Complete equipment for producing foam aluminum

A complete set of equipment and foamed aluminum technology, which is applied in the field of alloy manufacturing, can solve the problems of inability to realize fully automatic continuous production of foamed aluminum, inability to manufacture large-size and high-quality foamed aluminum, and complicated process flow, so as to improve product quality and process. Yield, the effect of reducing the loss of foamed aluminum and reducing the loss of reagents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

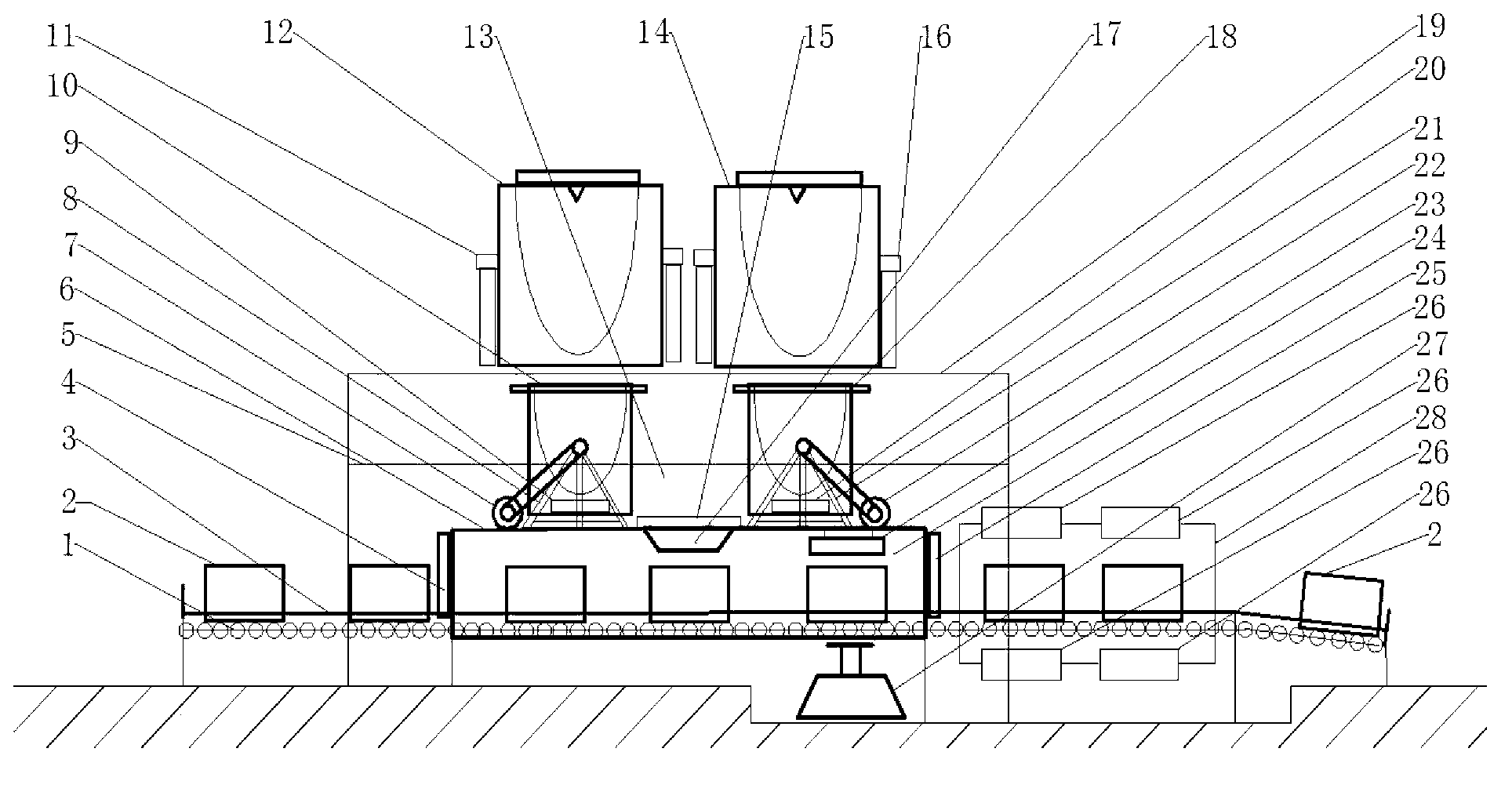

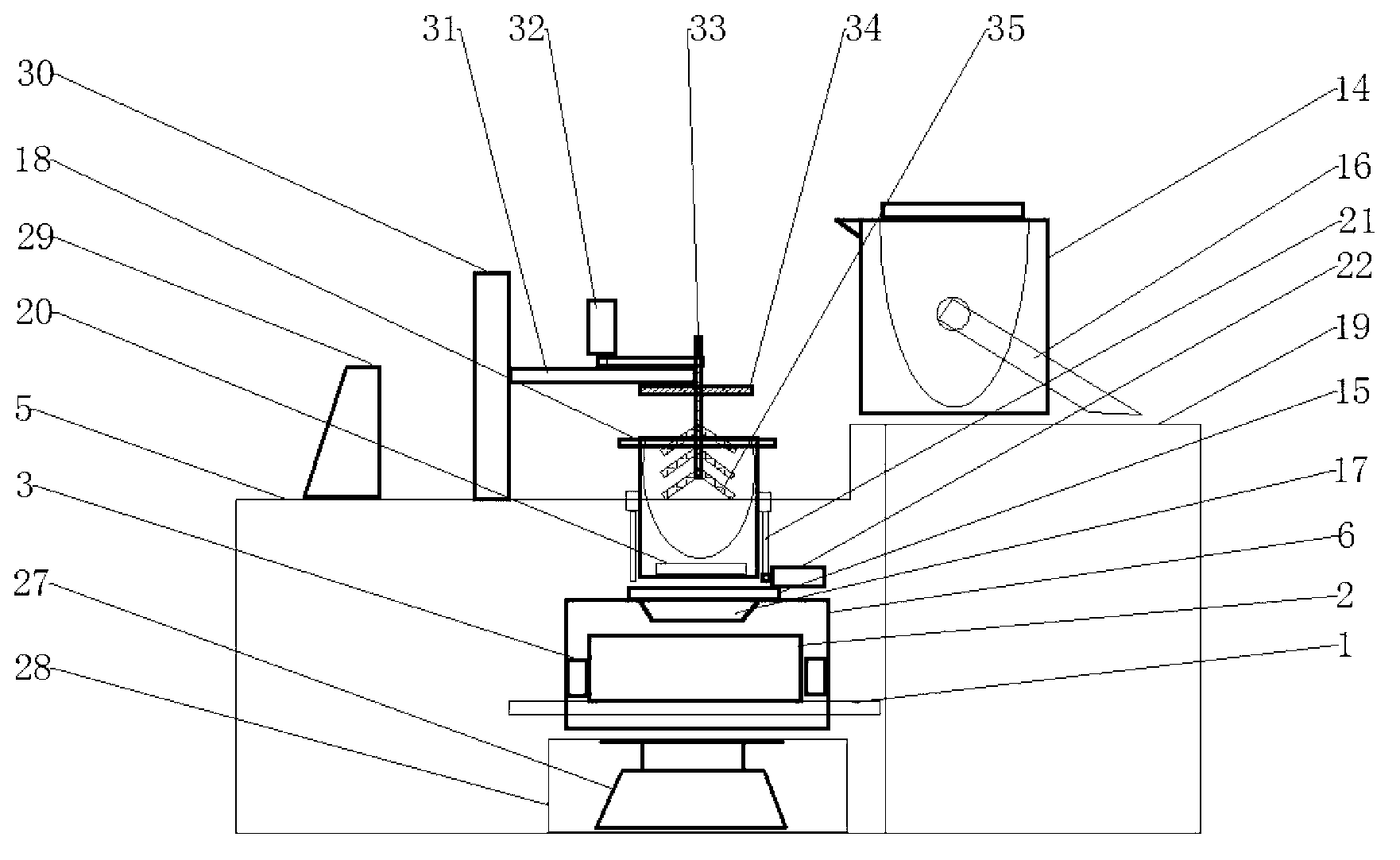

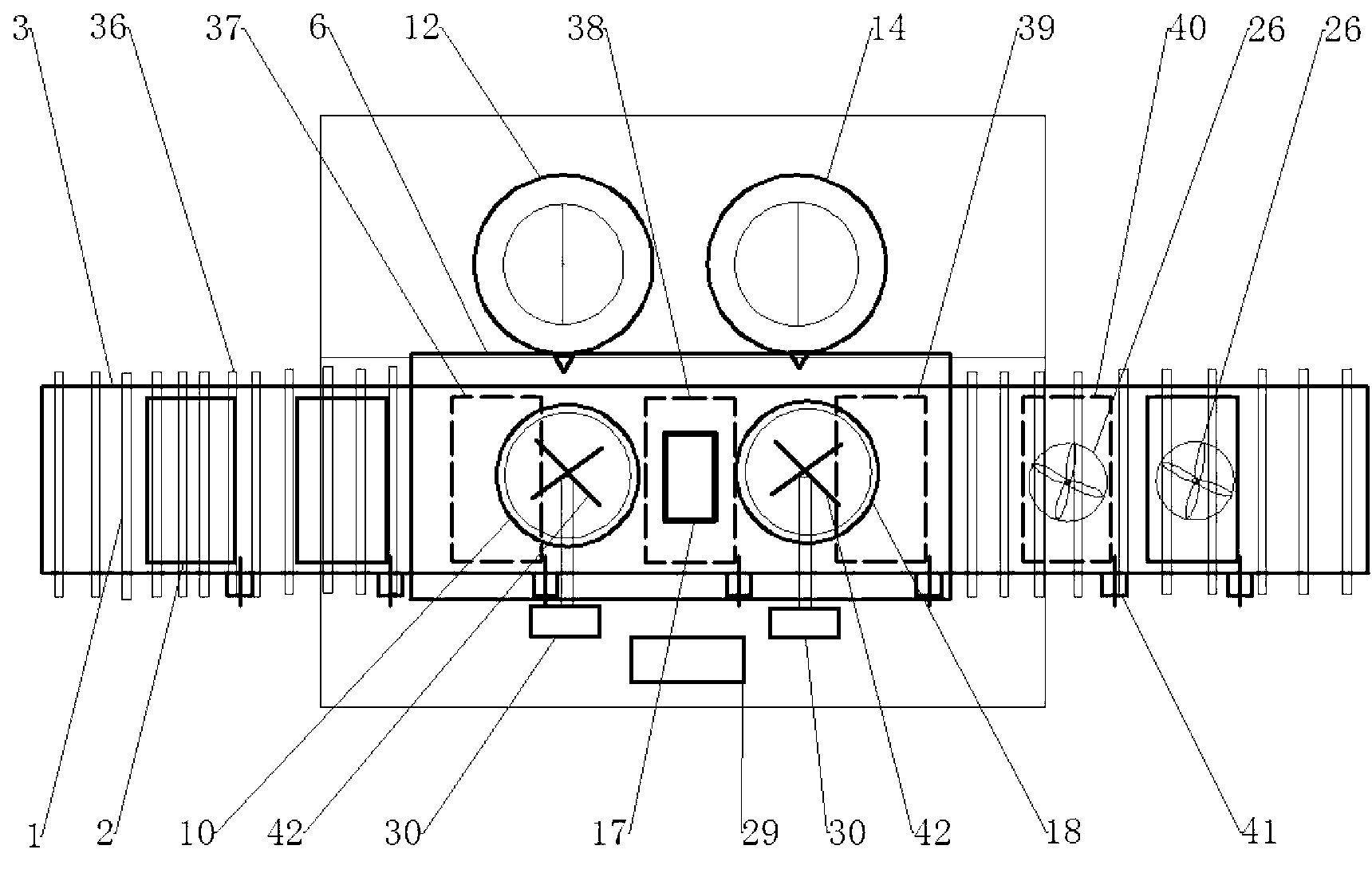

[0033] according to Figure 1 ~ Figure 4 The shown embodiment installs the complete set of equipment for producing foamed aluminum of this embodiment. Among them, the size of the sealed box holding furnace is 2500mm wide, 9000mm long and 1700mm high; the size of the melting furnace is 1400mm in diameter and 1300mm in height; the size of the stirring furnace is 1000mm in diameter and 1250mm in height; the size of the industrial fan The diameter is 900mm and the height is 800mm; the stirring paddle used is a titanium alloy stirring paddle.

[0034] The complete set of equipment that the present invention produces aluminum foam is in application, and its operation process is:

[0035] In the first step, a required amount of aluminum ingots is added to the melting furnace A12 and the melting furnace B14 for heating and melting.

[0036] In the second step, the mold 2 is placed on the transfer roller bed 1, the entrance furnace door 4 of the sealed box-type holding furnace 6 is l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com