Rotating pallet fork of forklift

A technology of forks and forklifts, which is applied to lifting devices and other directions, and can solve problems such as low production efficiency, inconvenient use, and complicated operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

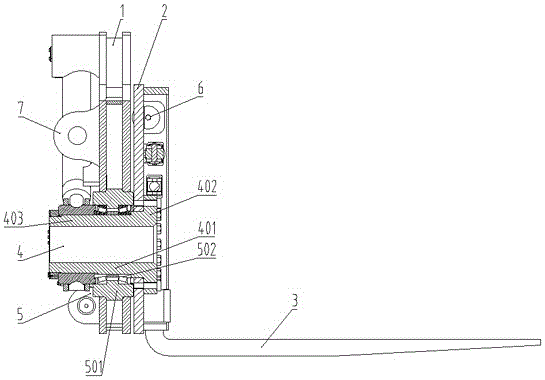

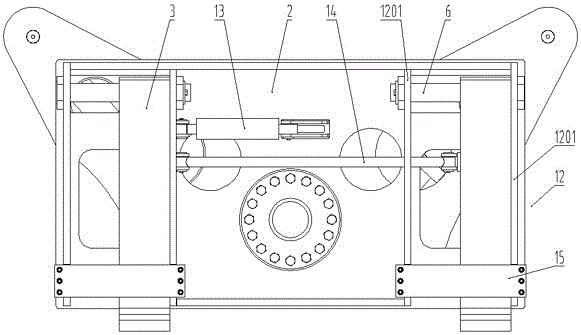

[0016] exist figure 1 Among them, a rotary fork of a forklift, which includes a fixed frame 1, a fork frame 2 and two forks 3.

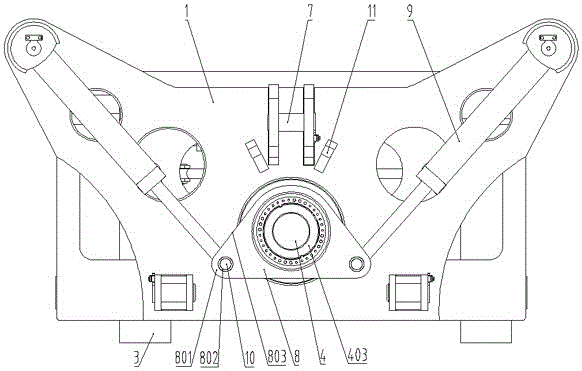

[0017] In order to facilitate the assembly of the fixed frame 1 and the fixed arm of the forklift, such as figure 2 As shown, a number of fixed ear seats 7 are welded on the fixed frame 1, and the fixed ear seats 7 pin-connect the fixed frame 1 to the fixed arm of the forklift. The number of fixing lugs 7 can be correspondingly set according to the fixed arm of the forklift. In this embodiment, there are three fixing lugs 7 , which are welded and arranged on the fixing frame 1 in a triangular shape.

[0018] exist figure 1 , image 3 Among them, the two forks 3 are symmetrically hinged on the fork frame 2 via the corresponding fork shafts 6 respectively.

[0019] exist figure 1 Among them, the present invention also includes a rotating shaft 4 , the rotating shaft 4 passes through the fixed frame 1 , and its support part 401 is rotatably arrang...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com