Turnover-type self-discharging semitrailer with low gravity centre supported by rear hub

A technology for rear wheel axles and semi-trailers, which can be used in the direction of vehicles that are inclined to carry and move, and can solve problems such as insufficient stability, poor safety, and increased operational difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

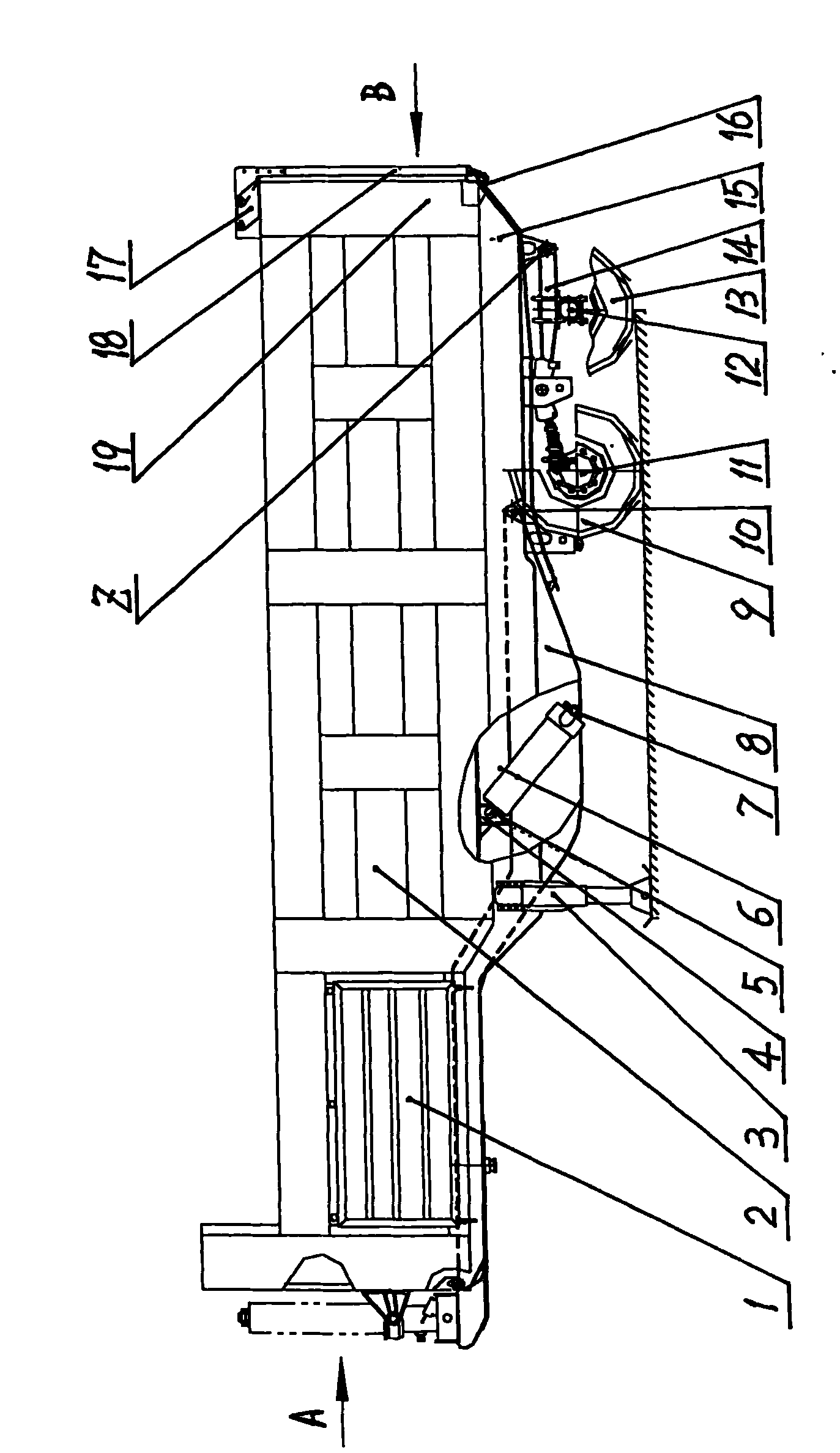

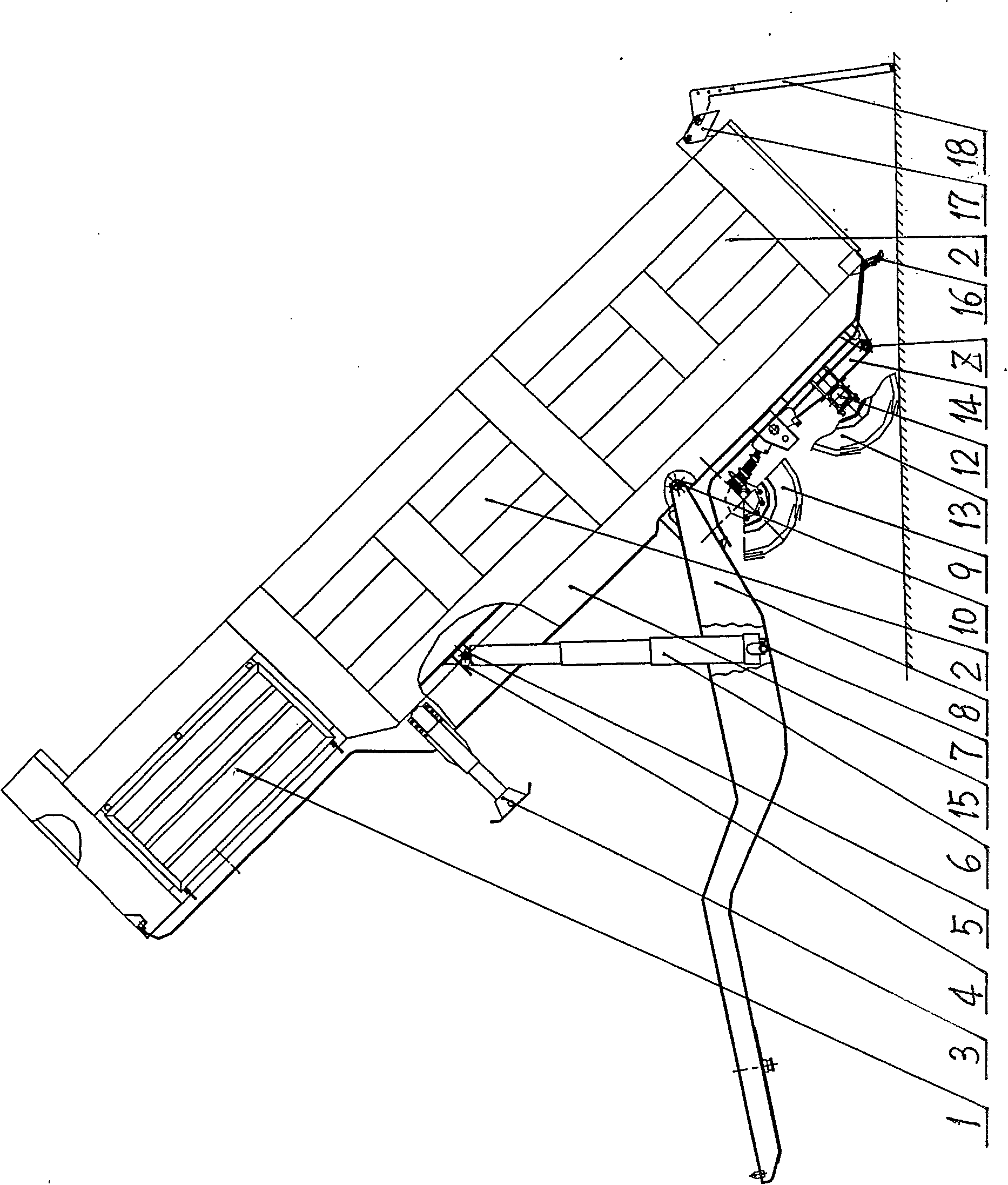

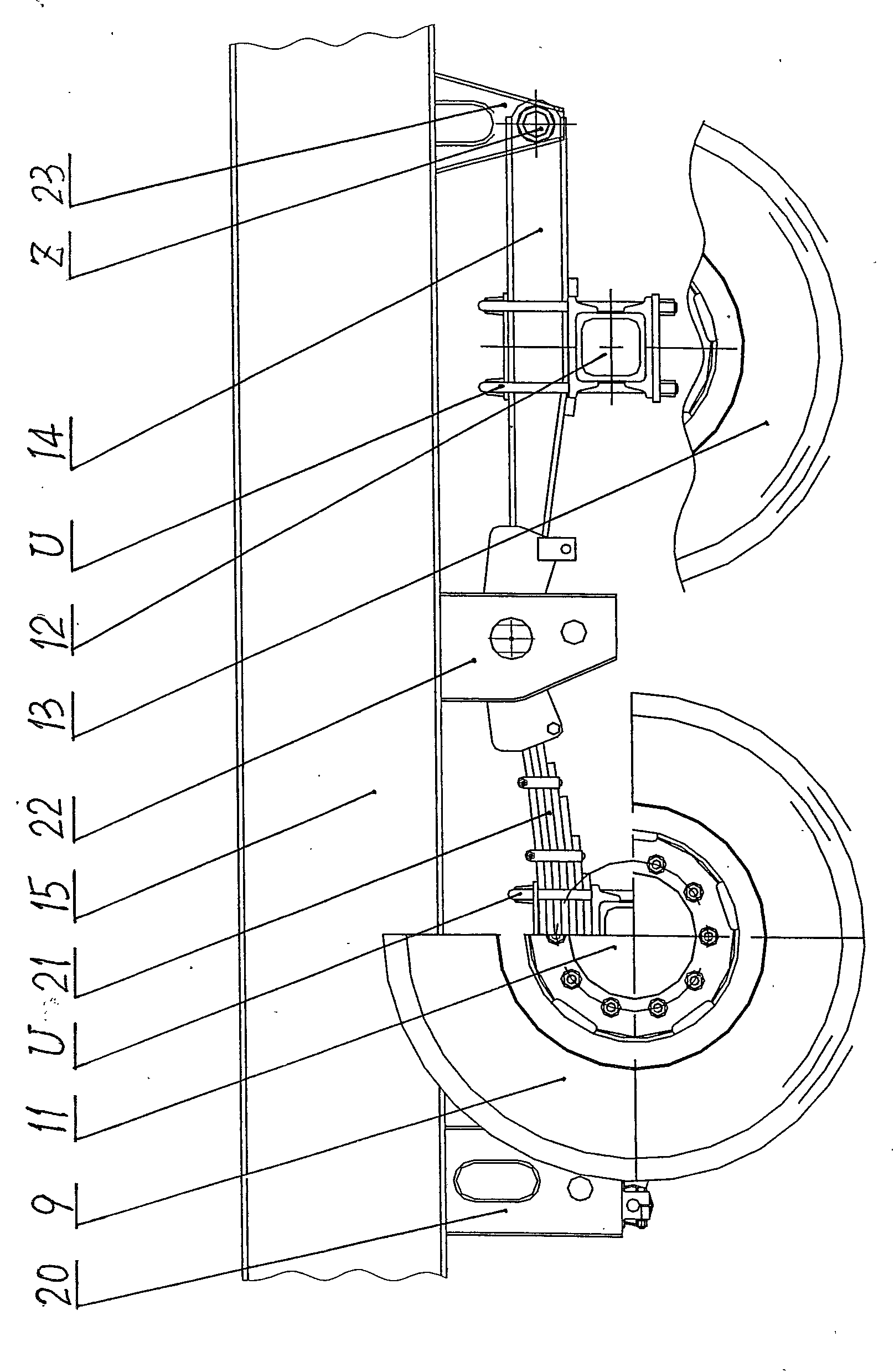

[0019] Specific embodiments of the present invention will be described below in conjunction with the accompanying drawings.

[0020] refer to figure 1 , 15 container underframes of the self-unloading container 2 of the present invention are installed on the chassis 8 of the semi-trailer, the bottom of the hydraulic lift cylinder 6 is connected with the fixed oil cylinder bracket 7 on the chassis 8 of the semi-trailer, and the top end is connected to the container fixed on the chassis 8 through the top pin 5. The lifting support 4 of box bottom frame 15 bottom surfaces is connected. Rigid suspension support 14 is mounted on the rear axle 12. Hinge bearing 17 is equipped with on post 19 tops after self-unloading container 2, is connected with the upper end of rear box plate 18, and the lower end is locked by hook drag cable mechanism 16.

[0021] refer to figure 2 , the hydraulic lifting cylinder 6 on the semi-trailer chassis 8 of the present invention lifts the dump contain...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com