Concrete performance test experimental device

A technology for testing experiments and concrete, which is applied in the field of concrete performance testing experimental devices, which can solve the problems of generating a large amount of dust and not being able to handle dust, and achieve the effects of cost saving, pollution reduction and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

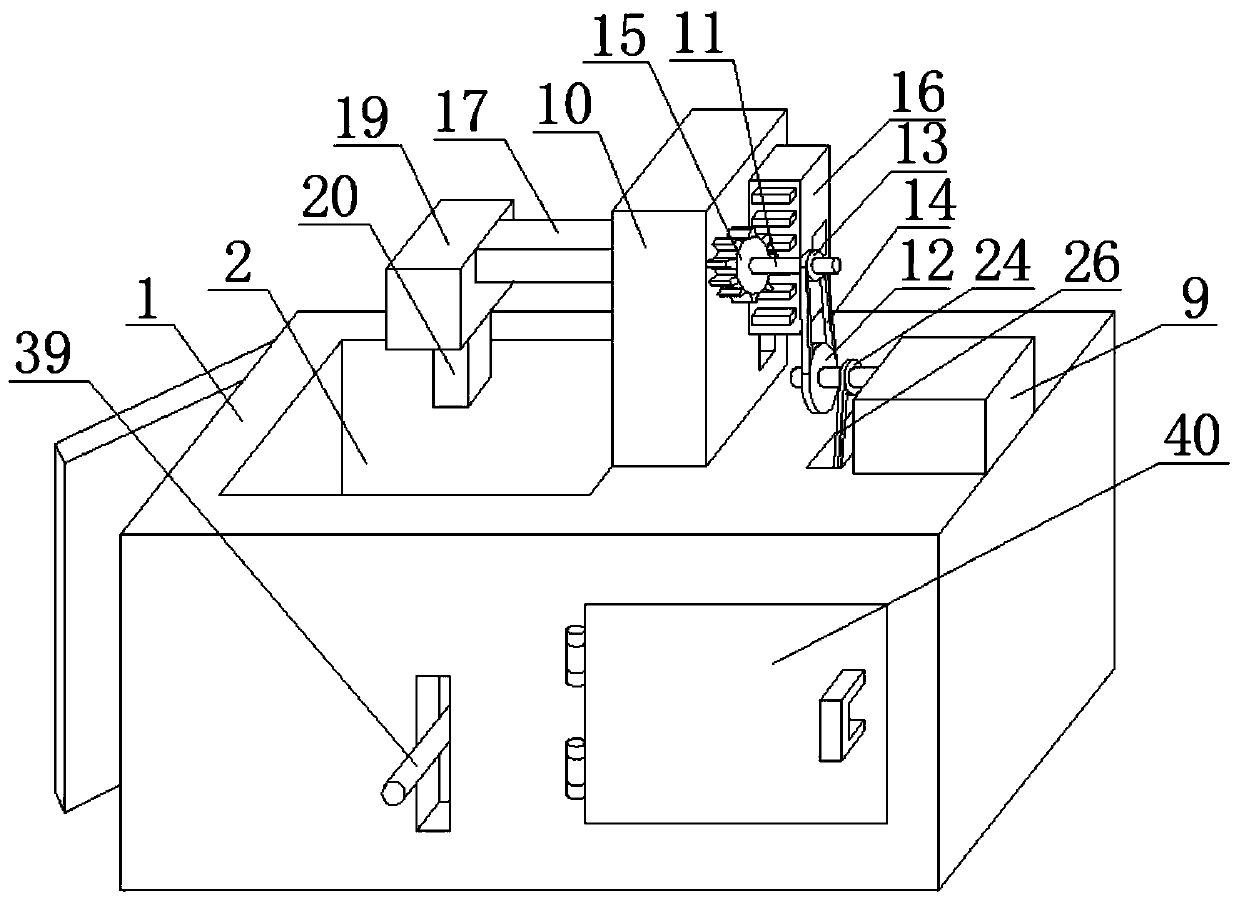

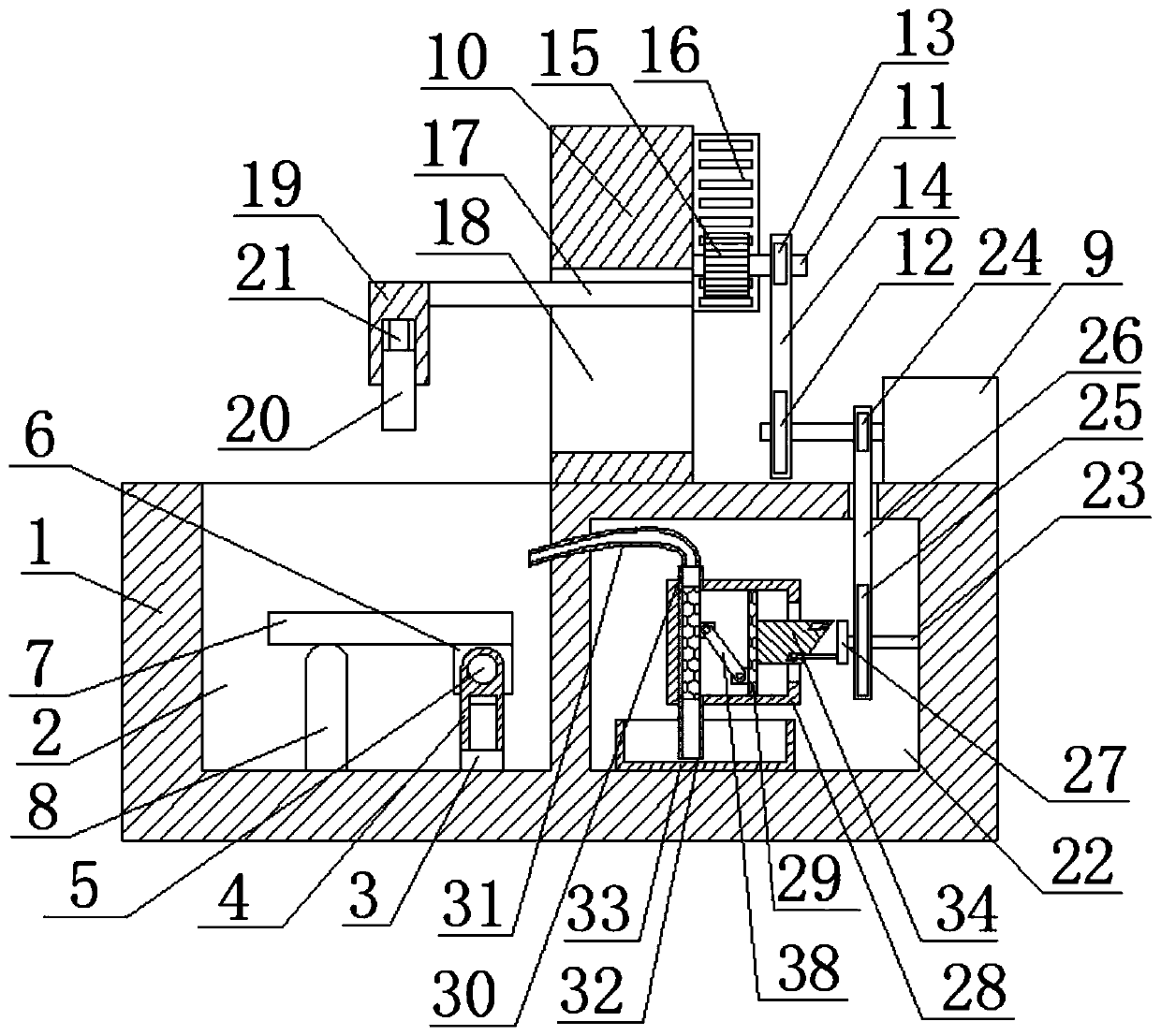

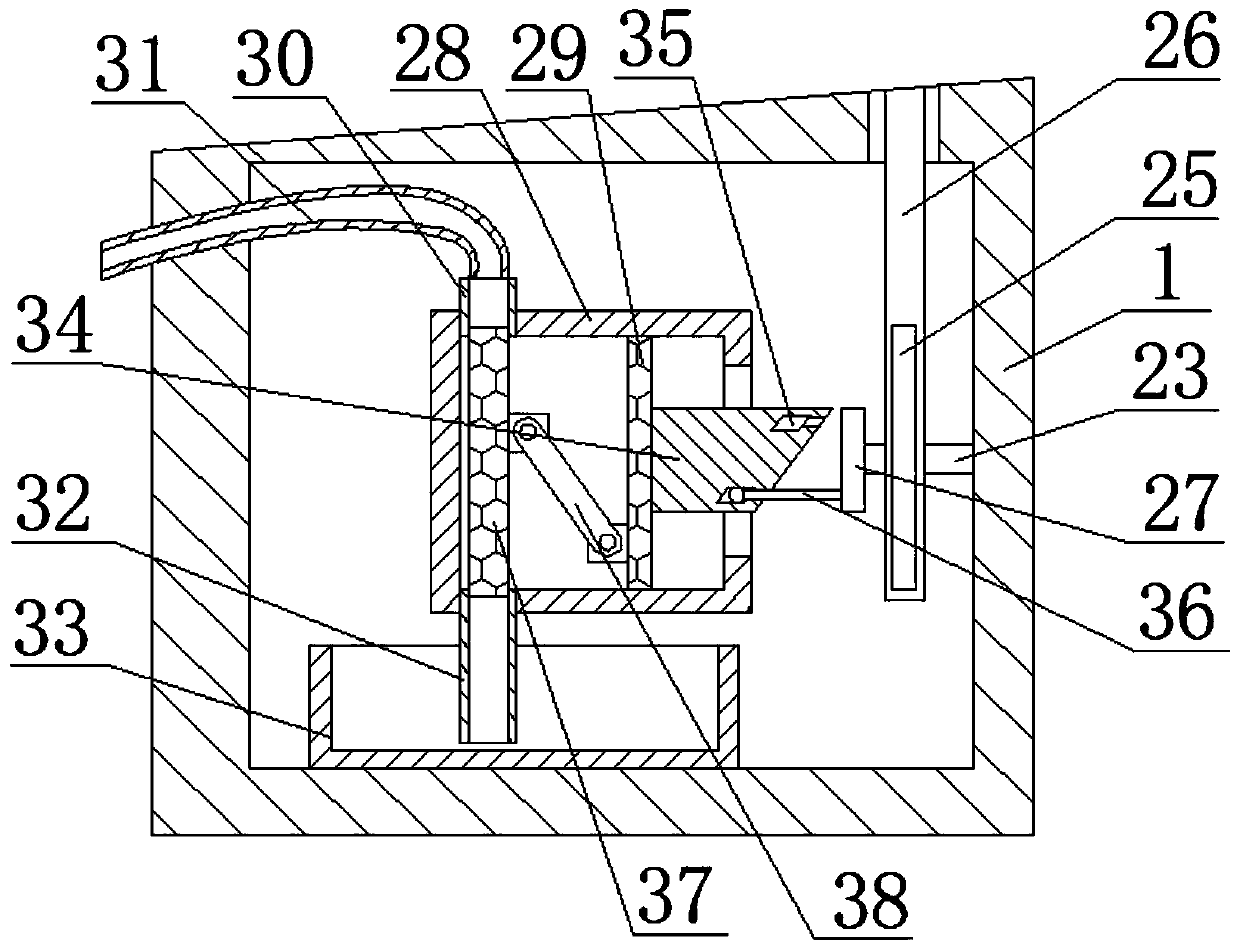

[0028] refer to Figure 1-5 , a concrete performance testing experimental device, comprising a pressure sensor 21 and a base 1, the top of the base 1 is provided with a first groove 2, the bottom of the first groove 2 is fixedly installed with a fixing seat 3, and the fixing seat 3 is slidably installed with a The sliding sleeve 4, that is, the fixed seat 3 and the sliding sleeve 4 are relatively slidably connected. The sliding sleeve 4 is provided with a round hole, and a round rod 5 is installed for rotation in the round hole. One end of the round rod 5 is fixedly installed with a fixed block 6, and the fixed block 6 The top of the first groove 2 is fixedly installed with a backing plate 7, and the bottom of the first groove 2 is fixedly installed with a support plate 8. The support plate 8 matches the backing plate 7 and is used to support the backing plate 7. The support plate 8 and the backing plate 7 correspond to each other. Contact but not connected, when the sliding s...

Embodiment 2

[0038] refer to Figure 1-5 , a concrete performance testing experimental device, including a pressure sensor 21 and a base 1, the top of the base 1 is provided with a first groove 2, the bottom of the first groove 2 is fixed with a fixing seat 3 by screws, and slides on the fixing seat 3 A sliding sleeve 4 is installed, that is, the fixed seat 3 is relatively slidingly connected with the sliding sleeve 4, and a round hole is provided on the sliding sleeve 4, and a round rod 5 is installed for rotation in the round hole. One end of the round rod 5 is welded with a fixed block 6, and the fixed block The top of 6 is fixed with a backing plate 7 by screws, and the bottom of the first groove 2 is fixed with a support plate 8 by screws. The support plate 8 cooperates with the backing plate 7 to support the backing plate 7. The support plate 8 In contact with but not connected to the backing plate 7, when the sliding sleeve 4 is lifted, one end of the backing plate 7 is raised, so t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com