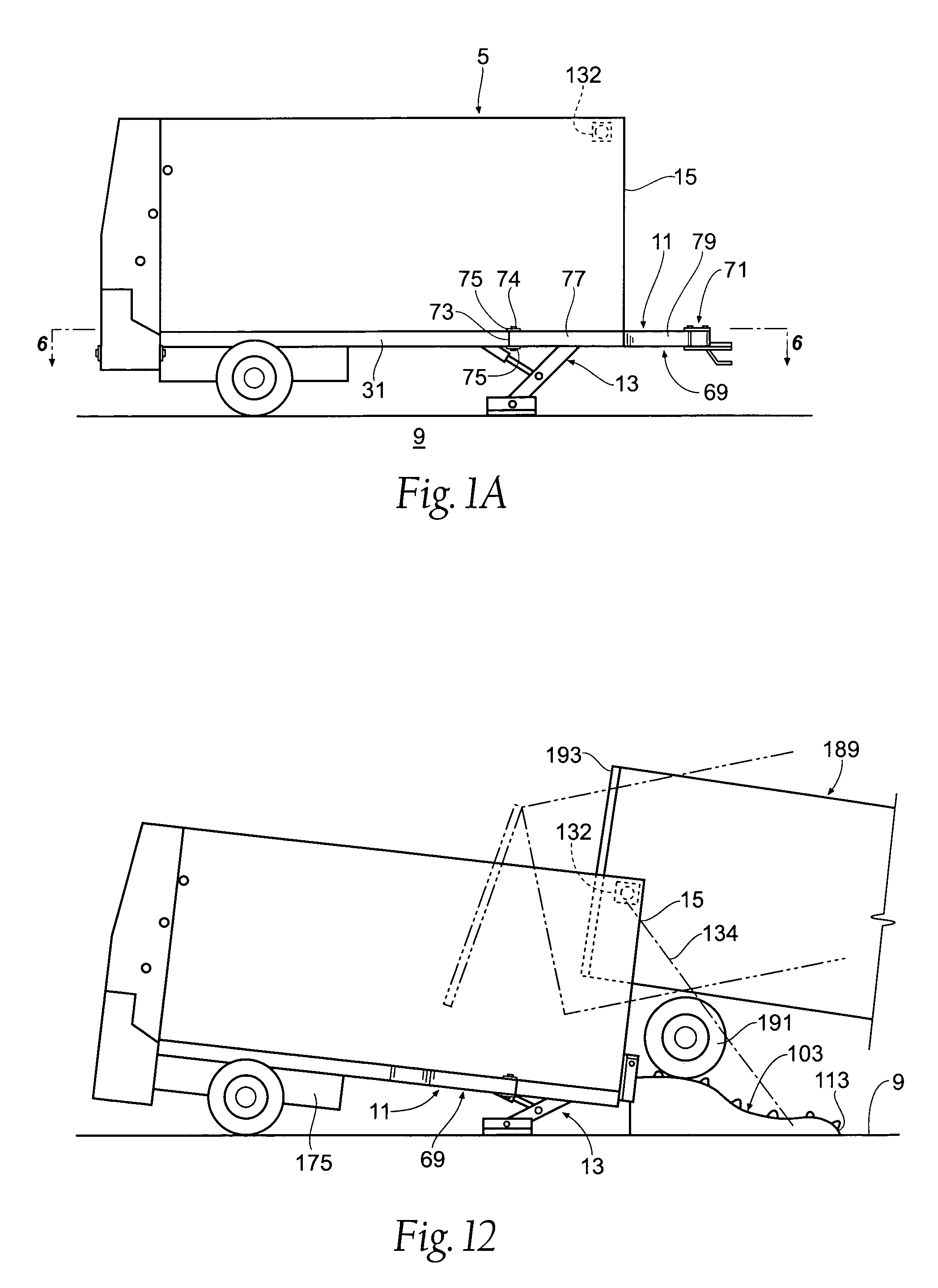

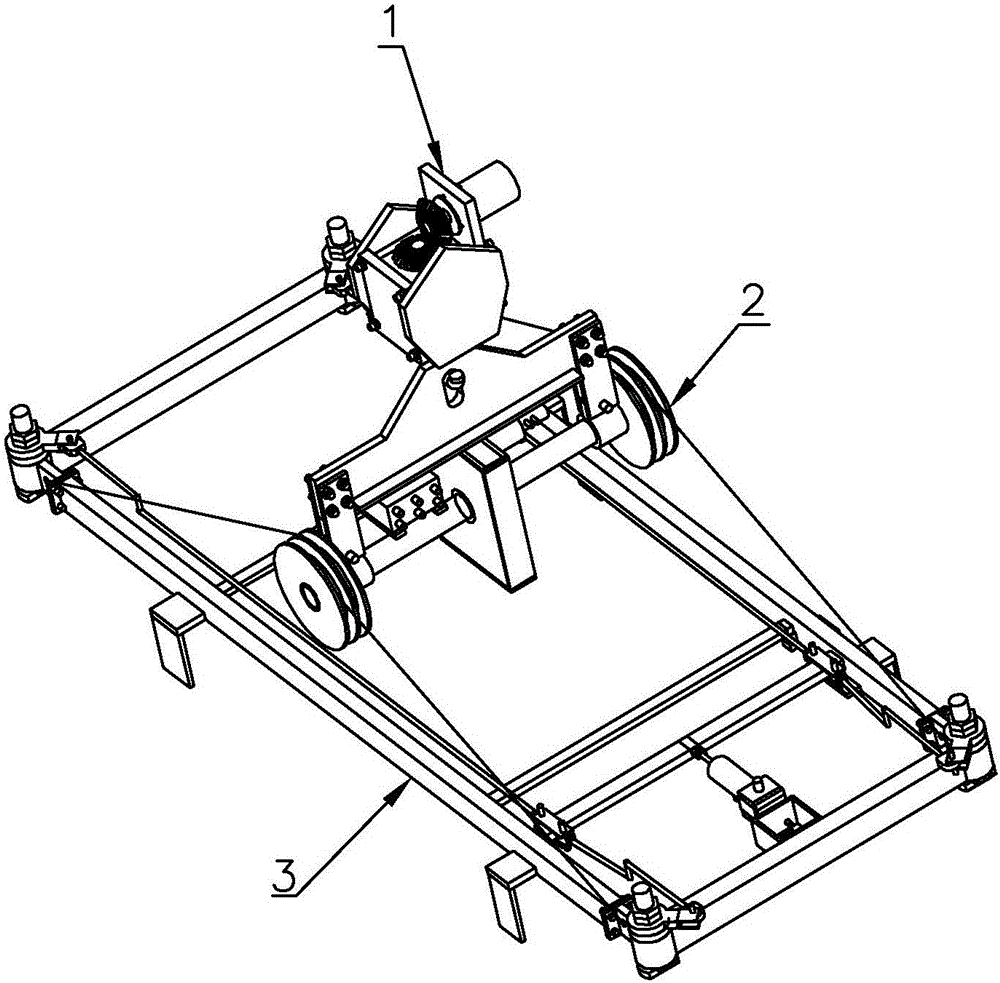

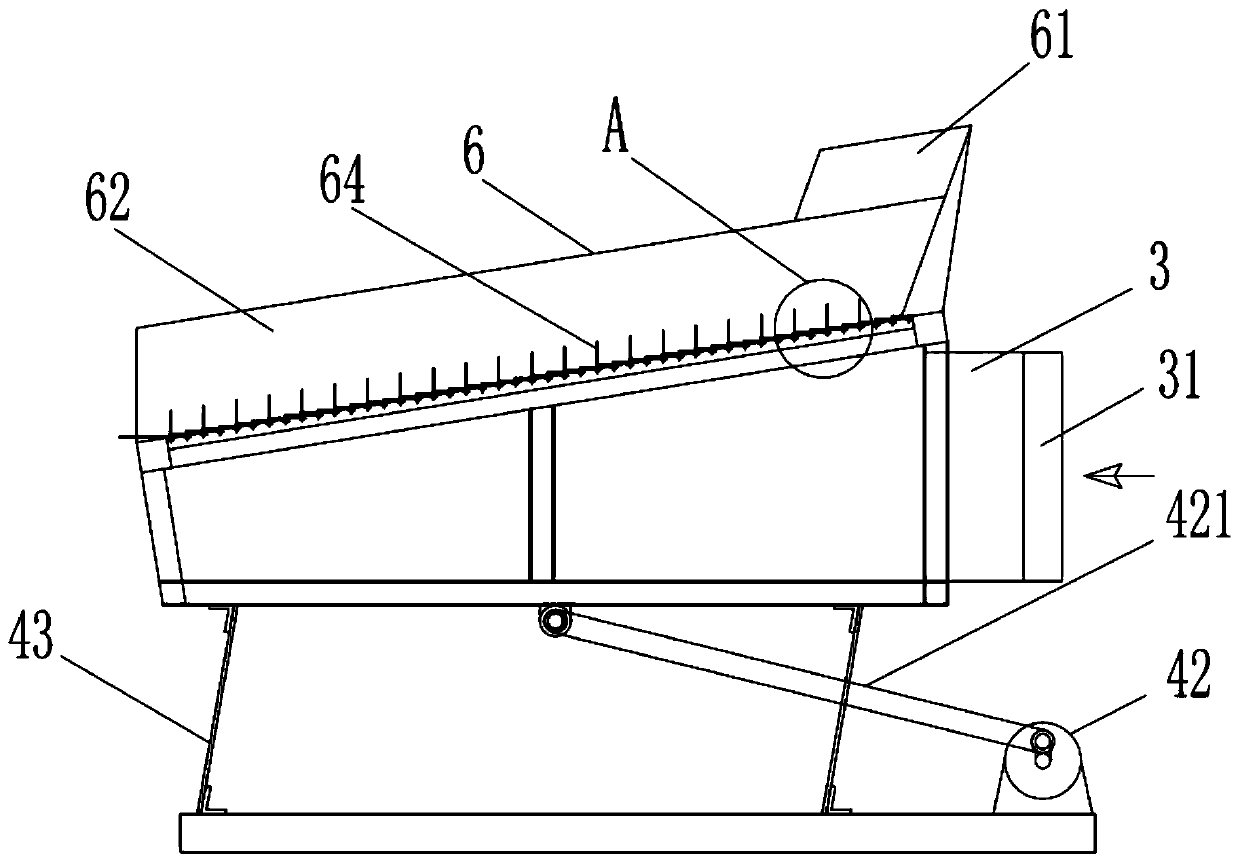

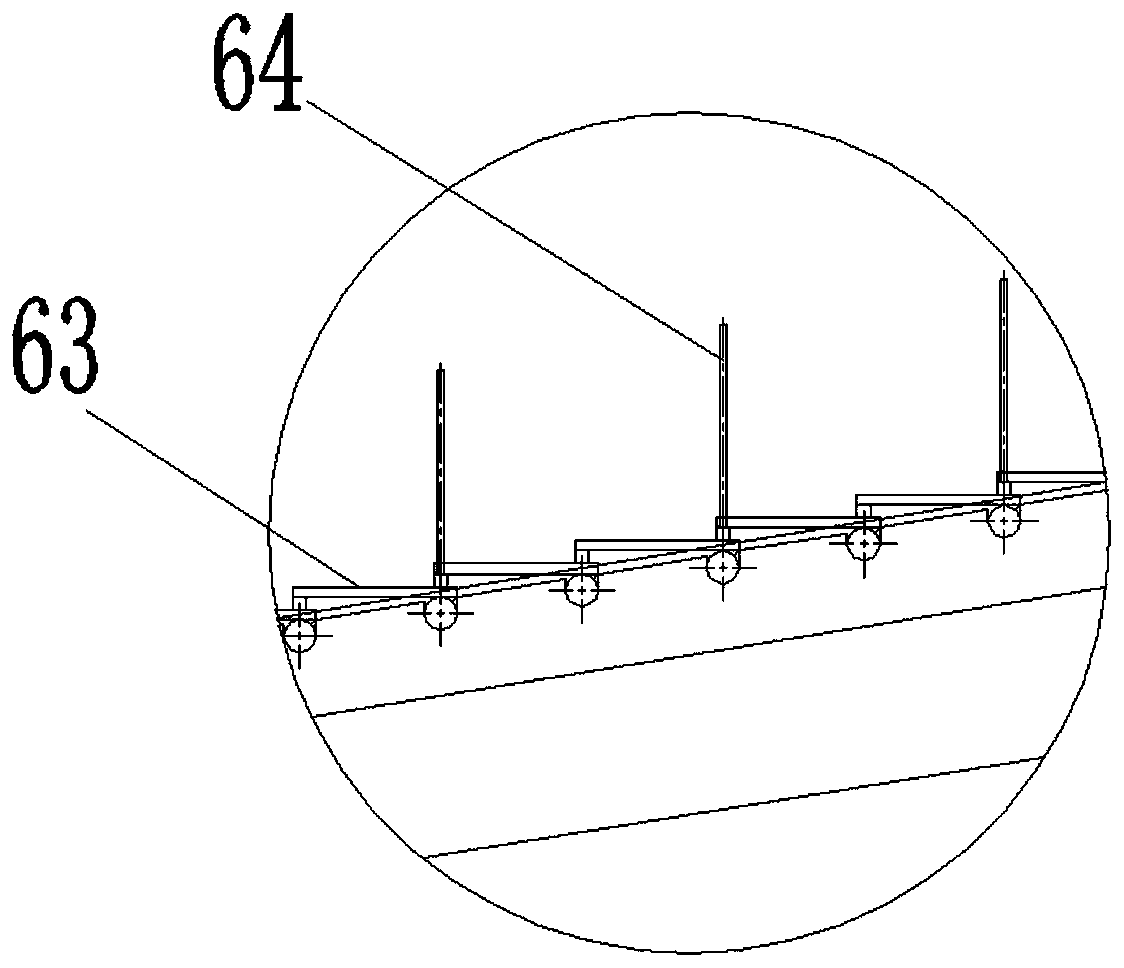

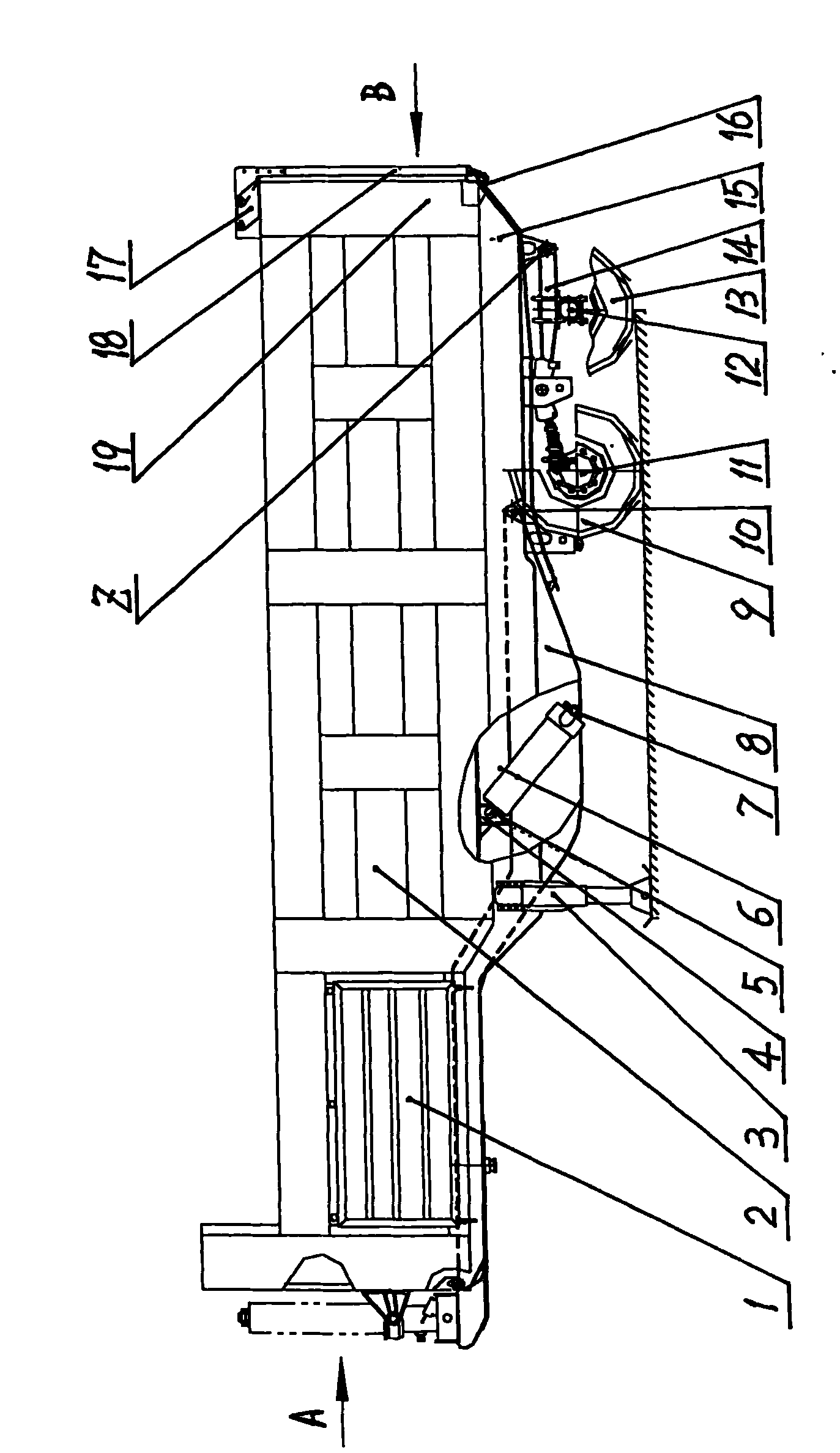

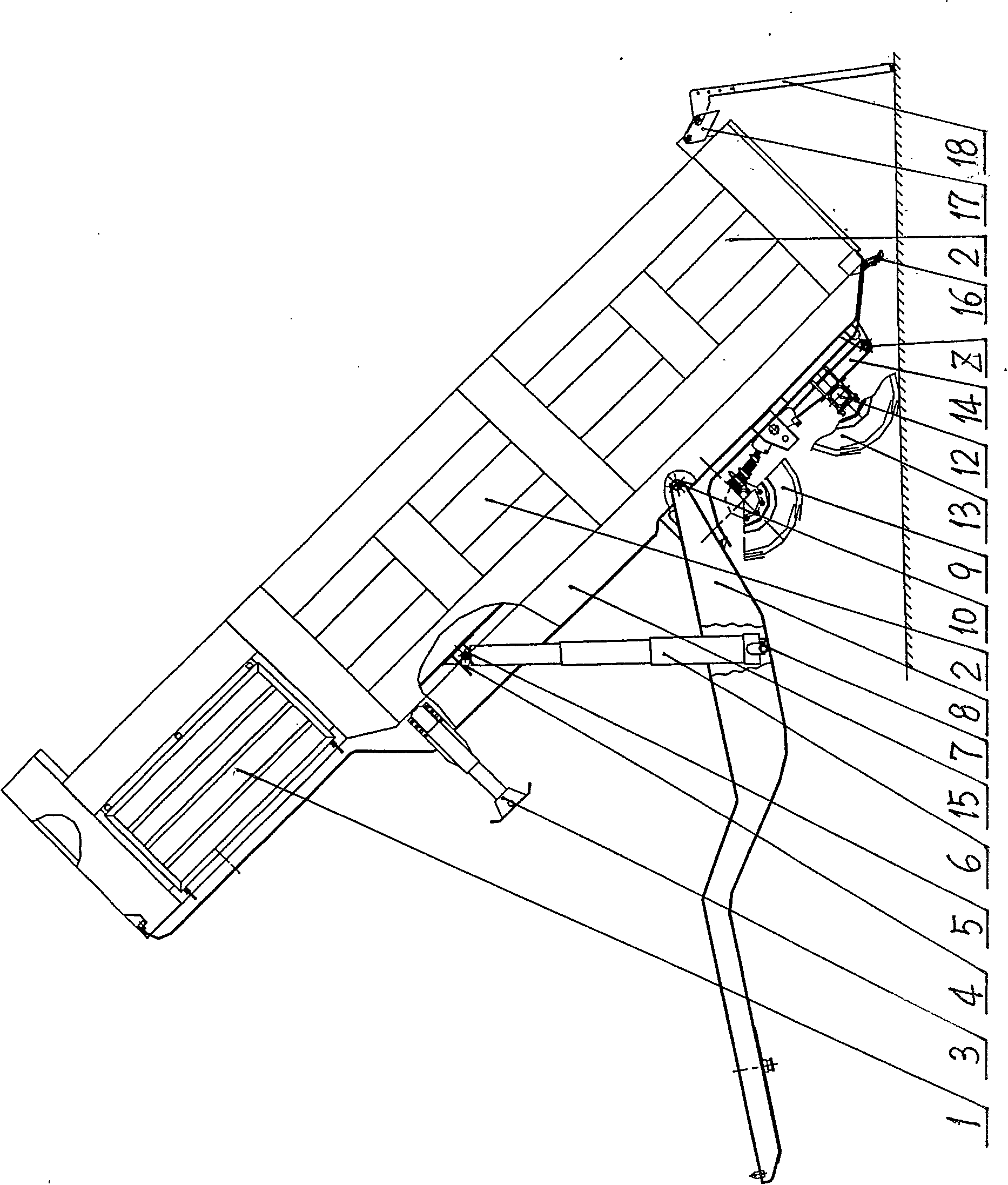

Agricultural transfer table

InactiveUS7025556B1Efficient transferImprove efficiencyLoadersAnimal feeding devicesAgricultural engineeringTruck

An agricultural transfer table enables rapid transfer of harvested agricultural material from a dump truck to a silo or the like. The agricultural transfer table comprises a box with an open front end. Apron chains in the box propel the material to the box back end, where cross chains discharge the material out a selected side. A prime mover and hydraulic system are part of the agricultural transfer table, so no source of external power is required to operate it. A tongue is closeable to enable the agricultural transfer table to be towed by a tractor. The tongue is openable to allow the truck to back up close to the agricultural transfer table front end. The front end is tiltable downwardly toward the ground. The truck back wheels back up ramps at the front box end. The ramps are storable inside the box when the agricultural transfer table is towed.

Owner:KOFFMAN MICHAEL J +1

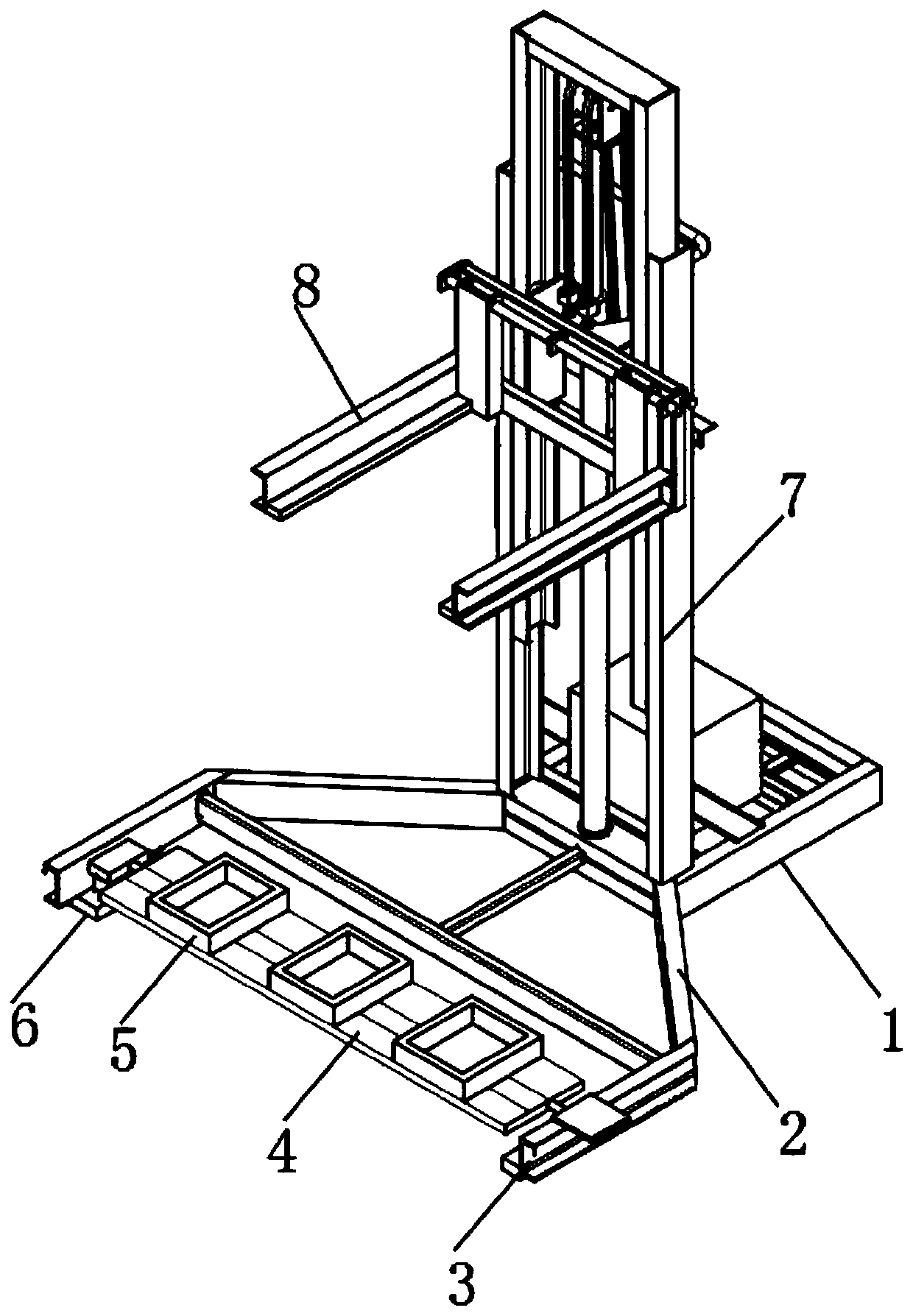

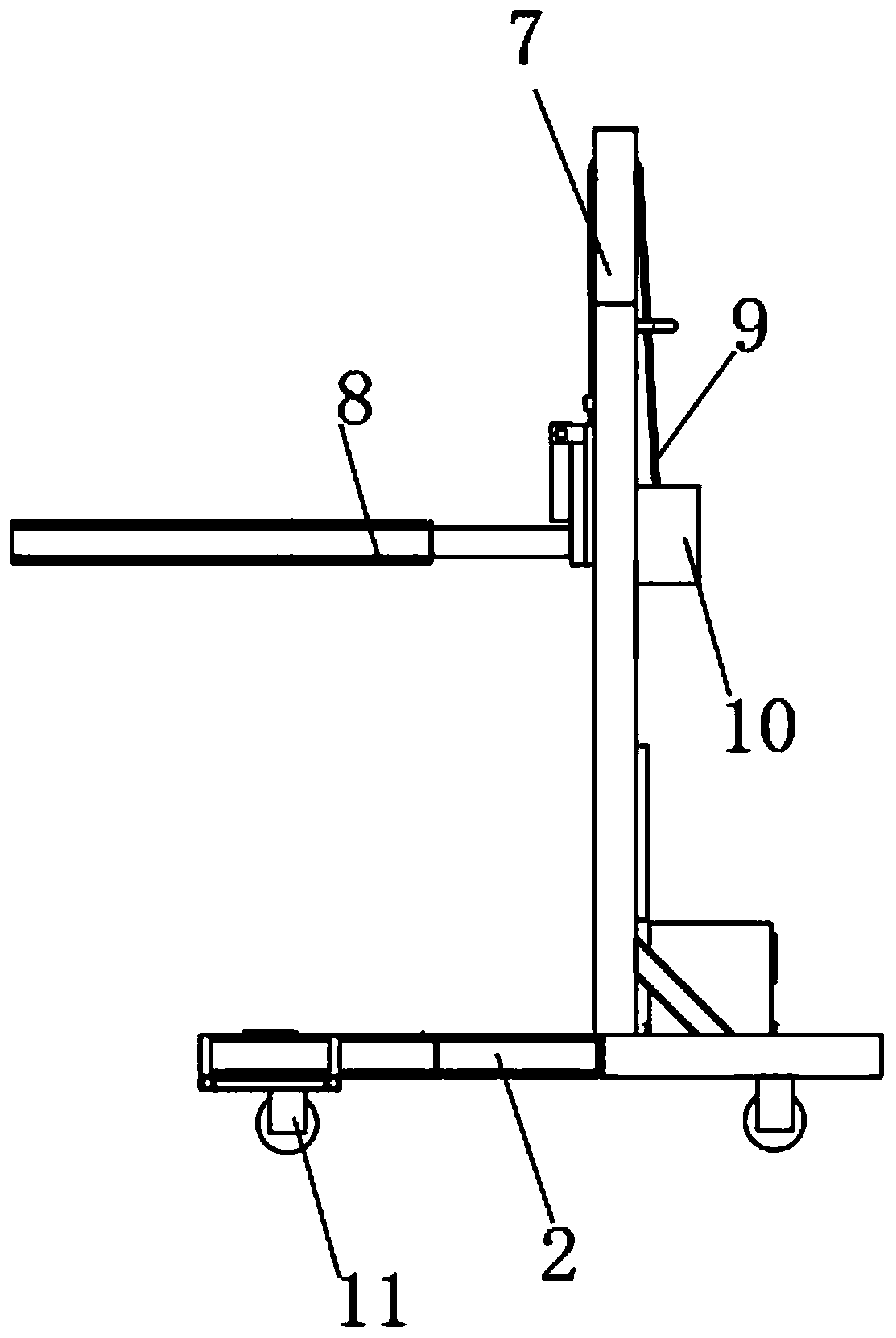

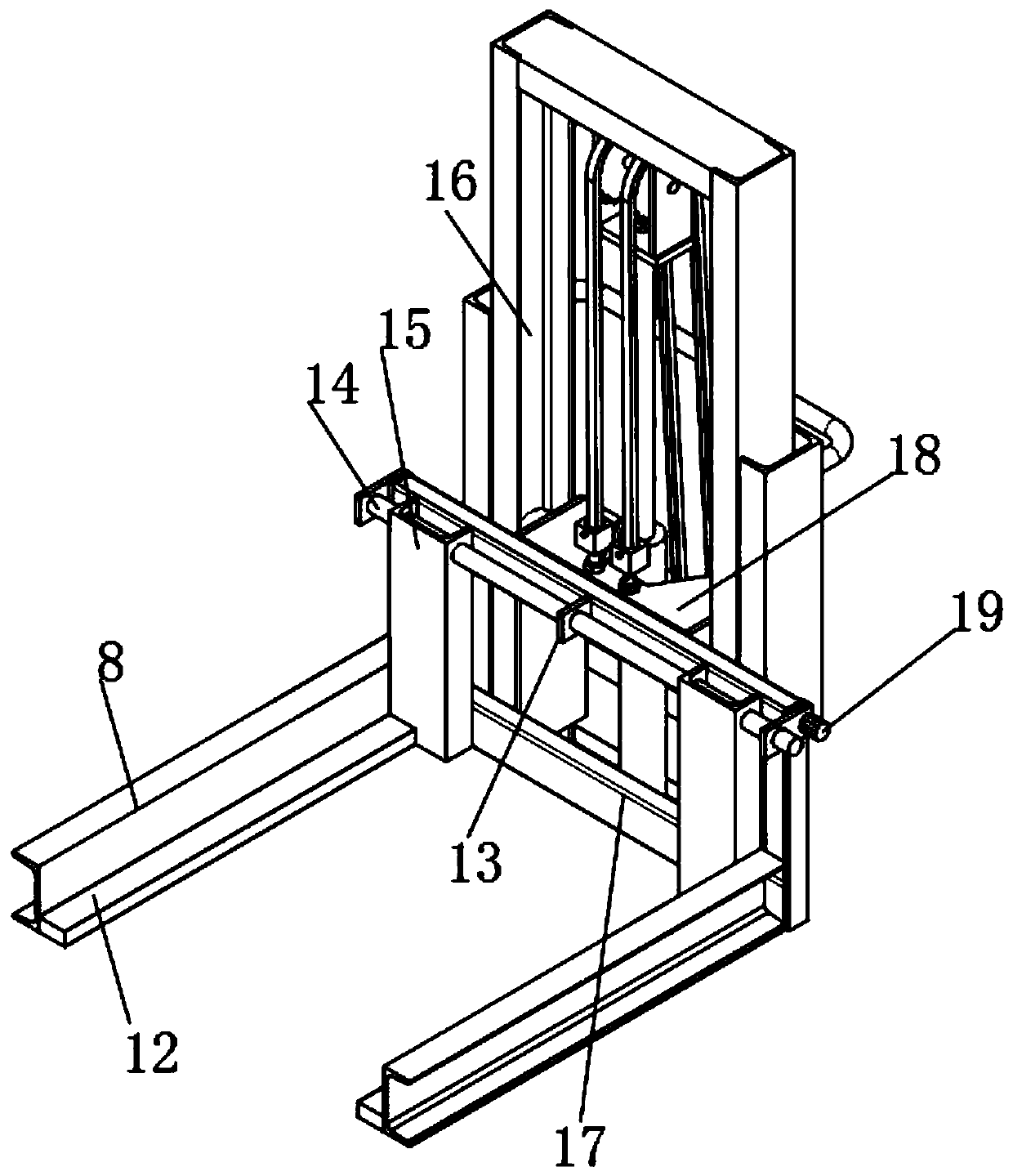

Rotating pallet fork of forklift

The invention discloses a rotating pallet fork of a forklift. The rotating pallet fork solves the problems that operation is complex and production efficiency is low when a traditional horizontal pallet fork dumps to unload goods. The rotating pallet fork comprises a fixing rack, a pallet fork carrier and two pallet fork bodies. The two pallet fork bodies are installed on the pallet fork carrier through corresponding pallet fork shafts. One rotating shaft penetrates through the fixing rack, wherein the supporting portion of the rotating shaft is arranged on the fixing rack in a rotating mode through a supporting piece, the connecting portion of the rotating shaft is fixedly connected with the pallet fork carrier, and the driving part of the rotating shaft is sleeved with an isosceles triangle driving base in a non-rotating mode. Two rotating shaft hydraulic cylinders are symmetrically hinged to the upper portions of the two sides of the fixing rack. Pistons of the hydraulic cylinders and hinged holes are hinged through hinged shafts correspondingly, and the hinged holes are symmetrically formed in the inner sides of two connecting angles of the triangle driving base. Two limit stops are symmetrically arranged on the fixing rack and located on the upper portion of the triangle driving base. The two rotating shaft hydraulic cylinders drive the triangle driving base to swing in a reciprocating mode between two side edges of the triangle driving base and the two limit stops. The rotating pallet fork of the forklift is simple in structure, convenient to operate, good in safety and high in production efficiency.

Owner:荣成中磊科技发展有限公司

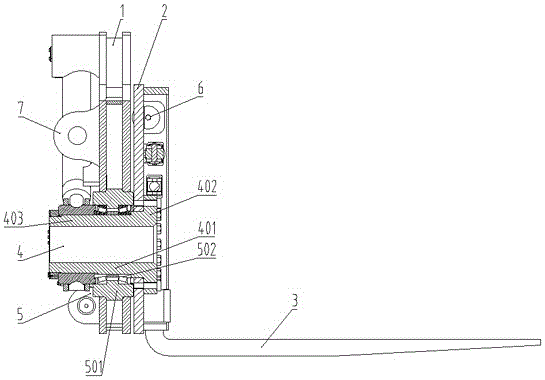

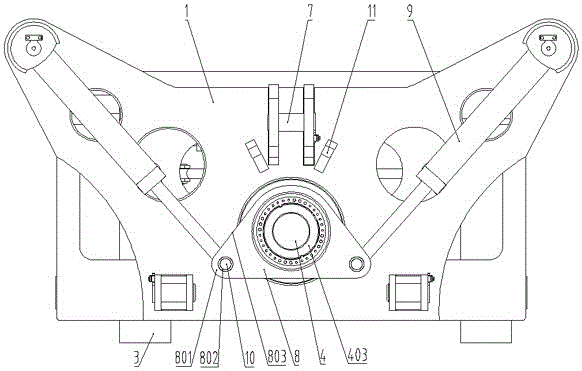

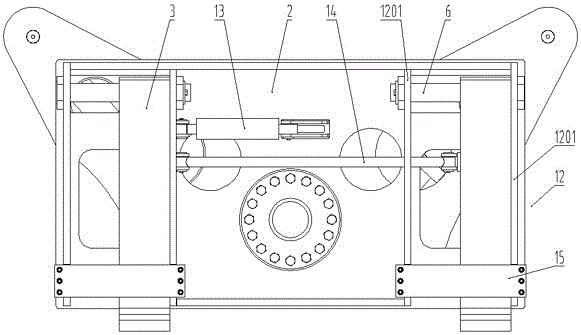

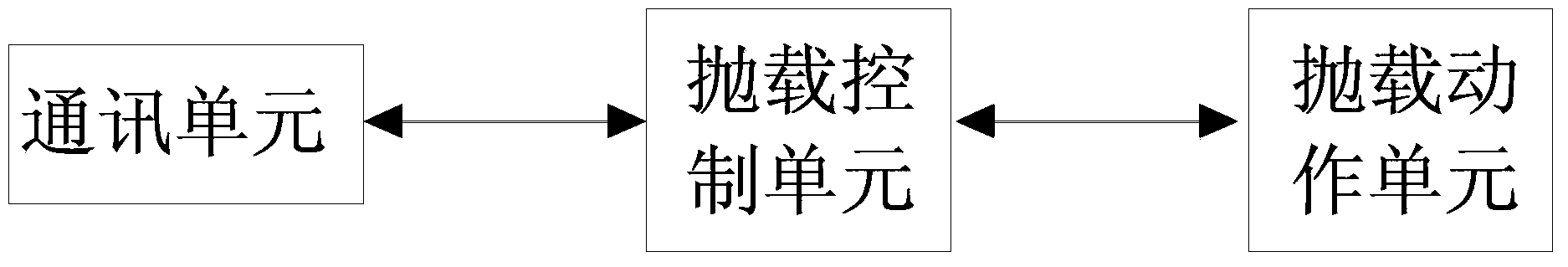

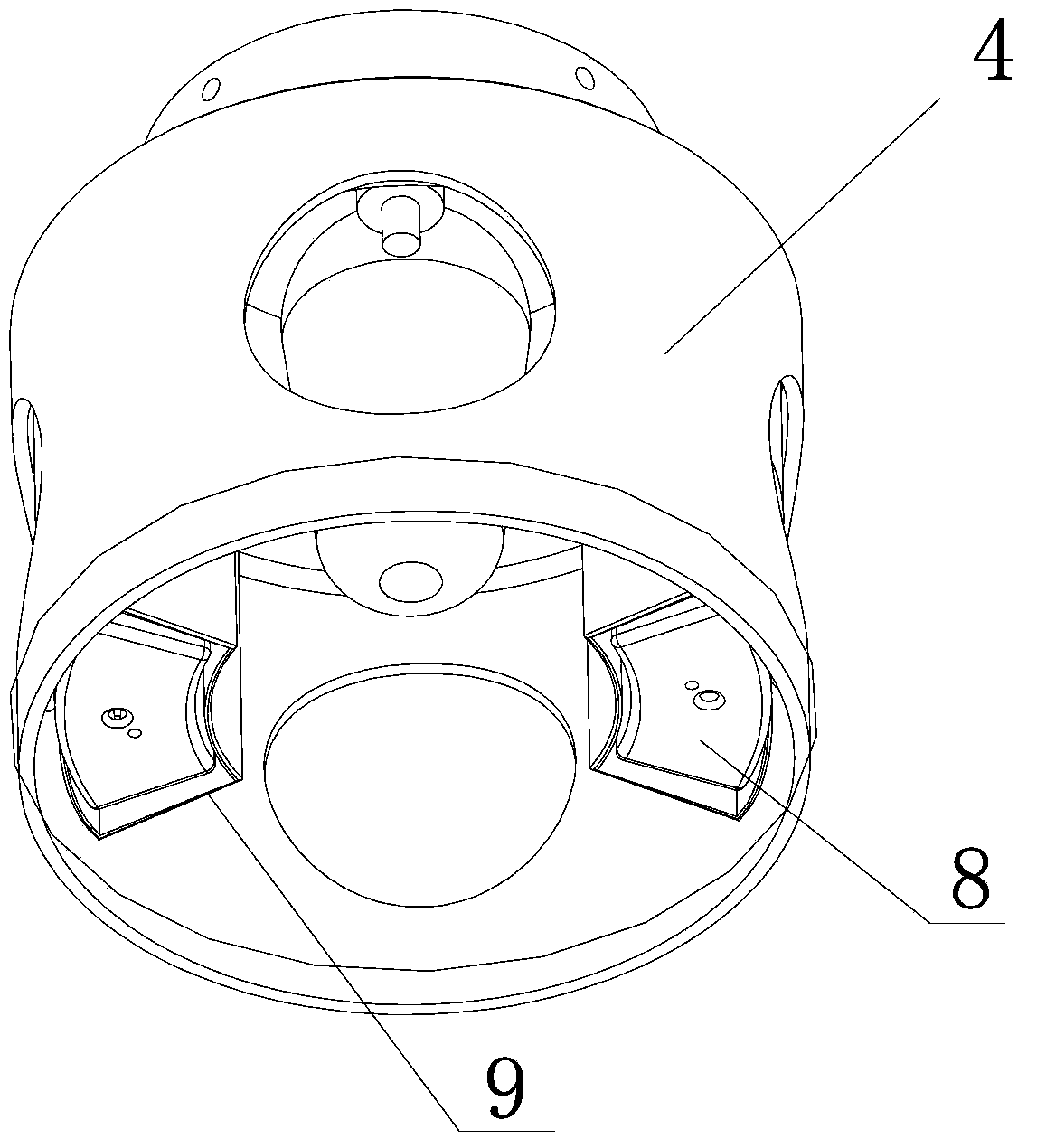

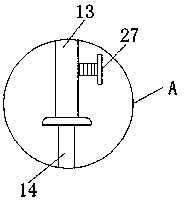

Load rejection device for underwater equipment

InactiveCN103507928AGood dumping effectGuaranteed releaseUnderwater equipmentLoad rejectionCommunication unit

The invention relates to a load rejection device for underwater equipment, and particularly relates to an electrochemical corrosion type load rejection device for an oceanographic instrument. The load rejection device for the underwater equipment comprises a communication unit, a load rejection control unit and a load rejection movement unit, wherein the communication unit communicates with the load rejection control unit, and the load rejection control unit is connected with the load rejection movement unit respectively through a cathode lead (2) and an anode lead (1). The load rejection device is simple and convenient and easy to operate, and a load rejection weight is only suspended every time before the load rejection device is in use.

Owner:QINGDAO INST OF MARINE GEOLOGY

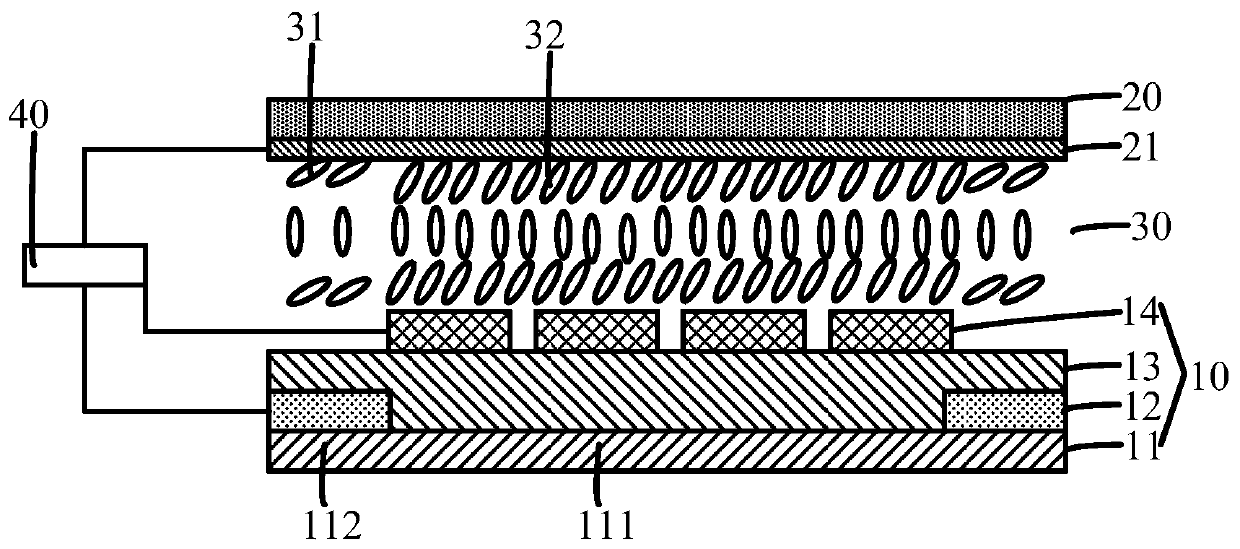

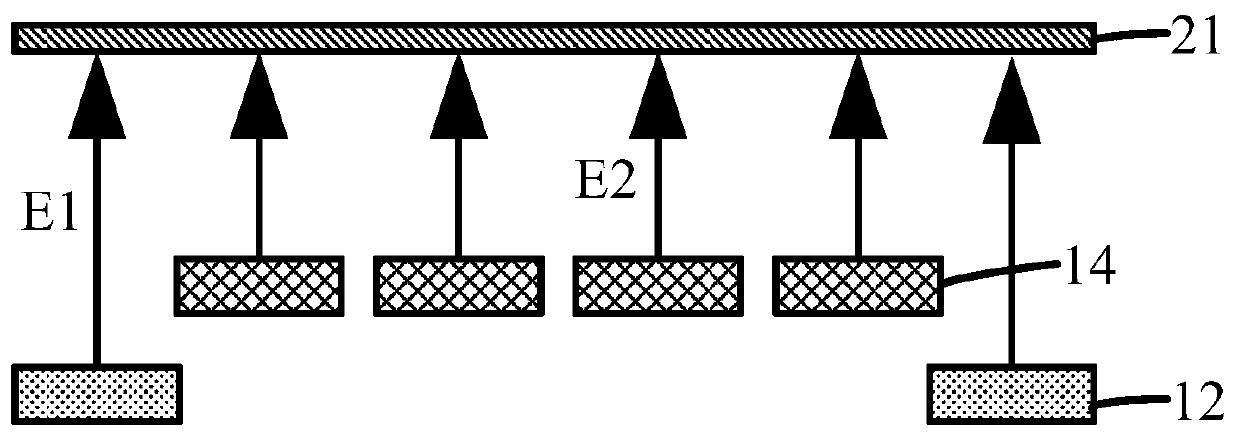

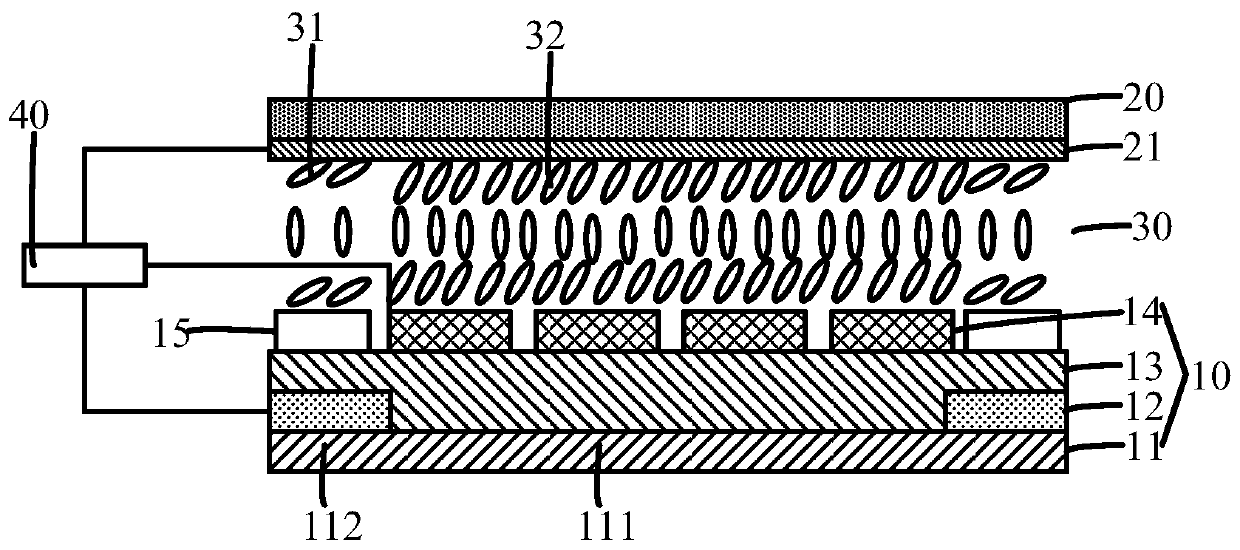

Liquid crystal display panel and liquid crystal display device

Owner:TCL CHINA STAR OPTOELECTRONICS TECH CO LTD

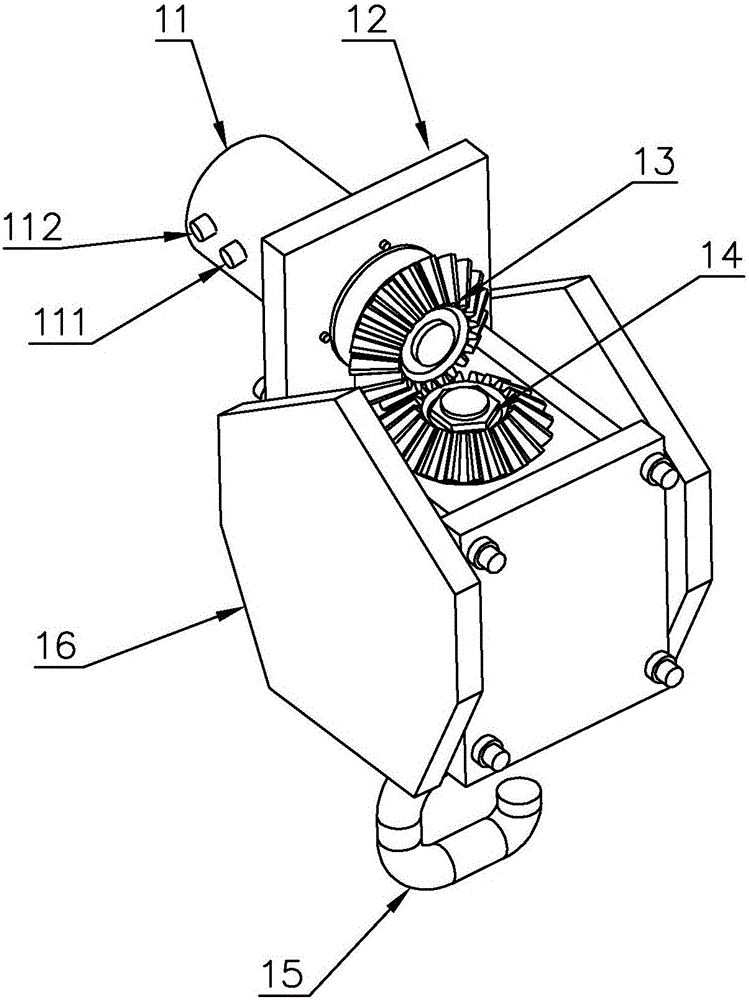

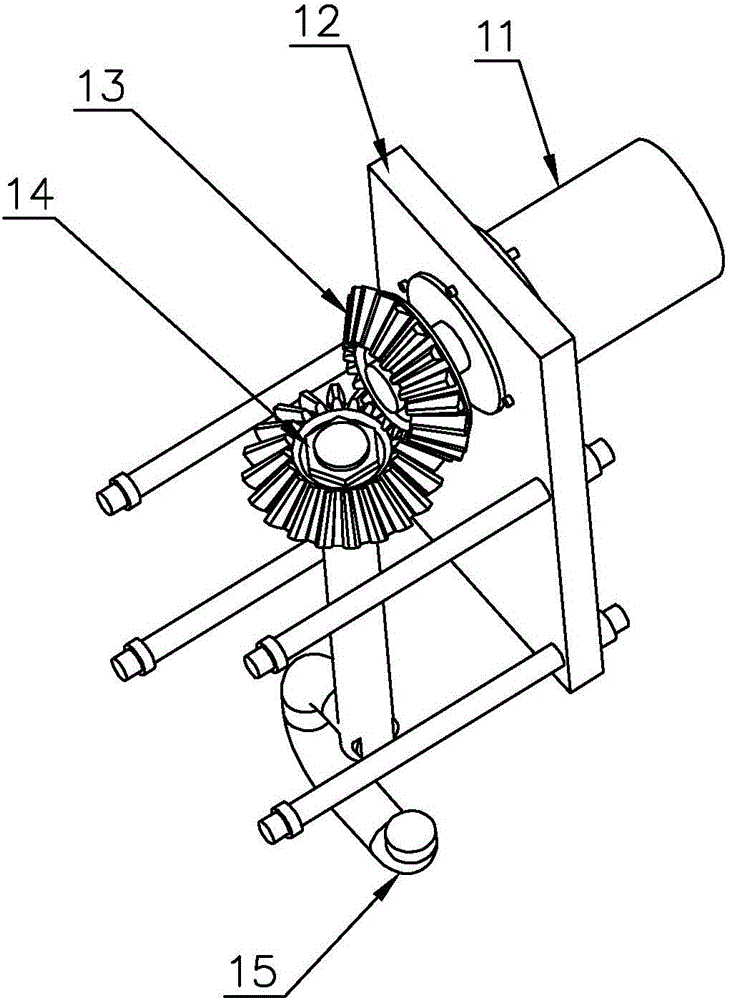

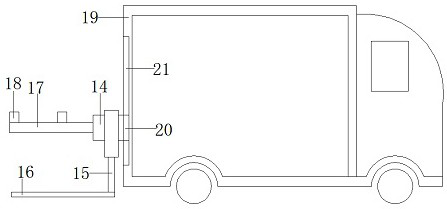

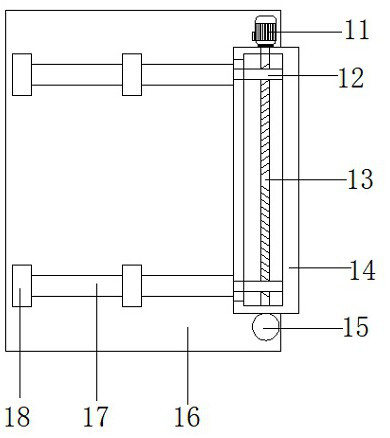

Container truck-mounted crane type angle adjusting device

ActiveCN105692424AAchieve transshipmentAchieve translationLoad-engaging elementsHydraulic motorSelf locking

The invention discloses a container truck-mounted crane type angle adjusting device. The container truck-mounted crane type angle adjusting device comprises a self-locking control rack, a hoisting adjusting mechanism and a lifting hook mechanism. The lifting hook mechanism comprises a hook, a hook support, a hydraulic motor II, a fixing plate and a bevel gear. The hook is located in a hanging hole of the hoisting adjusting mechanism. The hoisting adjusting mechanism comprises a lifting rack, a rotary shaft and rope winders. A steel wire rope is arranged on the rope winders, one end of the steel wire rope is fixed to the rope winders, and the other end of the steel wire rope is fixed to a connecting hole in the self-locking control rack. The self-locking control rack comprises connecting rods II, lock hooks, connecting rods I, a movable rod and pull rods. Transfer and horizontal movement of a container can be achieved, the container can incline relative to the ground at a large angle, bulk or barreled goods in the container can be rapidly dumped, time and labor are saved, manual loading and unloading are avoided, the labor intensity of workers is relieved, and working efficiency is improved.

Owner:张丙梓

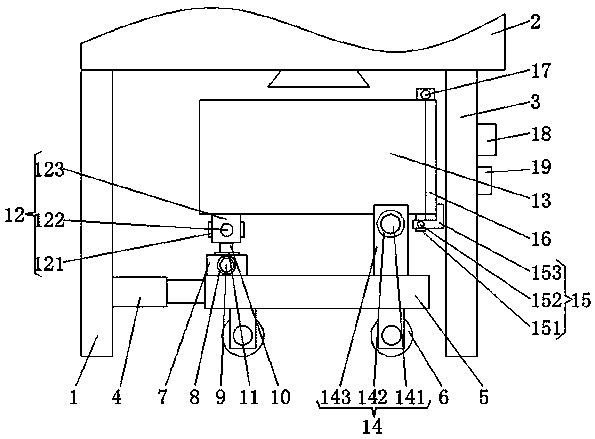

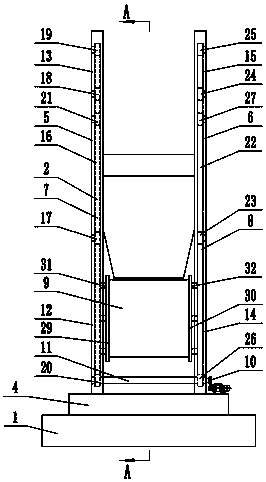

Auxiliary demolding device for injection mold as well as operation method of auxiliary demolding device

PendingCN111376443ALower the altitudeNot easy to shake and dropEngineeringElectrical and Electronics engineering

The invention discloses an auxiliary demolding device for an injection mold as well as an operation method of the auxiliary demolding device. The auxiliary demolding device comprises a base and a bearing frame; the base is fixedly mounted at one end of the bearing frame; brackets are vertically mounted on two sides of one end of the top of the base; an end part plate capable of moving up and downis mounted between the two brackets; a connecting plate is arranged on one side, close to the bearing frame, of the end part plate; a middle part plate is mounted on the middle part of one side, closeto the bearing frame, of the connecting plate; and screw rods are rotatably mounted between the two sides of the middle part plate and the two ends of the connecting plate. A third hydraulic column drives a pressing plate and an electromagnet plate on the end part of the pressing plate to abut against the exterior of a lower mold and then a fifth hydraulic pressing column drives a positioning plate to move downwards to press the bottom edge of the lower mold, so that the lower mold is more stable in a fixing frame and is insusceptible to waggle. A pull rope is shrunk and wound outside a winding shaft. The end part plate moves upwards to drive an upper mold to be separated from the lower mold, so that the mold is demolded safely and rapidly and is not liable to fall off, and damage to staff is avoided.

Owner:林冰莺

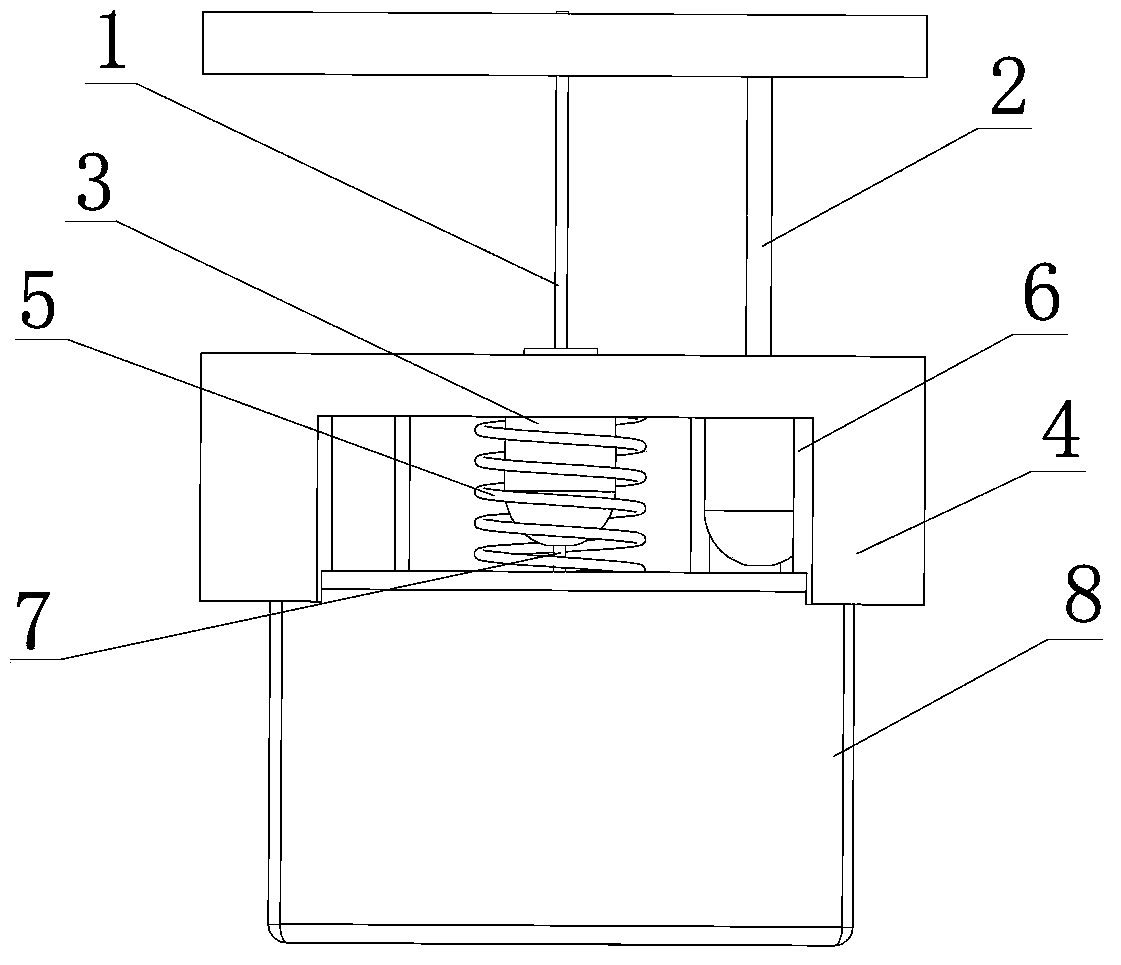

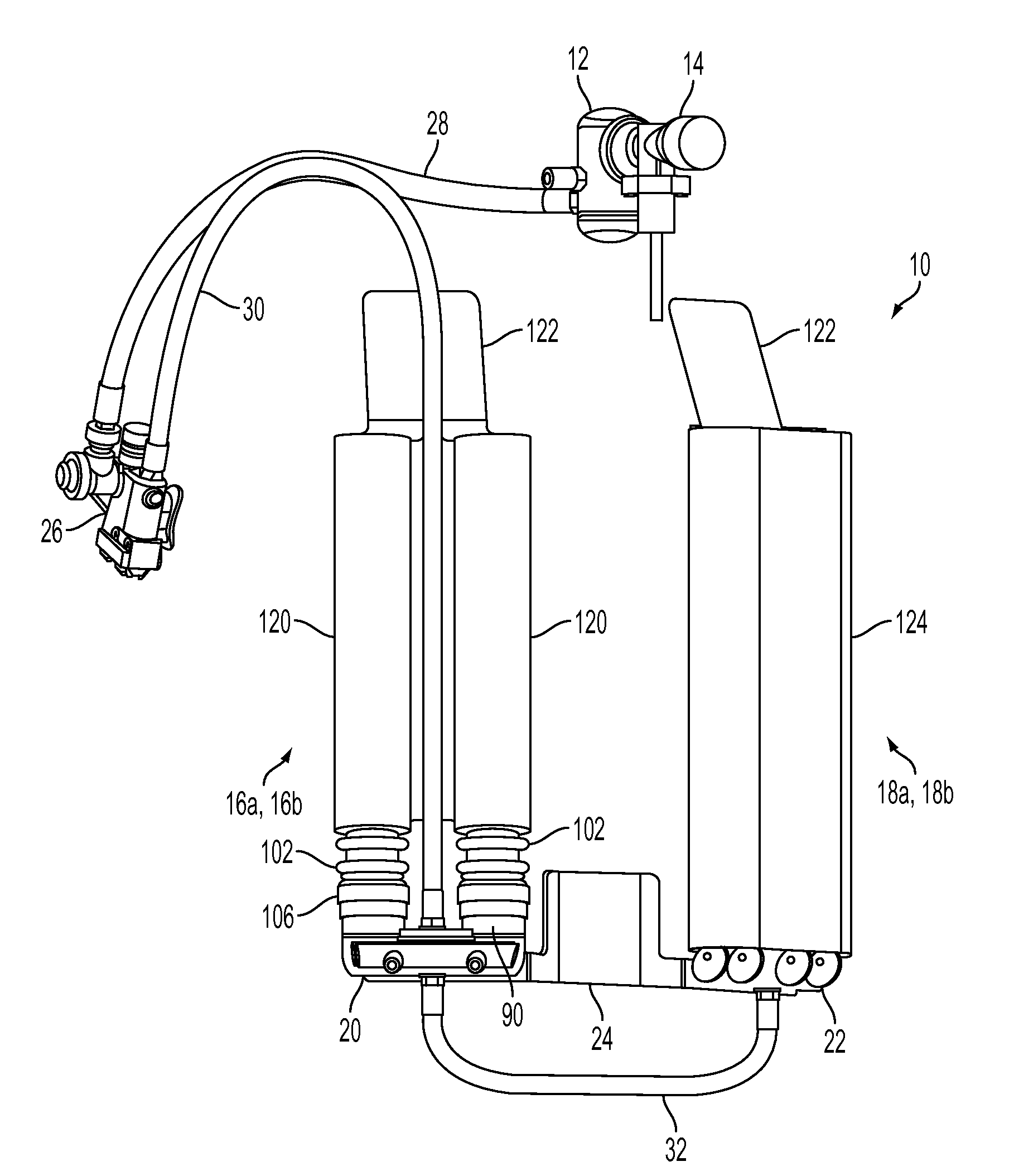

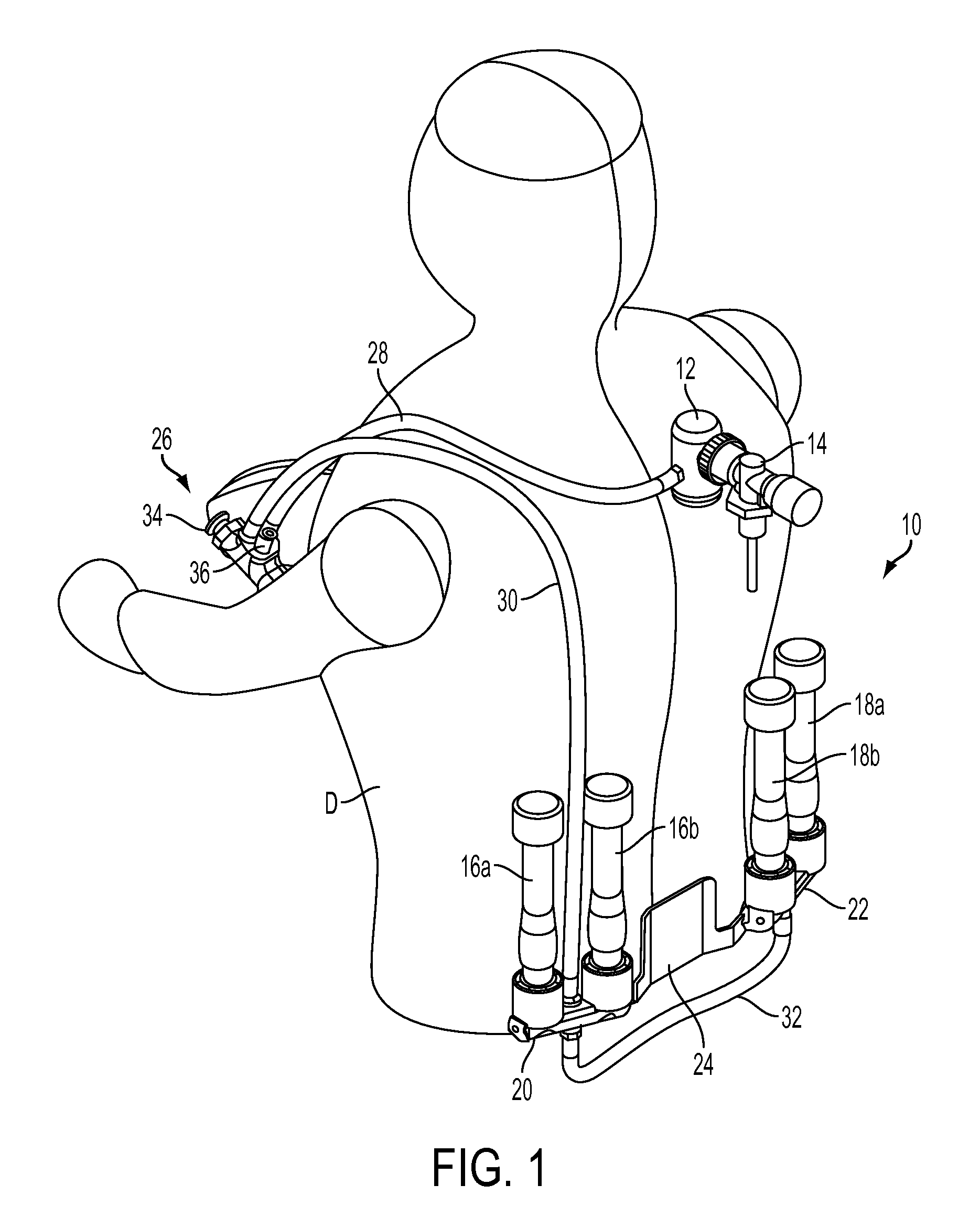

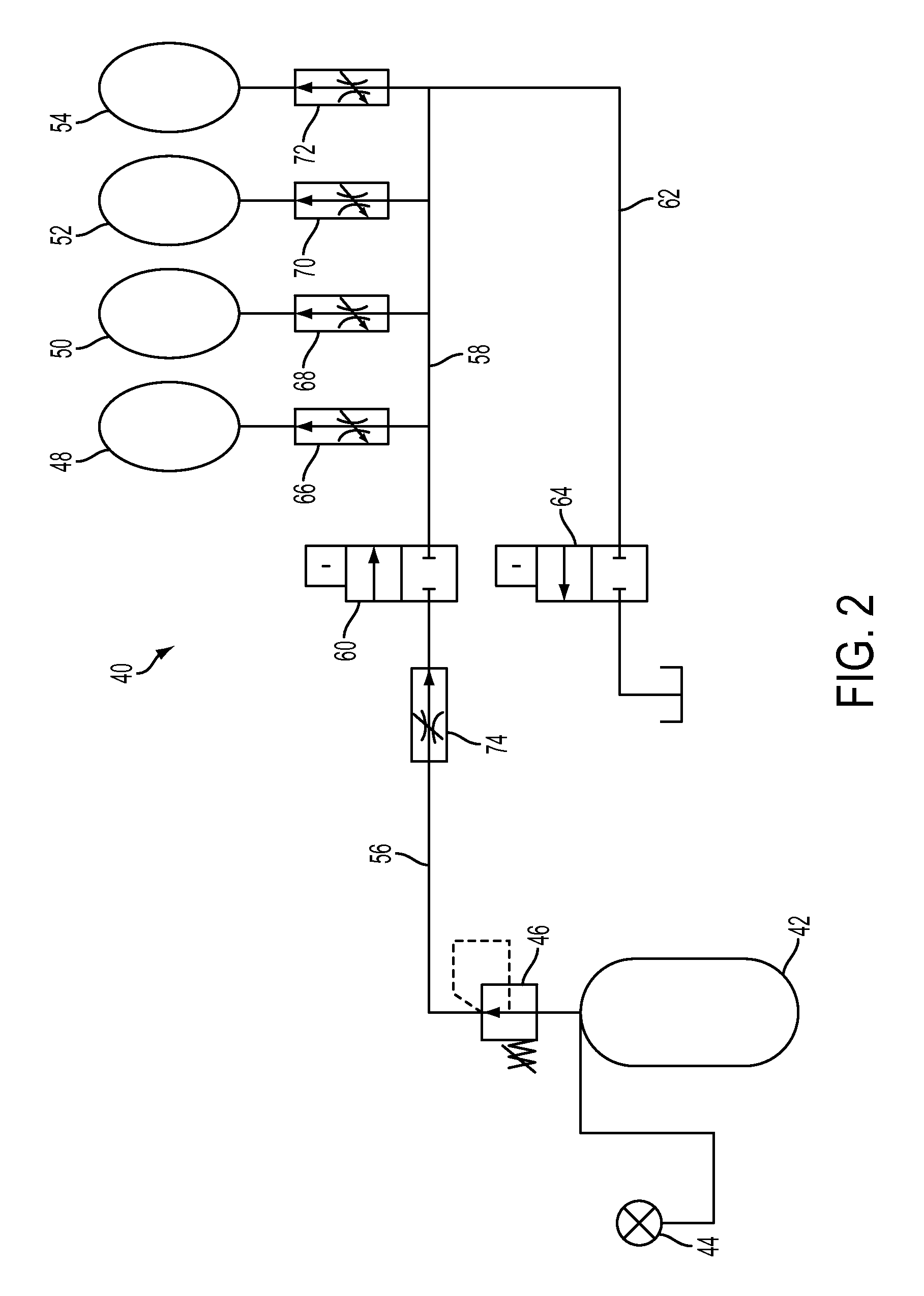

Method of and apparatus for bouyancy compensation for divers

ActiveUS20100329794A1Unbalanced blockDump air more rapidlyUnderwater equipmentAmbient pressureEngineering

An improved buoyancy compensation device having a lesser change in buoyancy with depth than conventional buoyancy compensation devices which use ambient pressure bladders is disclosed. The improved device comprises one or more elastic members that, throughout the working range of diving pressures and volumes, is always elastic and, when pressurized, maintains an internal air pressure that is always greater than the ambient pressure at any dive depth. The invention also relates to a method of providing a buoyancy compensation device with an elastic member having a lift versus depth characteristic that approaches the lift versus depth characteristic of a constant or fixed volume buoyancy compensation device.

Owner:MARKS LLOYD A

Water-absorbing and drying integrated type domestic floor accumulation water treatment equipment

The invention relates to water-absorbing and drying integrated type domestic floor accumulation water treatment equipment. The equipment comprises an accumulation water treatment equipment body, a pulling rod, pressing blocks, a drying fan and second hydraulic air cylinders, the upper left end of the accumulation water treatment equipment body is fixedly provided with a bracket, a water suction pipe is arranged on the bracket, a dust collection box is arranged at the upper right corner in the accumulation water treatment equipment body, the upper right end of the dust collection box is fixedlyprovided with a convex block, a dust suction pipe penetrates through the interior of the dust collection box, the bottom end of the dust suction pipe is connected with an extendable pipe, first hydraulic air cylinders are fixedly arranged on the inner wall of the accumulation water treatment equipment body, and the inner wall of each first hydraulic air cylinder is fixedly provided with a first connecting rod. The water-absorbing and drying integrated type domestic floor accumulation water treatment equipment has the advantages that the water-absorbing and drying integrated type domestic floor accumulation water treatment equipment is provided with water suction rolling columns, the water suction rolling columns can roll on the ground to quickly adsorb accumulation water on the ground, the tedious manual operation is avoided, and the accumulation water treatment efficiency is improved.

Owner:微微(杭州)信息技术有限公司

Outdoor airing use airing device for sliced earthworm processing

ActiveCN111964404AAvoid resurgenceQuick foldDrying gas arrangementsDrying machines with non-progressive movementsMedicinal herbsAgricultural science

The invention provides an outdoor airing use airing device for sliced earthworm processing and relates to the field of medicinal material processing. Two side plates used for supporting equipment, a sliced earthworm airing mechanism used for laying the earthworms and performing airing treatment on the earthworms, and a wind power guiding mechanism used for guiding the earthworms and performing wind power accelerating airing on the earthworms are included. The sliced earthworm airing mechanism and the wind power guiding mechanism are both arranged on the side plates. According to the outdoor airing use airing device for sliced earthworm processing, according to the problems of energy consumption, airing, damage and the like existing in the airing process of the earthworms, an ingenious andspecial airing device is designed, heat energy and wind power are concentrated for airing, influences by various factors such as weather on the finished product quality can be overcome, and thereforethe problems that generally cut earthworms cannot be easily overturned during airing and drying, airing is prone to be nonuniform, adhesion to the ground is easily caused during airing or drying, longtime is needed for airing and drying, and the processing efficiency is affected to a certain degree are effectively solved.

Owner:南京道图信息技术有限公司

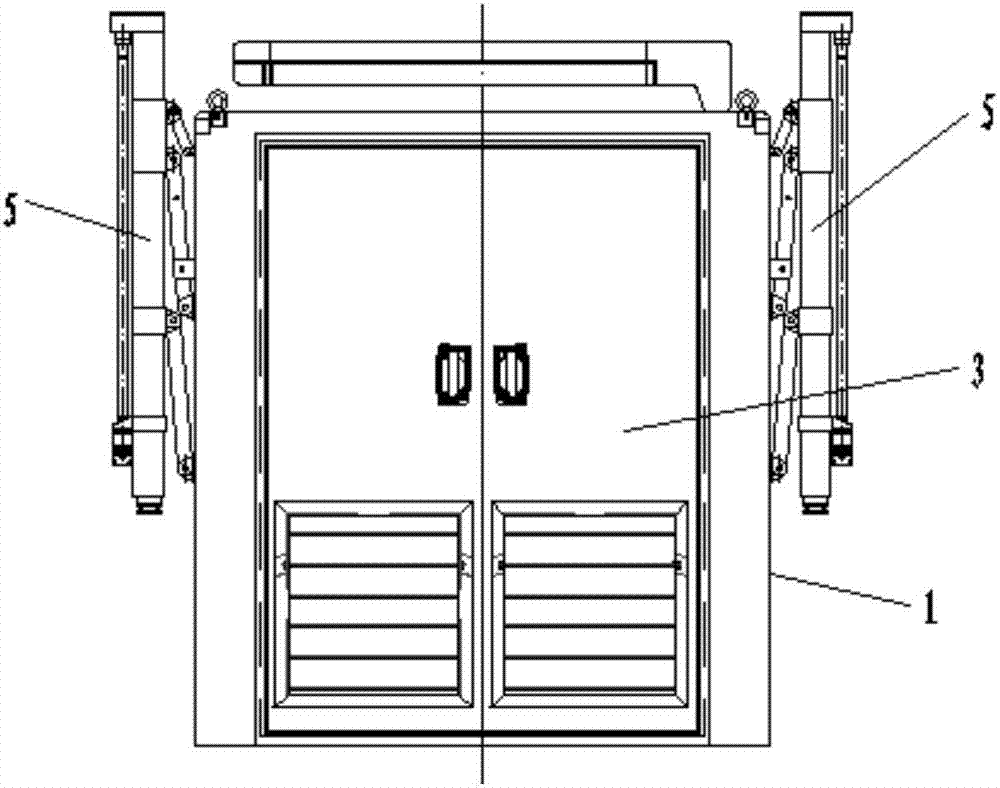

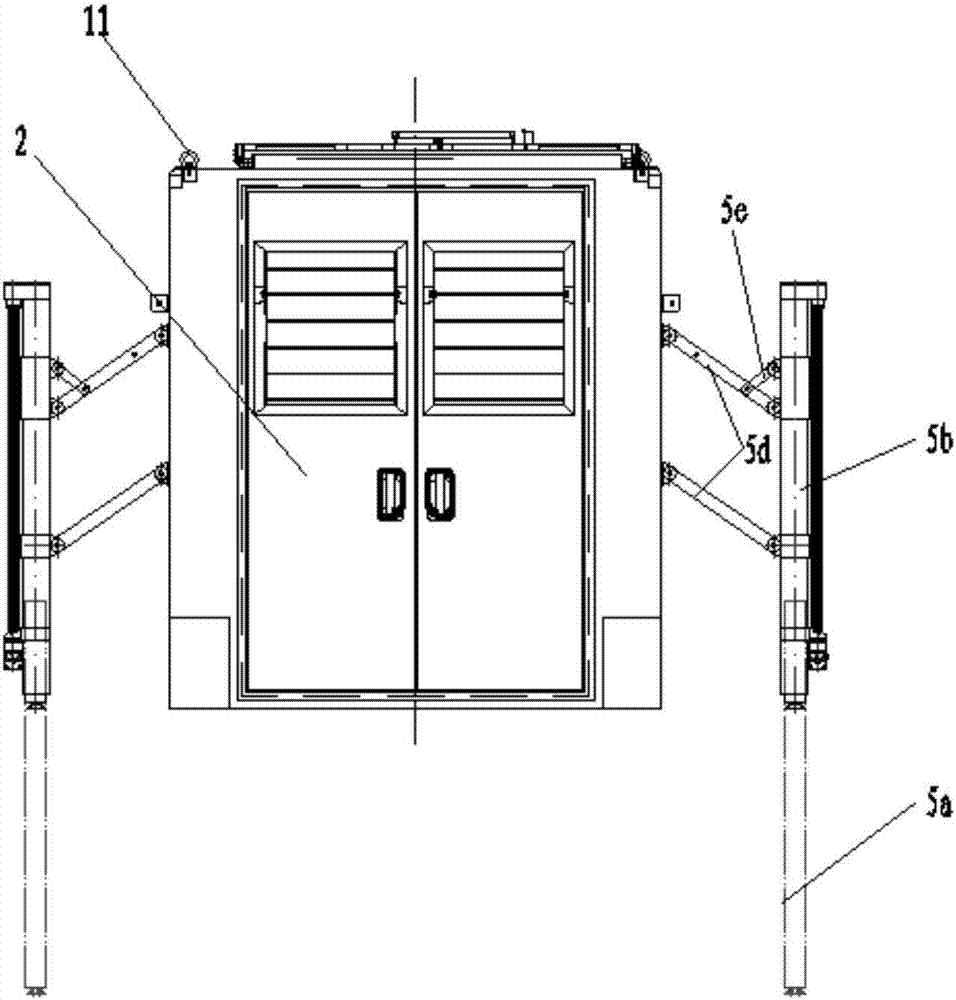

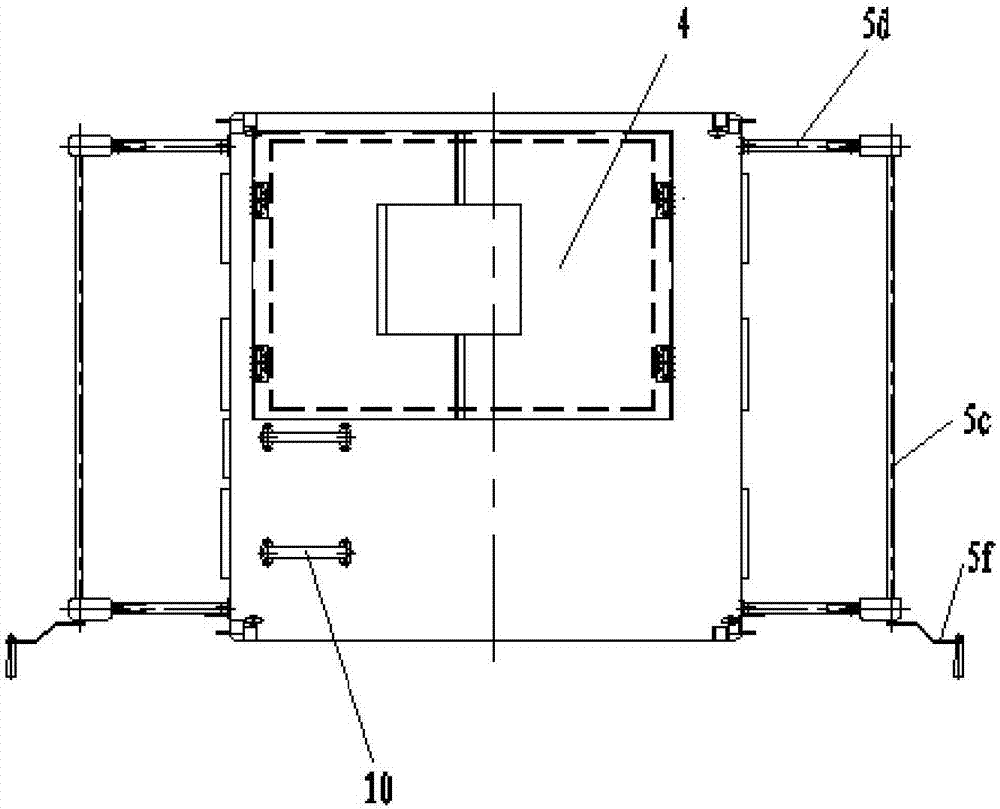

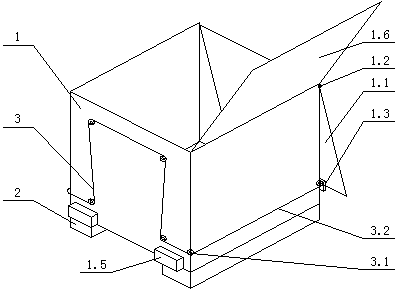

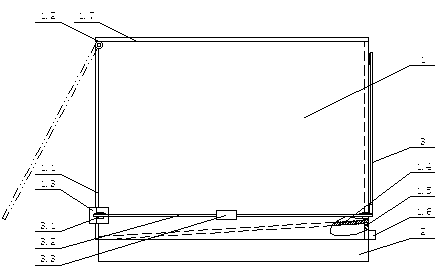

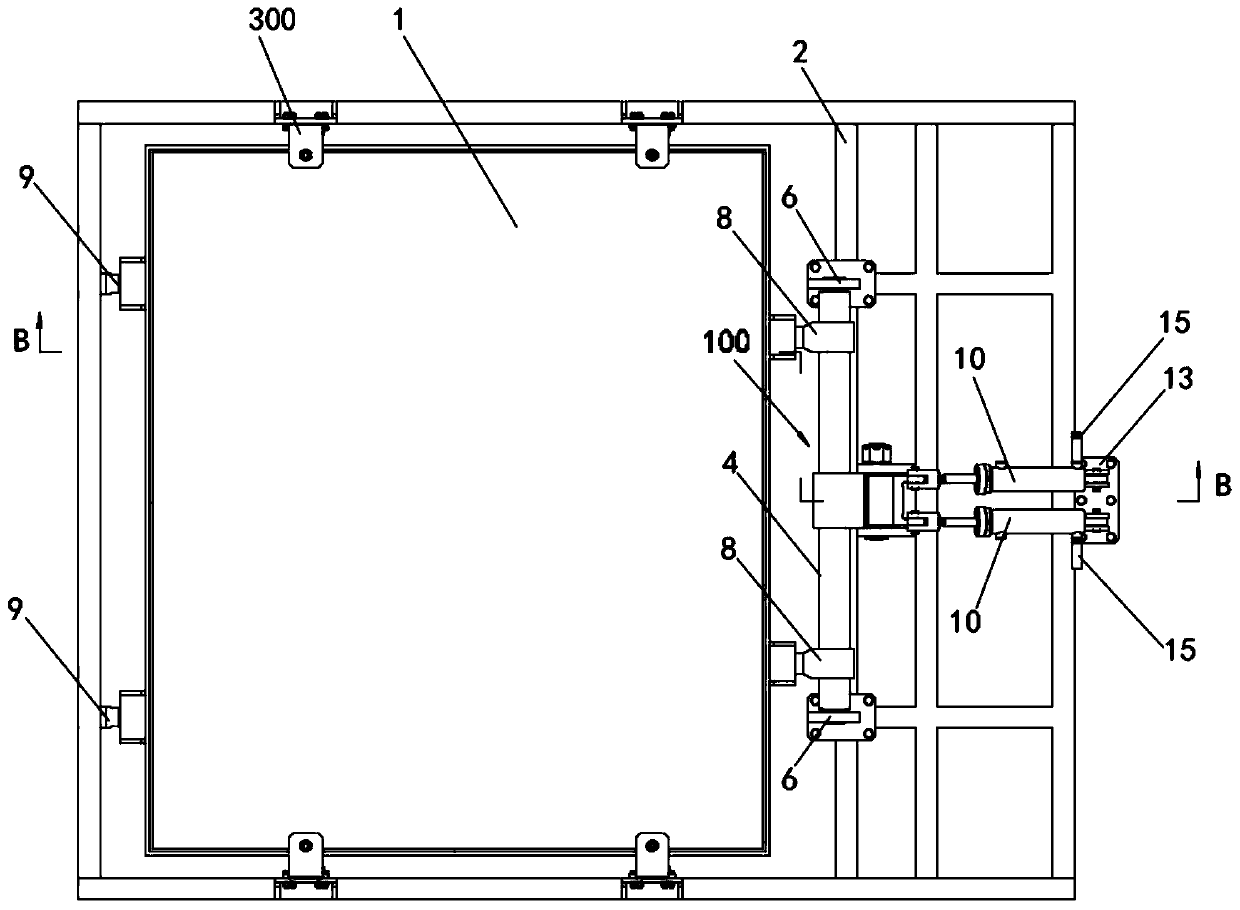

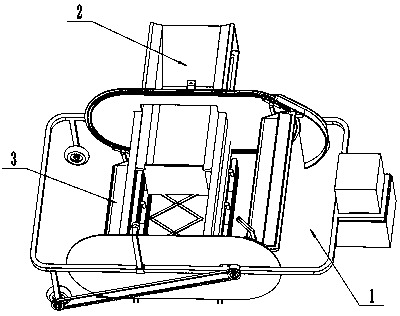

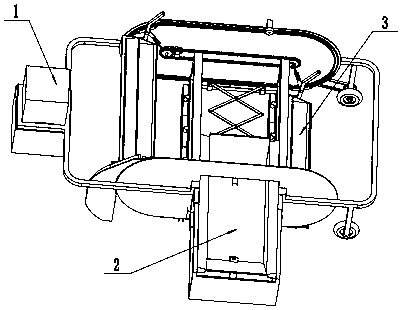

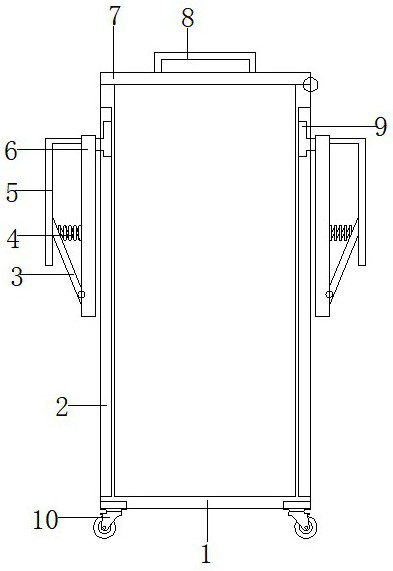

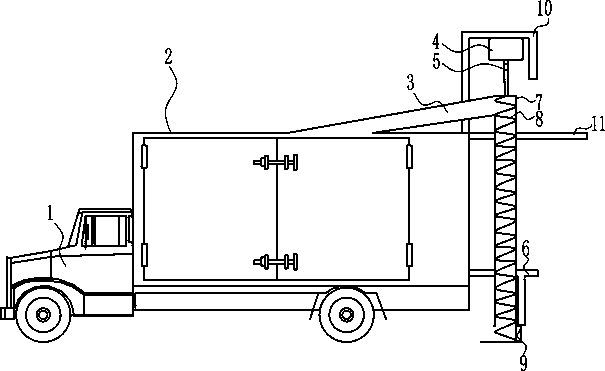

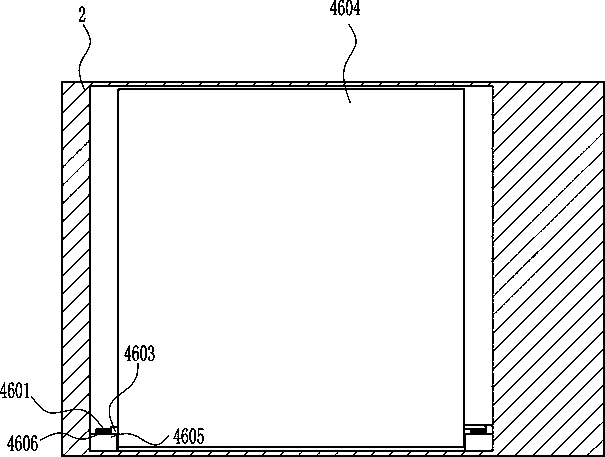

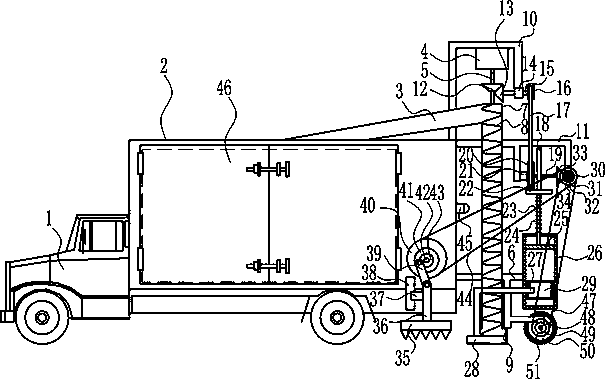

Box-type emergency base station capable of being lifted and self-unloaded

PendingCN107575054AEasy to carryImprove passabilityBuilding constructionsIndustrial buildingsPickup truckEngineering

The invention discloses a box-type emergency base station capable of being lifted and self-unloaded. An inner cavity of a box body is divided into an antenna bin and an equipment bin. The left side wall and the right side wall of the box body each are externally provided with a hand-operated folding and lifting supporting mechanism. Each hand-operated folding and lifting supporting mechanism comprises two telescopic supporting legs which are arranged front to back at intervals. Each telescopic supporting leg is sleeved with a corresponding fixing stand column in a penetrating mode from bottomto top. Each telescopic supporting leg is fixedly provided with a rack. The two telescopic supporting legs located on the same side achieve linkage expansion and contraction of the two telescopic supporting legs on the same side through a horizontal bar, gears and a hand-operated cranking bar, wherein the gears are fixedly arranged on the horizontal bar in a sleeving mode and mesh with the two racks one by one, and the hand-operated cranking bar drives one of the gears to rotate. Each fixing stand column is hinged to the outer side ends of two oblique supporting rods which are arranged parallelly up and down at intervals. The inner side end of each oblique supporting rod is hinged to the corresponding side wall of the box body. Each fixing stand column is further hinged to the outer side end of a locking rod. The box-type emergency base station meets load requirements of a small pickup truck, can be quickly deployed in a narrow area, and does not occupy a transport chassis after beingself-unloaded.

Owner:CHONGQING DIMA IND

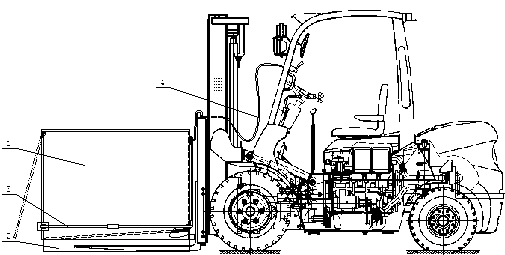

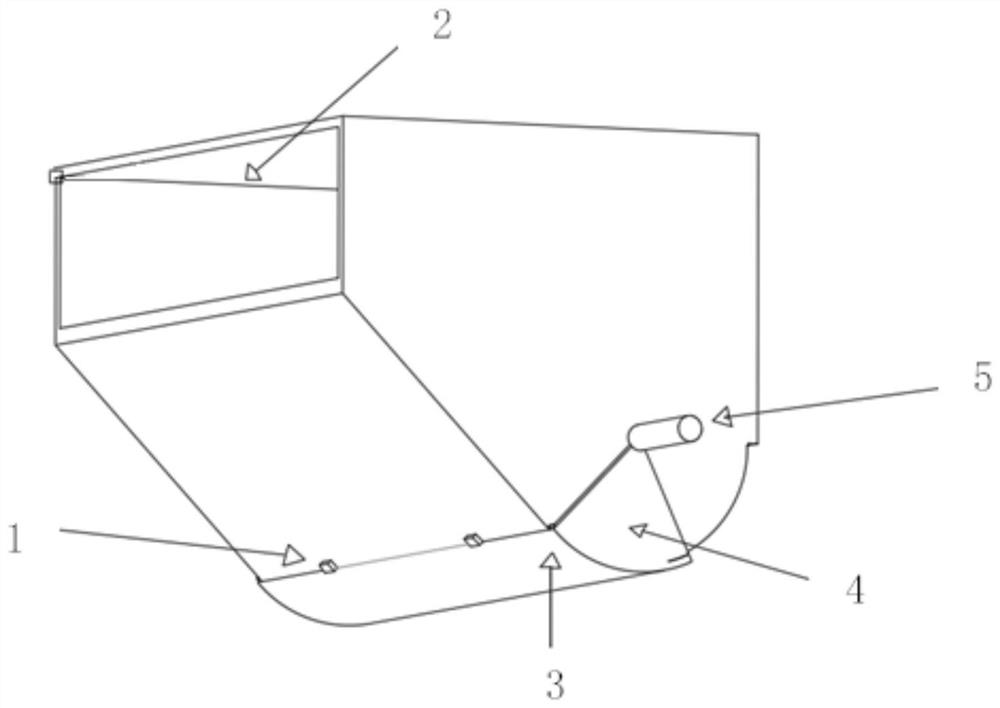

Transferring device

The invention discloses a transferring device. The transferring device comprises a hopper body (1), plugholes (2), a traction mechanism (3) and a stay wire mechanism (4), wherein the hopper body adopts a box structure and is provided with a moveable front hopper plate; the top of the front hopper plate is hinged with the front upper part of the hopper body; lock pin mechanisms are arranged below and in front of two side hopper plates vertical to the front hopper plate; two plugholes are fixedly mounted below the hopper body; the traction mechanism comprises a guide wheel I and a steel wire rope; the stay wire mechanism is arranged on a forklift and comprises an operating handle, a stay wire, a guide wheel II and a hanger. The transferring device can control the lock pin mechanisms by operating the stay wire mechanism so as to open and close the front hopper plate, and broken glass can be completely toppled without turning over the hopper, so that time and resources are saved, the transferring efficiency is improved and the operating safety is guaranteed.

Owner:JIANGSU YETAI GLASS

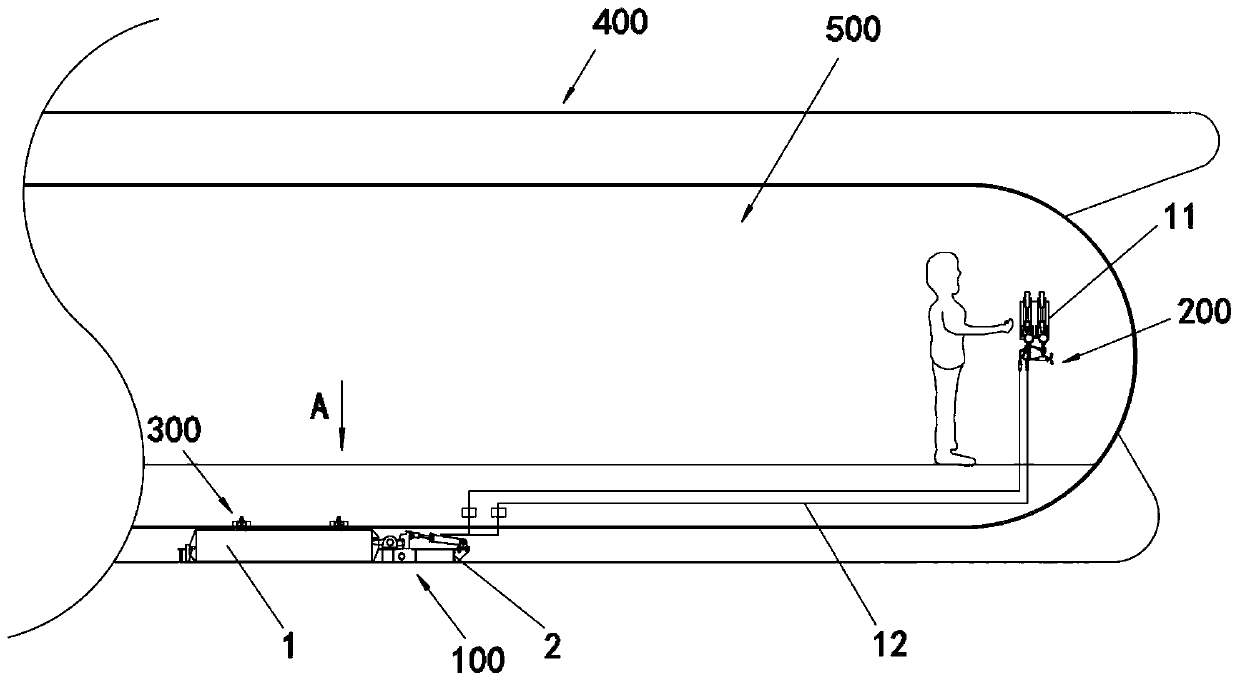

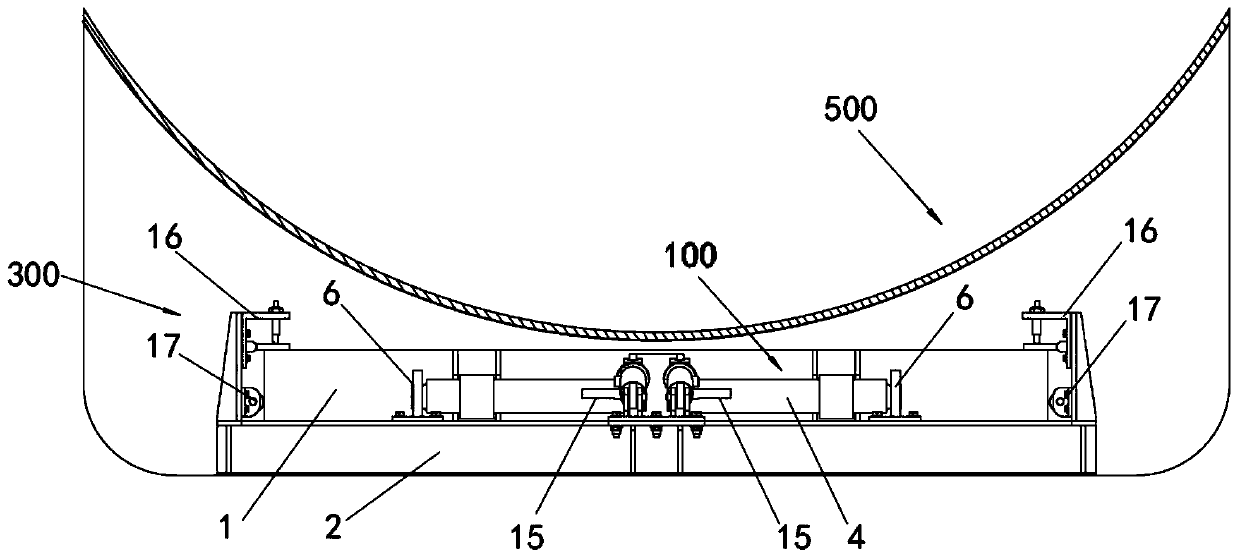

Underwater emergency load rejection device

InactiveCN111137426AQuick dumpFloating fastUnderwater vesselsUnderwater equipmentMarine engineeringReliability engineering

The invention discloses an underwater emergency load rejection device. The underwater emergency load rejection device comprises a submersible, a rack is installed at the bottom of the middle standingface of the submersible, a releasing mechanism is installed in the middle of the rack, a heavy block box is installed at the rear portion of the rack, a driving assembly is installed at the front portion of the rack, and the heavy block box is released through the releasing mechanism under the power of the driving assembly. The underwater emergency load rejection device is compact and reasonable in structure and convenient to operate, the load rejection device is installed in a flat space, the emergency capacity is high, safety and reliability are achieved, operation is easy, remote load rejection and rapid floating of the submersible can be manually and rapidly achieved when a power source is lost in an emergency, and the safety of personnel and the submersible is guaranteed.

Owner:CHINA SHIP SCIENTIFIC RESEARCH CENTER (THE 702 INSTITUTE OF CHINA SHIPBUILDING INDUSTRY CORPORATION)

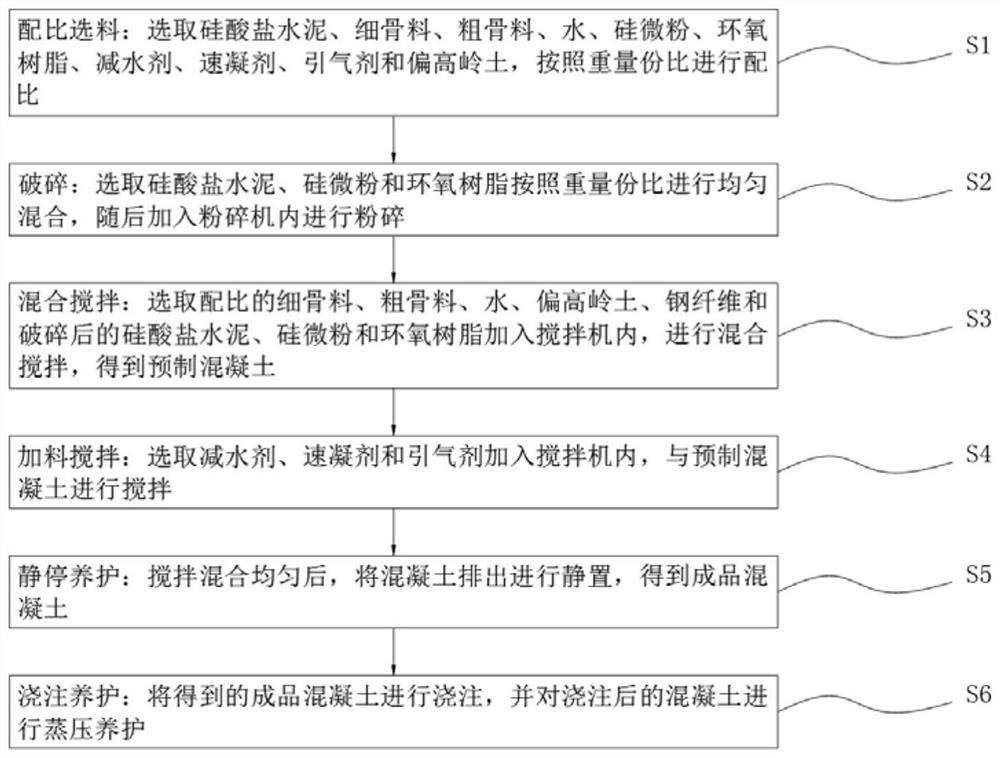

Preparation process of high-strength wear-resistant concrete

The invention discloses a preparation process of high-strength wear-resistant concrete. The concrete is prepared from the following components in parts by weight: 300 to 400 parts of Portland cement,500 to 900 parts of fine aggregate, 950 to 1250 parts of coarse aggregate, 180 to 190 parts of water, 20 to 40 parts of silica powder, 50 to 80 parts of epoxy resin, 5 to 12 parts of steel fiber, 1 to4 parts of a water reducing agent, 6 to 12 parts of an accelerator, 0.15 to 0.6 part of an air entraining agent and 40 to 65 parts of metakaolin. The structure of the concrete is scientific and reasonable; the preparation method is safe and convenient to use; and the prepared concrete is high in strength and not prone to damage during heavy pressing and collision, the overall strength of the prepared concrete during use is improved, the wear resistance of the concrete is improved, and the setting rate of the concrete is increased, so the market competitiveness of the prepared concrete is improved.

Owner:卫凤仪

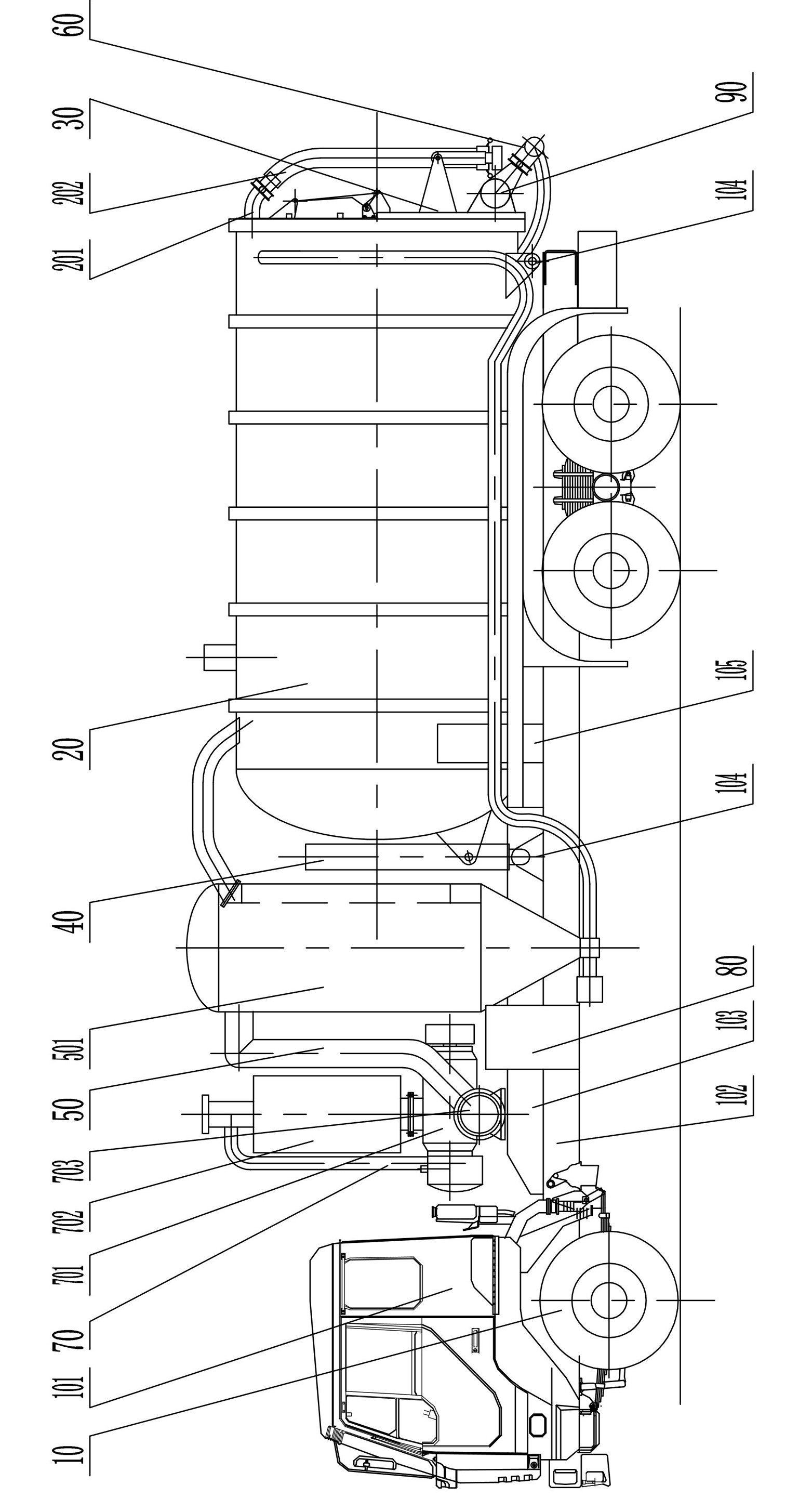

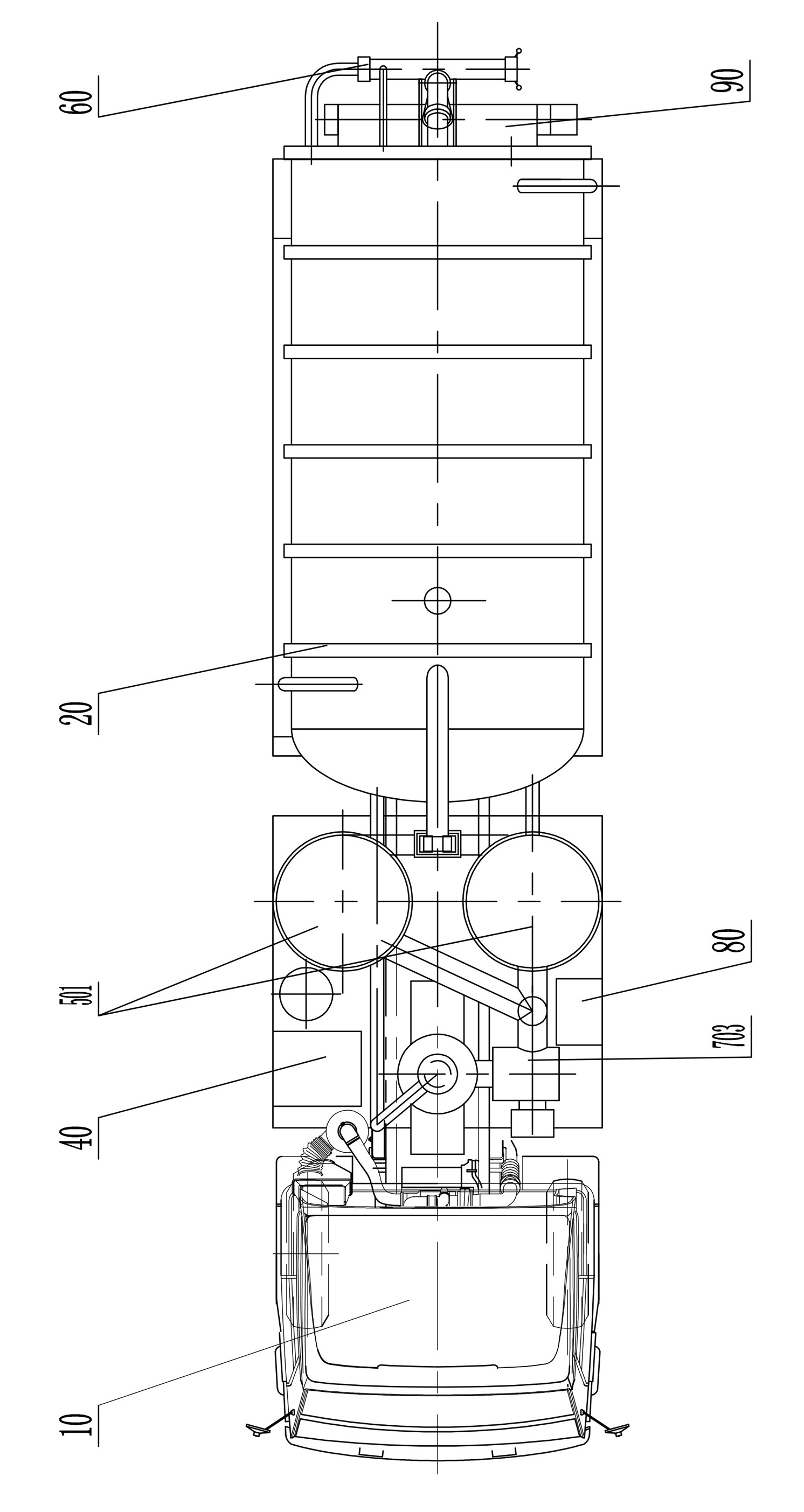

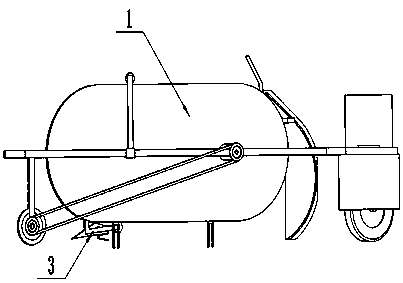

Industrial vacuum tank vehicle

ActiveCN101927724ASimplify the overall layoutReduce vehicle weightLarge containersItem transportation vehiclesAutomotive engineeringMaterial storage

The invention discloses an industrial vacuum tank vehicle. The industrial vacuum tank vehicle comprises a chassis, and a material storage tank, a tailgate component, a hydraulic dump component, a dual-loop whirlwind cloth bag combination filter, a pneumatic unloading device, a two-way vacuum system, a control system and an auger stripper which are arranged on the chassis, wherein the tail end, far away from a cab, of the material storage tank is hinged on the chassis; the bottom of the front end, close to the cab, on the material storage tank is hinged with the hydraulic dump component; the tailgate component is arranged at the tail end of the material storage tank; the top part of the tailgate component is provided with a material suction pipe; the material suction pipe is communicated with the two-way vacuum system after passing through the dual-loop whirlwind cloth bag combination filter; the auger stripper is fixed on the lower part of the tailgate component; and the outlet end of the auger stripper is provided with the pneumatic unloading device which is communicated with the dual-loop whirlwind cloth bag combination filter through a pipeline. The industrial vacuum tank vehicle has the advantages of simple and compact structure, low cost, high environmental protection property, wide application range, high maneuverability, high energy saving property and the like.

Owner:长沙凯瑞重工机械有限公司

Waste slag processing device convenient in use for blast furnace ironmaking equipment

InactiveCN108728595AEasy to useEasy to handleRecycling and recovery technologiesProcess efficiency improvementSlagEngineering

The invention discloses a waste slag processing device convenient in use for blast furnace ironmaking equipment. The waste slag processing device comprises a supporting plate, wherein the upper surface of the supporting plate is fixedly connected with a blast furnace body; the right side of the lower surface of the blast furnace body is fixedly connected with two supporting legs; in addition, thetwo supporting legs are respectively positioned on the front side and the back side of the lower surface of the blast furnace body; a first electric push rod is fixedly connected below the right sidesurface of the supporting plate. According to the waste slag processing device convenient in use for the blast furnace ironmaking equipment, the first electric push rod is arranged to enable the blastfurnace body to drive a box body to rightwards move to the right side of the blast furnace body through a rotation device, a second electric push rod is arranged and extends to drive the box body torotate around a second spindle through the flexible rotation of a first spindle and a movement device, waste slag in the box body can fall into a prepared small cart from the box body, so that the labor intensity of people for cleaning waste slag is lightened, and convenience is brought to people to clean the waste slag.

Owner:周佩龙

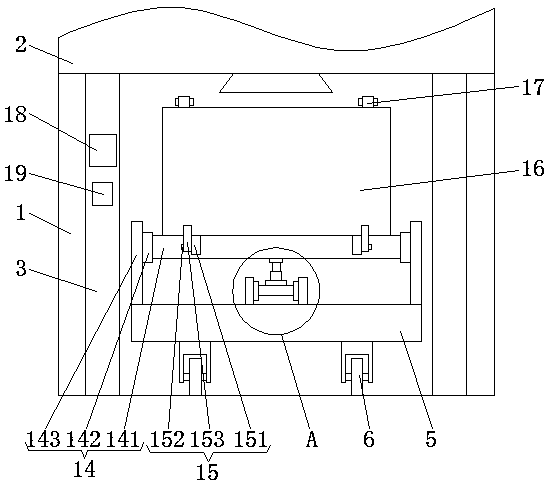

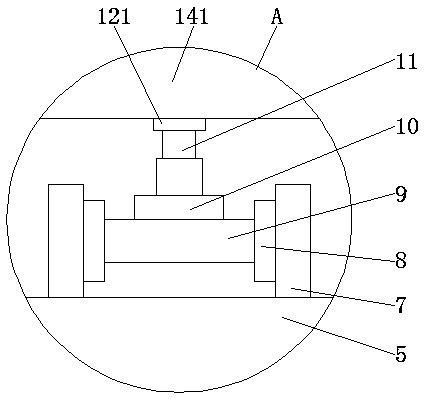

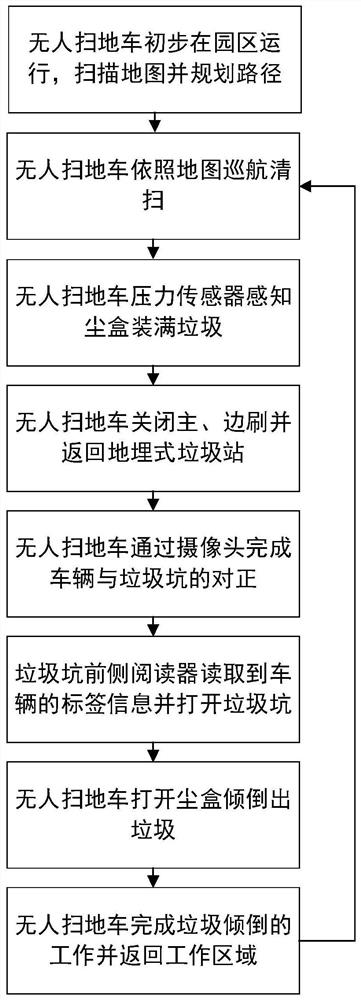

Unmanned street sweeper vehicle-mounted dustbin automatic cleaning system and method

PendingCN113353499ATo achieve collaborative useImplement an automatic cleanup methodRefuse receptaclesRefuse transferringIn vehicleVisual inspection

The invention discloses an unmanned street sweeper vehicle-mounted dustbin automatic cleaning system and method. The system comprises an unmanned street sweeper dustbin and a buried garbage station, and the method comprises the following steps that a park map is automatically collected by using an unmanned street sweeper, and the unmanned street sweeper heads for the garbage recycling station along a pre-planned path; after the sweeper enters the garbage recycling station, the automatic connection between the unmanned street sweeper and the buried garbage recycling station is realized by utilizing an AI visual inspection technology; after connection is successful, a top bin door of the buried garbage station is automatically opened towards the two sides, the unmanned street sweeper automatically opens a dustbin door located at the bottom of a hopper, and garbage dumping is completed; and after dumping is completed, the garbage recycling station bin door and the unmanned street sweeper dustbin door are automatically closed, and the sweeper returns to the operation pause point according to the planned path to continue to start sweeping work. The intelligent degree of the unmanned street sweeper is improved, and the labor intensity of sanitation workers is reduced.

Owner:NANTONG UNIVERSITY

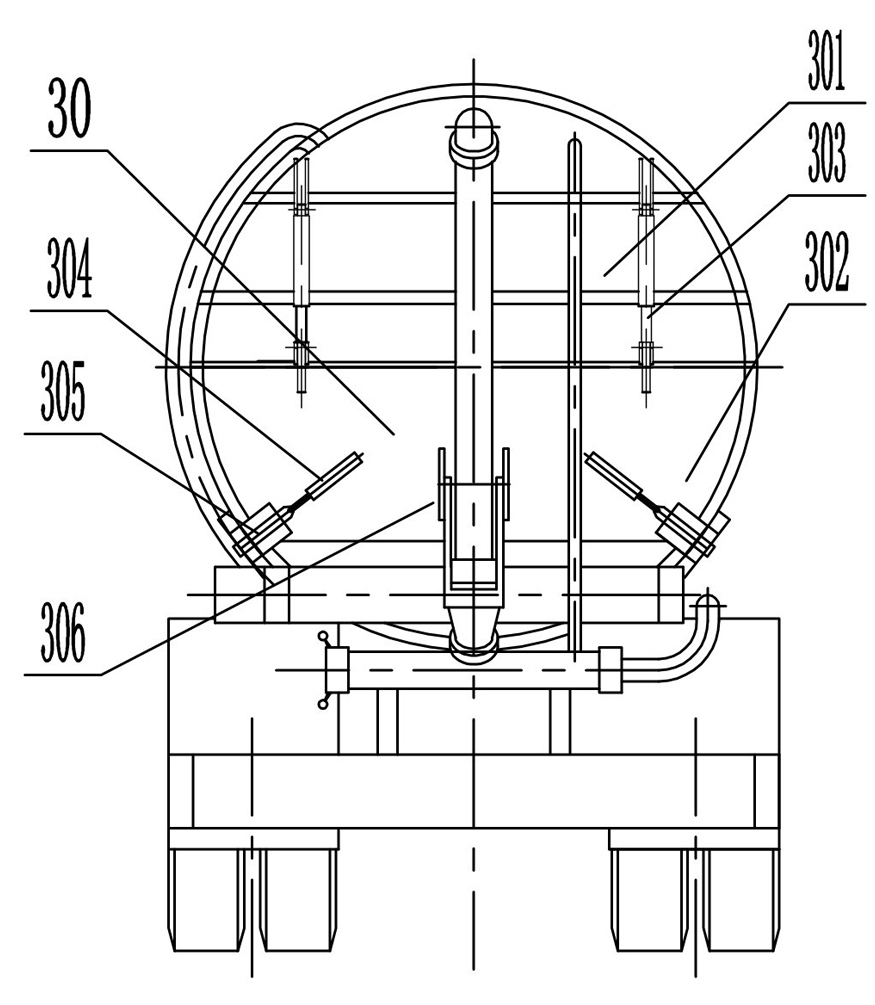

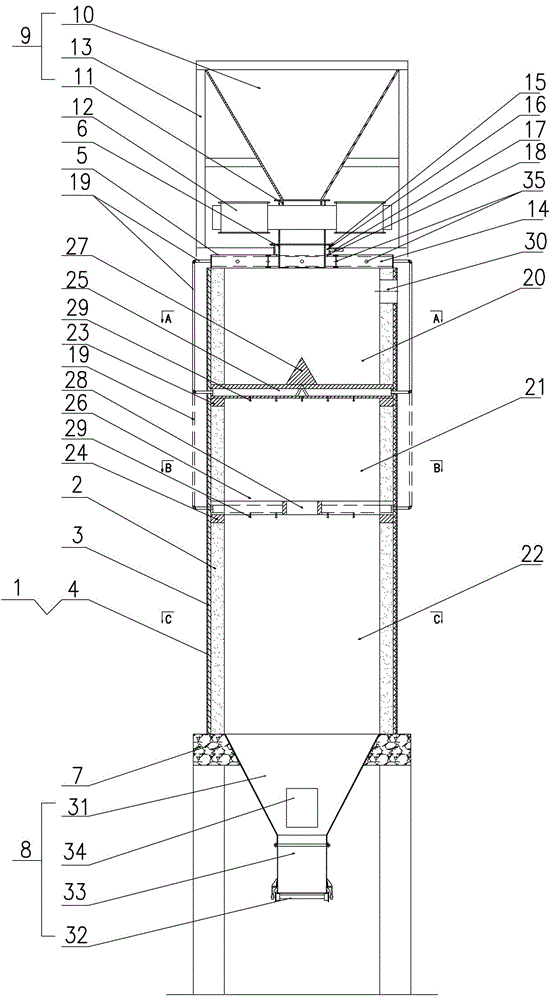

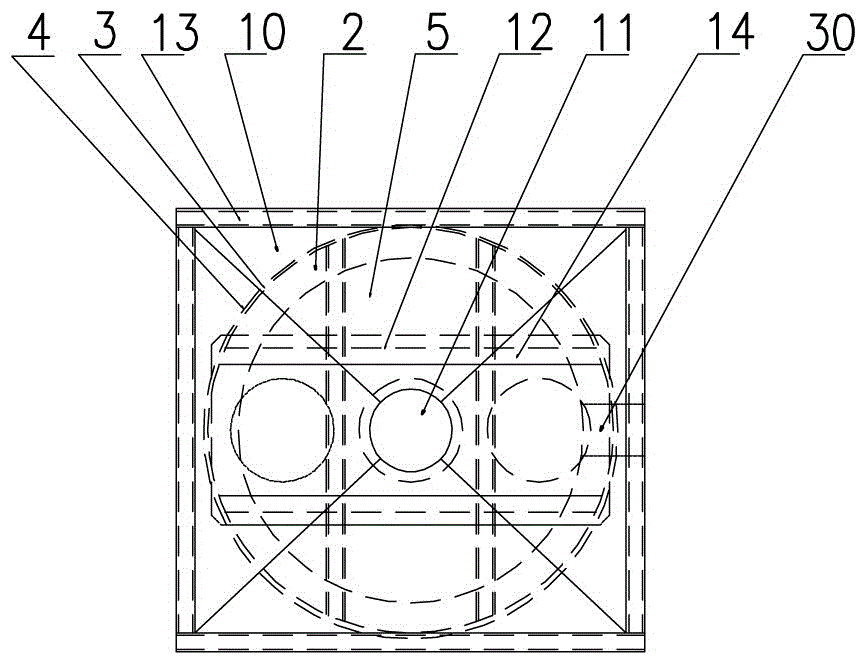

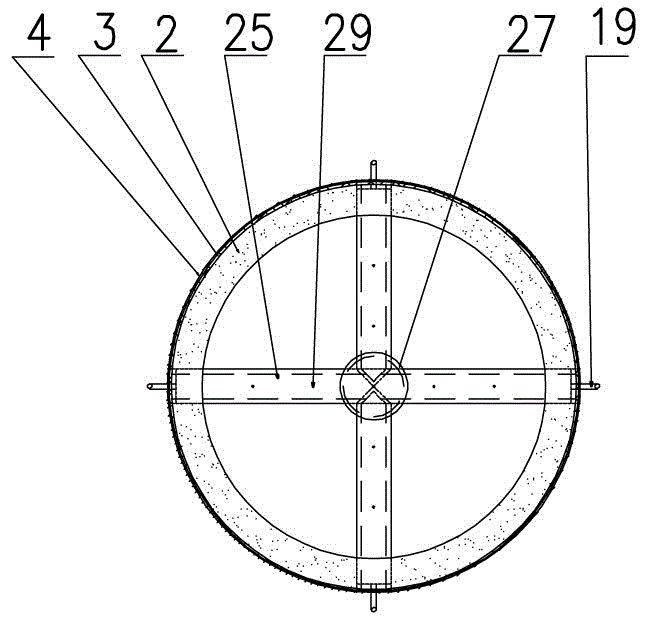

Efficient energy-saving stable type steel slag pyrolyzer

ActiveCN106435067AIncrease productivityGuaranteed uptimeCharge composition/stateCharge treatment typeButt jointSlag

The invention relates to the technical field of comprehensive utilization of steel slag, in particular to an efficient energy-saving stable type steel slag pyrolyzer. The pyrolyzer is provided with a pyrolyzer body, a water-cooling pyrolyzer cover is arranged at the top of the pyrolyzer body, a feeding pipe is arranged in the center of the pyrolyzer cover, a pyrolyzer top charging device is arranged above the pyrolyzer cover, and a discharging device is arranged at the bottom of the pyrolyzer body; a vapor bath-cooling belt, a spray fast-cooling belt and a tank-type hot disintegrating belt are sequentially arranged in the pyrolyzer body from top to bottom, the working linings corresponding to the vapor bath-cooling belt, the mist spray fast-cooling belt and the tank-type hot disintegrating belt are each separated by an upper joist ring and a lower joist ring, an upper cross type bearing beam and a lower cross type bearing beam are arranged above the corresponding upper joist ring and the corresponding lower joist ring respectively, the inner of each cross type bearing beam is of a hollow communication structure, an atomization nozzle is arranged on the bottom face of each cross type bearing beam, and the end heads of the upper cross type bearing beam and the lower cross type bearing beam are in butt joint with water outlet pipes of the water-cooling pyrolyzer cover respectively. The pyrolyzer is clever in design and good in tank-type hot disintegrating effect, and can achieve automation control of the whole process from dumping the molten steel slag into the pyrolyzer to discharging the molten steel slag out and stable transformation and utilization of the sensible heat of the molten steel slag, and is a revolutionary improvement to steel slag processing devices.

Owner:SHAOGUAN QUJIANG SHENGDA EQUIP & MATERIALS

Circulating automatic tipping bucket sweeper

ActiveCN110924342AIncrease cleaning speedLiberate manpowerRoad cleaningRefuse vehiclesBrushControl theory

The invention discloses a circulating automatic tipping bucket sweeper. The dustpan comprises a main body structure, a garbage storage part and a movable dustpan part, the main body structure comprises a main body frame, side baffles, a sweeping brush, dustpan slideways and a walking part, the side baffles are fixedly installed on the two sides of the main body frame, the dustpan slideways are fixedly installed in the middles of the side baffles, and the sweeping brush is fixedly installed on the lower end faces of the dustpan slideways; the walking part is arranged on the main body frame; thegarbage storage part is mounted in the dustpan slideway in a sliding manner; the motor drives the chain to rotate so as to drive the dustpan to rotate to collect ground garbage and transport the ground garbage to the position above the garbage can. The swing rod touches the stop rod to enable the dustpan to turn over to dump garbage into the garbage can; when the dustbin is full, the servo electric cylinder A drives the telescopic mechanism to extend so as to drive the dustbin to move to the outside, the servo electric cylinder B pushes the dustbin to dump garbage, labor and money are saved,the road sweeping efficiency is improved, and automatic and quick road sweeping is achieved.

Owner:山东一马绿能环保设备有限公司

Shredded preserved vegetable carrying and stirring device

InactiveCN108378326AAchieving stirringRealize blankingConveyorsRotary stirring mixersVegetable processingEngineering

The invention provides a shredded preserved vegetable carrying and stirring device, and belongs to the technical field of preserved vegetable processing equipment. The shredded preserved vegetable carrying and stirring device comprises a carrying and dumping mechanism and a stirring and seasoning mechanism, wherein a first lifting chain of the carrying and dumping mechanism is arranged on a firstbearing chain wheel, a first guiding chain wheel, a second guiding chain wheel, a third guiding chain wheel and a second supporting chain wheel in a closed surrounding manner; a second lifting chain is arranged on a third supporting chain wheel, a fourth guiding chain wheel, a fifth guiding chain wheel, a sixth guiding chain wheel and a fourth supporting chain wheel in the closed surrounding manner; a hopper of a discharging hopper assembly is mounted between a hopper first supporting plate and a hopper second supporting plate; stirring blades of the stirring and seasoning mechanism are mounted on a stirring supporting shaft at equal intervals; a sauce collecting opening of a sauce circulating assembly is connected with a sauce collecting tank through a sauce collecting pipe; and a sauce feeding opening is connected with the sauce collecting tank through a sauce feeding pipe. Through the adoption of the shredded preserved vegetable carrying and stirring device provided by the invention, shredded preserved vegetables can be quickly carried and lifted, and can be automatically dumped into a stirrer.

Owner:桐乡市大周商贸有限公司

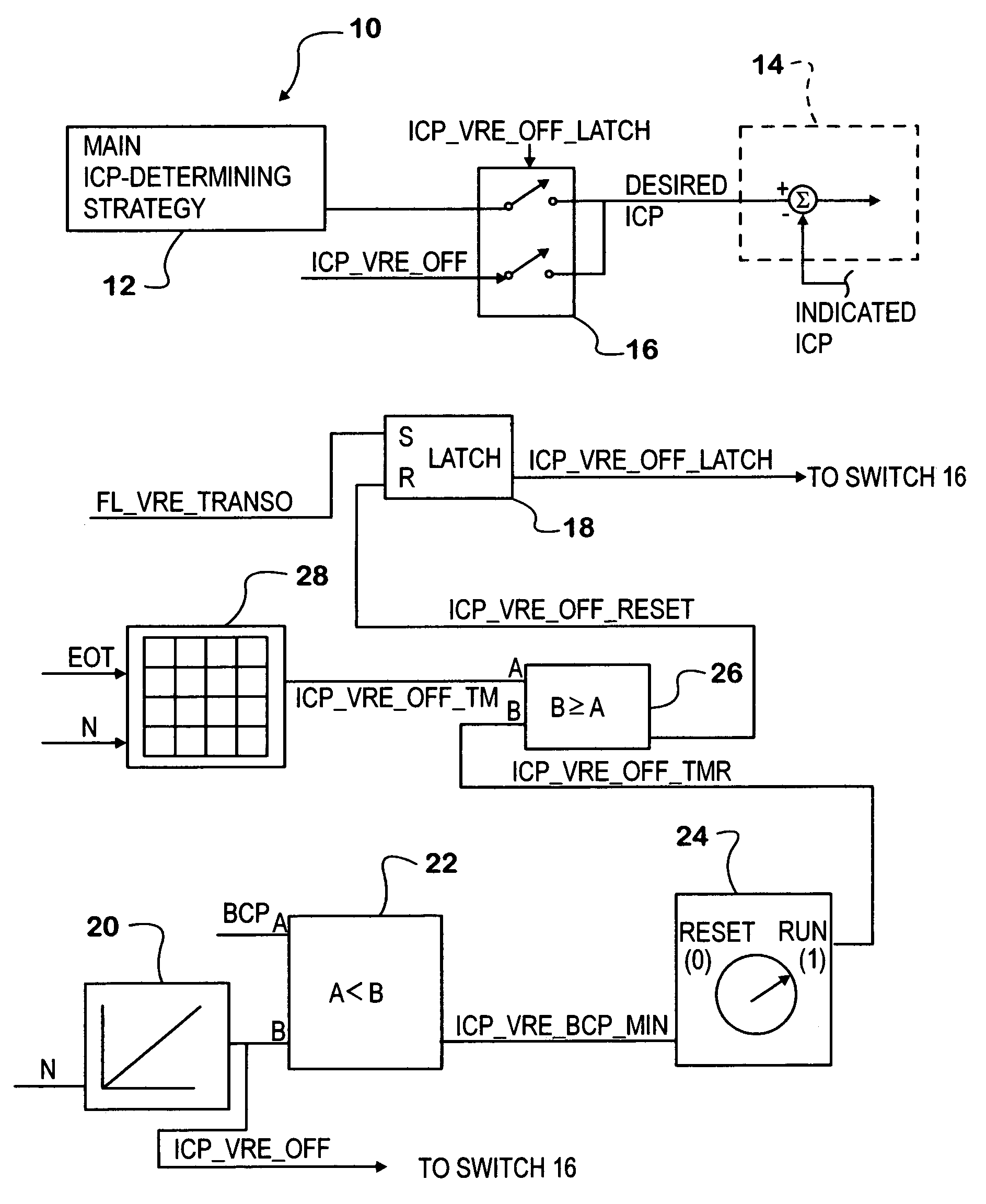

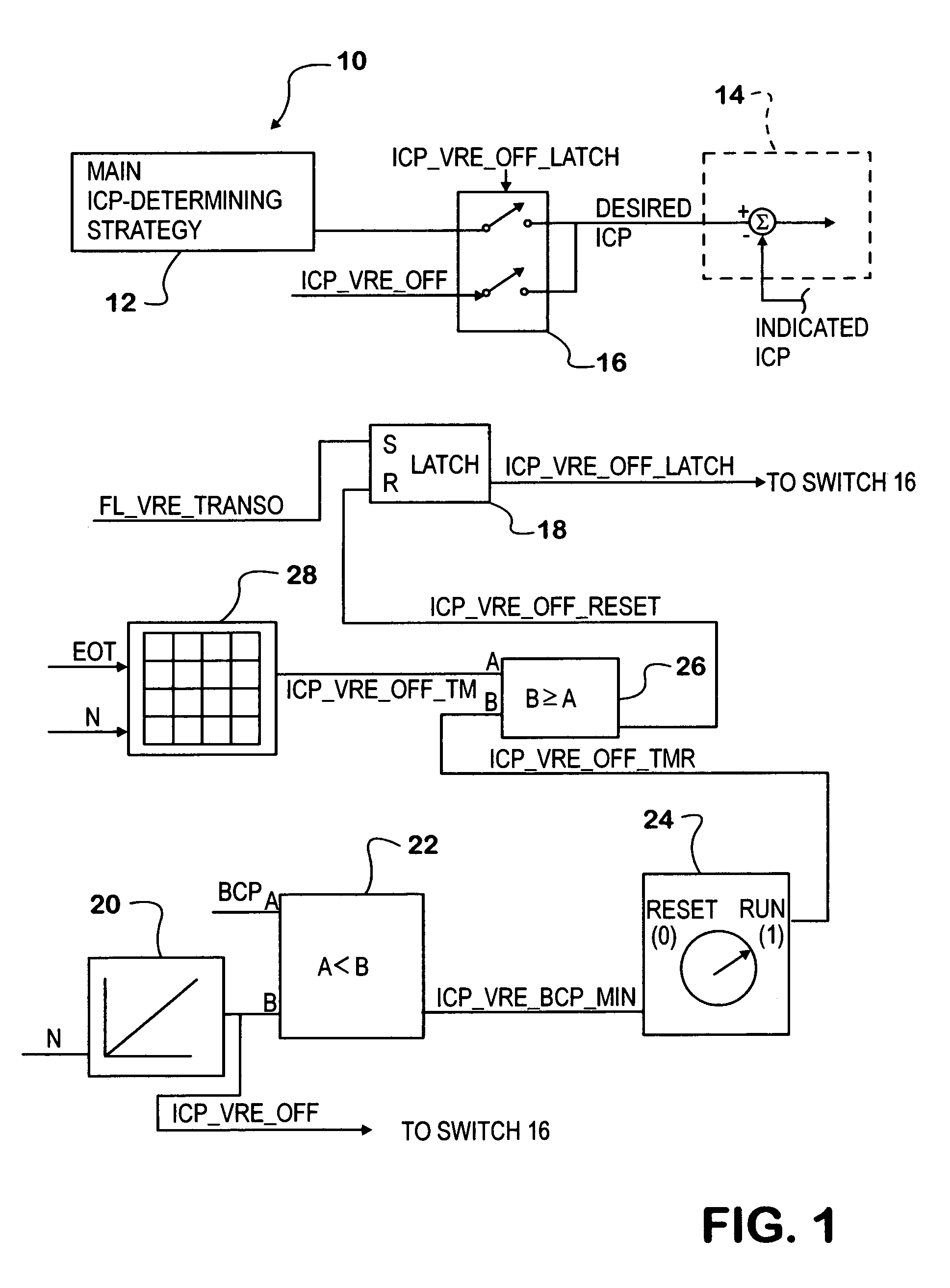

Strategy for engine fueling during return to positive power flow after engine brake de-activation

ActiveUS7055496B1Reduce smoke productionQuick dumpElectrical controlFuel-injection pumpsControl systemActuator

An internal combustion engine that propels a vehicle has a fuel injection system for injecting fuel into engine cylinders at desired injection control pressure. A control system controls activation and de-activation of a hydraulic actuator for an engine brake. A processor processes data to develop data for desired injection control pressure. Transitional injection control pressure data is used as desired injection control pressure during a transition time interval that commences with de-activation of the engine brake caused by the relief of pressure of the control fluid for allowing resumption of positive power flow from the engine for propelling the vehicle and that ends after the processor has determined the existence of a predetermined correlation between the transitional injection control pressure data and data indicating pressure of the control fluid.

Owner:INT ENGINE INTPROP CO LLC

Concrete performance test experimental device

PendingCN111351698AReduce pollutionEasy to useMaterial strength using single impulsive forceArchitectural engineeringElectric machinery

The invention belongs to the technical field of building material detection devices, and especially relates to a concrete performance test experiment device. A large amount of dusts can be generated when existing concrete is crushed, but an existing testing device cannot treat dust. The device comprises a pressure sensor and a base, a first groove is formed in the top of the base, a fixed seat isfixedly mounted at the bottom of the first groove, a sliding sleeve is slidably mounted on the fixed seat, a round hole is formed in the sliding sleeve, a round rod is rotationally mounted in the round hole, a fixed block is fixedly mounted at one end of the round rod, and a base plate is fixedly mounted at the top of the fixed block. By arranging the base plate, concrete can be placed on the baseplate and the base plate can be lifted up during testing, so that the tested and broken concrete can be quickly poured out; and a motor drives a pressing column to perform testing, and meanwhile, allstructures in a shell can be driven to be linked, so that dust generated by the broken concrete is sucked into water.

Owner:LANZHOU UNIVERSITY OF TECHNOLOGY

Special garbage can facilitating lifting of recycling truck

InactiveCN112407669AQuick dumpShorten the timeRefuse receptaclesRefuse vehiclesStructural engineeringProcess engineering

The invention discloses a special garbage can facilitating lifting of a recycling truck, and relates to the technical field of garbage cans. In order to solve the problems that an existing garbage cancannot be quickly lifted by the garbage recycling truck, after lifting, the garbage in the garbage can cannot be quickly dumped into a compartment, time and labor are wasted, the operation is complicated, and the garbage dumping efficiency is reduced, according to the scheme, the special garbage can comprises a garbage can body and a compartment; clamping mechanisms are arranged on the outer walls of the two sides of the garbage can body; a first sliding groove is formed in the outer wall of the left side of the compartment in the height direction of the compartment; and a first slider is slidably installed in the first sliding groove. The design is novel; the operation is simple; when a supporting plate, an L-shaped plate and other parts are arranged, the garbage can body can be clampedby supporting rods and then lifted upwards by the supporting plate; the garbage can body can be tilted upwards; and then the garbage is quickly dumped into the compartment. The time is saved; and thegarbage recycling efficiency is improved.

Owner:CHANGDE DINGCHENG LINYU AUTOMOTIVE PARTS

Convenient-type snow removal vehicle for municipal roads

The invention relates to a snow removal vehicle, in particular to a convenient-type snow removal vehicle for municipal roads. The convenient-type snow removal vehicle for municipal roads aims at achieving the technical purposes of removing snow fast and thoroughly and providing convenience for dumping the snow. In order to achieve the technical purposes, the convenient-type snow removal vehicle for municipal roads includes a vehicle body, a vehicle box, a connection passage, a motor, a first rotating shaft, a third bracket, a conveying passage and the like. The vehicle box is arranged on the vehicle body, a first bracket is arranged on the top of the vehicle box through screws, the motor is arranged at the inner bottom of the first bracket through screws, an output shaft of the motor is connected with the first rotating shaft through a coupler, and spiral vanes are arranged at the bottom of the first rotating shaft. The effects of removing snow fast and thoroughly and providing convenience for dumping the snow are achieved, removal of a great amount of snow can be conducted quickly, and a crushing toothed plate can achieve a crushing effect on snow blocks on the ground to prevent the situation that the snow blocks are solidified and cannot be conveyed.

Owner:唐春桃

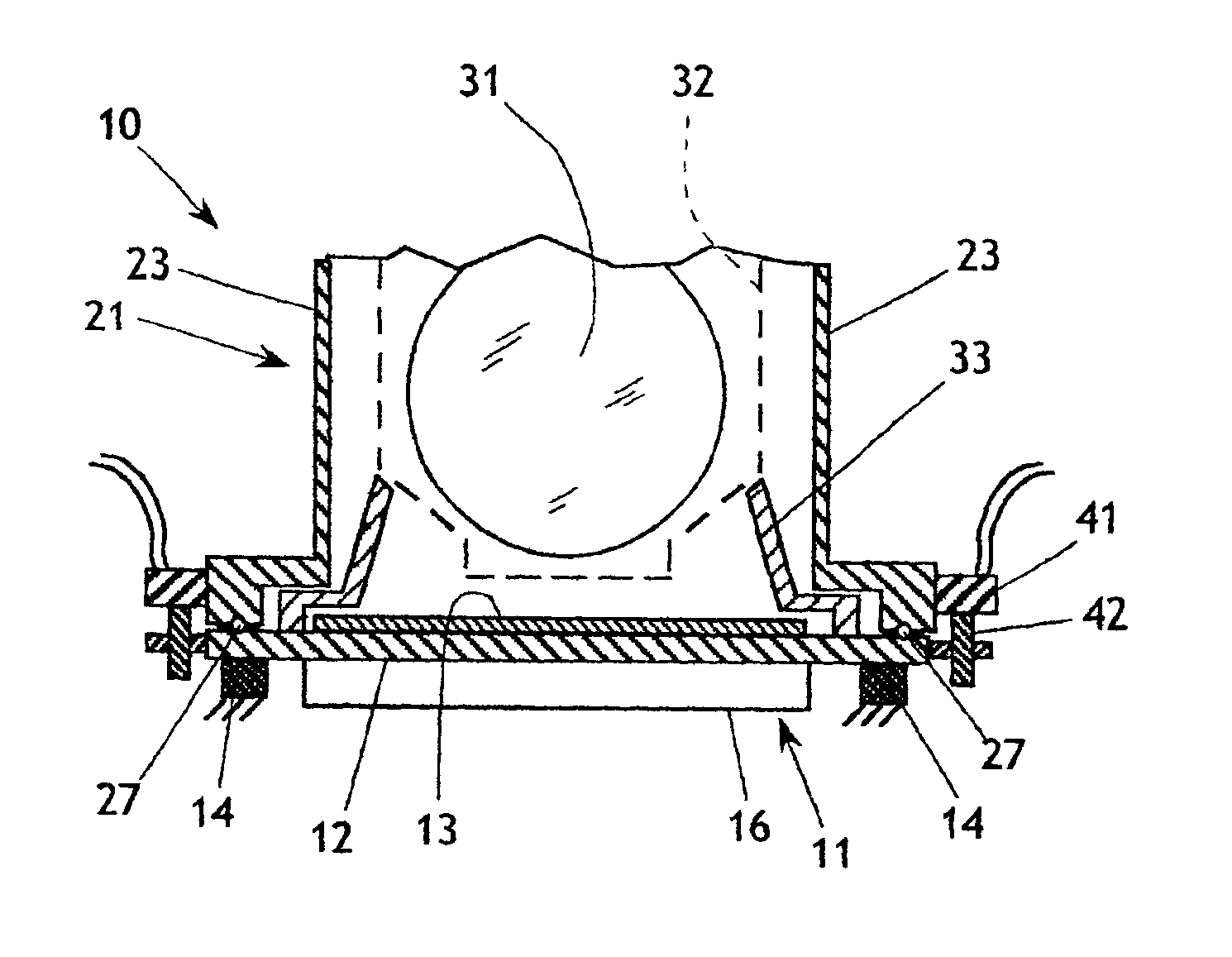

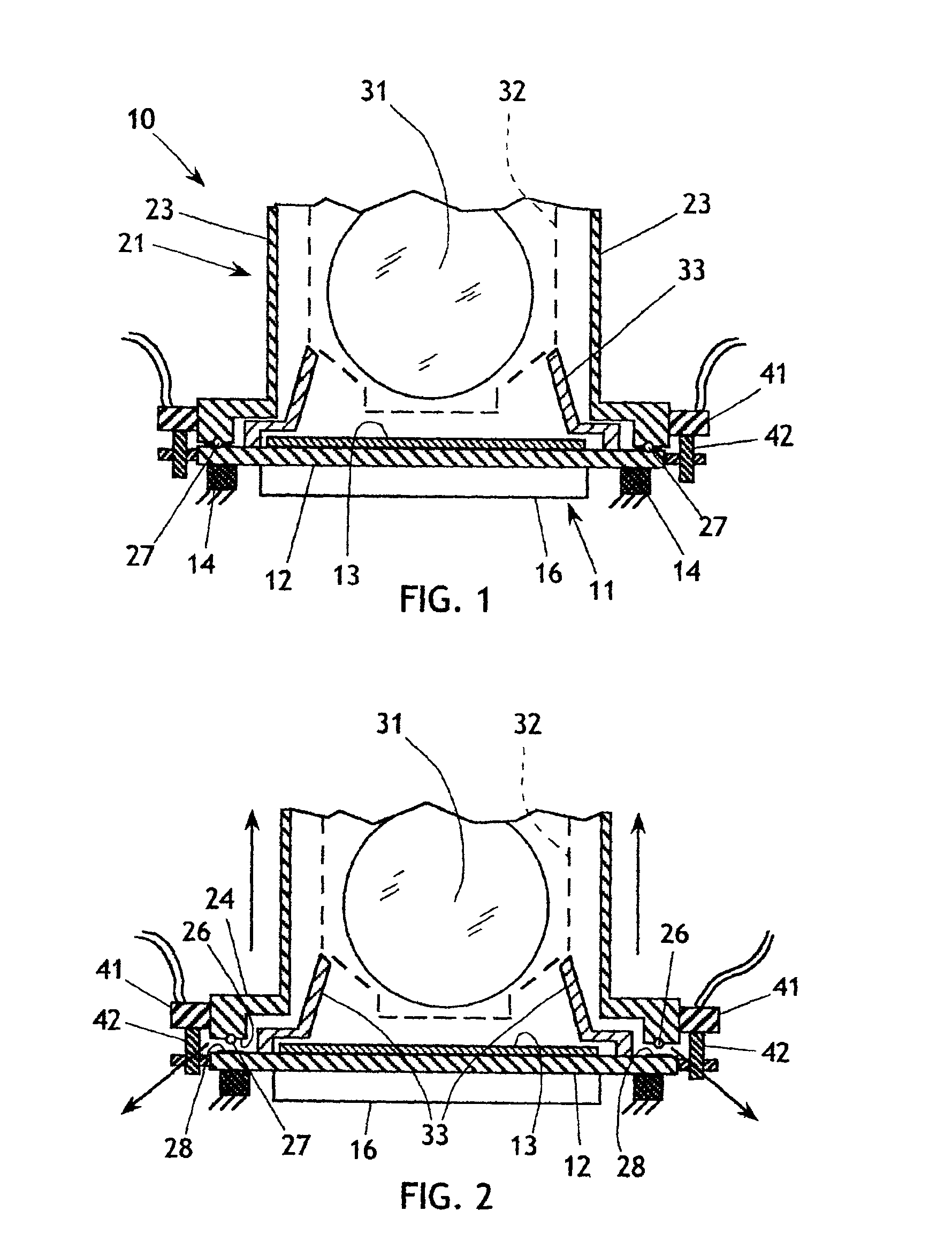

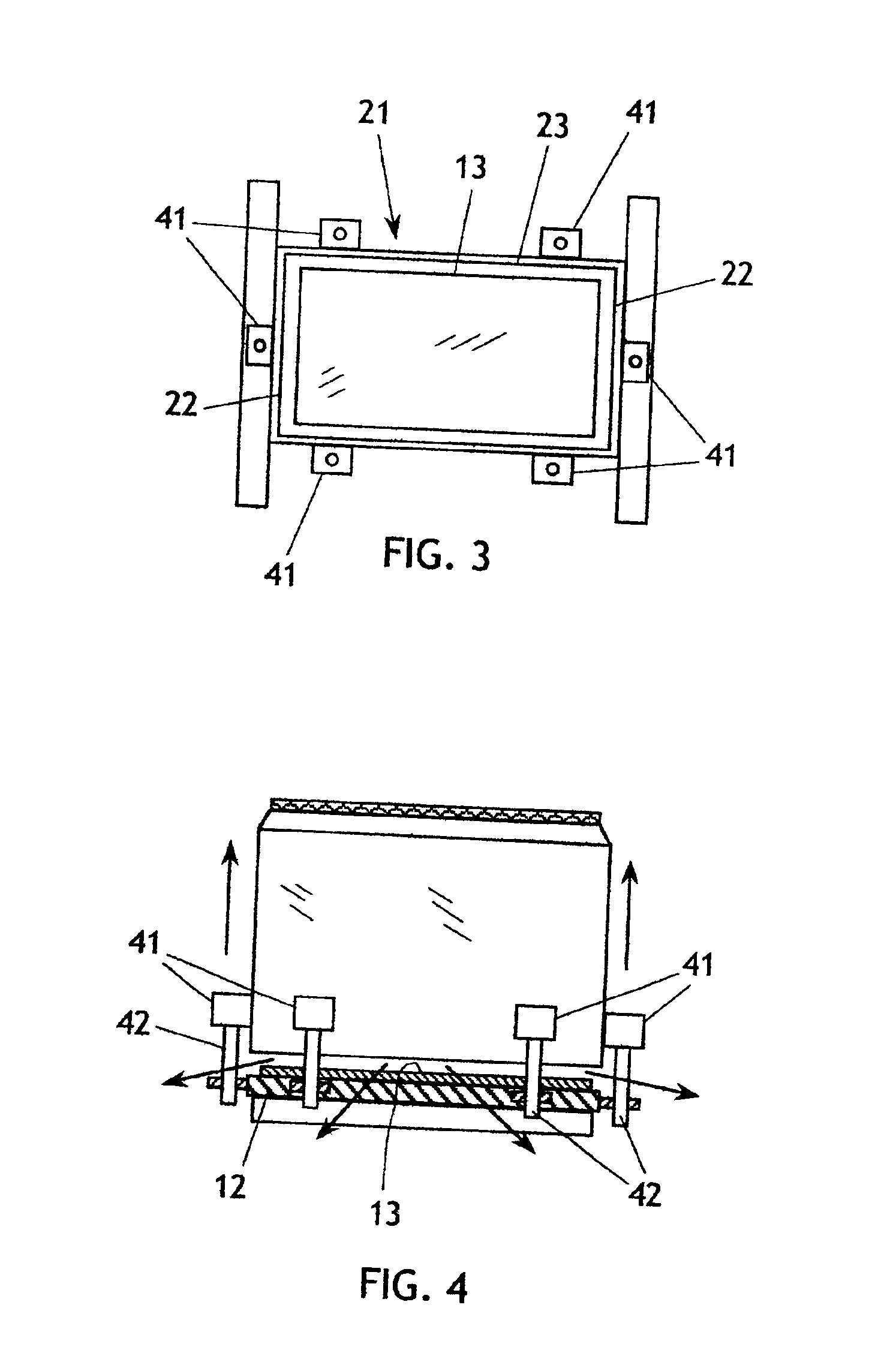

Processing tank with improved quick dump valve

InactiveUS6837253B1Less mechanical shockQuick dumpElectrostatic cleaningSemiconductor/solid-state device manufacturingTransducerLinear actuator

A liquid process tank that provides a quick dump feature includes a fixed bottom wall assembly and moveable tank side walls that contain liquid and also act as a quick dump valve for the liquid. The bottom wall assembly includes an acoustic transducer secured thereto. The tank side walls are secured to a plurality of linear actuators adapted for vertical movement. A seal is secured to the lower edge of the side wall assembly to impinge on a land surface that extends about the perimeter of the bottom wall assembly. The linear actuators are retracted to draw join the bottom and side wall assemblies to retain liquid, or activated in unison to drive the tank walls upwardly from the fixed bottom wall assembly, creating a bottom opening in the tank that quickly discharges all the liquid from the tank.

Owner:IMTEC ACCULINE

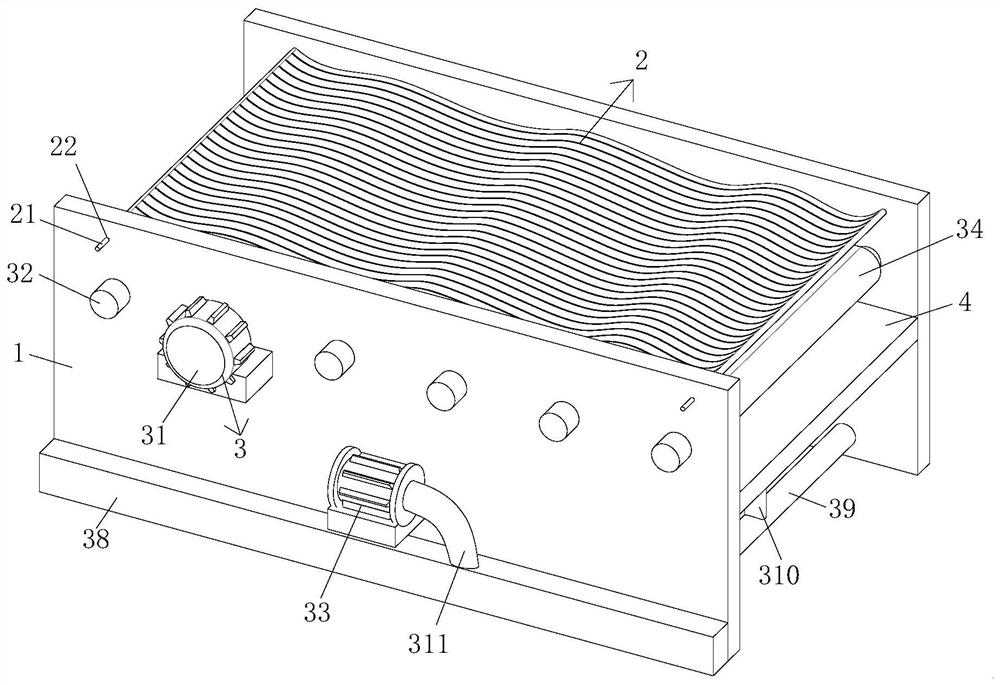

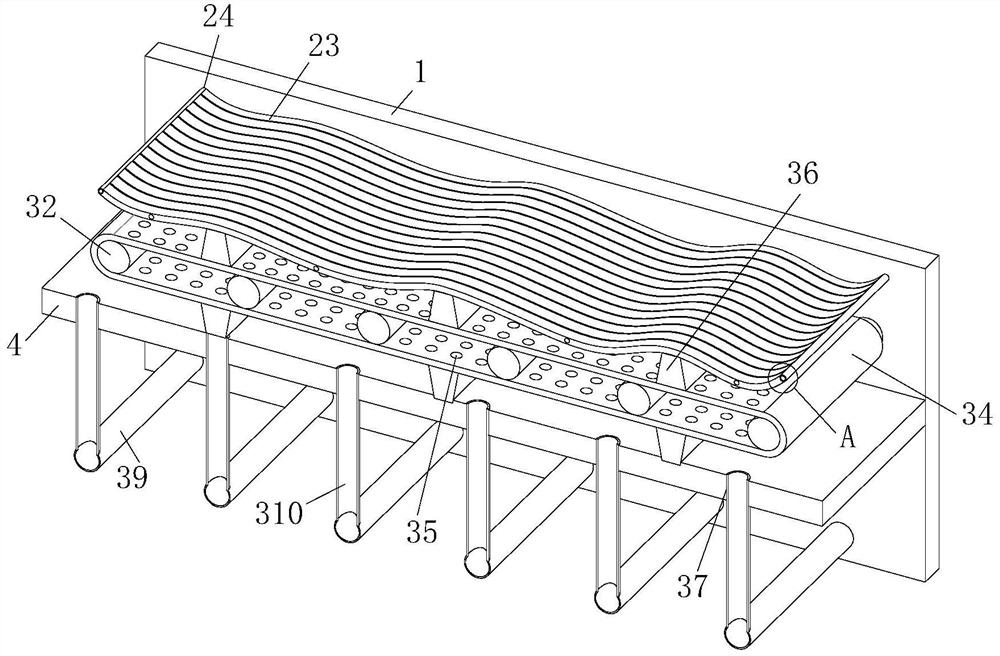

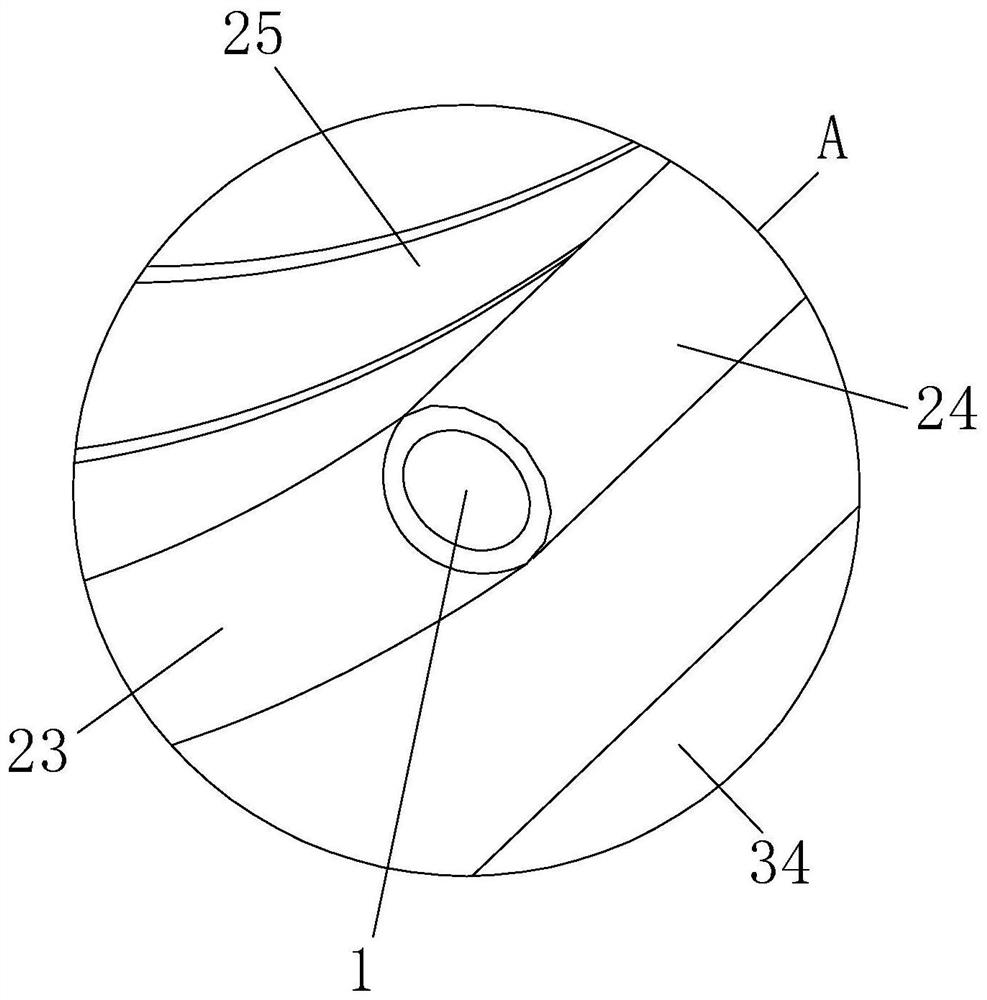

Wine-making grain dross spreading airing and yeast adding integrated machine

PendingCN110540907AAvoid breedingAvoid easy cloggingAlcoholic beverage preparationYeastMaterial supply

The invention discloses a wine-making grain dross spreading airing and yeast adding integrated machine, and relates to the technical field of wine-making grain dross spreading equipment. The wine-making grain dross spreading airing and yeast adding integrated machine is mainly used for solving the problems that grain dross blocks ventilation holes, and yeast needs to be manually added. According to the main structure, the wine-making grain dross spreading airing and yeast adding integrated machine comprises a rack and a material supplying mechanism; a scattering roller and a spreading airing bed are sequentially arranged on the position, below the material discharging end of the material supplying mechanism, of the rack, the spreading airing bed comprises a plurality of bed boards which are sequentially arrayed and partially overlapped, and fans blowing air towards the spreading airing bed are arranged on the upper part and the lower part of the spreading airing bed correspondingly; ayeast box is further arranged on the rack, and the material discharging end of the yeast box is connected with a spiral material conveying device; and a material conveying belt, a material mixing hopper and a transferring material box are sequentially arranged below the spreading airing bed and the material discharging end of the spiral material conveying device. The wine-making grain dross spreading airing and yeast adding integrated machine provided by the invention can effectively prevent the grain dross from blocking an air channel and being caked, and meanwhile can further automatically complete spreading airing and yeast adding of the grain dross, and thus manpower is saved.

Owner:许兴萍

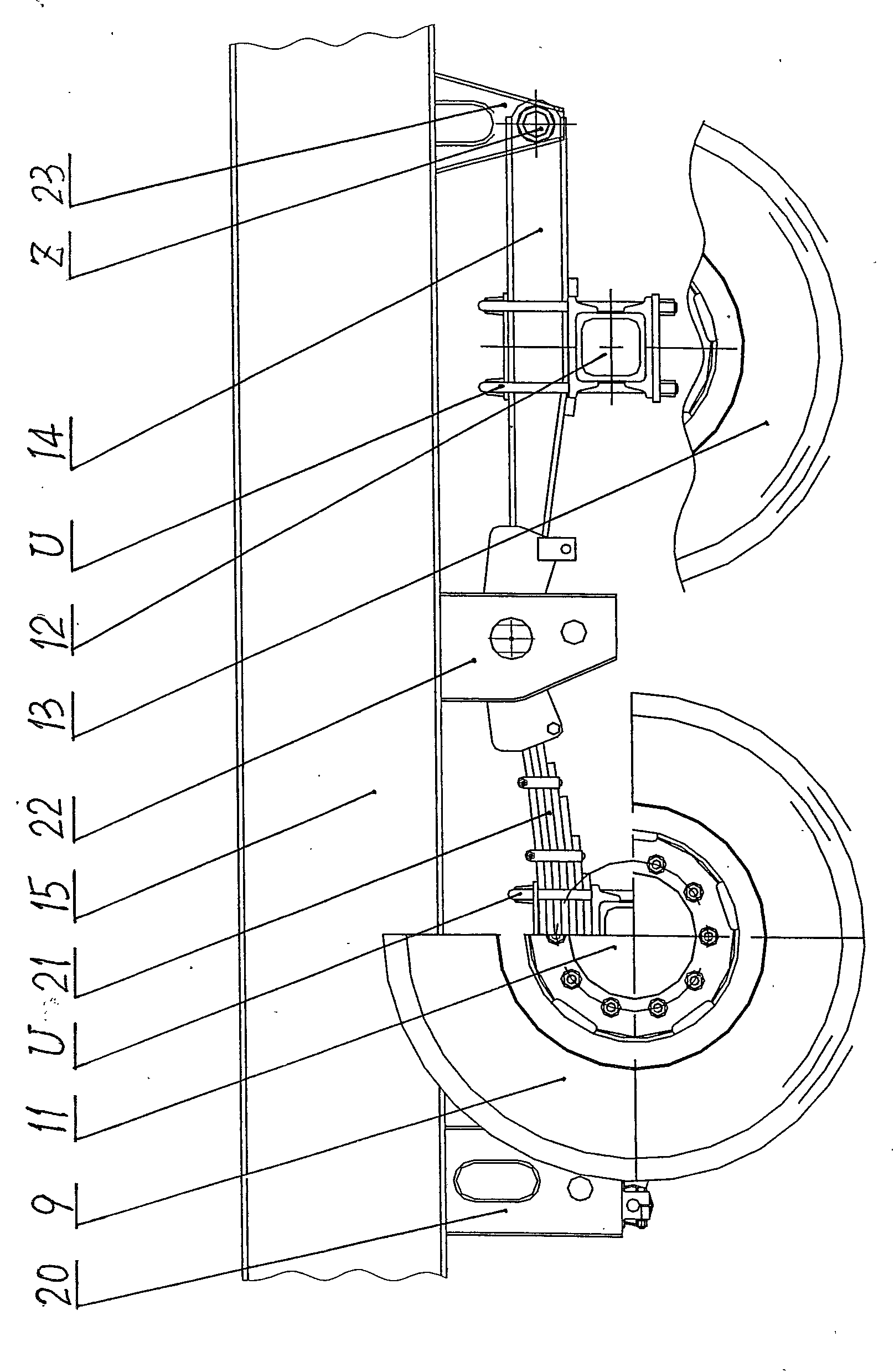

Turnover-type self-discharging semitrailer with low gravity centre supported by rear hub

InactiveCN101786433AQuick dumpReasonable structureVehicle with tipping movementHydraulic pumpEngineering

The invention discloses a turnover-type self-discharging semitrailer with the low gravity centre supported by a rear hub. A turnover centre of a self-discharging container (2) is a turnover central pin shaft (10) that a semitrailer chassis (8) is connected with a container bottom frame (15), and a rear hub (12) is used as a turnover support point. A lower-opening back box plate (18) is arranged on the back end surface of the self-discharging container (2) and matched with a hook inhaul cable mechanism (16); a hydraulic lifting cylinder (6) is arranged on an oil cylinder support (7) of the semitrailer chassis (8), and the top end of the cylinder is connected to a raising support (4) of the container bottom frame (15). A hydraulic pump (39) pumps the hydraulic oil into a lifting valve (35),and the hydraulic oil enters a hydraulic lifting cylinder (6) when the hydraulic pump (39) is operated, the cylinder raises up the front part of the self-discharging container (2), the container bottom frame (15) uses the rear hub (12) as a support point, the self-discharging container (2) turns backwards around the turnover central pin shaft (10), an inhaul cable (S) is loosened to enable the hook (G) to be automatically loosened, and the lower end of the back box plate (18) is opened to dump the goods. The invention has the advantages of low gravity centre for discharging and favorable stability, increases the security and realizes automation of opening the box and discharging.

Owner:山东迅力特种汽车有限公司

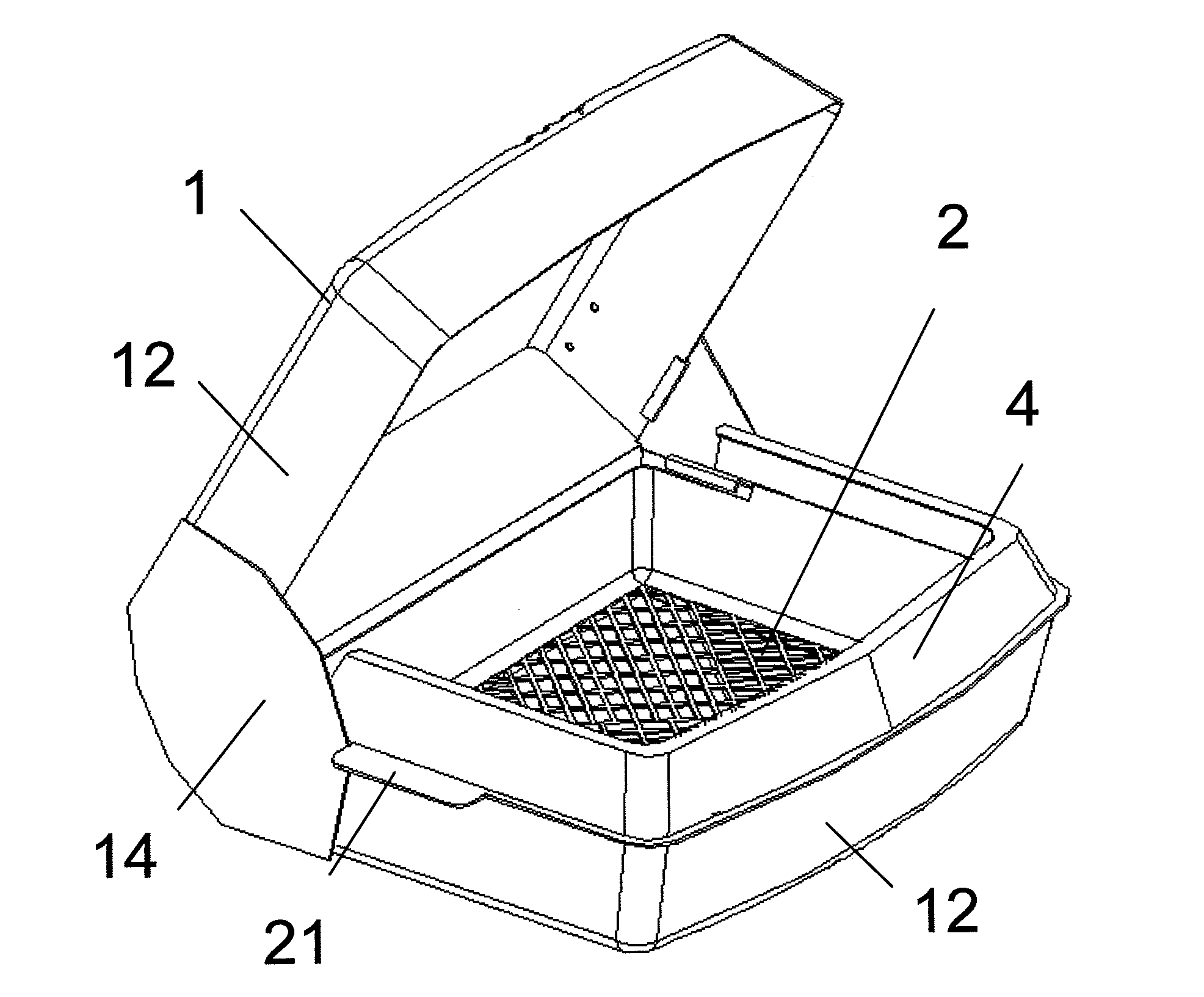

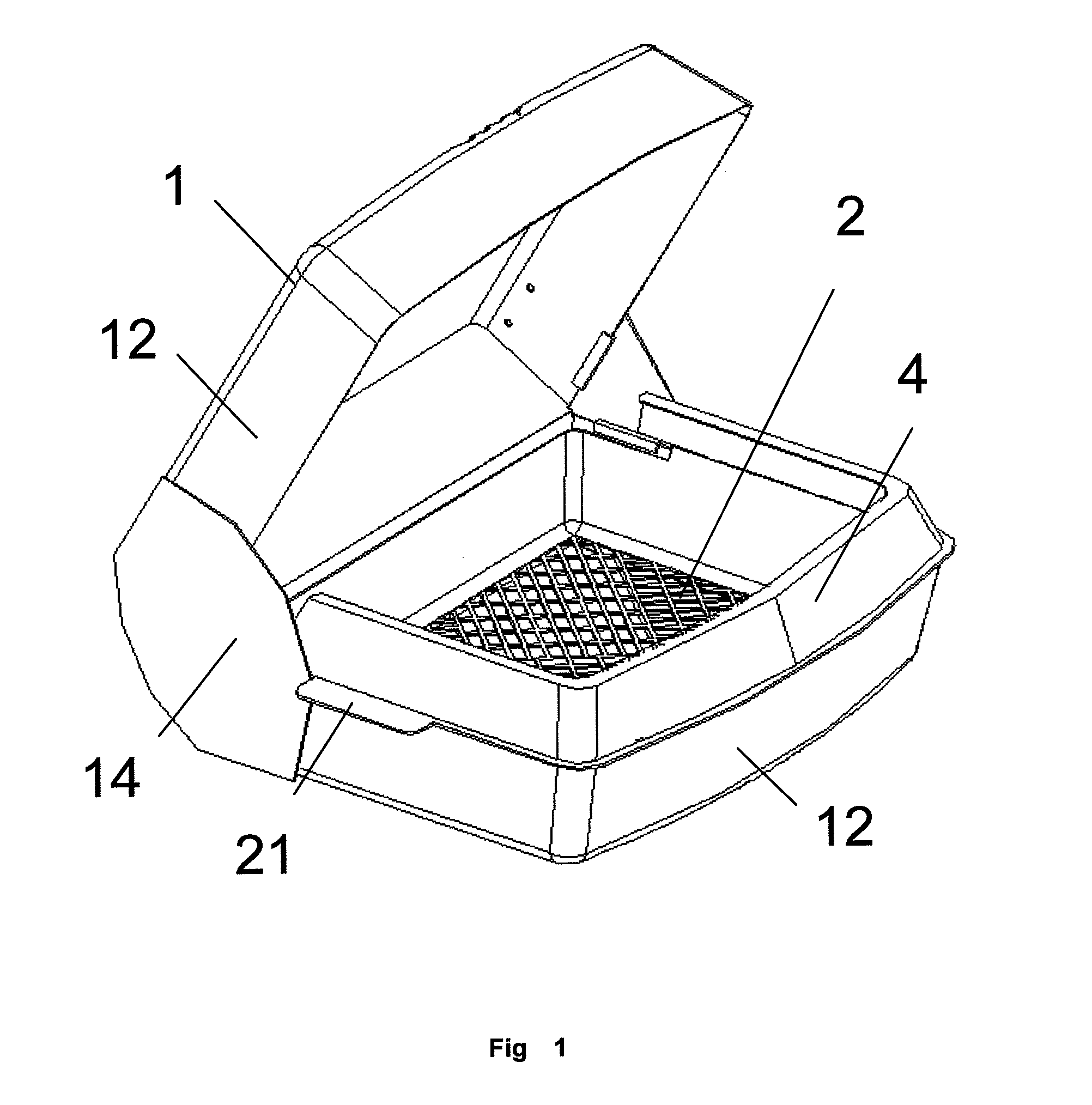

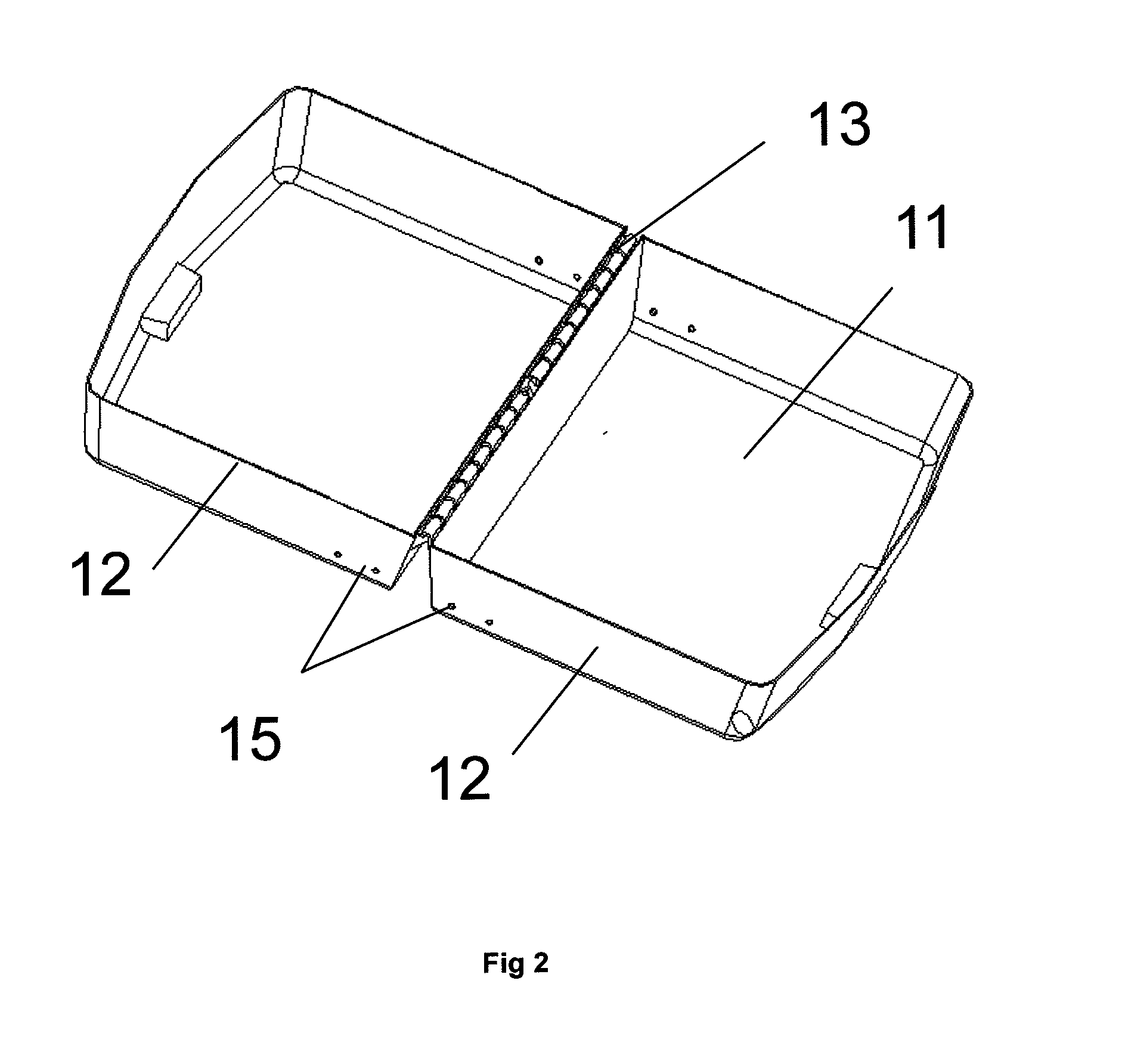

Pet excrement box

InactiveUS20130269622A1Hygienic and convenientQuick dumpAnimal housingOther apparatusStructural engineeringCompanion animal

A pet excrement box includes an outer box (1) and an inner tray (2) which is detachable from the outer box (1). The outer box (1) has a V-shaped opening. At least one side of the outer box (1) is formed with an accommodation space (11) to accommodate the inner tray (2). The inner tray (2) has two sides perpendicular to the opening of the outer box (1) and each having a suspension portion (21). The suspension portion (21) is hanged on an edge of the accommodation space (11) of the outer box (1). The pet excrement box of the present invention can dump the excrements on the sands quickly. Ordinarily, the user can use a shovel (3) to clean the excrements on the inner tray (2). It is convenient and hygienic to clean the pet excrement box.

Owner:LEIVAIRE +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com