Wine-making grain dross spreading airing and yeast adding integrated machine

An all-in-one, grain grain technology, applied in the preparation of alcoholic beverages, can solve the problems of affecting ventilation, labor consumption, and contamination of the whole cellar grain grains, etc., to avoid bacterial growth, save labor, and facilitate cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

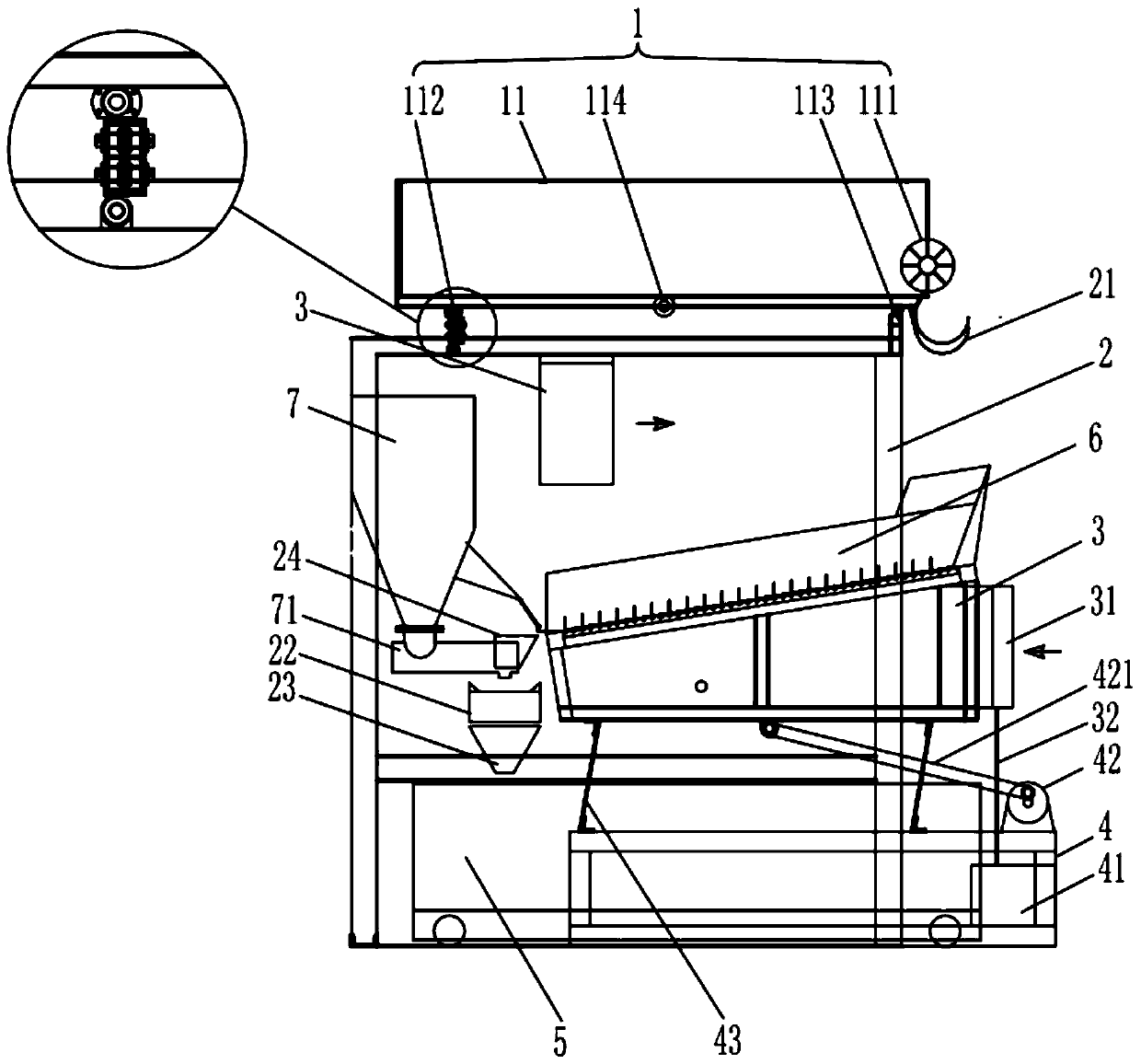

[0045] The specific embodiment of the present invention is as Figure 1-3 As shown in the figure, an all-in-one machine for spreading, airing, and adding koji for brewing grains includes a frame 2 and a feeding mechanism 1 arranged above it.

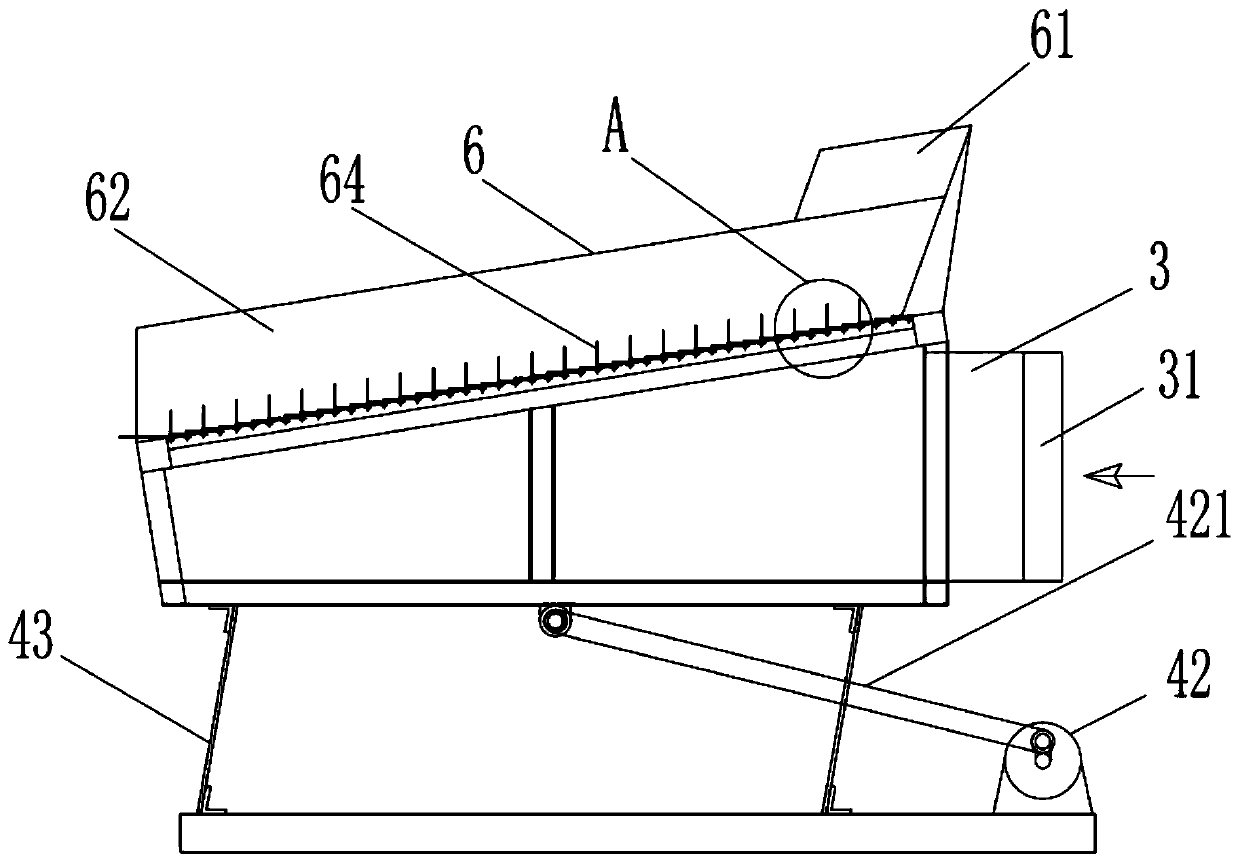

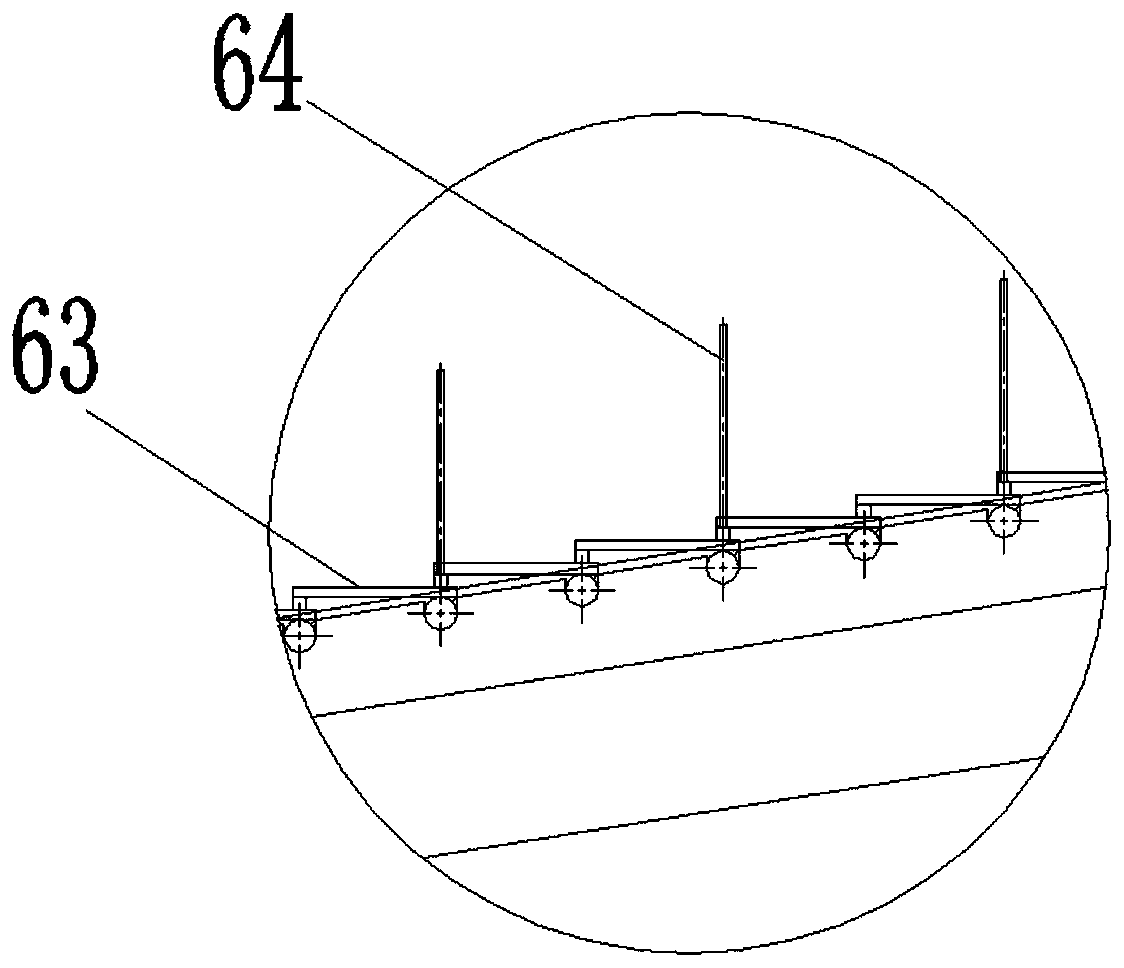

[0046] Wherein, the frame 2 is provided with a breaking roller 21 and a drying bed 6 successively below the discharge end of the feeding mechanism 1 . The airing surface of the airing bed 6 is arranged obliquely and includes a plurality of bed boards 63 arranged in sequence and partially overlapping. Above and below the airing bed 6, fans 3 blowing toward the airing bed 6 are provided. Also be provided with song medicine box 7 on the frame 2. The discharge end of the curved medicine box 7 is connected with a screw feeding device 71 . A feeding belt 22 , a mixing hopper 23 and a transfer bin 5 are arranged successively below the discharge end of the drying bed 6 and the screw feeding device 71 . The screw feeding device 71 in this emb...

Embodiment 2

[0057] Such as Figure 4-5 As shown, the difference between this embodiment and Embodiment 1 is that no connecting rod 421 , vibrator 42 and leaf spring 43 are arranged below the airing bed 6 . Thinning teeth 64 are not provided on the bed board 63 . Instead, a transmission chain 65 connecting a plurality of bed boards 63 in series is provided at both ends of the bed board 63 . The drive shaft 66 for driving the transmission chain 65 is provided below the transmission chain 65 . The drive shaft 66 cooperates with the transmission chain 65 to move the bed board 63 and transport the material to the discharge end of the airing bed 6 .

Embodiment 3

[0059] Such as Figure 6 As shown, the difference between this embodiment and Embodiment 1 is that: the feeding mechanism 1 includes a hopper 12 . A discharge port is provided on the side wall of the side wall of the hopper 12 close to the breaking roller 21 . The hopper 12 is provided with a guide plate 121 inclined towards the discharge port. A feed exciter 122 is provided on the lower surface of the guide plate 121 . The guide plate 121 cooperates with the feed exciter 122 to quickly discharge the grain grains in the hopper 12 from the discharge port. Moreover, in this embodiment, a baffle can also be provided at the discharge port. By controlling the position and size of the baffle, the size of the discharge port is controlled, and then the discharge volume is controlled.

[0060] Real-time example 4

[0061] Such as Figure 7 As shown, the difference between this embodiment and Embodiment 1 is that: the feeding mechanism 1 includes a conveying belt 13 whose discharg...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com