Manipulator device for feeding garbage

A manipulator and garbage technology, which is applied to conveyor objects, transportation and packaging, etc., can solve the problems of loss of lifting weight, slow grabbing speed, and large weight, so as to reduce production and operation costs, improve grabbing efficiency, and improve grabbing Get fast effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

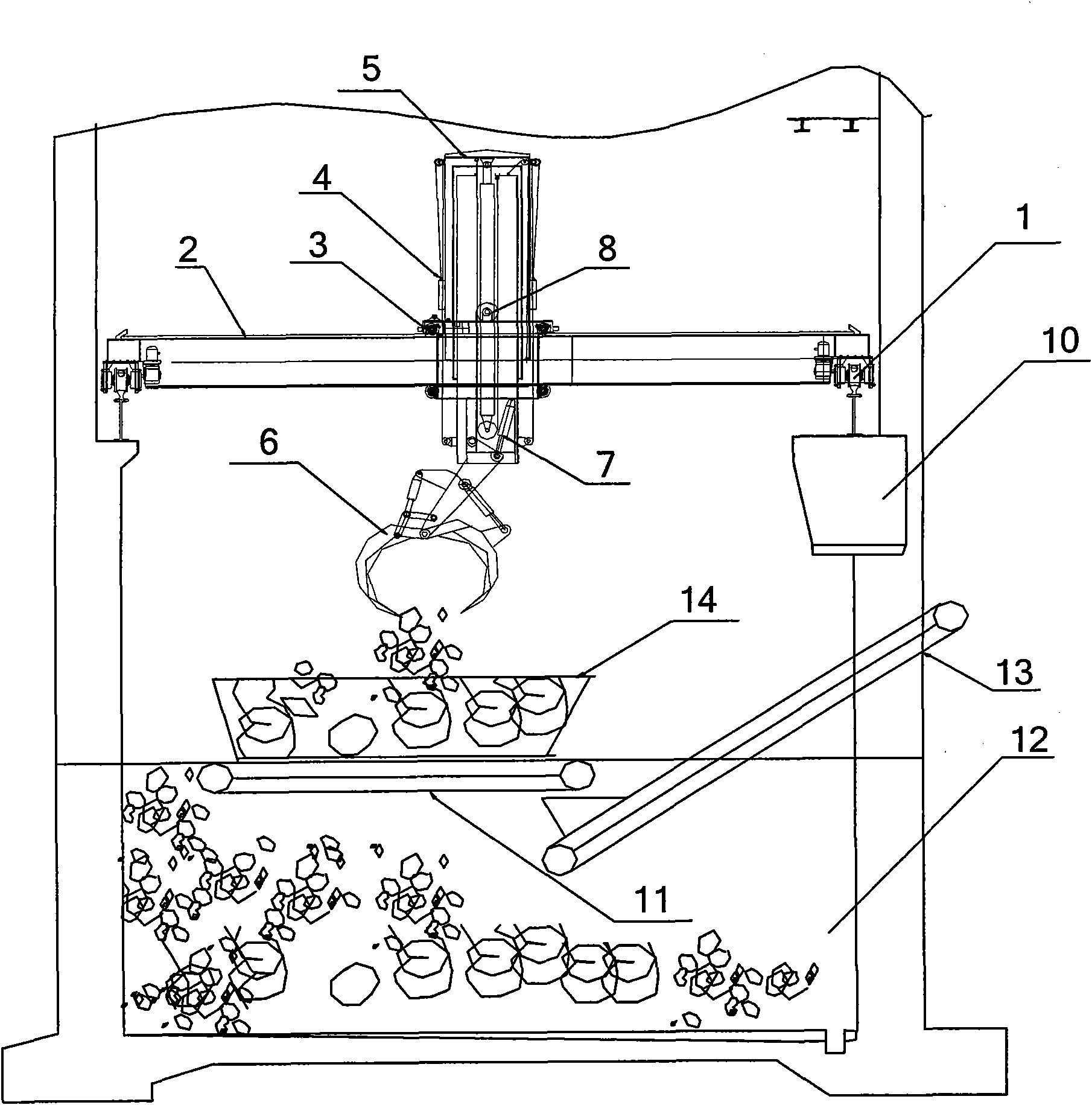

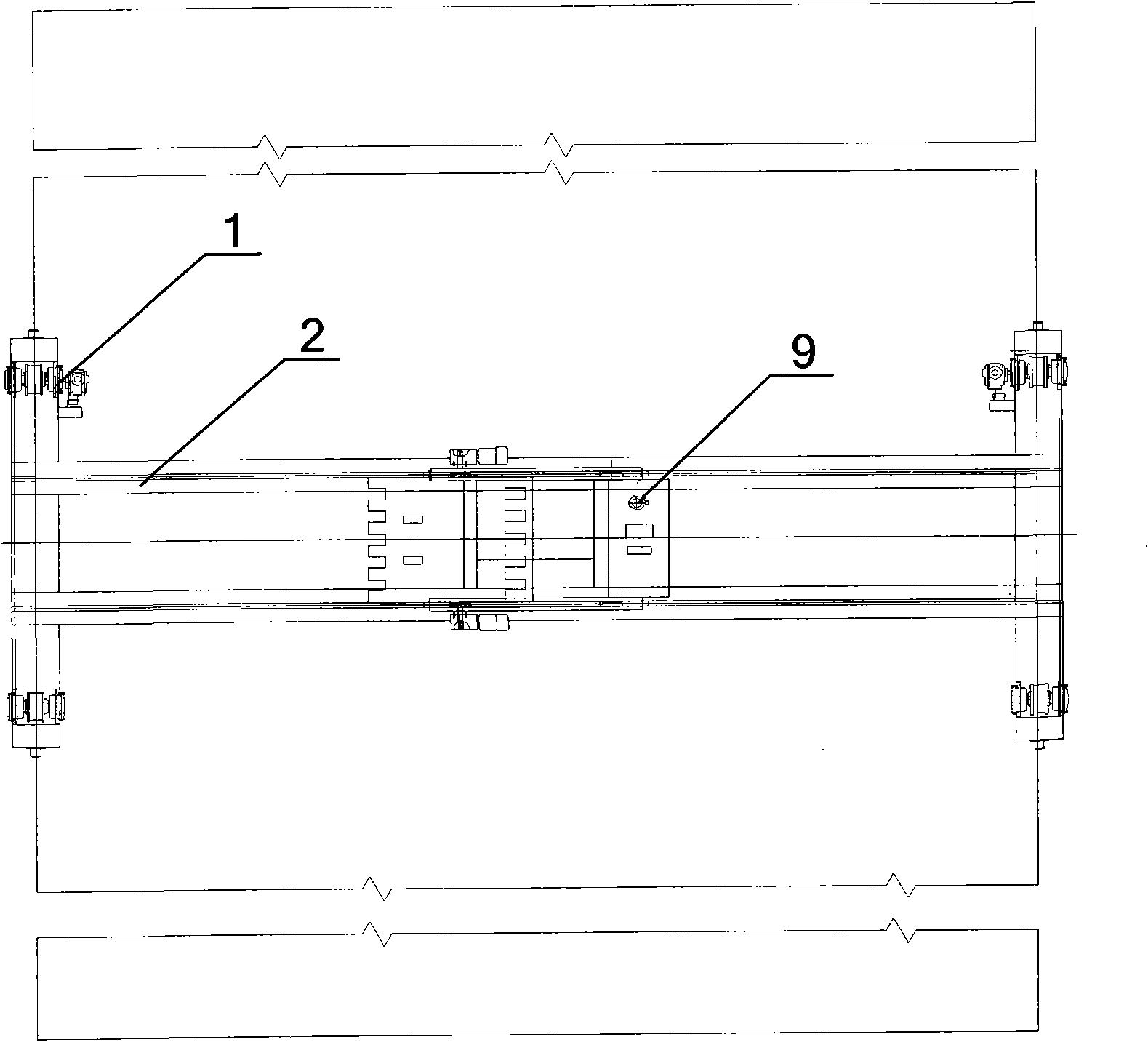

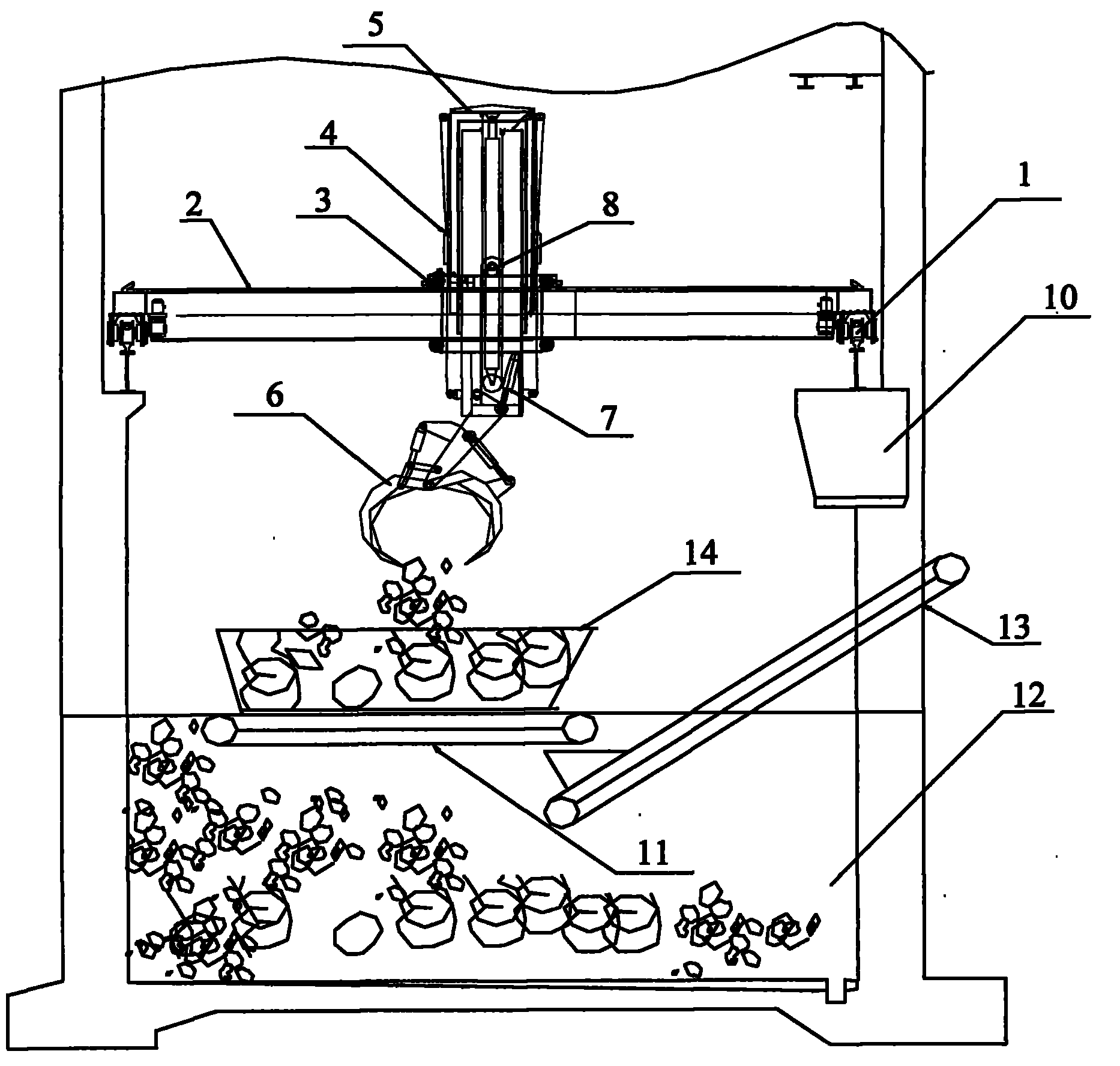

[0018] This embodiment provides a manipulator device for loading garbage, which is used to load garbage when handling garbage, such as figure 1 , 2 As shown, the manipulator device includes: a beam 2, a cart traveling mechanism 1, a trolley traveling device 3, an up and down moving mechanism 4, a manipulator swinging device 7, a grabbing manipulator 6 and a hydraulic device 9;

[0019] Wherein, the two ends of the crossbeam 2 are arranged on the traveling mechanism 1 of the cart, and the traveling wheels of the traveling mechanism 1 of the cart are arranged on the track of the material pit 12 (or unloading hall), which can drive the crossbeam 2 to move along the track;

[0020] The trolley running device 3 is arranged on the beam 2, and the trolley running device 3 is composed of a frame body, wheels and a driving device, wherein the frame body is a frame structure, the frame body is provided with wheels, and the driving device is arranged on the frame body, and the wheels are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com