Patents

Literature

85results about How to "Precise expansion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Equipment fault diagnosis method

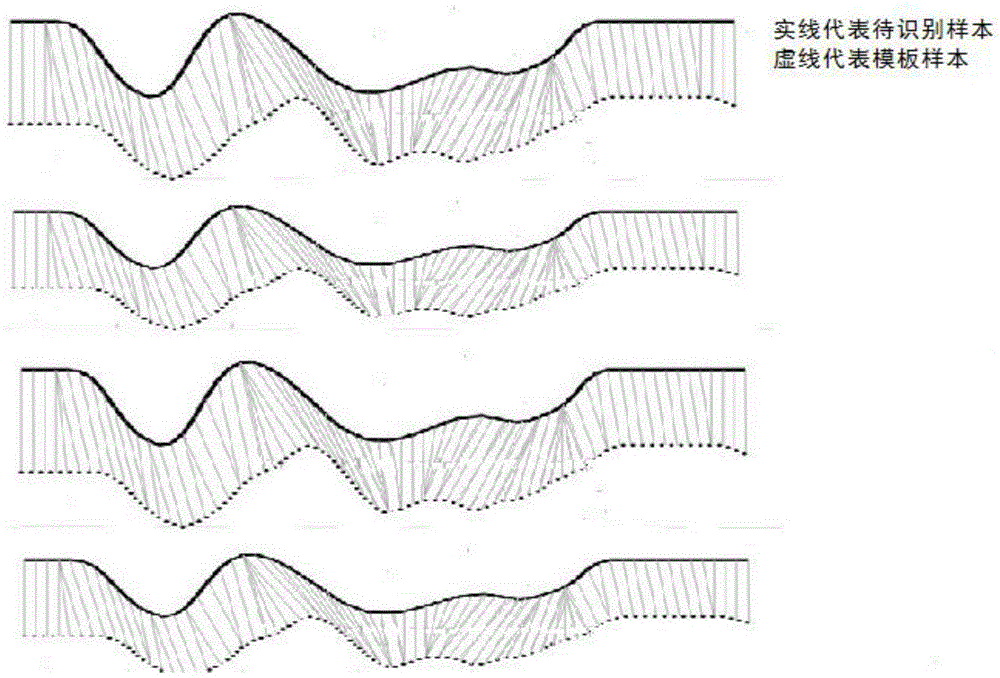

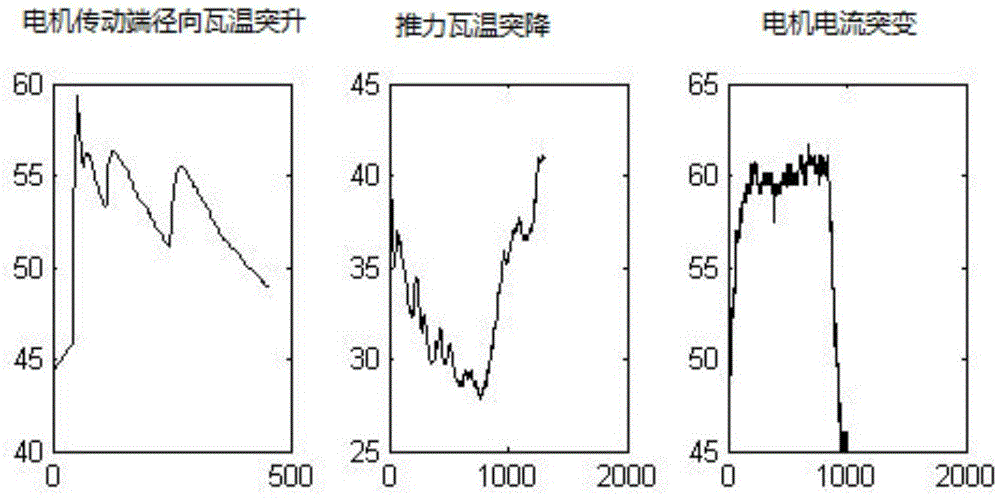

ActiveCN105467975AEfficient deploymentPrecise expansionData processing applicationsElectric testing/monitoringPattern matchingDiagnosis methods

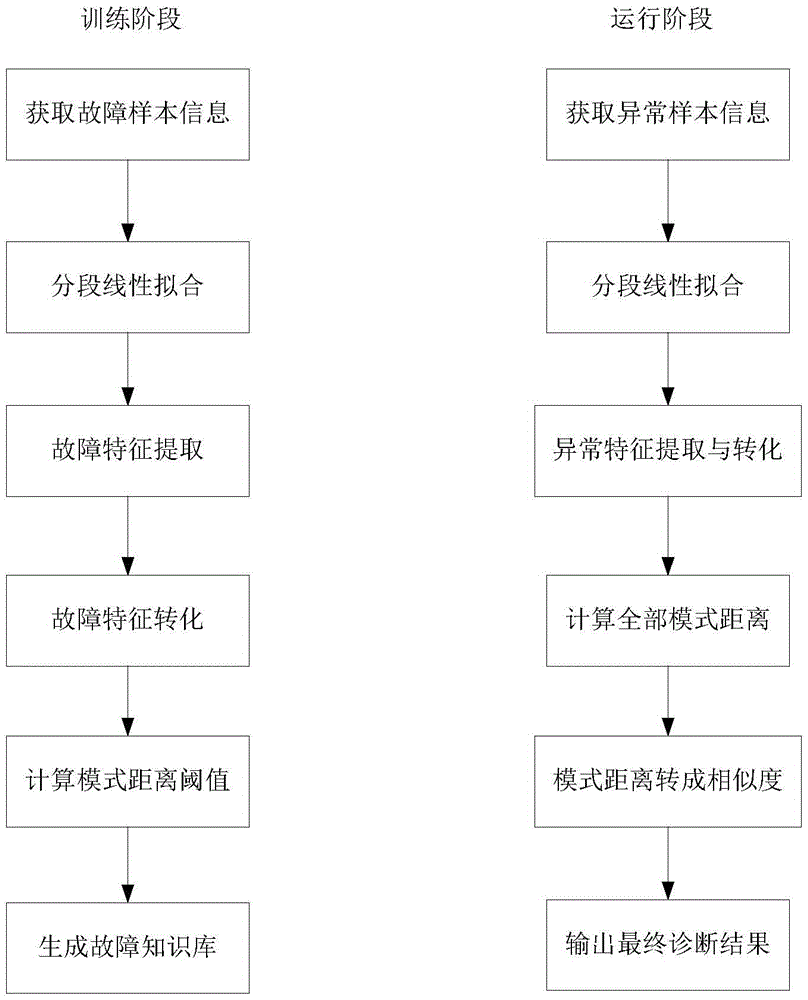

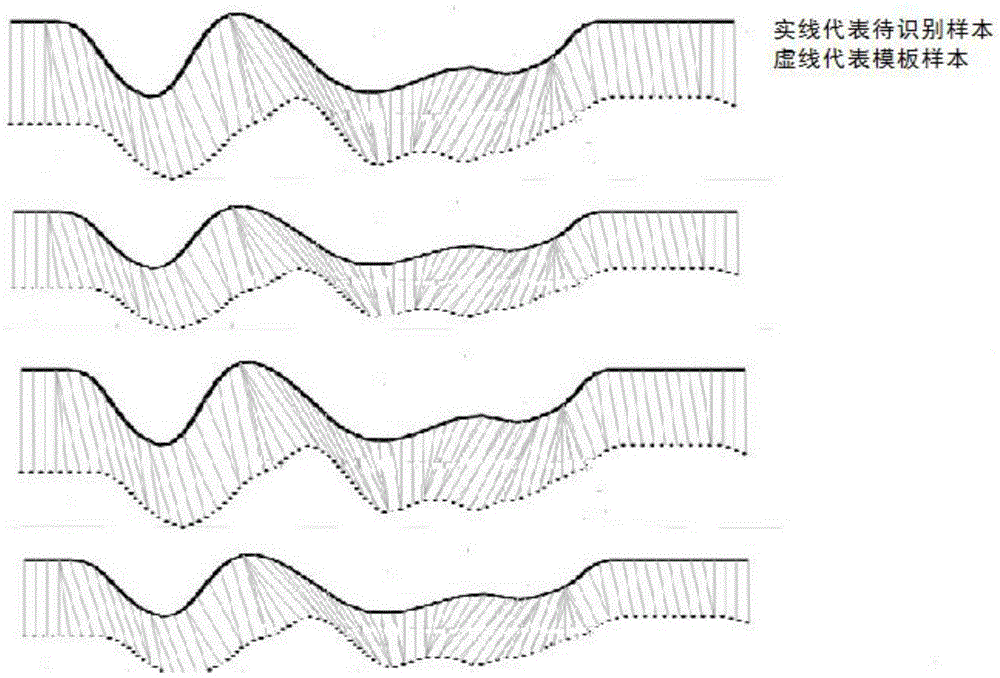

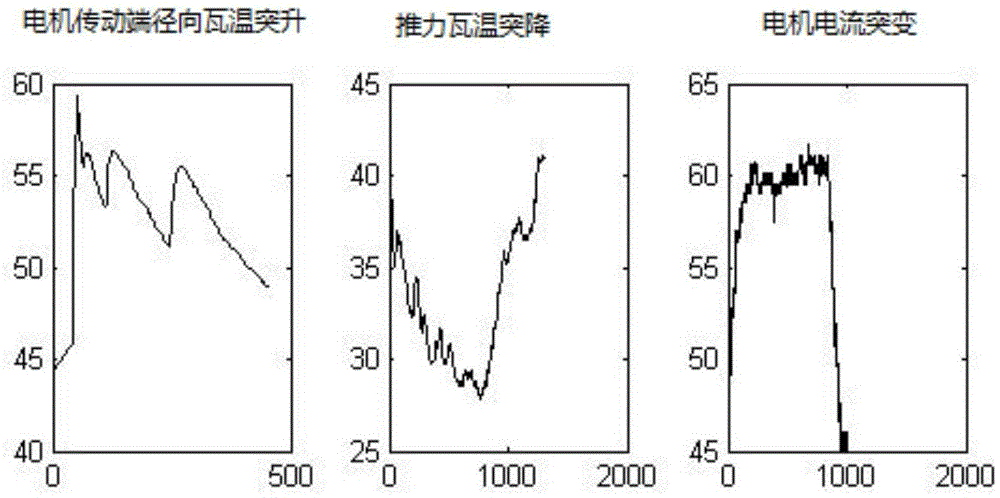

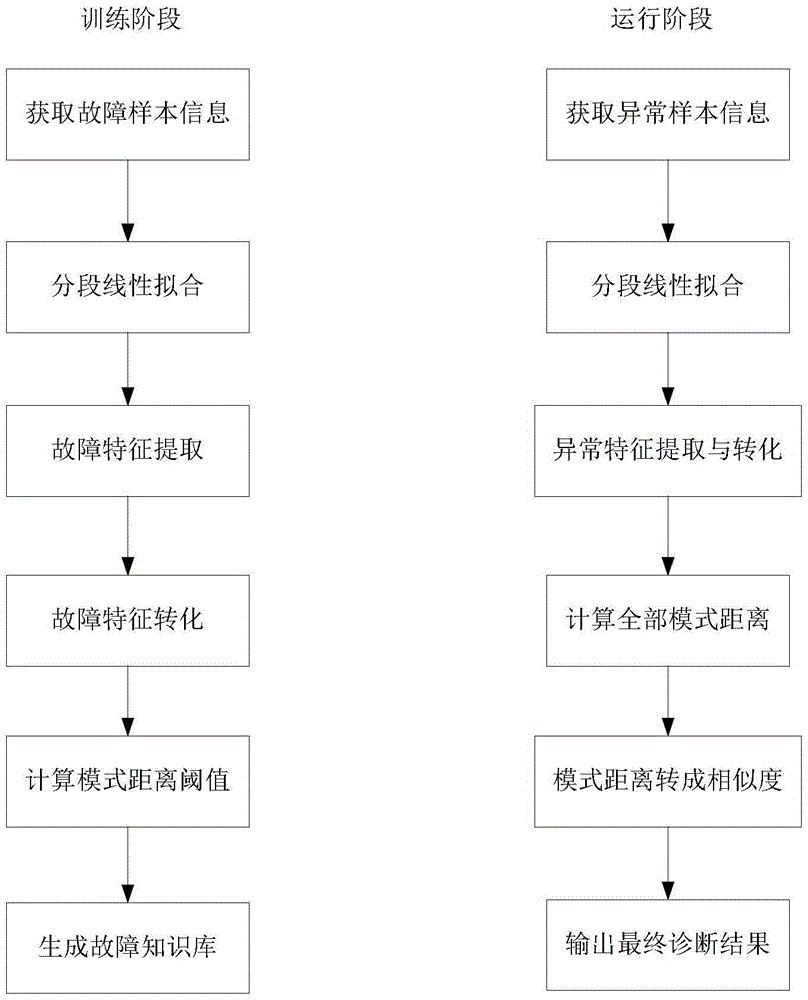

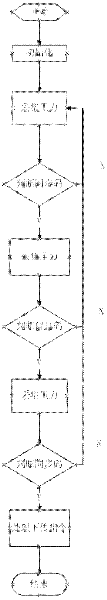

An equipment fault diagnosis method successively comprises fault diagnosis training steps and fault diagnosis operation steps. The method focuses on a data form characteristic essence and combines a multi-dimensional segmentation fitting algorithm and an optimized dynamic time warping algorithm based on equipment fault data to carry out pattern expression of modeling and distance threshold extraction, and extract form characteristics from the found equipment abnormity data to carry out mode matching, so that an equipment data fault type can be identified and a reason diagnosis function is realized. In this way, the difficulties in current fault diagnosis technologies that similarity degrees among the fault data can hardly be described efficiently and accurately can be solved.

Owner:SHANDONG LUNENG SOFTWARE TECH

Equipment fault diagnosis method based on multidimensional segmentation fitting

ActiveCN105631596AEfficient deploymentPrecise expansionTechnology managementResourcesDiagnosis methodsPattern matching

The invention discloses an equipment fault diagnosis method based on multidimensional segmentation fitting. The method successively comprises a fault diagnosis training step and a fault diagnosis operation step. The method realizes mode expression and distance threshold extraction functions of modeling through combining a multidimensional segmentation fitting algorithm and an optimized dynamic time bending algorithm by focusing on the essence of data form characteristics on the basis of equipment fault data, and realizes equipment data fault type identification and cause diagnosis functions by performing mode coupling through extracting form characteristics of discovered equipment abnormal data, thereby solving the problem of incapability of efficiently and accurately describing the similarity degree between fault data by use of a conventional fault diagnosis technology.

Owner:SHANDONG LUNENG SOFTWARE TECH

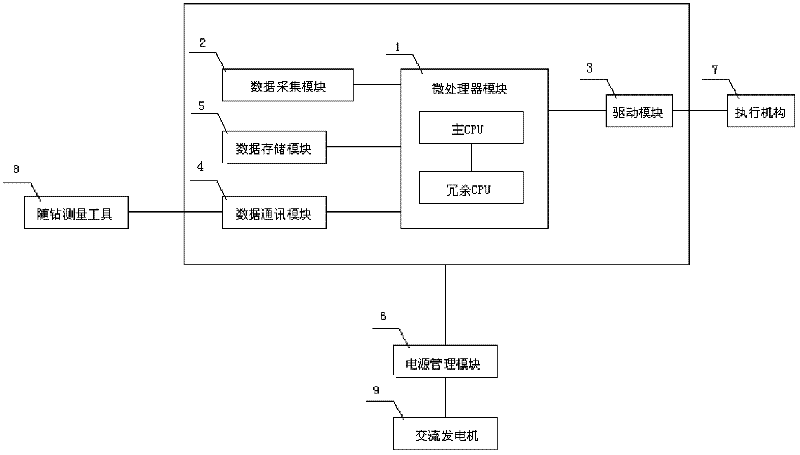

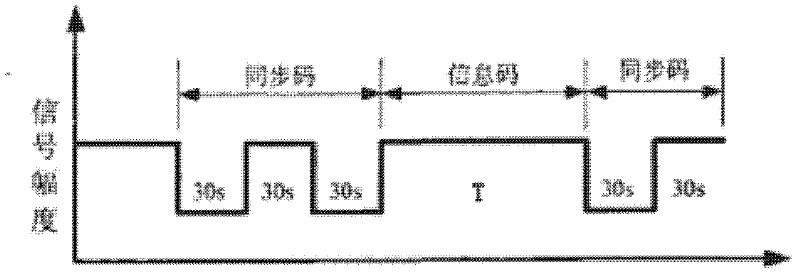

Measuring and controlling device used for rotary steering drilling system and measuring and controlling method utilizing same

ActiveCN102383777AAdjust target scalingAccurate measurement of eccentric displacementSurveyConstructionsProportion integration differentiationComputer module

The invention relates to a measuring and controlling device used for a rotary steering drilling system and a measuring and controlling method utilizing the same. The device comprises a microprocessor module, a data acquisition module, a driver module, a data communication module, a data storage module and a power management module. The method comprises the following steps: 1) carrying out pressure pulse coding on the control instruction on the ground and transmitting the code to the microprocessor module under the shaft; 2) carrying out system initialization and self check and checking whether a main CPU (central processing unit) works normally, if no, switching to a redundant CPU; 3) using the microprocessor module to decode the pressure pulse to obtain the instruction transmitted by the pressure pulse; 4) using a system to acquire data and calculating the deviation angle and high-side tool face angle of the position of a current rotary steering drilling tool, the eccentric displacement of the current rotary steering drilling tool and the displacement extension of an actuating mechanism; and 5) decoding the pulse instruction, carrying out PID (proportion integration differentiation) control on the calculated displacement extension of the actuating mechanism and adjusting the displacement extension of the actuating mechanism. The device is used for the static biased directional rotary steering drilling tool, and can be used for accurately measuring the eccentric displacement of the tool and simultaneously controlling the expansion amount of wing ribs more accurately.

Owner:CHINA NAT OFFSHORE OIL CORP +1

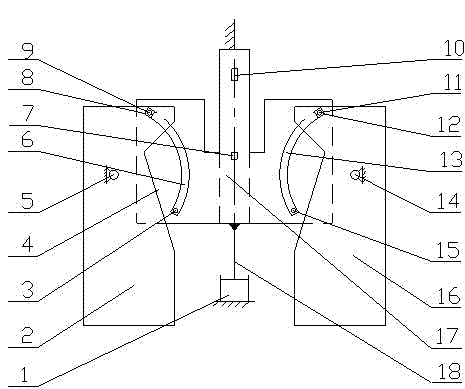

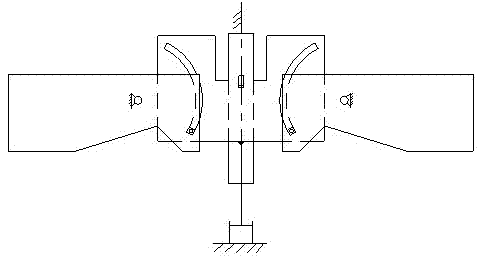

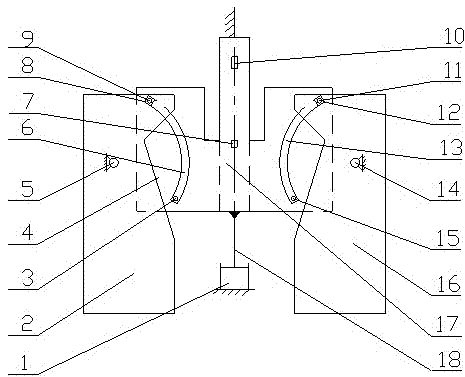

Longitudinal unfolding mechanism for direct-connected folding wing

The invention relates to a longitudinal unfolding mechanism for a direct-connected folding wing. At present, folding wings of all missiles have functions of one time unfolding and locking, and the unfolding time of the folding wings of all the missiles is very short, the unfolding and locking impact is higher, and the interference on the posture of a flying missile is higher. By adoption of a direct-connected cam mechanism design idea, the reliable locking of folding wings of the missiles can be realized at a time. Power is supplied by a gas actuator cylinder and directly drives a cam to movealong a guide rail; and a driven sliding block on the missile wing is contacted with a chute of the cam and moves in the chute of the cam to realize unfolding of the folding wing. By the longitudinalunfolding mechanism, the minimization of a wrapping space of the folding wing is realized, the mechanism is compact, and high-precision and high-reliability folding, unfolding and locking can be realized easily.

Owner:ZHEJIANG SCI-TECH UNIV

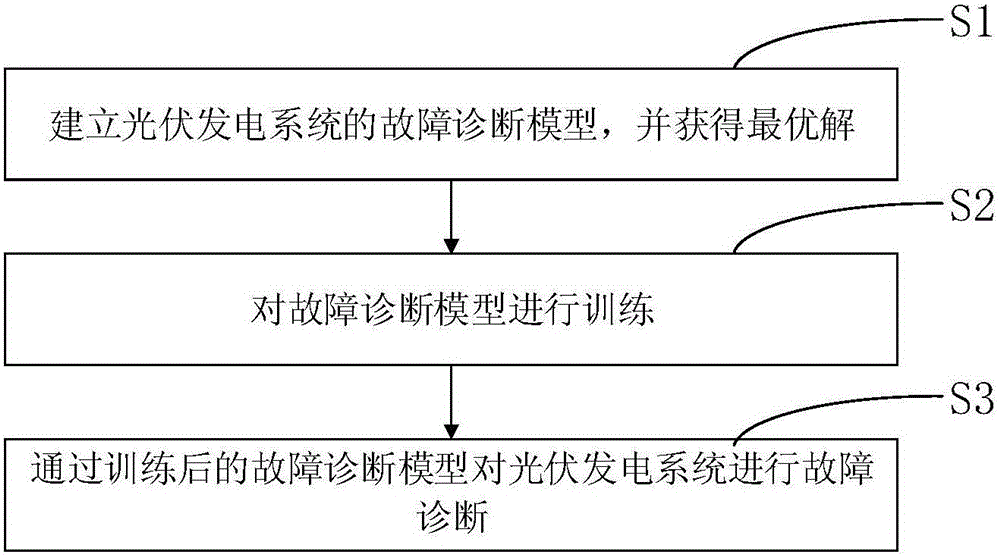

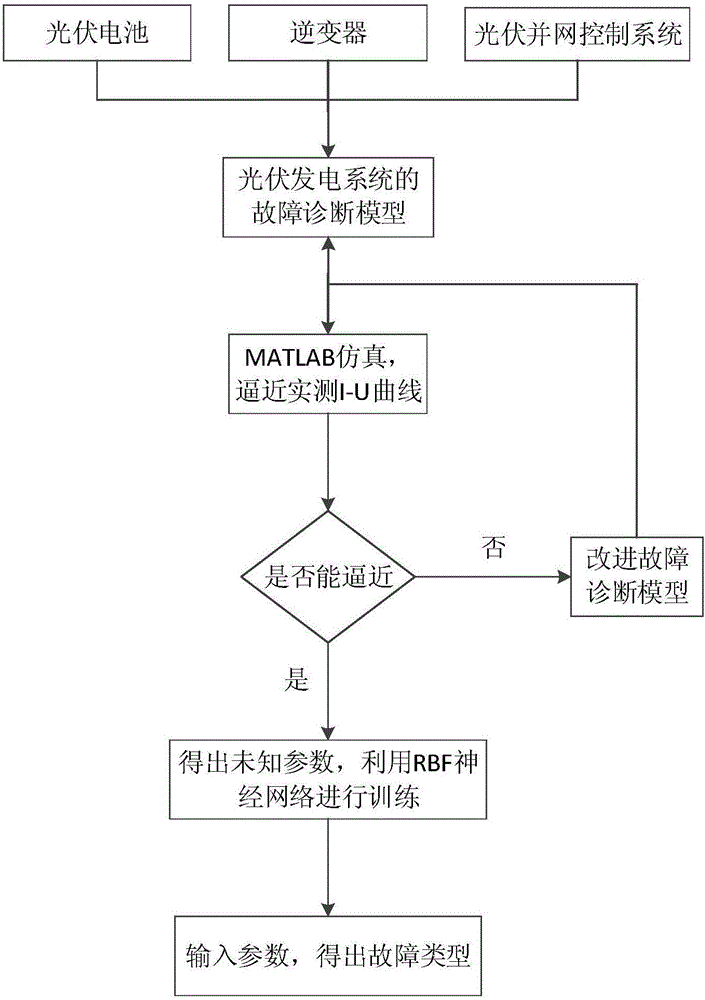

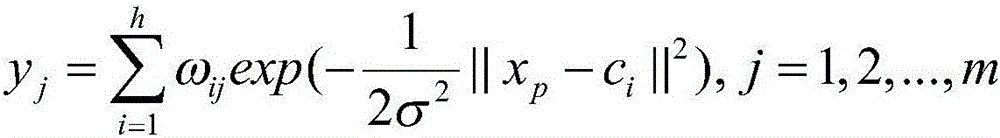

Parameter identification-based photovoltaic power generation system fault diagnosis method and system

InactiveCN106067758AExtended power generation timeImprove power generation efficiencyPhotovoltaic monitoringPhotovoltaic energy generationDiagnosis methodsControl system

The invention relates to a parameter identification-based photovoltaic power generation system fault diagnosis method and a parameter identification-based photovoltaic power generation system fault diagnosis system. The parameter identification-based photovoltaic power generation system fault diagnosis method includes the following steps that: the fault diagnosis model of a photovoltaic power generation system is built, and the optimal solutions of the fault diagnosis model are obtained; the fault diagnosis model is trained; and fault diagnosis is carried out on the photovoltaic power system based on the trained fault diagnosis model. According to the parameter identification-based photovoltaic power generation system fault diagnosis method of the invention, according to problems which easily appear in the photovoltaic power generation system, namely, open-circuiting and short-circuiting of a photovoltaic battery assembly, the overload of an inverter and the failure of a control system, the parameter identification-based photovoltaic power generation system fault diagnosis model under a mismatch condition is built; an I-U curve is obtained according to the data of a photovoltaic power plant in different working conditions; analog simulation is carried out on the actually-measured I-U curve, so that the optimal solutions of the parameters of the model are obtained; an RBF neural network is utilized to train the model, so that the trained fault diagnosis model is obtained; and test samples or real-time samples of the photovoltaic power plant are inputted to the model, so that fault diagnosis can be carried out.

Owner:HOHAI UNIV CHANGZHOU

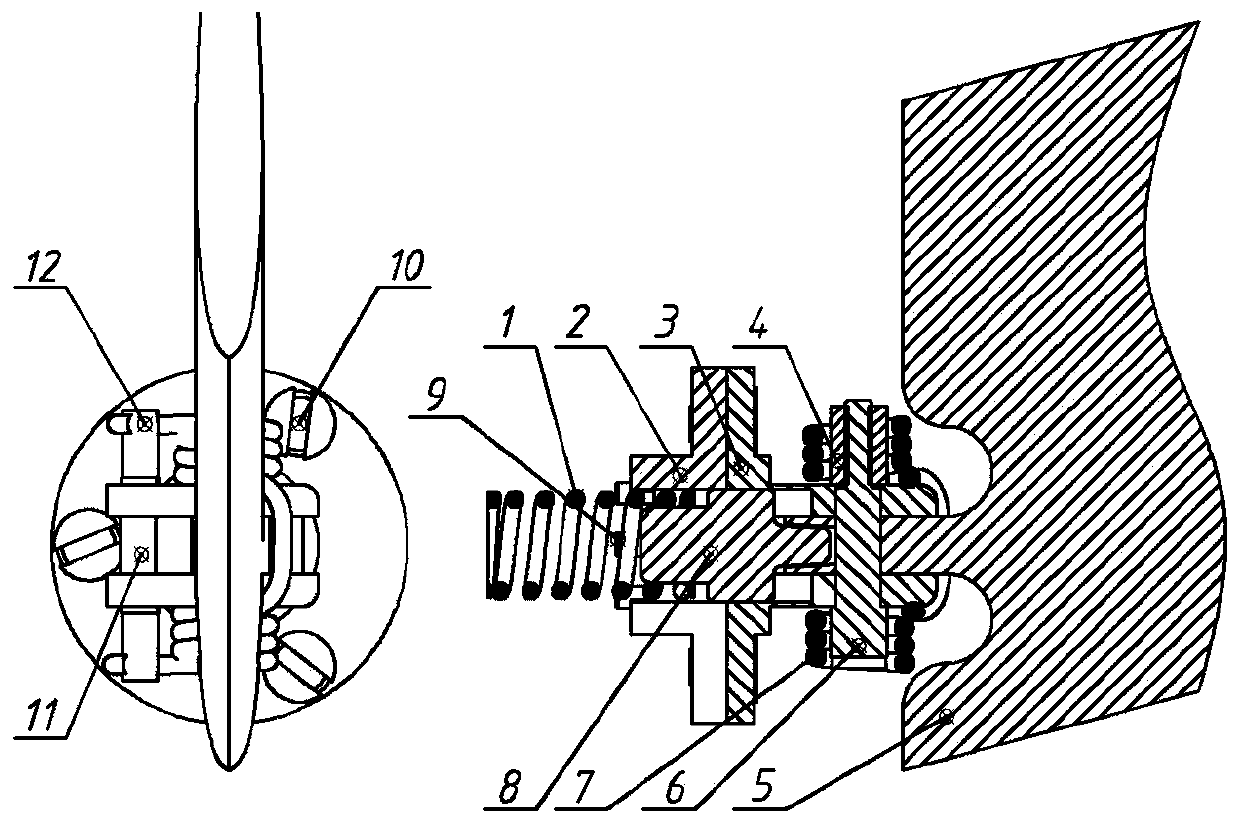

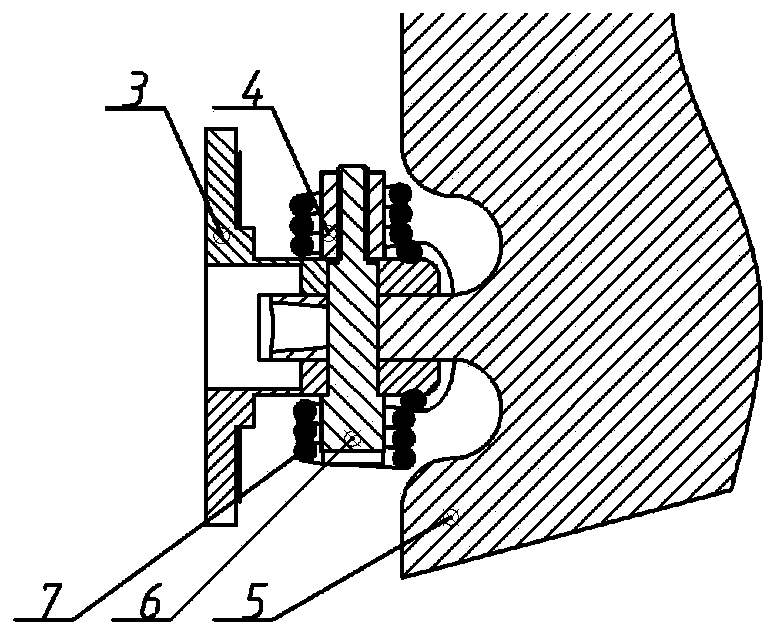

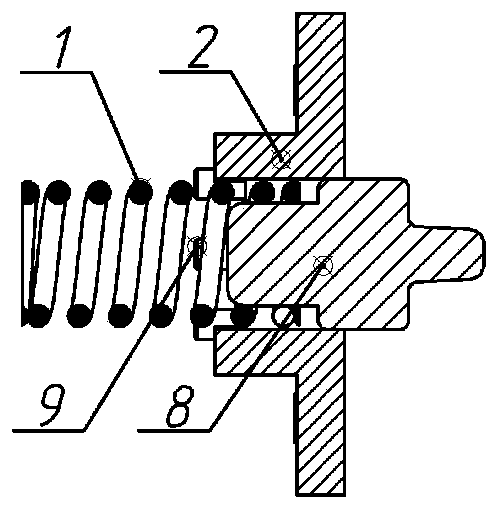

Redundant locking type longitudinal expansion mechanism of folding wing

InactiveCN102226671AGuaranteed stabilityExpanded area is largeSelf-propelled projectilesSelf lockingActuator

The invention relates to a redundant locking type longitudinal expansion mechanism of a folding wing. The existing missile folding wing has the once expansion locking function and has the defects of extremely short expansion time, great expansion locking impact and great posture interference on a missile in flight. The longitudinal expansion mechanism provided by the invention adopts the design idea that a worm mechanism and a ball nut are combined, wherein the mechanism can realize the once reliable locking of the folding wing; the power of a gas actuator cylinder drives the nut to move; a screw shaft is linked with a worm, thereby driving a worm gear to rotate around a wing shaft; and the locking of the folding wing is realized by utilizing the self-locking action of the worm. The longitudinal expansion mechanism provided by the invention realizes the minimization of the enveloping space of the folding wing, has the advantage of compact structure and is easy to realize the folding, the expansion and the locking with high accuracy and high reliability.

Owner:ZHEJIANG SCI-TECH UNIV

Method for molding hyperbolic streamlined bridge abutment moulding plate space surface

ActiveCN101347897AAccurate locationSmooth transitionSpecial data processing applicationsNumerical controlThree-dimensional space

The invention relates to a shaping method of a space curved surface of a hyperbolic streamline shape bridge pier template; the shaping method includes the following steps: in AutoCAD, the radian of the space curved surface along the height direction is replaced by a segmented chord, and the maximum gap between a segmented arc and a corresponding chord is not larger than 1.5mm; a three-dimensional space model is established in Pro / E, and refining and flattening are carried out to obtain a precise expanded view of the space curved surface; the expanded view in Pro / E is transformed into a CAXA formatted file, proper kneading is carried out on the border splines of the expanded view to obtain an optimized expanded view of the curved surface, the optimized expanded view of the curved surface is transformed into program codes which are sent to a numerical control under water plasma cutting machine to finish cutting; a three-axis roller is adopted for arc rolling according to the radius of the arc corresponding to each segmented curved surface to shape the space curved surface; each shaped segmented space curved surface is treated with welding shaping on a clamping fixture from two sides to the middle to finish the manufacturing of the space curved surface. The shaping method of the invention can improve the shaping quality of the space curved surface, enhance work efficiency and reduce material waste in cutting.

Owner:CRRC TANGSHAN CO LTD

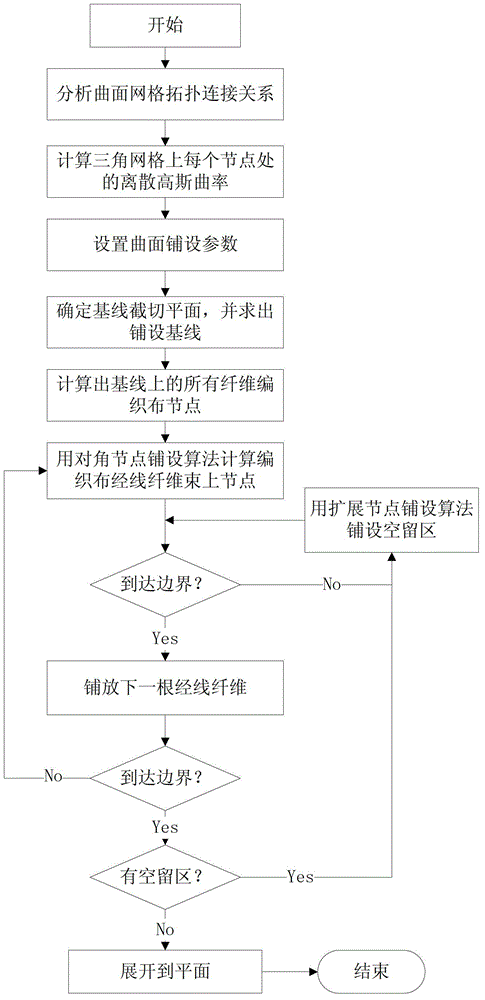

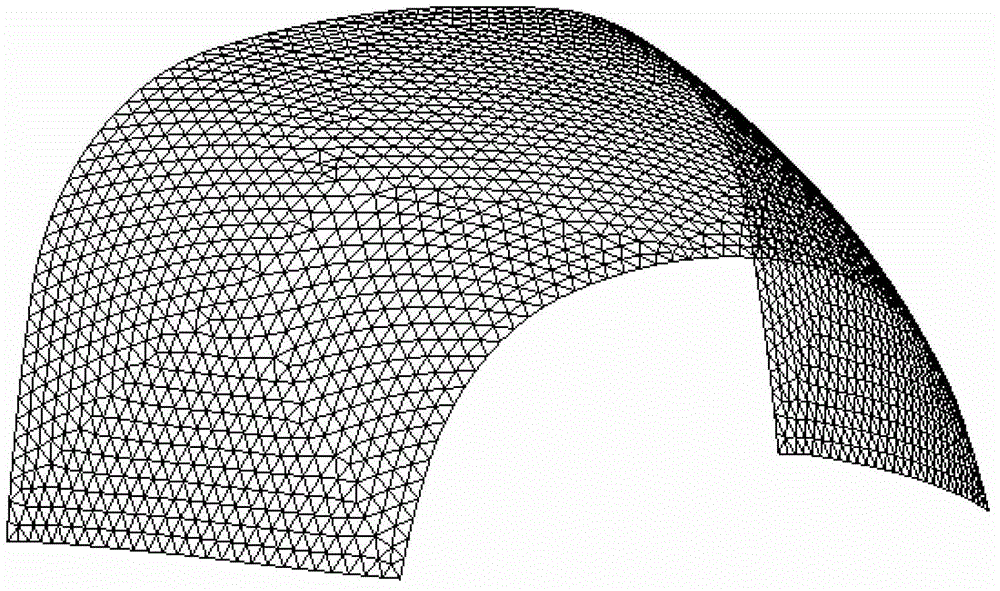

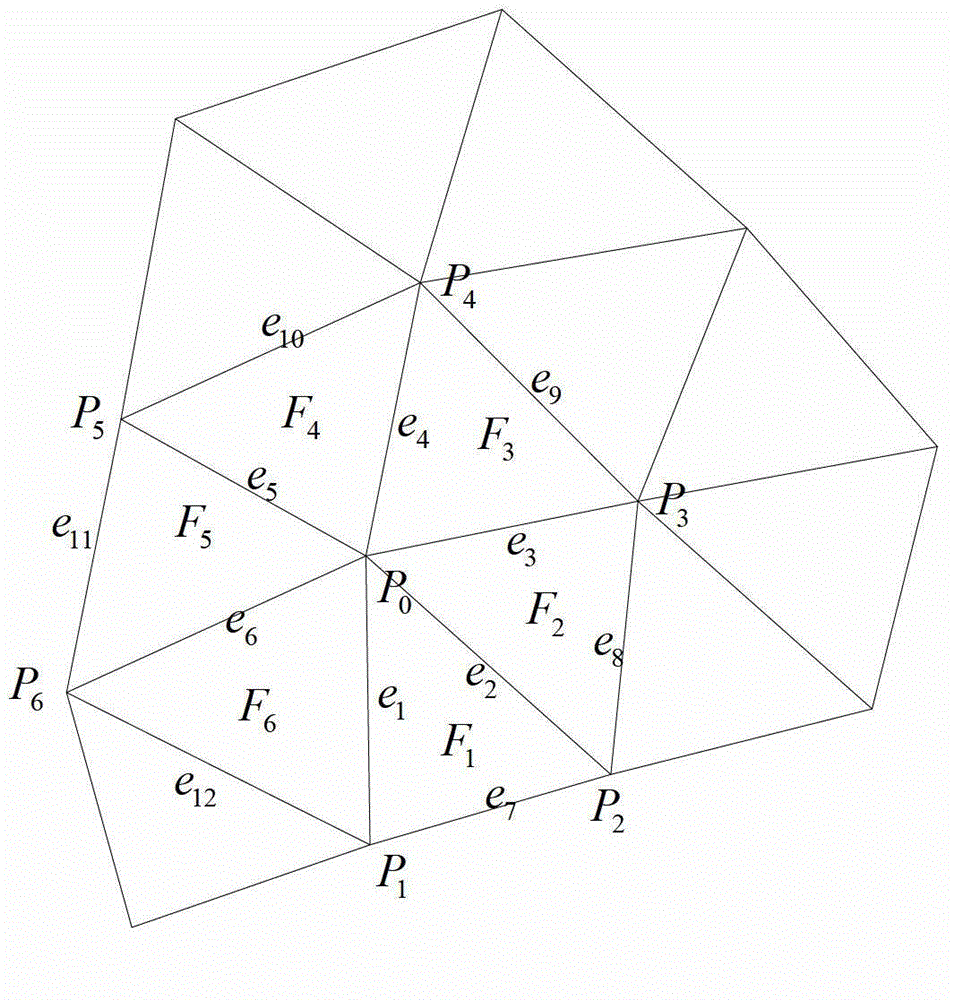

Laying spreading method for composite material

InactiveCN102867082AExpand quickly and accuratelyPrecise expansionSpecial data processing applicationsTime complexityComputer science

The invention relates to a laying spreading method for a composite material. The method is technically characterized in that a Tchebychev Net model is combined with a spring model, so that the composite material can be quickly and accurately spread on a complex curved surface, and a simulation result is more accurate than that of the conventional geometrical spreading method; a local searching algorithm is adopted for node scanning, so that time complexity is lowered into a constant; and an expanding node laying method is adopted, so that a laying blank area generated by a dual-baseline method is eliminated.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

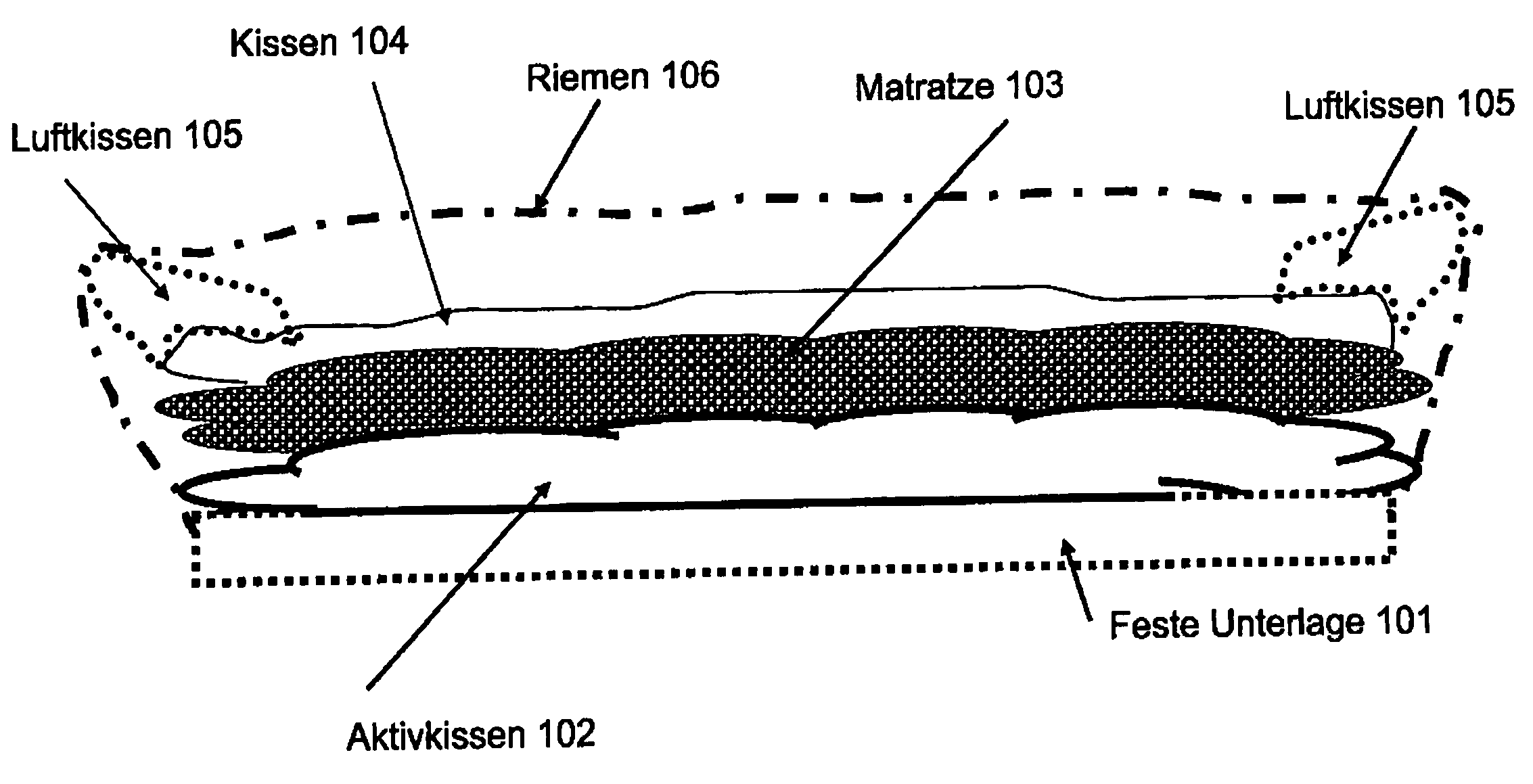

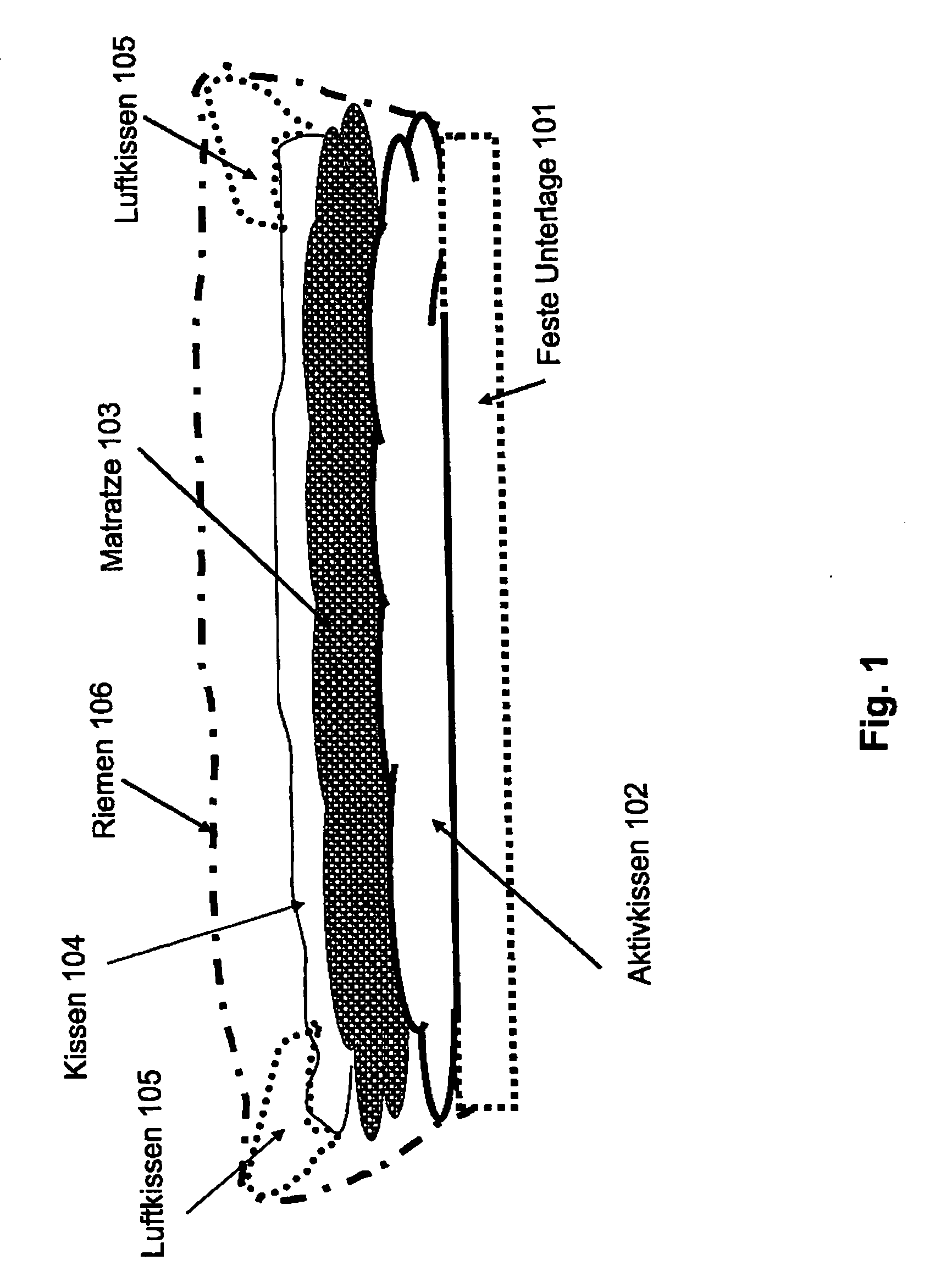

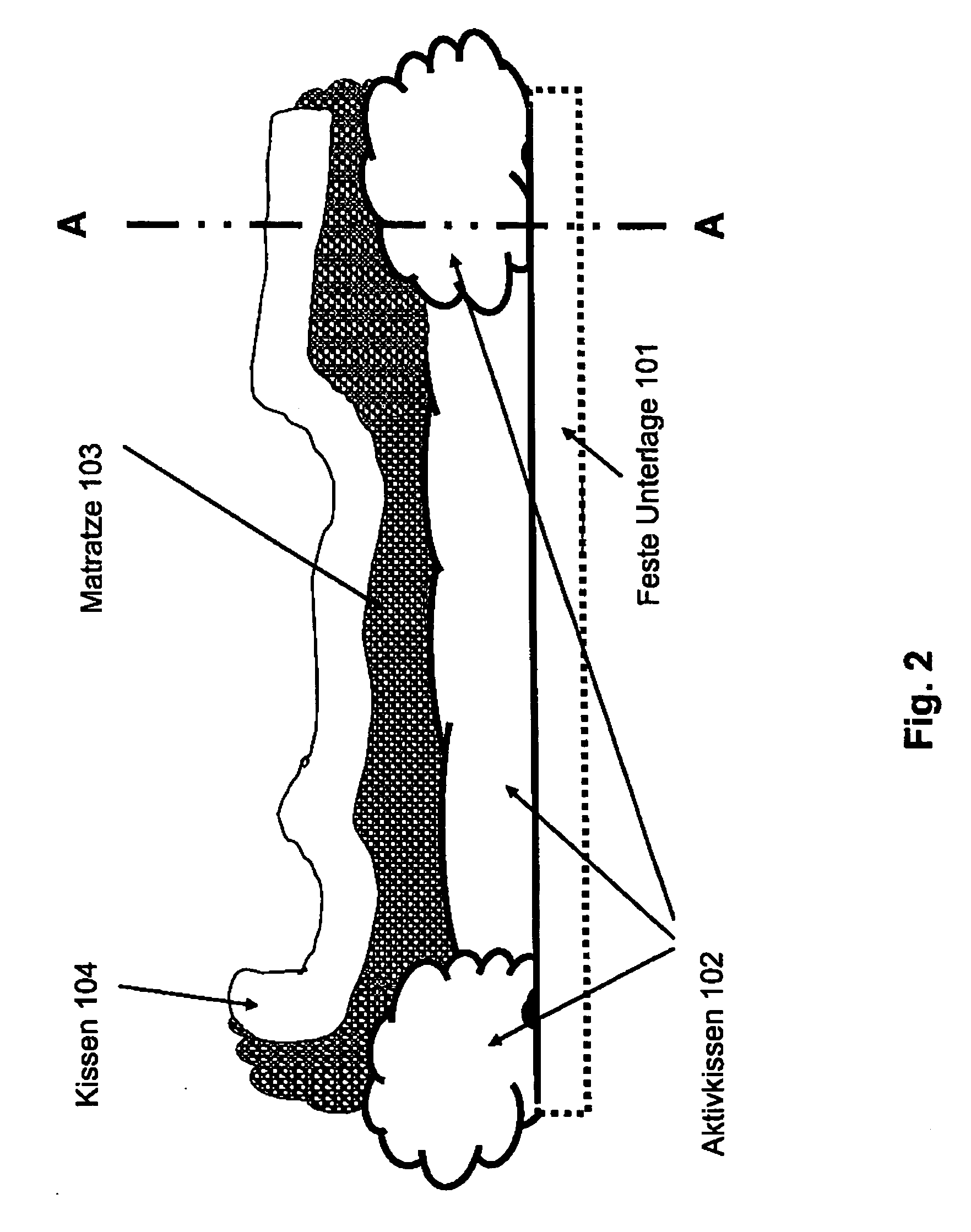

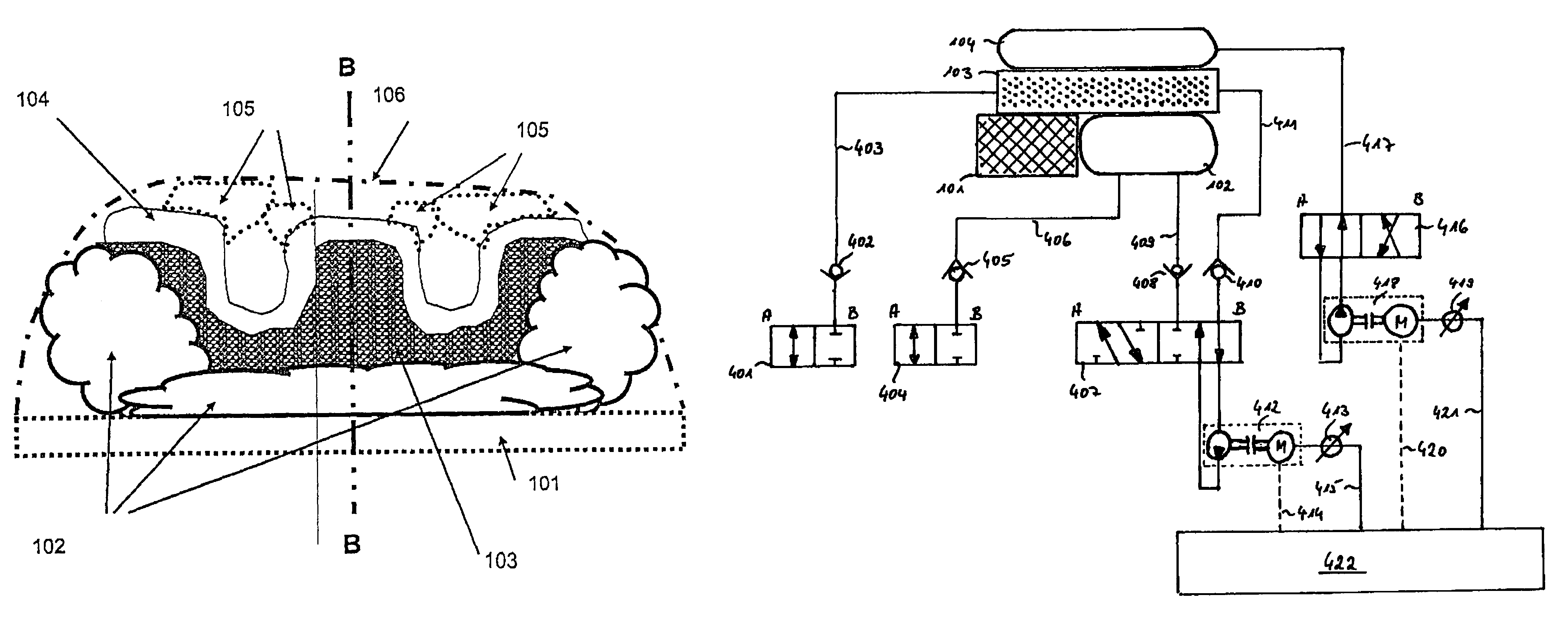

Device and method for carefully settling a patient in a defined position

InactiveUS20080313816A1Easy to usePrecise expansionStuffed mattressesSpring mattressesPhysical medicine and rehabilitationControl signal

The invention relates to a device and a method for the gentle placement of a patient in a defined position. In order to provide a device for the placement of patients which both allows gentle positioning and at the same time holds the patient in a defined position, the device according to the invention comprises a mattress having a surface able to adopt a flexible state, as a result of being subjected to a first control signal, and a rigid state, as a result of being subjected to a second control signal, a cushion which is filled with a fluid, rests on the mattress and comprises a flexible wall in the region of the patient or the body part of the patient resting on the cushion, and a fluid pump which is connected via a valve to the fluid in the cushion and via which the internal pressure and / or the internal volume of the cushion may be adjusted to a predetermined value.

Owner:BOHM STEPHAN +2

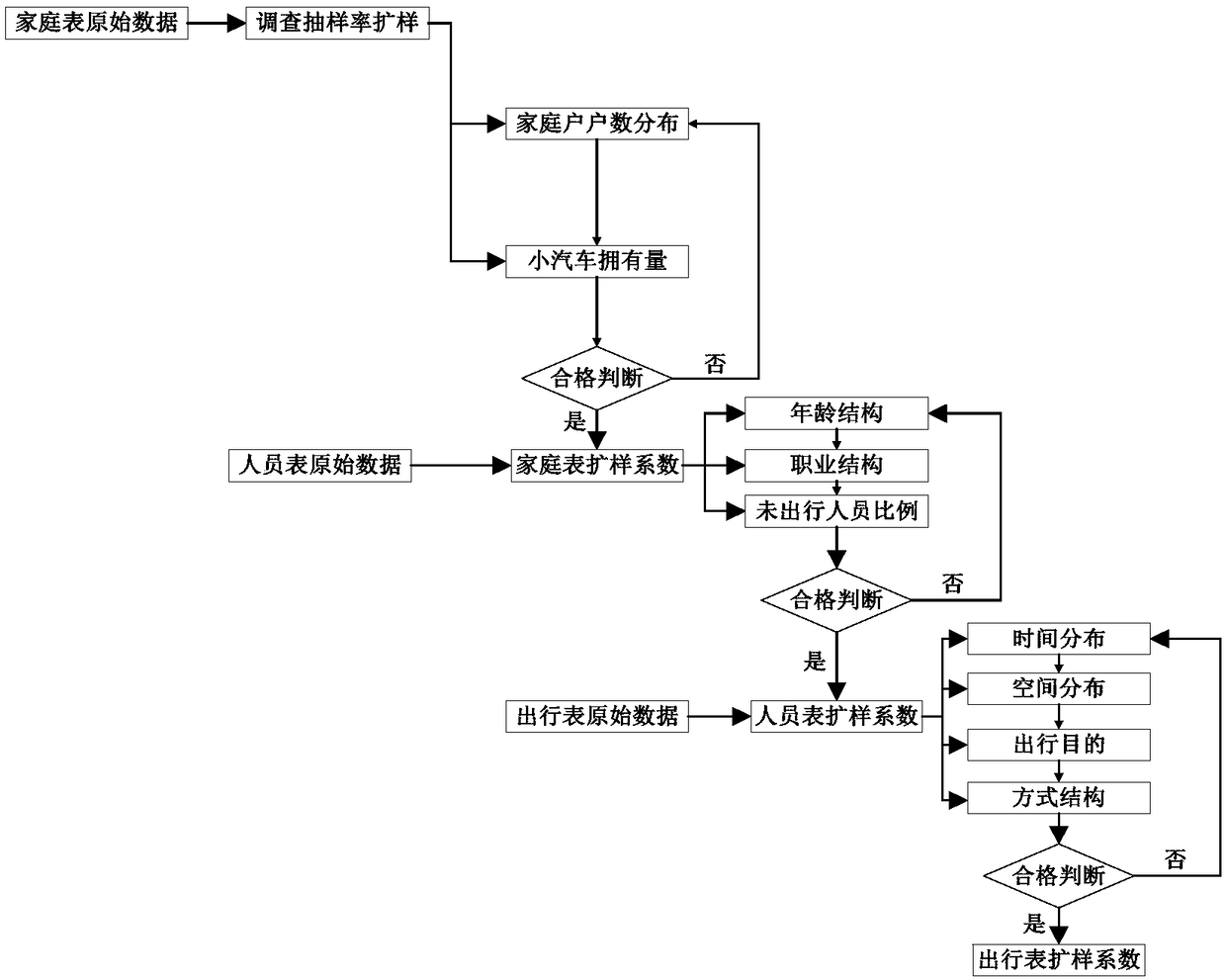

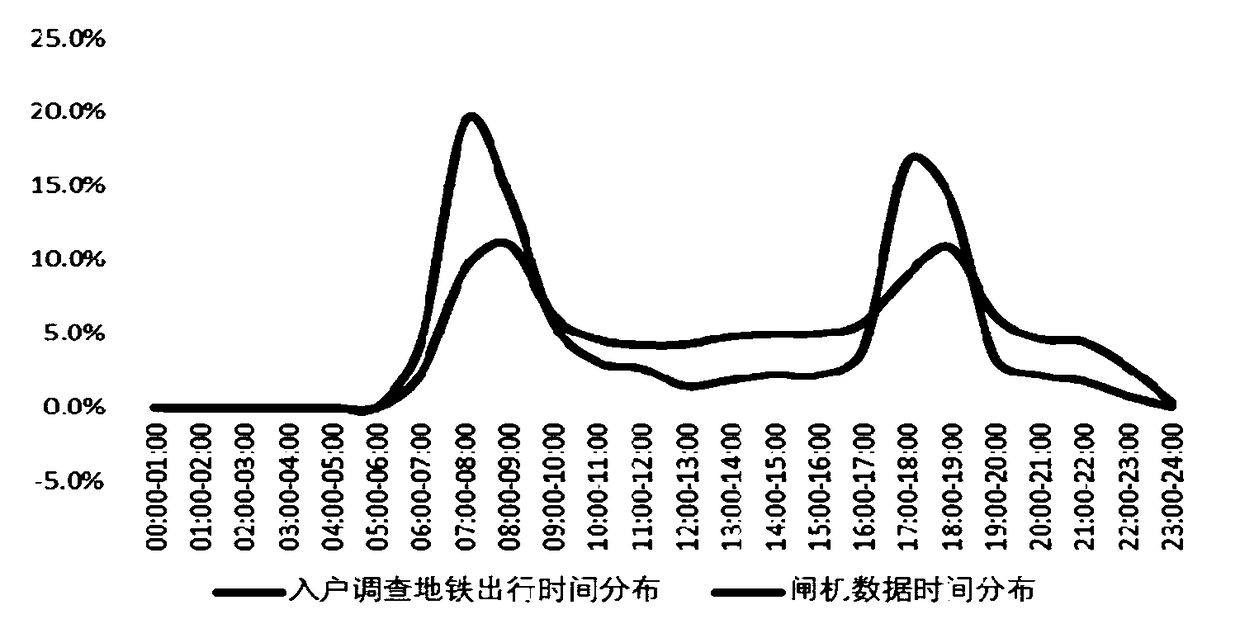

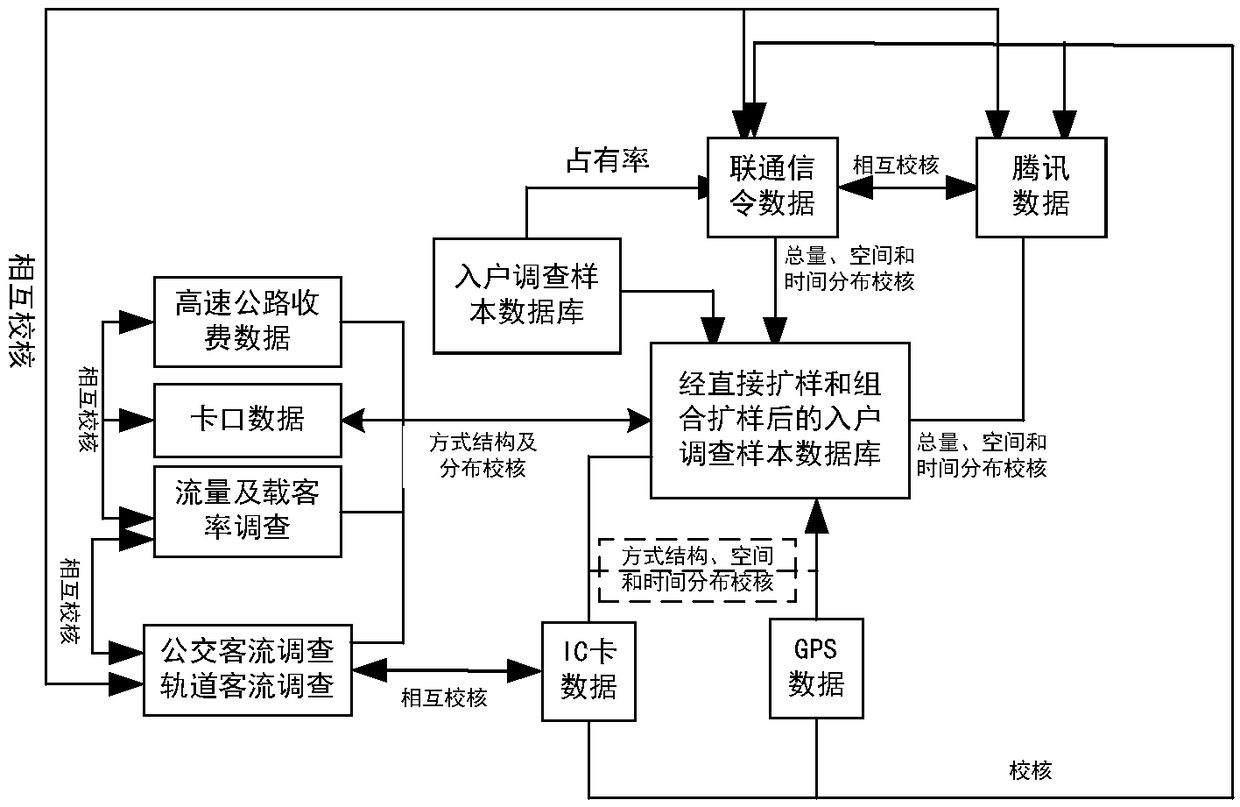

Resident travel survey comprehensive sample expanding and checking method based on combination of big data and traditional method

InactiveCN108629972ARestoring travel characteristicsConducive to mining silent travelDetection of traffic movementSpecial data processing applicationsTravel surveyFull sample

The invention provides a resident travel survey comprehensive sample expanding and checking method based on the combination of big data and a traditional method. The method comprises the following steps: step 1, carrying out overall preliminary checking work by utilizing multi-source big data; step 2, carrying out the classified checking operation: carrying out the classified checking operation onpreliminarily corrected travel features according to two types of travel features, namely commuting travel and non-commuting travel; step 3, re-correcting the overall constraint: re-correcting the overall constraint of travel data after being subjected to the classified checking operation. According to the invention, based on the large-sample or quasi-full-sample characteristics of multi-source big data, the silent travel can be conveniently excavated, so that most real resident travel characteristics are restored. In addition, the real-time performance and the accuracy of big data are utilized, so that the comprehensive sample expansion of a resident travel survey is more accurate and more timely.

Owner:广州市交通规划研究院

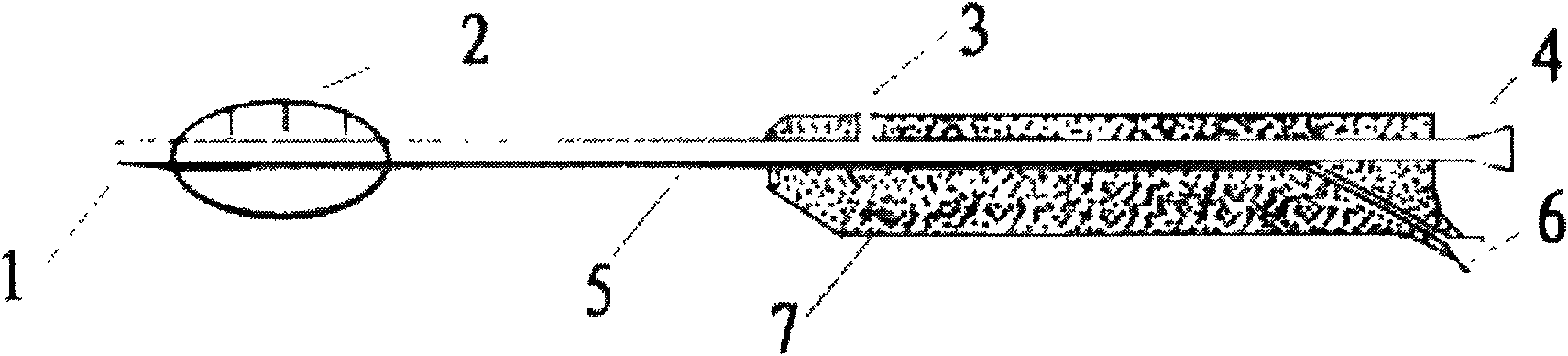

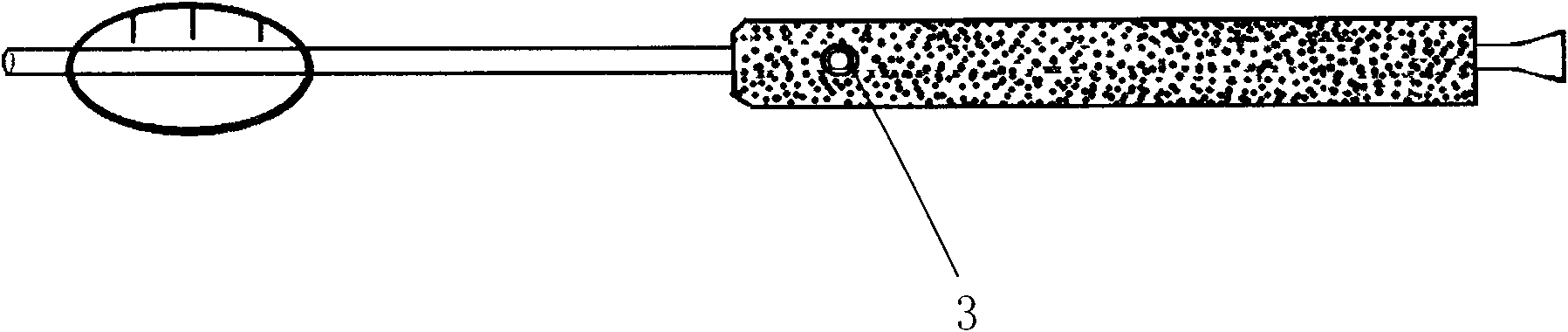

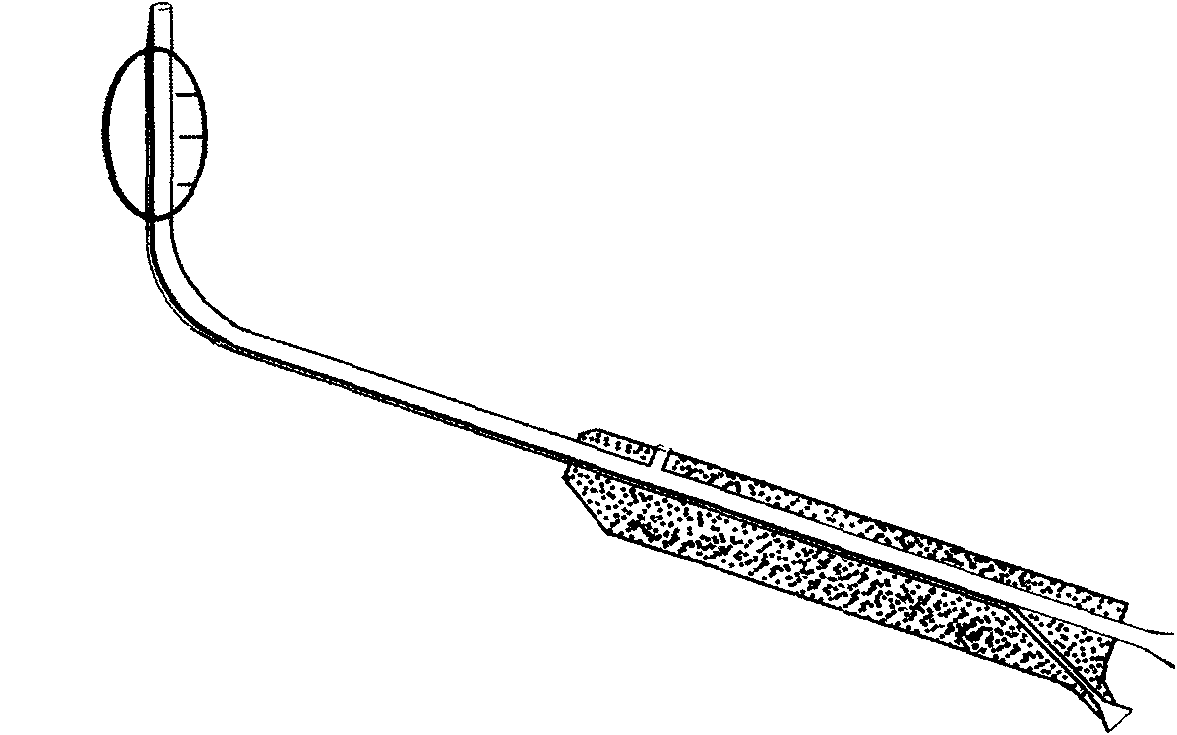

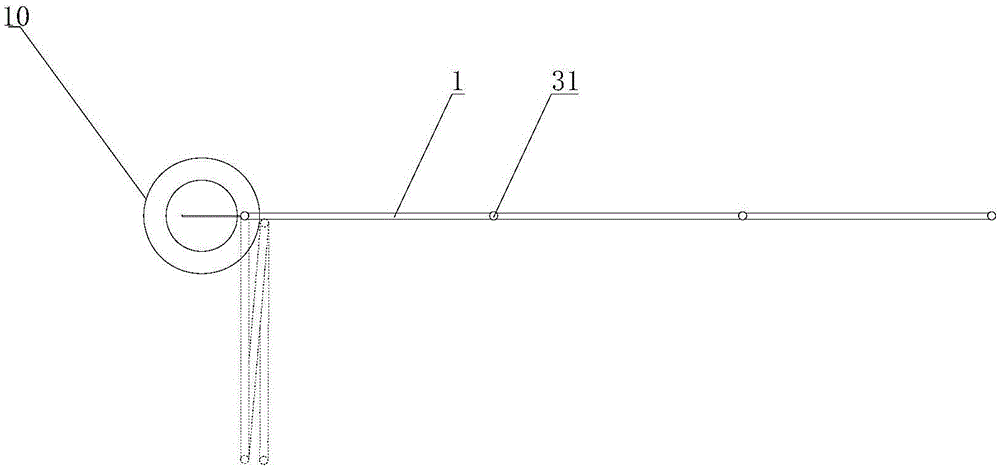

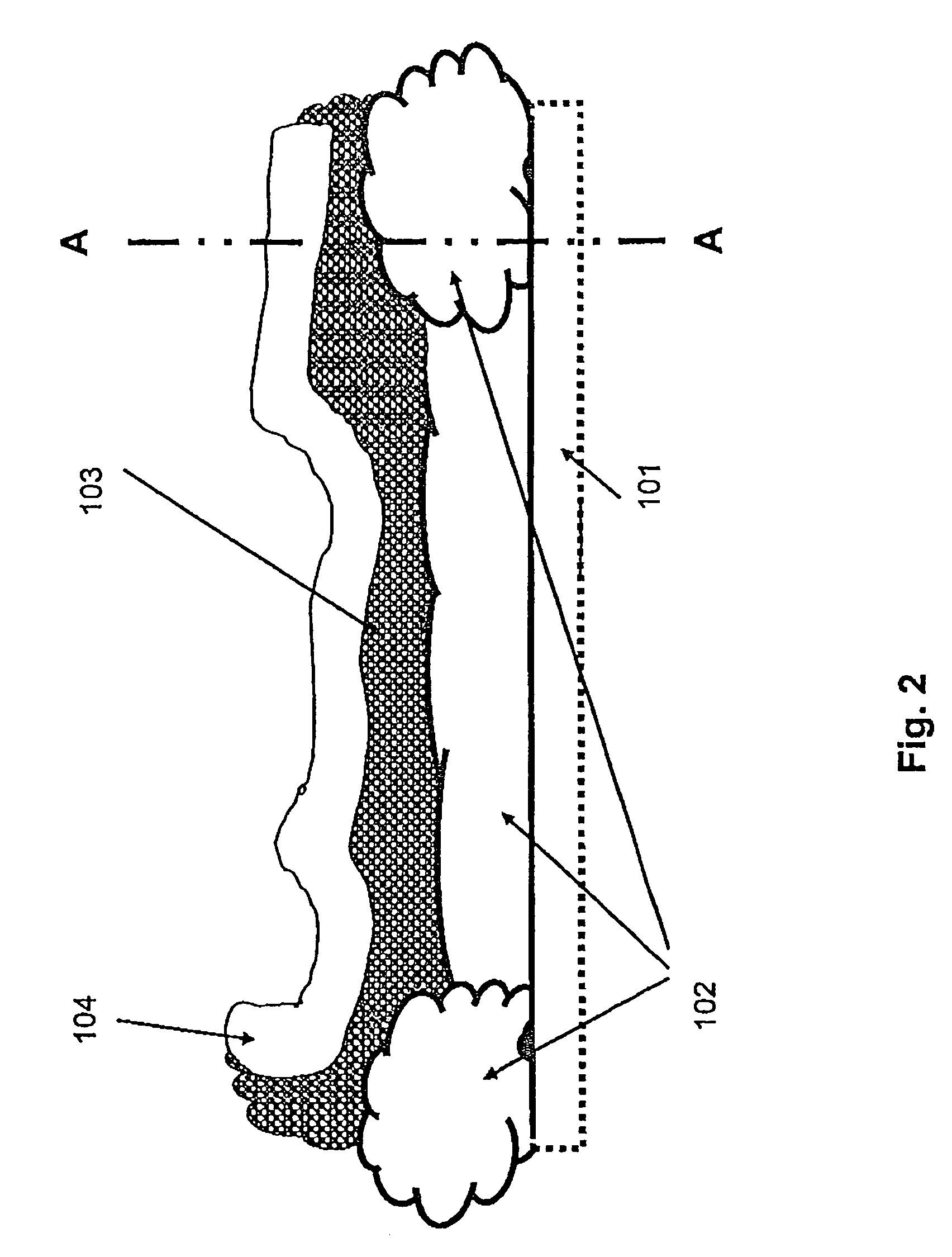

Nasal sinus ball pouch expansion suction tube

The invention discloses a device for expanding natural aditus antrum of nasal sinus in nasal sinus operation, which belongs to the field of medicinal appliance and particularly relates to a catheter having expanding and sucking functions for nasal sinus surgical operation. The catheter is made of hard silica gel material and is an expansion and suction catheter which comprises an air bag, an inflating tube and a suction tube and is applicable to nasal sinus operation in many aspects, wherein the inflating tube is attached on the side wall of the suction tube, and the air bag with scale marks is positioned on the head side of the catheter. An operation handle is arranged on the tail side of the catheter. The catheter can be positioned under a nasal endoscopic and directly inserted into the natural aditus antrum of nasal sinus. The structure of the catheter is simple and the operation of the catheter is convenient. The catheter can accurately expand the aditus antrum of nasal sinus and lays a foundation for the implementation of the operation.

Owner:田永胜

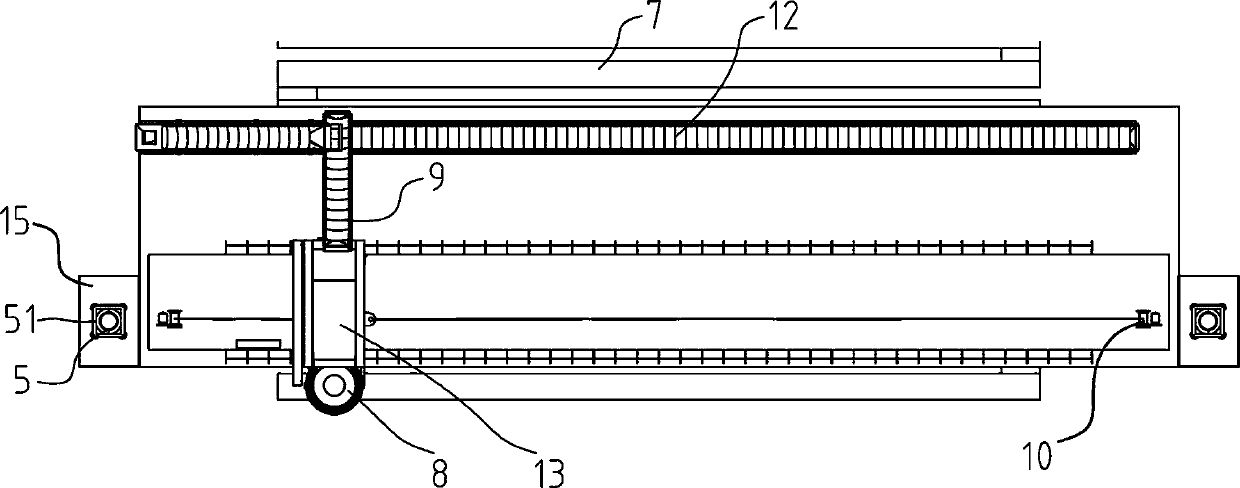

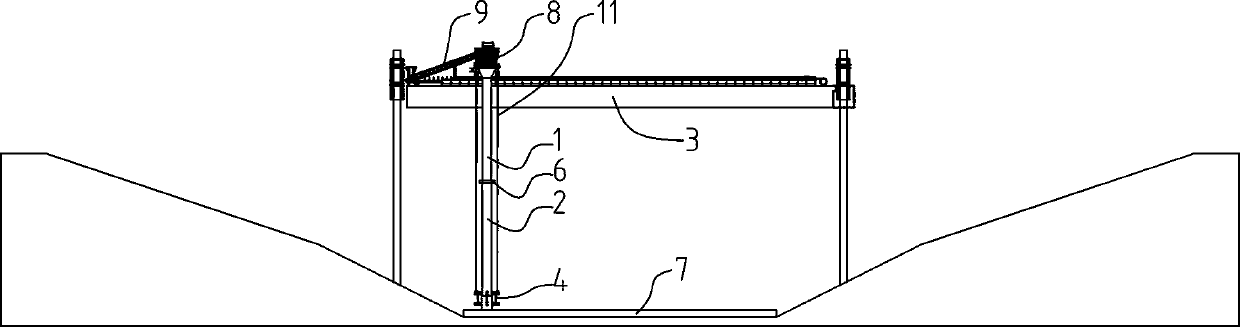

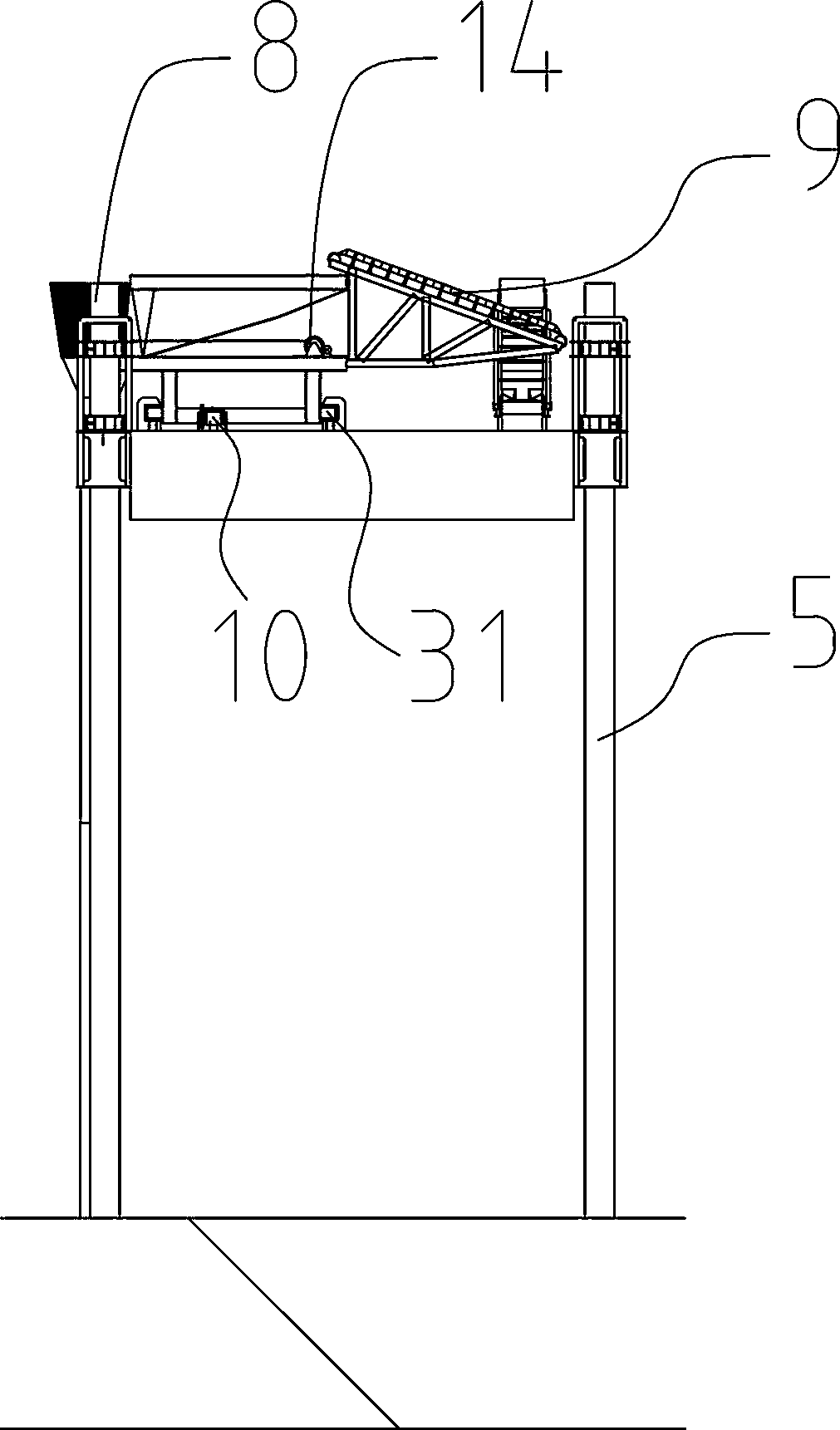

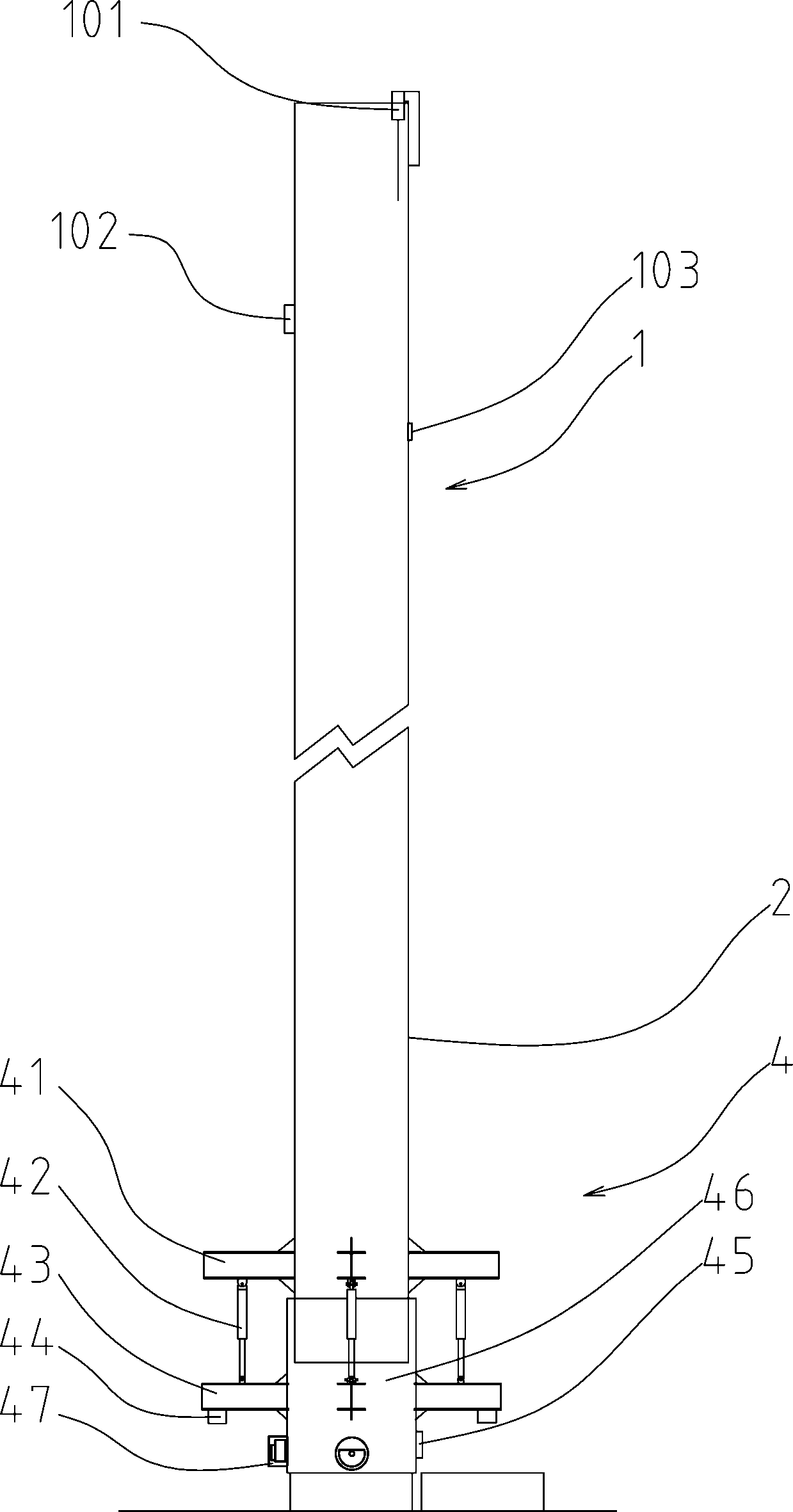

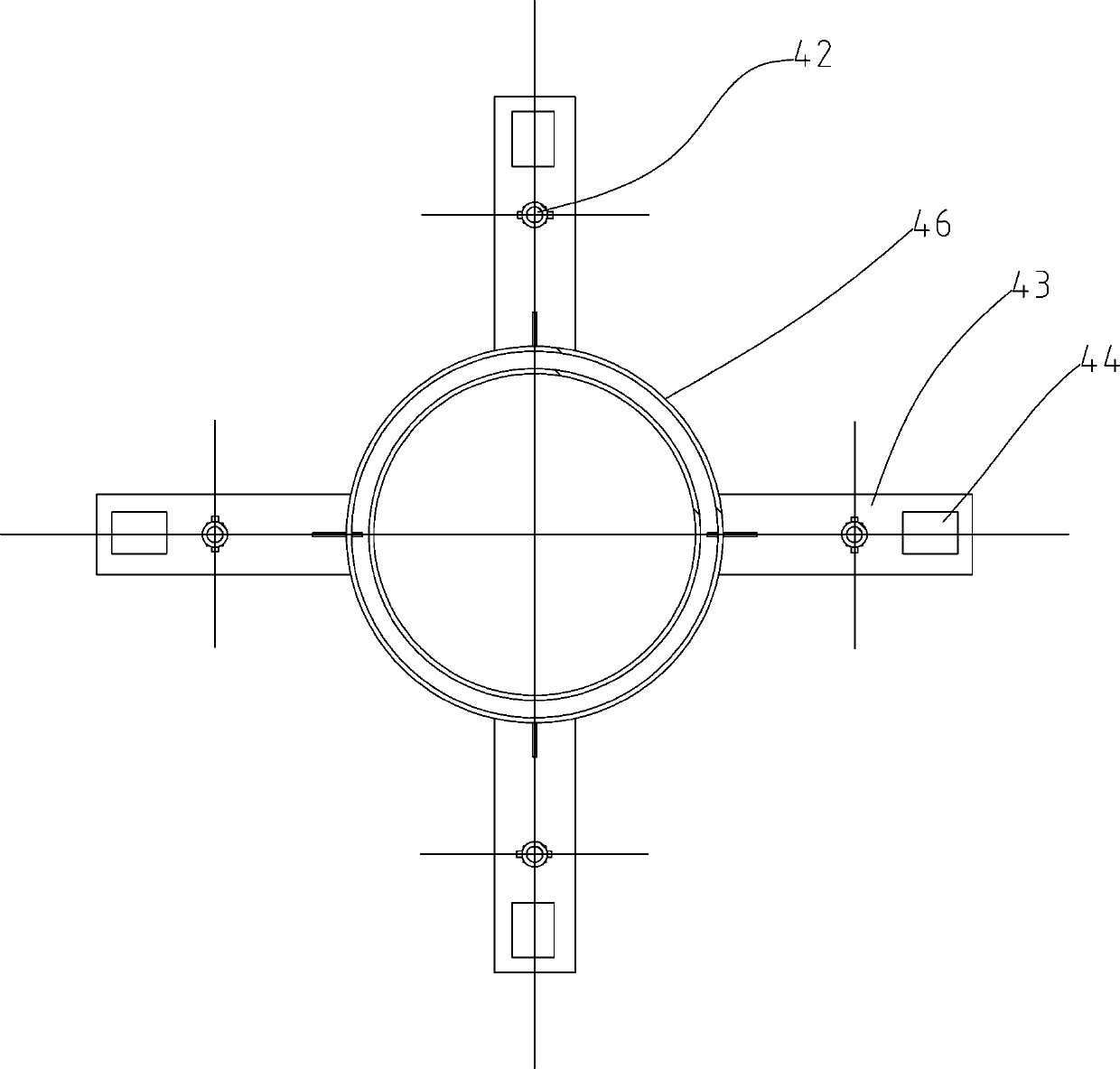

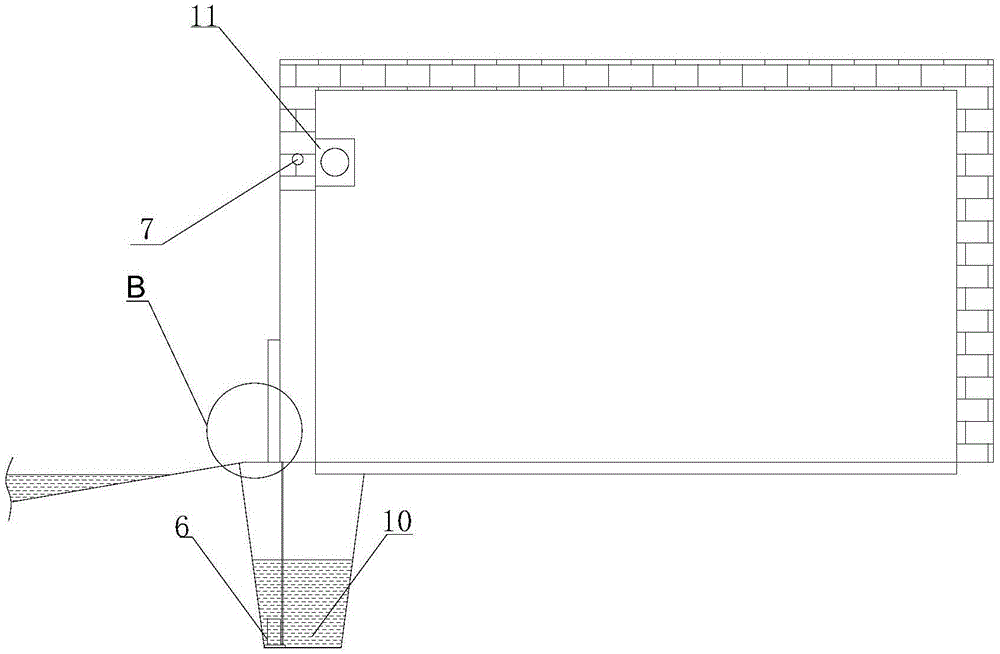

Floating-type underwater gravel base bed continuous leveling ship

PendingCN109898514AAdjustable lengthPrecise thickness controlWaterborne vesselsFoundation engineeringSternBuilding construction

The invention provides a floating-type underwater gravel base bed continuous leveling ship, which comprises a hull. Lifting positioning piles are arranged at a bow and a stern of the hull and slidablyconnected with the hull; a conveying trolley is further arranged and driven by a driving device to slide in the length direction of the hull, an articulated chute is arranged on the conveying trolley, a material feeding opening is formed in the top end of the articulated chute, and the bottom end of the articulated chute is close to the water bottom; and one or more conveying belts for supplyingmaterials to the conveying trolley are further arranged. By adopting the scheme that the positioning piles and the hull are slidably connected in the horizontal direction, after riprapping construction is completed in an area, precisely guided continuous moving can be achieved by moving the positioning piles and the hull in a reciprocating mode, thus the situation that the hull needs to be re-positioned every time when the hull is moved is avoided, and high-precision and continuous Z-shaped riprapping paving construction is achieved through the articulated chute.

Owner:CCCC SECOND HARBOR ENG

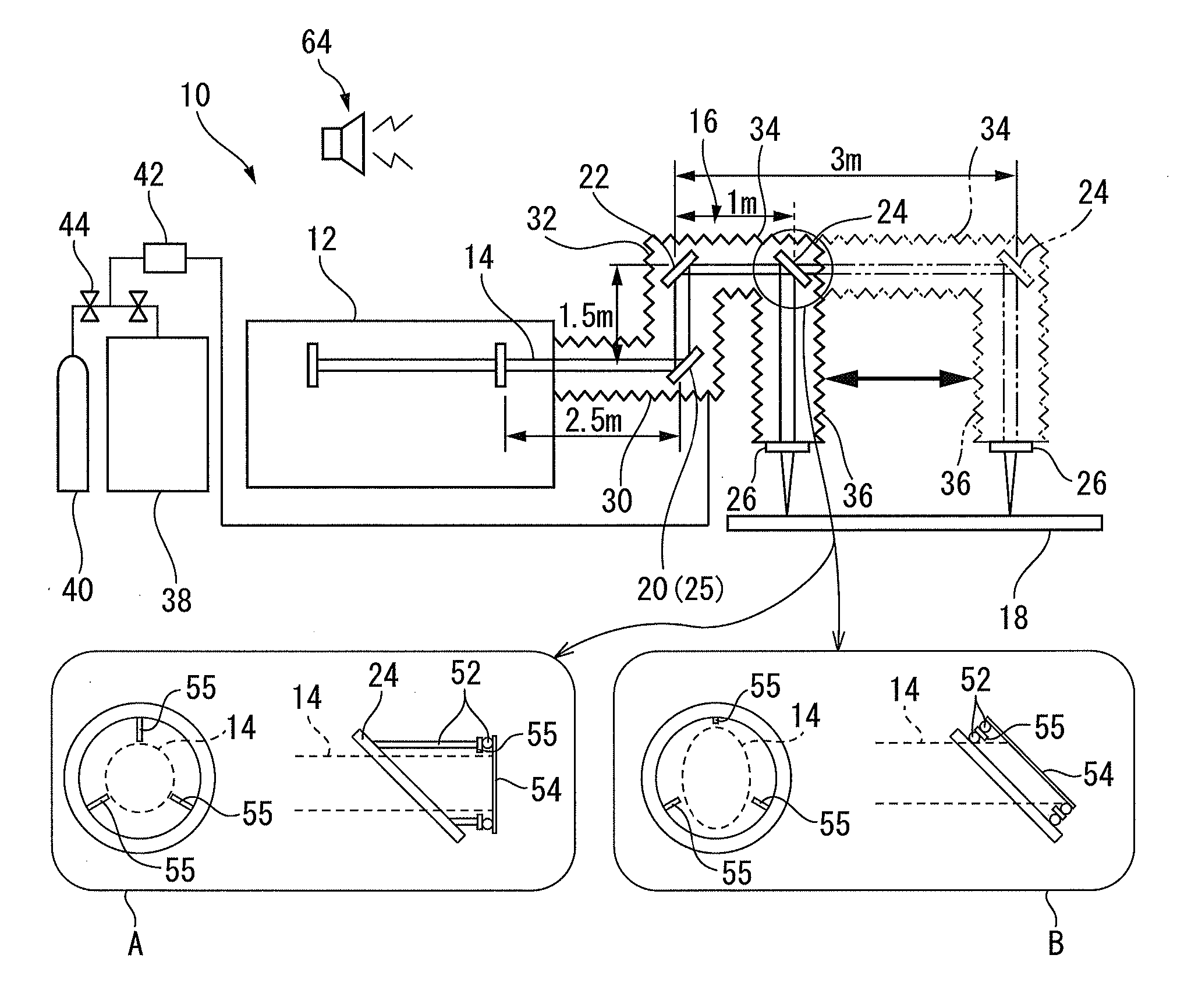

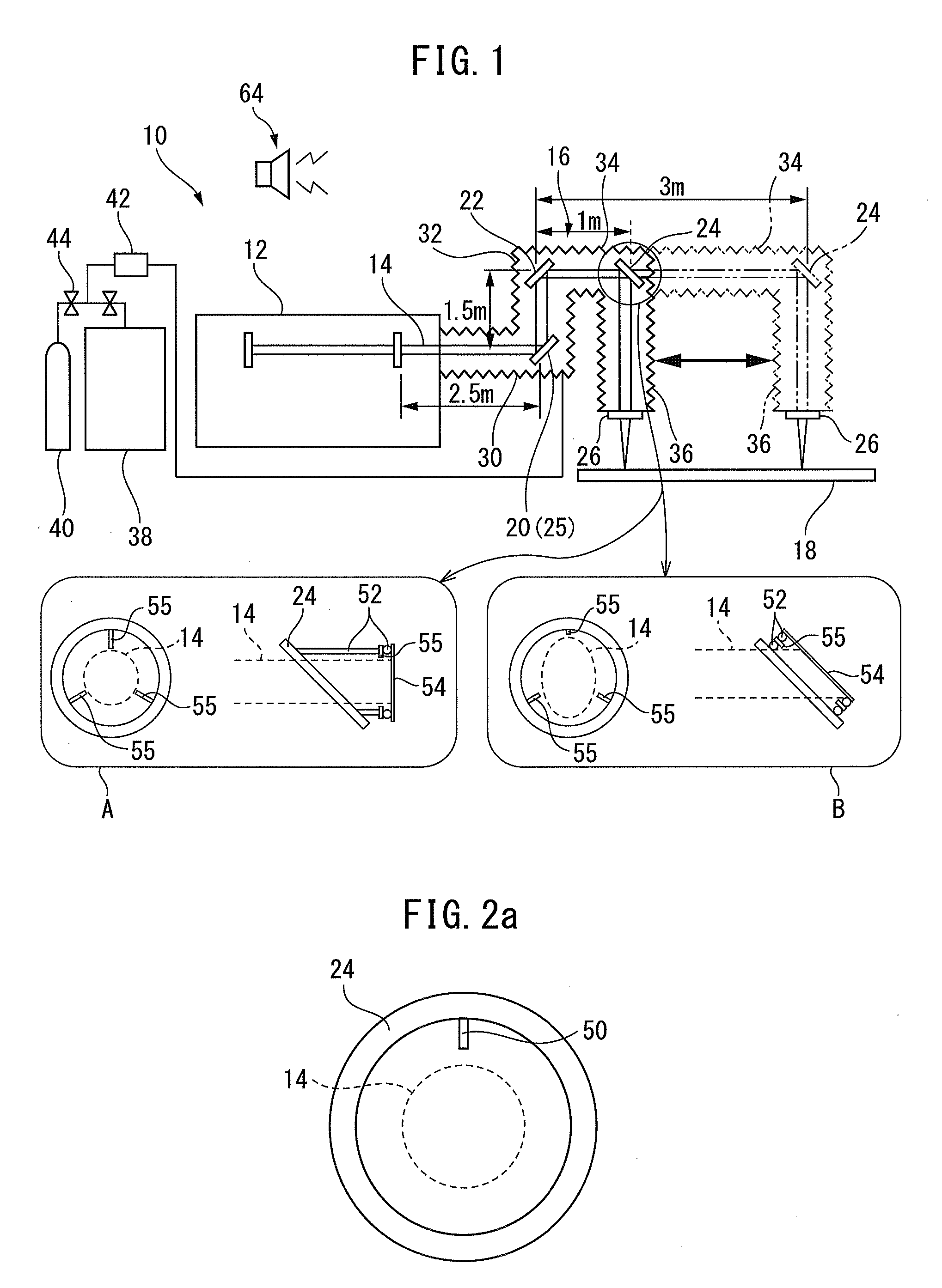

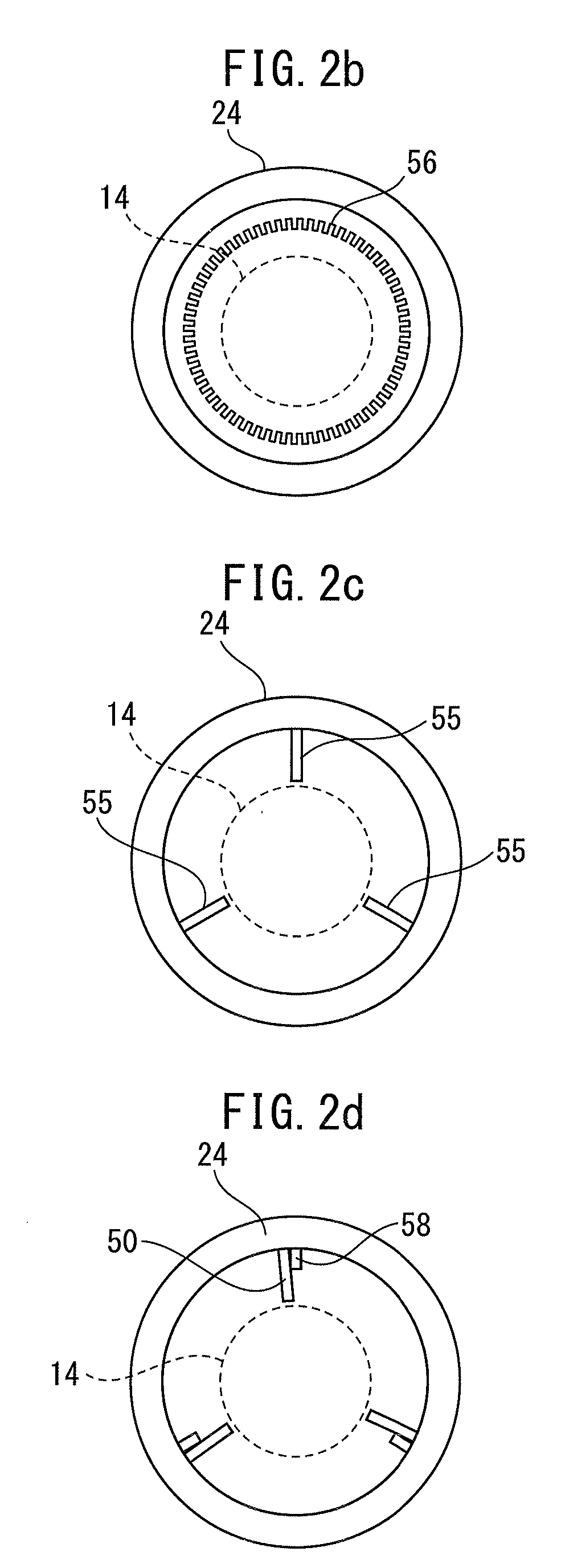

Laser processing device having function for monitoring propagation of laser beam

InactiveUS20150268040A1Simple structurePrecise expansionUsing optical meansLaser beam welding apparatusLaser processingLight beam

A laser processing device having a simple structure and a means for accurately detecting expansion and misalignment of a laser beam. A sensor, which receives the laser beam after transmitting through a half mirror, is arranged on a back surface of the half mirror opposed to a front surface which reflects the laser beam. The sensor is positioned via a heat insulating material between the back surface of the half mirror and a shield plate for shielding or absorbing the laser beam after transmitting through the half mirror, so that the sensor is thermally-independent from the other components. The sensor is positioned so that the sensor does not receive the laser beam after transmitting through the half mirror in the normal state, and so that the sensor directly receives the laser beam after transmitting through the half mirror when the laser beam is expanded or misaligned.

Owner:FANUC LTD

Space cam-spiral combined repeated folding and unlocking mechanism

The invention relates to a space cam-screw combined type repeatedly folding-unfolding unlocking mechanism. An existing folding wing only has a one-off unfolding locking function so as to not repeatedly fold and unfold. According to the space cam-screw combined type repeatedly folding-unfolding unlocking mechanism disclosed by the invention, a design idea in combination with a space cam mechanism and a screw mechanism is adopted so that the rotation of a motor is converted into a linear motion of a cylindrical cam along a guide rail through a screw pair; furthermore, a driven pin is driven by the cylindrical cam to move along a cam channel so that the folding wing is repeatedly folded and unfolded; and moreover, an unlocking pin on the cam and a pin hole of the folding wing are used for entering and separating to unlock and lock the folding wing. The driven pin on the folding wing ensures that the redundancy in finally folding and unfolding positions is reliably positioned. According to the space cam-screw combined type repeatedly folding-unfolding unlocking mechanism disclosed by the invention, an enveloping space of the folding wing is minimized, the structure is compact, and thefolding wing is easy to fold, unfold, unlock and lock with high precision and high reliability.

Owner:ZHEJIANG SCI-TECH UNIV

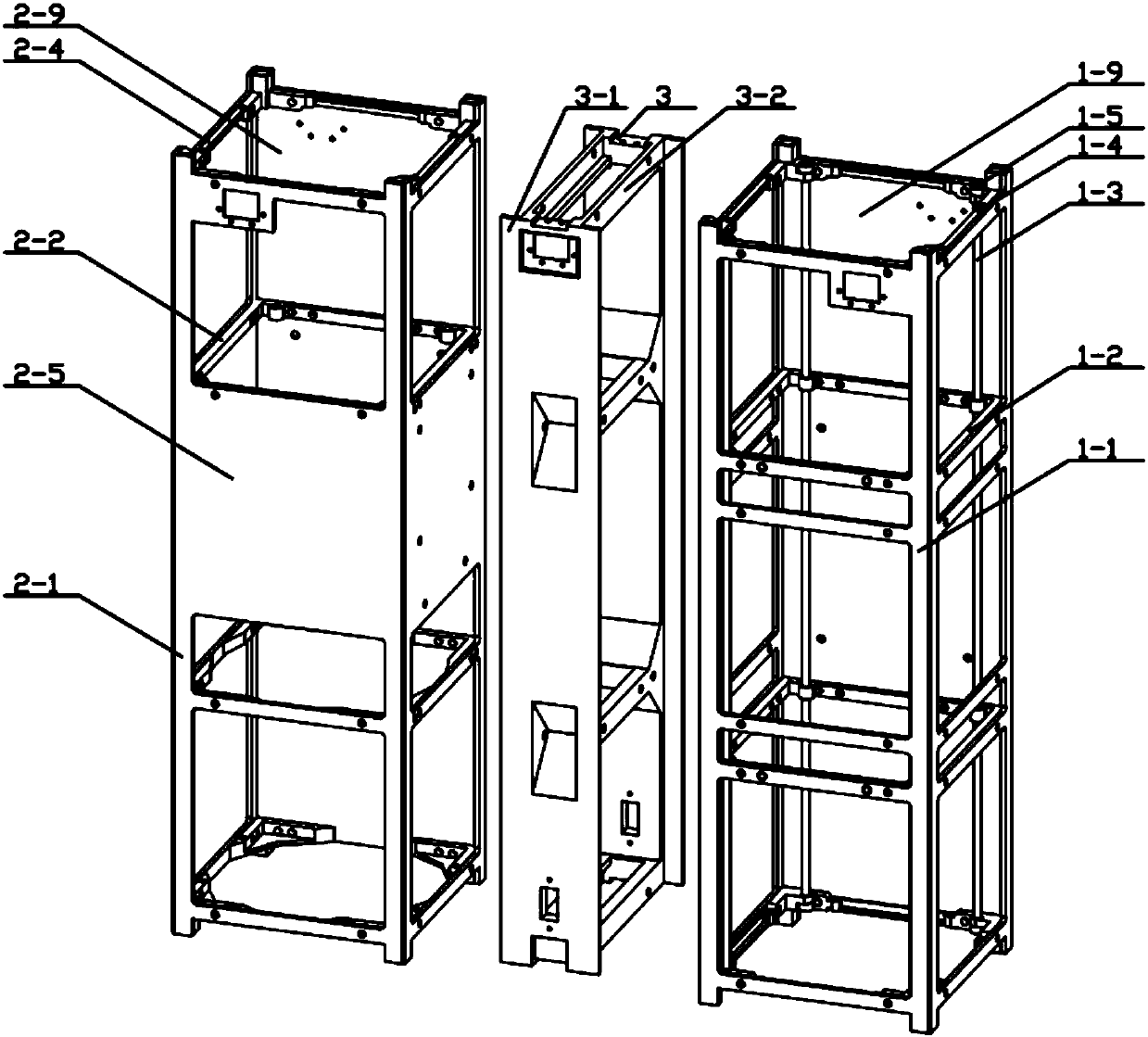

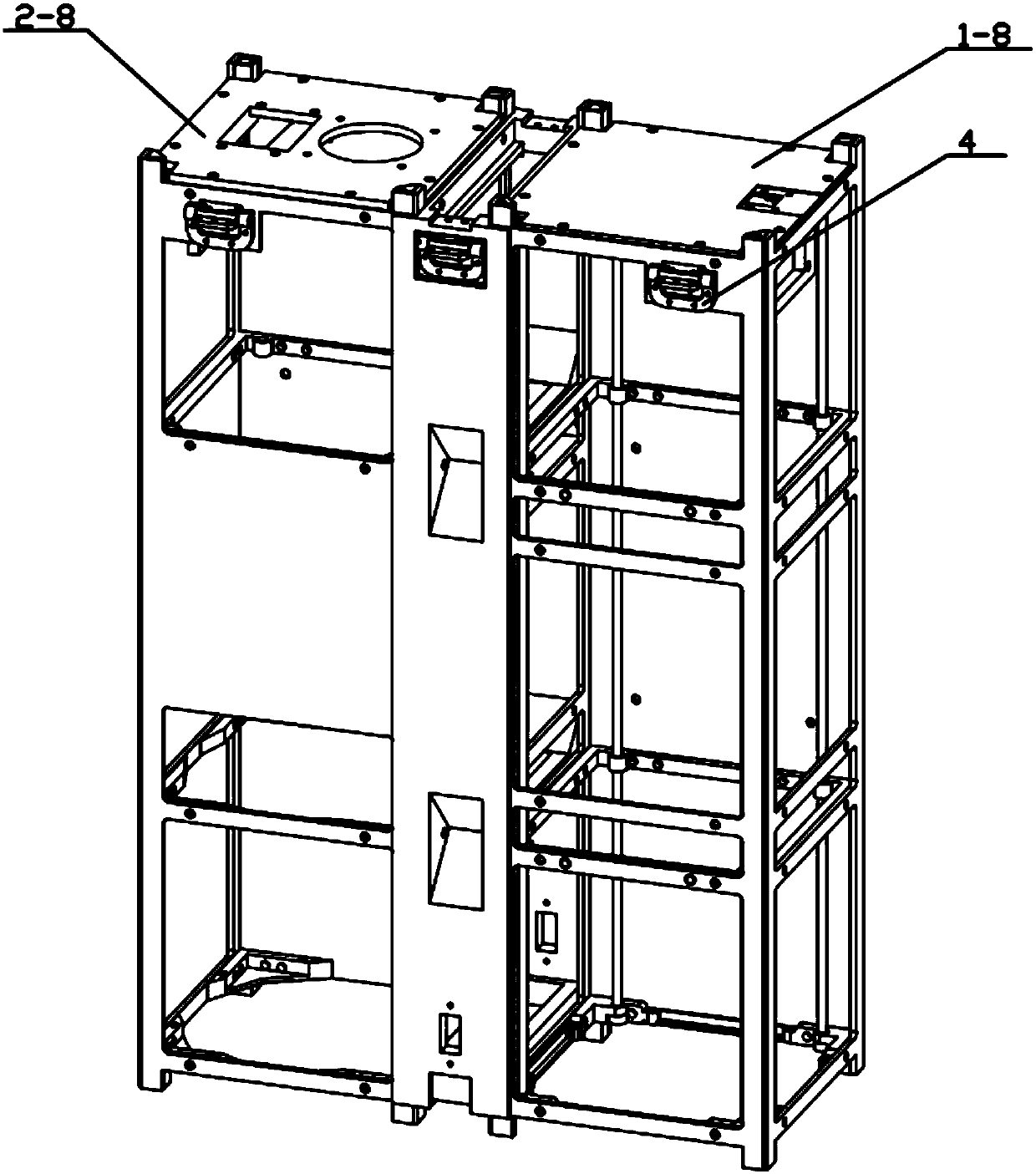

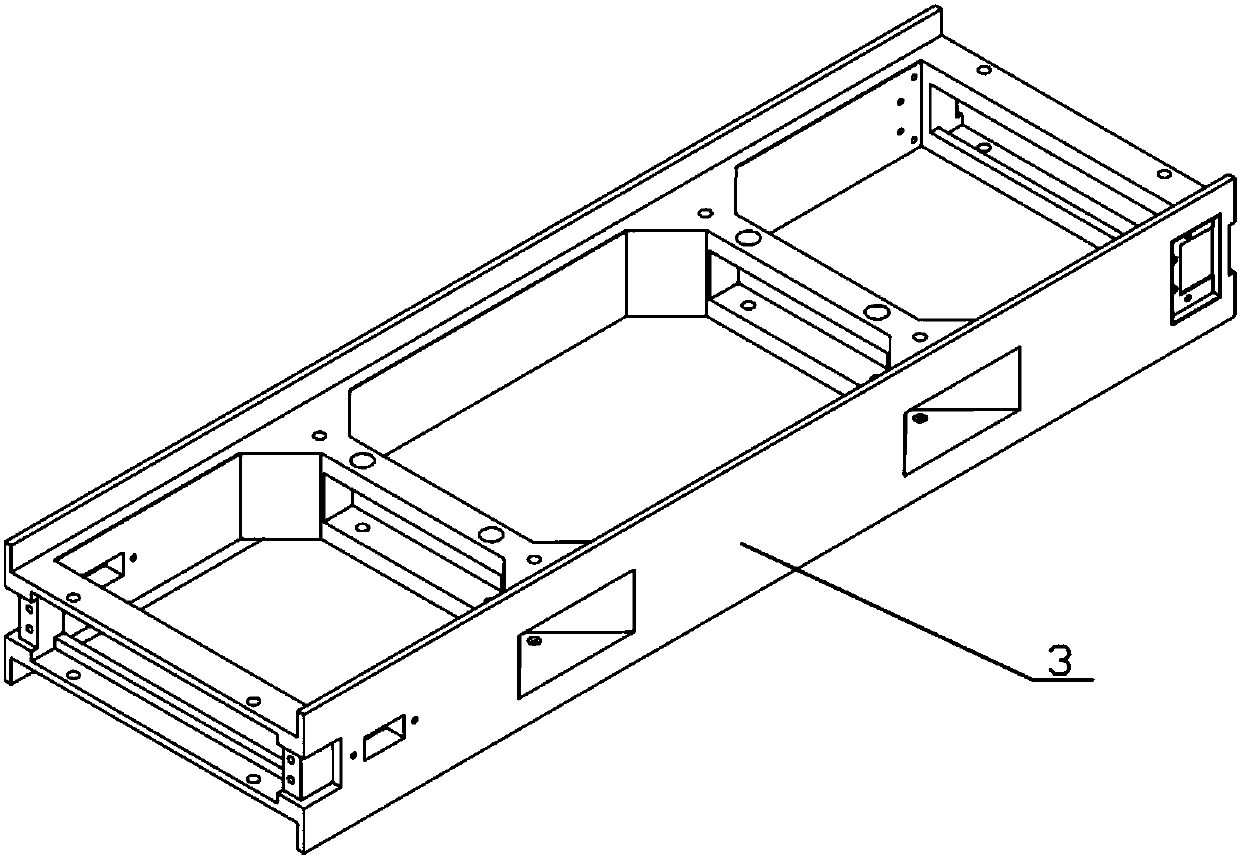

Six-unit cubesat main force bearing structure

PendingCN107902107AGuaranteed parallelismSuccessful launchArtificial satellitesStructural engineeringRocket

The invention discloses a six-unit cubesat main force bearing structure. The six-unit cubesat main force bearing structure is formed by means of the method that two three-unit cubesat main frames cooperate with each other through a connecting frame. The main frames are each of a cuboid frame structure, end covers are arranged at the two ends of each main frame in the direction of the long edge, and middle frameworks are arranged in the middles of the main frames. Four screws are arranged in each main frame and penetrate through the corresponding middle framework to be fixed to the end covers of the two ends of the corresponding main frame, and six hinges are arranged on the connecting frame and the two main frames. The assembly difficulty of a cubesat is lowered, and the integrity of innerlayout is improved. According to the six-unit cubesat main force bearing structure, the main frames are of an integrated structure and connected through the connecting frame making contact with the main frames in a large area so that the parallelism between guiding rails can be ensured, the six-unit cubesat main force bearing structure and a cubesat-rocket separating device are not jammed in launching, and successful launching is ensured.

Owner:NANJING UNIV OF SCI & TECH

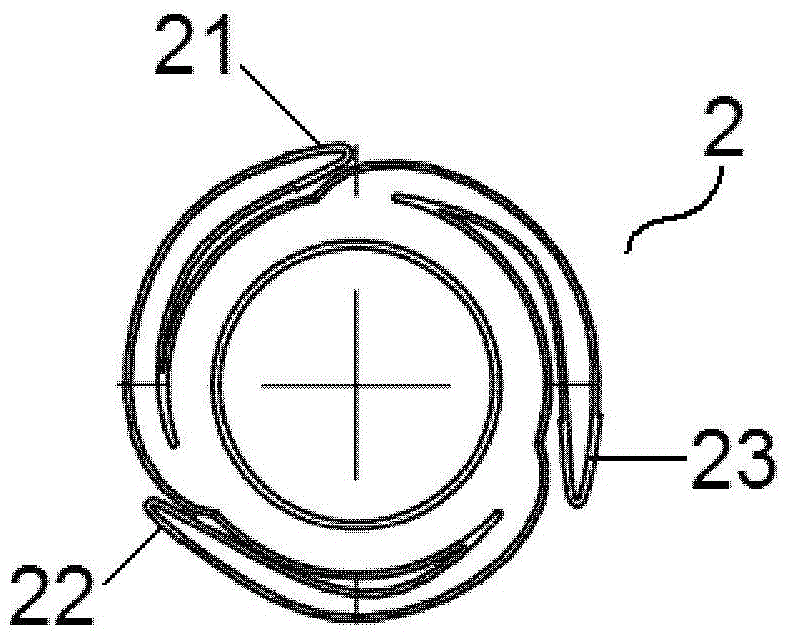

Unfolding method of circular cylinder wall and cylindrical surface during eccentric oblique intersection

InactiveCN103559405APrecise expansionResolve local contactSpecial data processing applicationsTransformerStructural engineering

The invention relates to an unfolding method of a circular cylinder wall and a cylindrical surface during eccentric oblique intersection, and belongs to the technical field of transformer sheet-metal processing. The method adopts the technical scheme that an actual section of the cylinder wall in any unfolding position is a rectangle, and in order to avoid interference of the cylinder wall and the cylindrical surface under ideal assembly, the axial length of the section rectangle of the cylinder wall is required to be reduced, so that the length of the section rectangle is equal to an axial minimum distance from a section coordination edge to a plain end of the cylinder wall. With the adoption of the method, multiple coordinate points can be obtained, and an unfolding curve of coordination ends of the cylinder wall can be drawn by utilizing the obtained points, so that an unfolding diagram of the cylinder wall is drawn. The method has the positive effects that precise unfolding of the circular cylinder wall and the cylindrical surface during the eccentric oblique intersection is realized; the problems that the coordination ends of the cylinder wall are partially contacted during butting, and gaps appear at other parts are solved; welding operation is facilitated; the welding quality is improved; and the actual height of the cylinder wall of an ascending flanged base is ensured.

Owner:BAODING TIANWEI GRP CO LTD

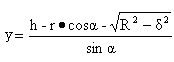

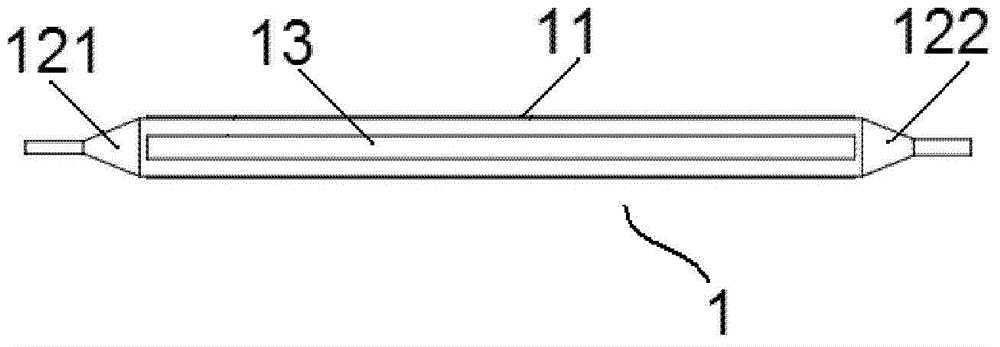

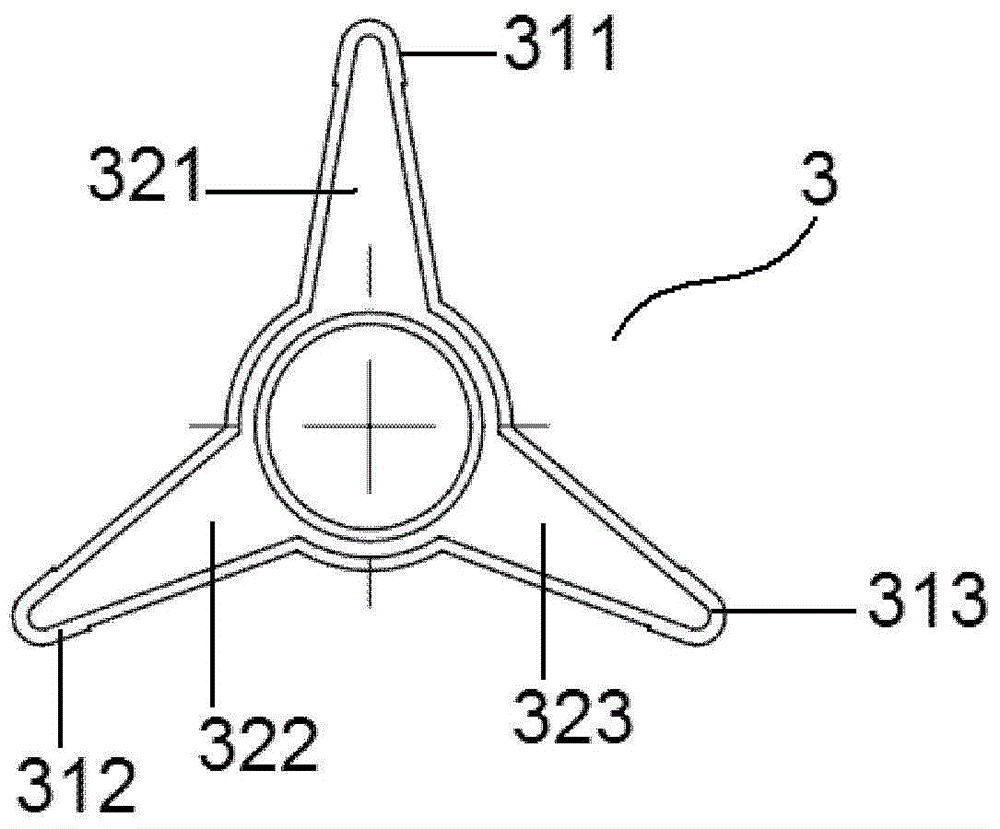

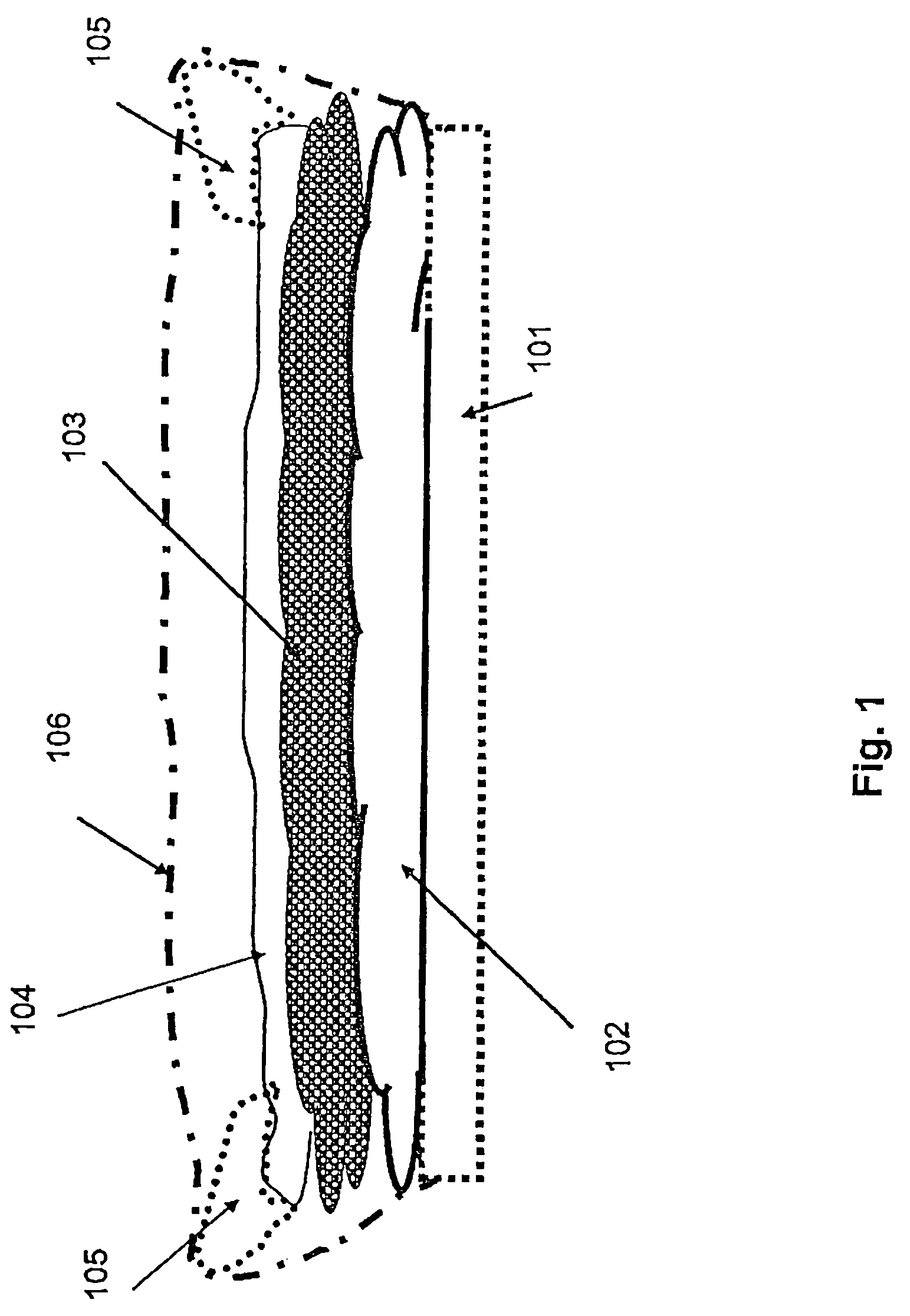

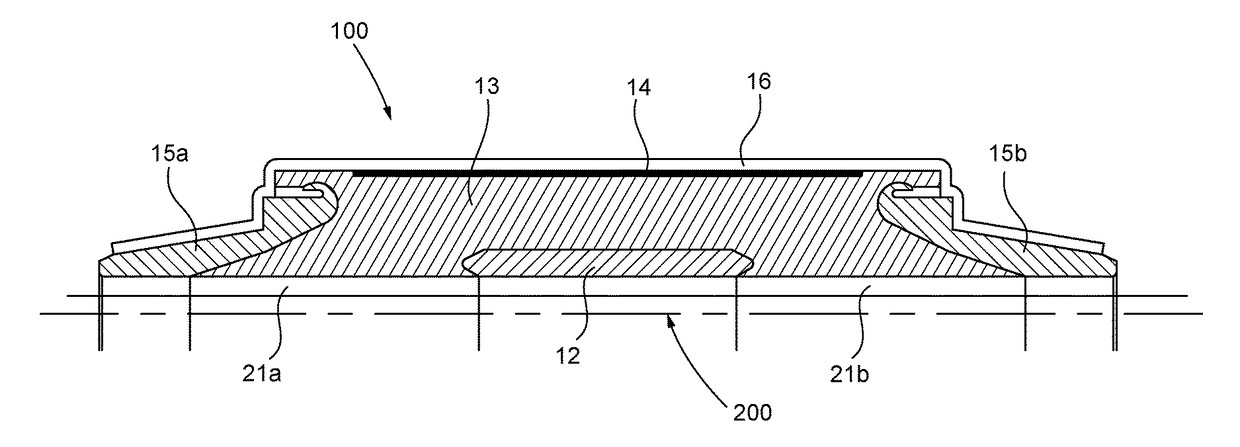

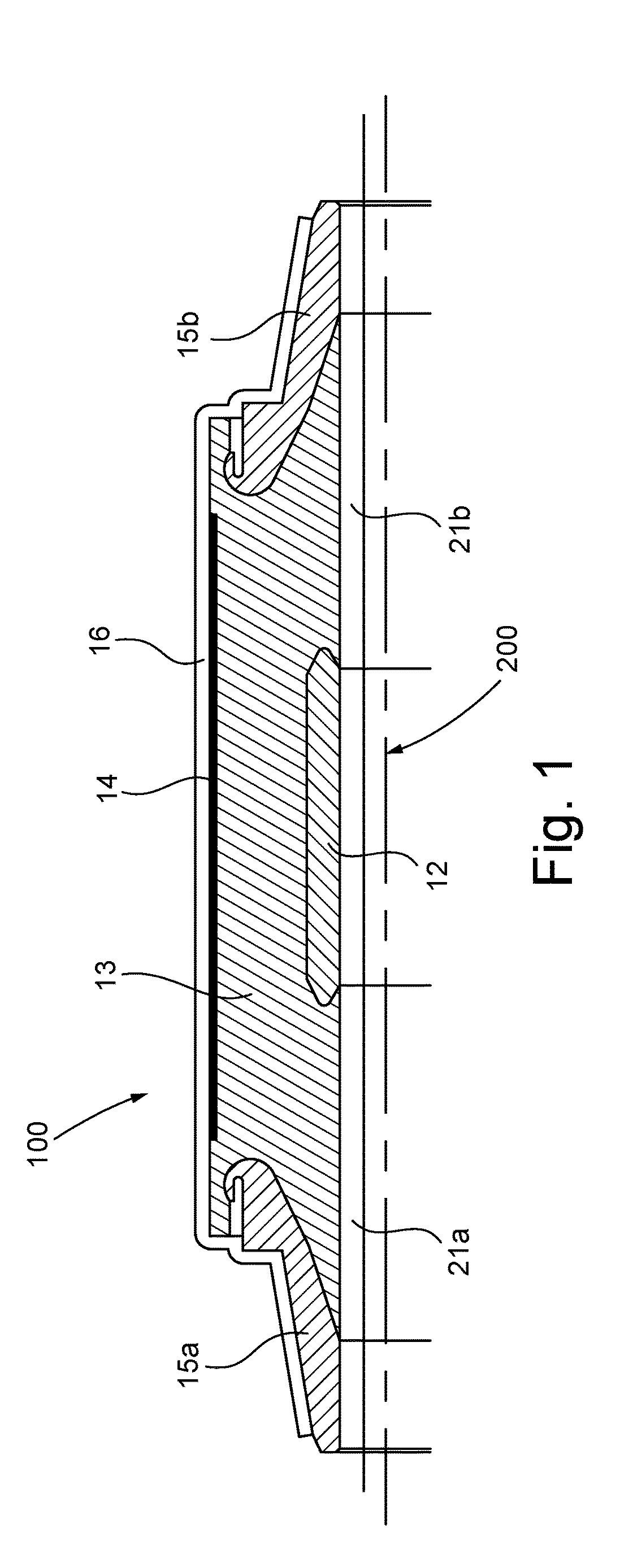

Medical balloon and manufacturing method thereof, balloon dilatation catheter

ActiveCN104645487ASmall Profile DiameterEasy to withdrawBalloon catheterSurgeryBalloon dilatation catheterMedicine

A medical balloon (1; 2; 3; 4; 5) and a manufacturing method therefor. The medical balloon (1; 2; 3; 4; 5) has a relatively small contour diameter after the pressure of the balloon is released, and has a good capability of passing through a diseased region. The medical balloon (1; 2; 3; 4; 5) comprises a balloon conical portion (121, 122) and a balloon straight segment (11). The balloon straight segment (11) is circumferentially provided with multiple raised longitudinal ribs (13; 21, 22, 23; 311, 312, 313; 411, 412; 511, 512, 513) arranged spaced apart from one another. The longitudinal ribs (13; 21, 22, 23; 311, 312, 313; 411, 412; 511, 512, 513) can be formed by coating a strip-shaped coating layer onto the balloon straight segment (11).

Owner:SHANGHAI MICROPORT MEDICAL (GROUP) CO LTD

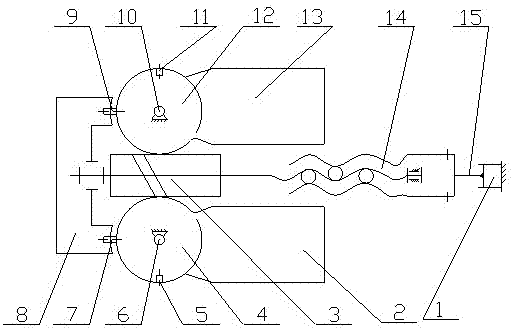

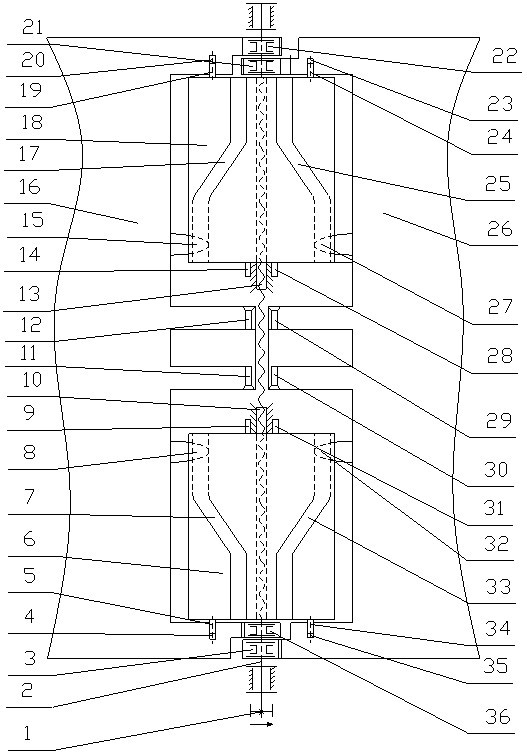

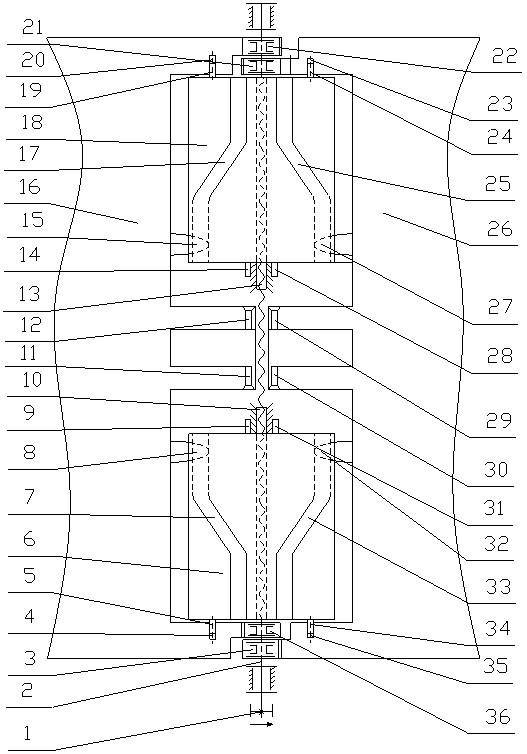

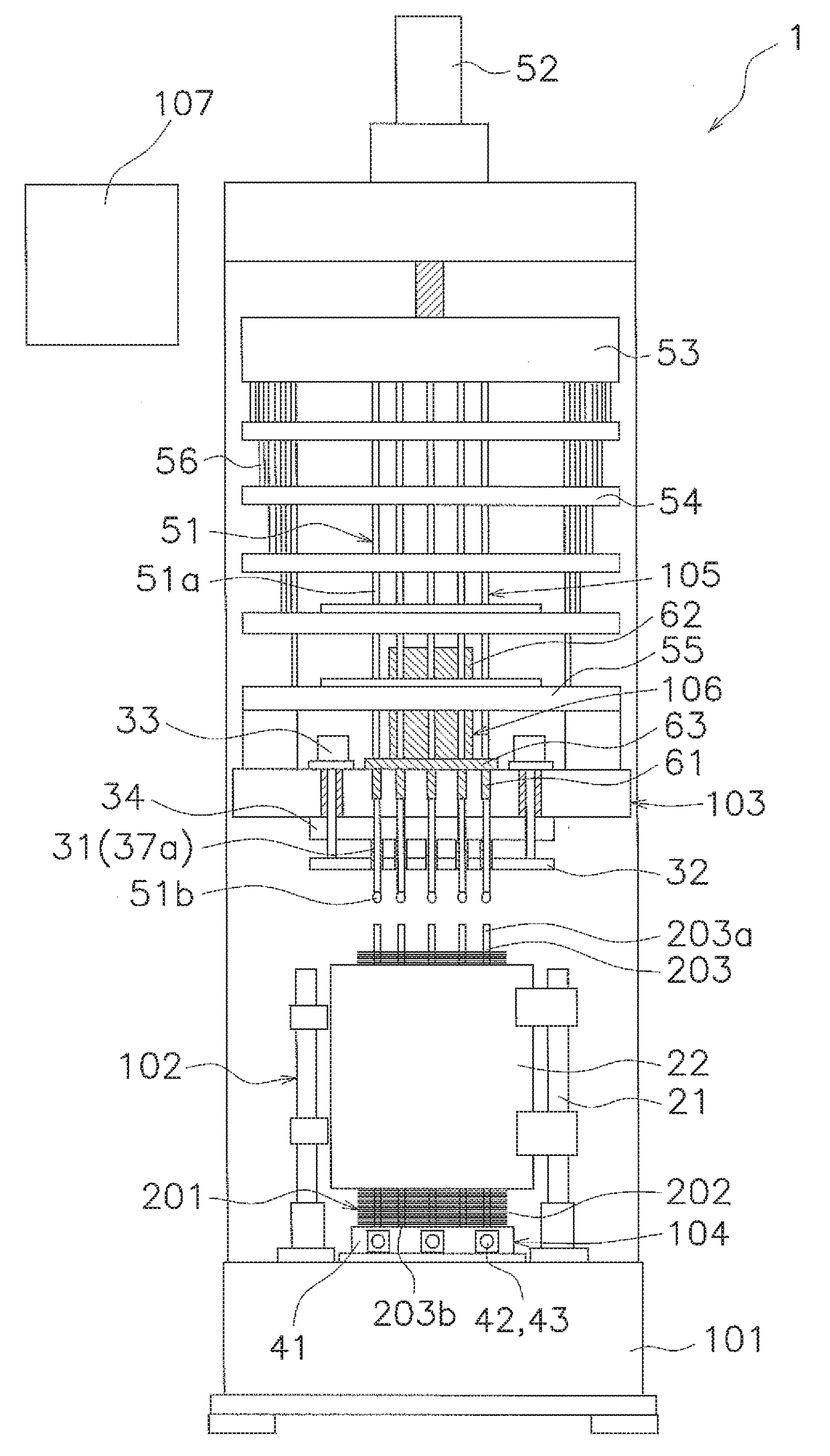

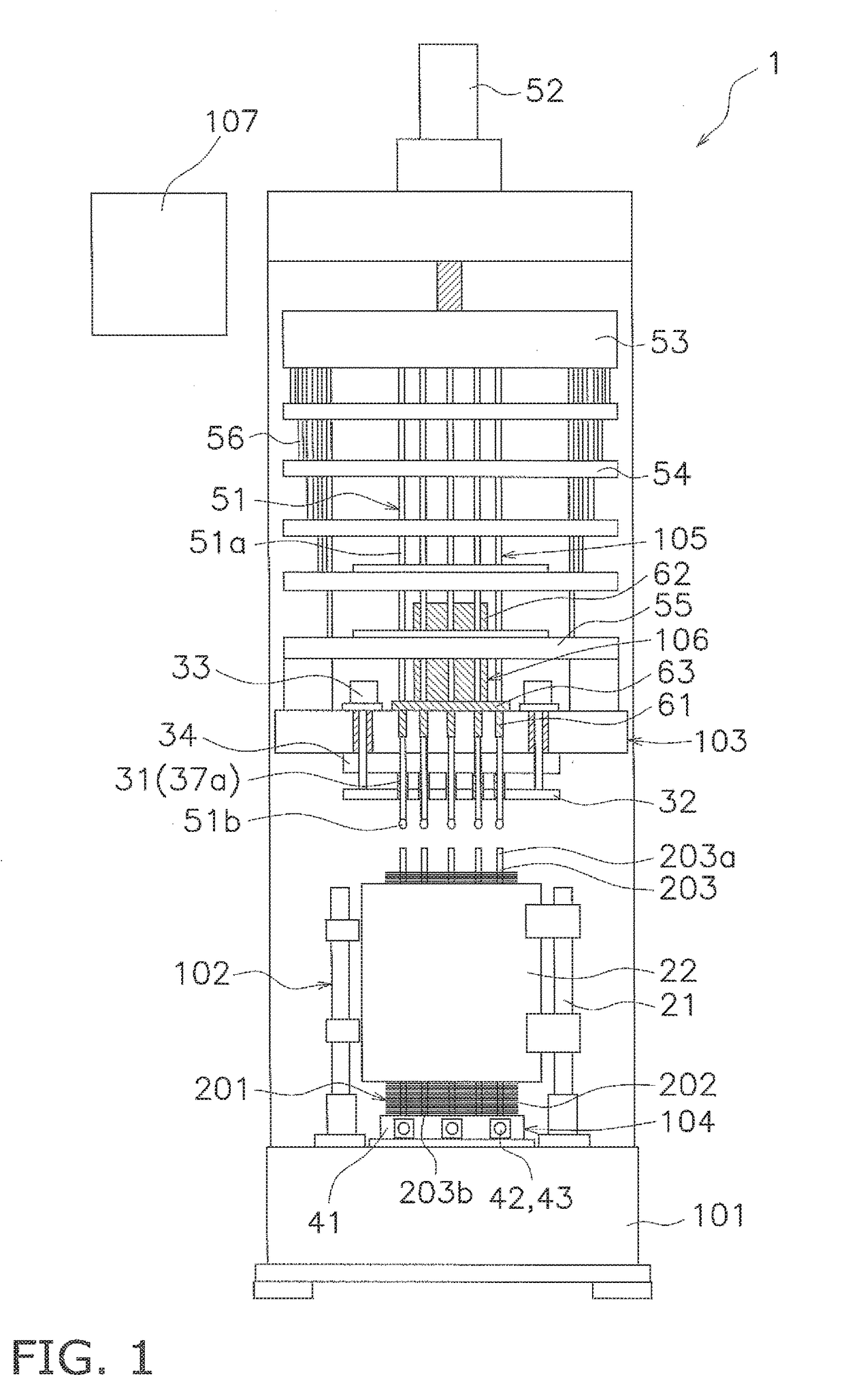

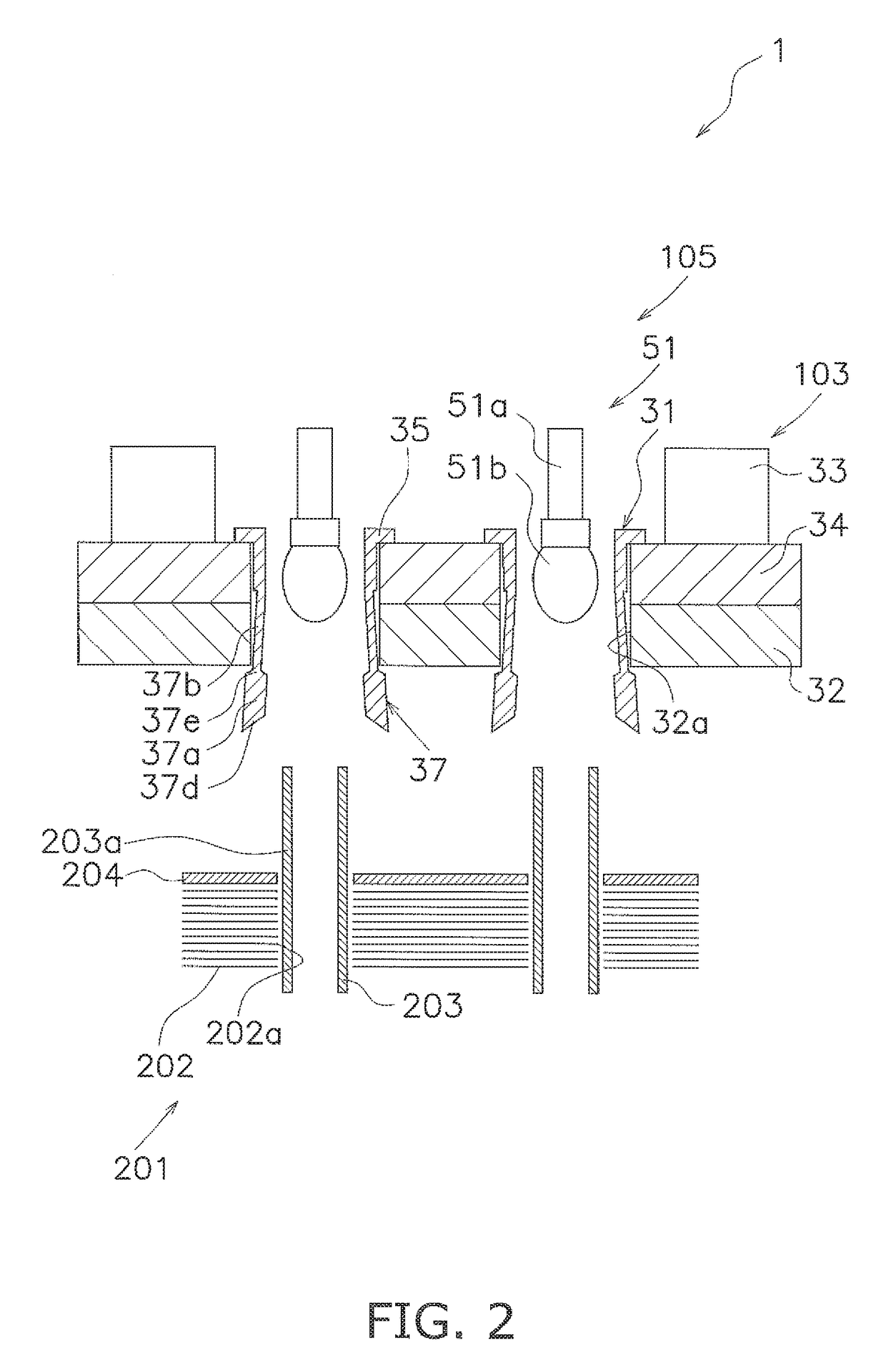

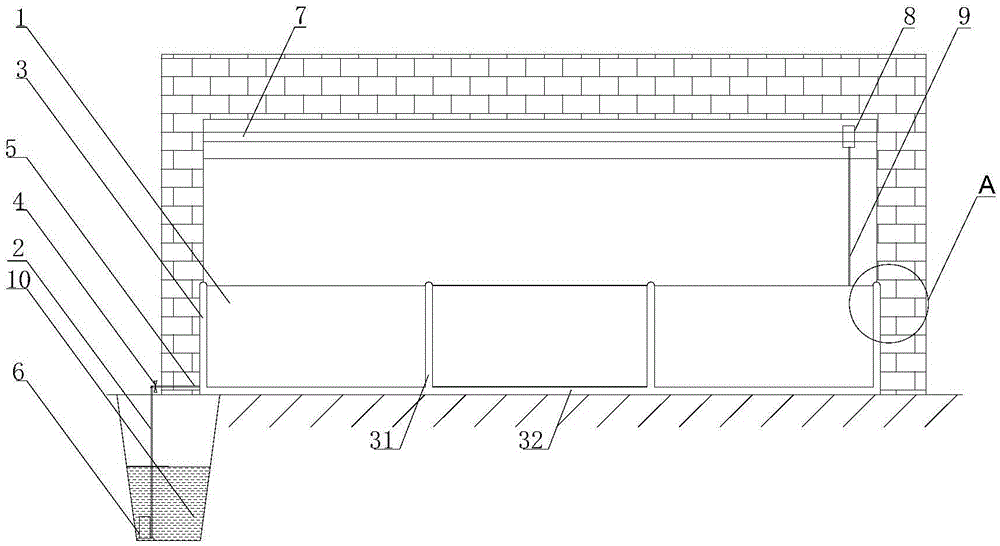

Heat transfer tube expansion apparatus

ActiveUS9592576B2Suppressing variation in forceProcess stabilityHeat exchanger fasteningTubular elementsEngineeringHeat transfer coefficient

A heat transfer tube fixing apparatus of a heat transfer tube expansion apparatus has grasping sections and a moving section. The grasping sections grasp one axial direction end sections of a plurality of heat transfer tubes in a state where the heat transfer tubes are inserted in a plurality of heat transfer fins. The moving section switches between a first state of covering the surroundings of the grasping sections and a second state of not covering the surroundings of the grasping sections by moving in the axial direction of the heat transfer tubes. The grasping sections fix the heat transfer tubes so as not to move in the axial direction and the heat transfer fins and the heat transfer tubes are fixed by the heat transfer tubes expanding in a state where the moving section is in the first state.

Owner:DAIKIN IND LTD

Underwater gravel foundation bed laying device and method

PendingCN110004933APrecise thickness controlAdjustable lengthFoundation engineeringMarine site engineeringSternConveyor belt

The invention provides an underwater gravel foundation bed laying device and method. The underwater gravel foundation bed laying device comprises a hull, wherein a transportation trolley is arranged on the hull, the transportation trolley is driven by a driving device to slide in the length direction of the hull, a sliding tube is arranged on the transportation trolley, a material conveying port is formed in the top end of the sliding tube, and the bottom end of the sliding tube is close to the bottom of the water. The underwater gravel foundation bed laying device is further provided with atleast one conveyor belt for feeding the transportation trolley; buoyancy tank sliding rails are arranged at the positions of a ship bow and a stern of the hull, the buoyancy tank sliding rails are slidably connected with the hull, and positioning columns which can be lifted and lowered are arranged on the two buoyancy tank sliding rails and the hull; and the buoyancy tank sliding rails are of a folded structure. By adopting a scheme in which two foldable buoyancy tank sliding rails and the hull are alternately positioned through the positioning columns and relatively slid, after the riprap construction in an area is completed, the reciprocating movement of the positioning columns and the hull can achieve precise guided continuous movement, the condition that the hull is positioned every time the hull is moved is avoided, and high-precision continuous Z-shaped riprap paving construction is achieved through the sliding tube.

Owner:CCCC SECOND HARBOR ENG

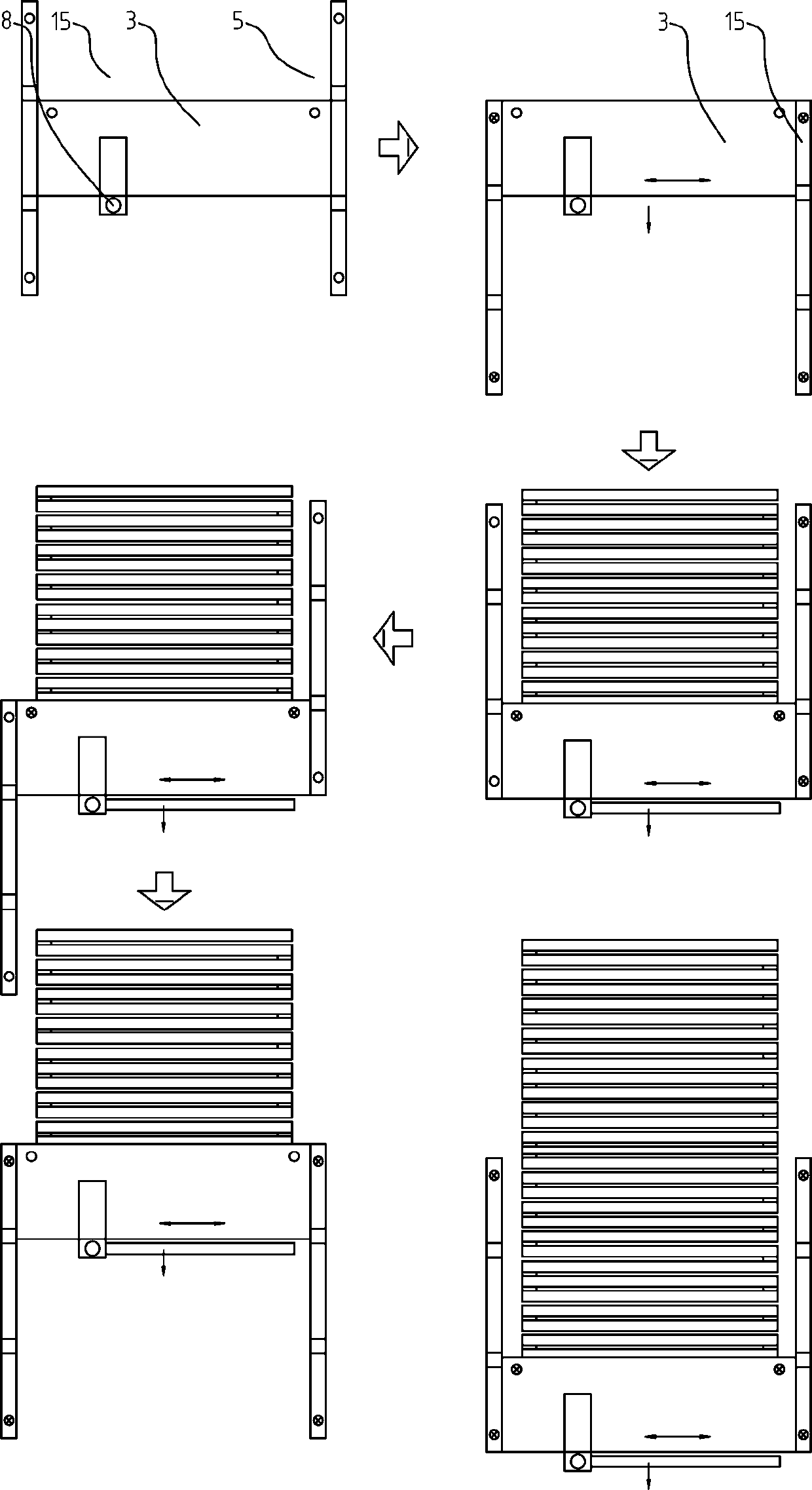

Flood prevention baffle and working method thereof

ActiveCN105134048APrecise expansionExpand quicklyDoor/window applicationsRain/draught deflectorsWater sourceHard water

The invention discloses a flood prevention baffle and a working method thereof and relates to flood prevention devices. The flood prevention baffle is simple and firm in structure and good in sealing effect. The baffle comprises two or more stop blocks, flexible water bags, a hard water outlet, a pipeline, a water pump, a valve guide device and a water source. The flood prevention baffle has the advantages that in case of flood attack, the baffle can be accurately unfolded to stop flood and be folded and put away after the flood steps back, and other work is not affected; the baffle is constituted by the two or more stop blocks and the flexible water bags, and the structure is simple; the height of the baffle is 50-120 cm, and the baffle is small in size and convenient to transport; the stop blocks are connected through stand water bags, bottom edge water bags are arranged at the bottom edges of the stop blocks, and the total sealing effect is good; the guide device is adopted, and the baffle can be unfolded rapidly; the guide device further plays the function of reinforcing the flood prevention baffle, so that the flood prevention baffle is not prone to being shattered through flushing; the stand water bags and the bottom edge water bags are utilized for sealing spaces between the baffle and a wall and the ground, no additional sealing strip is needed, and the cost is saved.

Owner:JIANGSU ELECTRIC POWER CO +3

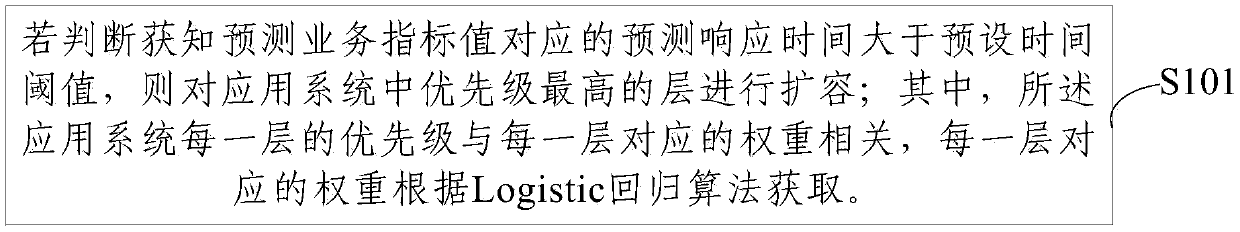

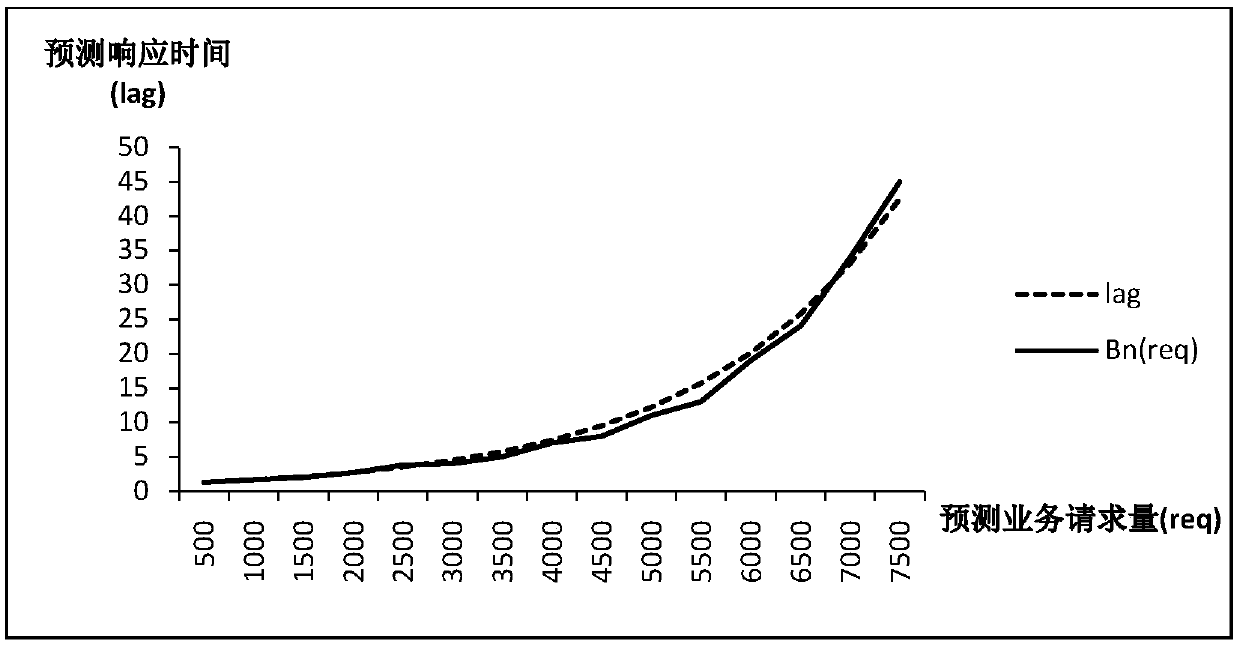

Application system capacity expansion method, device and equipment

ActiveCN110532154AAccurate expansionImprove efficiencyResource allocationHardware monitoringSystem stabilitySystem capacity

The embodiment of the invention provides an application system capacity expansion method, device and equipment, and the method comprises the steps: carrying out the capacity expansion of a layer withthe highest priority in an application system if the prediction response time corresponding to a prediction service index value is judged to be greater than a preset time threshold value, wherein thepriority of each layer of the application system is related to the weight corresponding to each layer, and the weight corresponding to each layer is obtained according to a Logistic regression algorithm. According to the application system capacity expansion method, device and equipment provided by the embodiment of the invention, the weight is obtained according to the Logistic regression algorithm and then the priority of each layer of the application system is obtained, so that the corresponding priority can be obtained according to the influence degree of each layer on the response time. According to the method and the device, the capacity of the layer with the highest priority is expanded, the capacity of the application system can be accurately expanded under the condition that the application system is not transformed and a production system is not influenced, the maximization of the expansion effect is ensured, the method and the device are more accurate and higher in efficiency, and the stability of the system is not impacted.

Owner:CHINA MOBILE GROUP ZHEJIANG +1

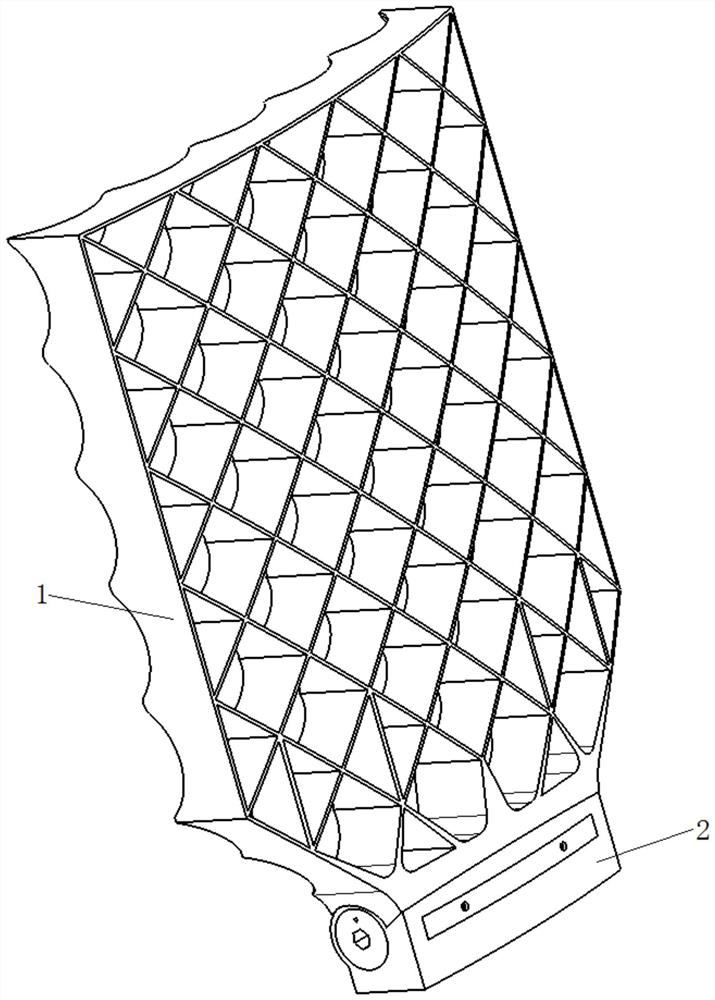

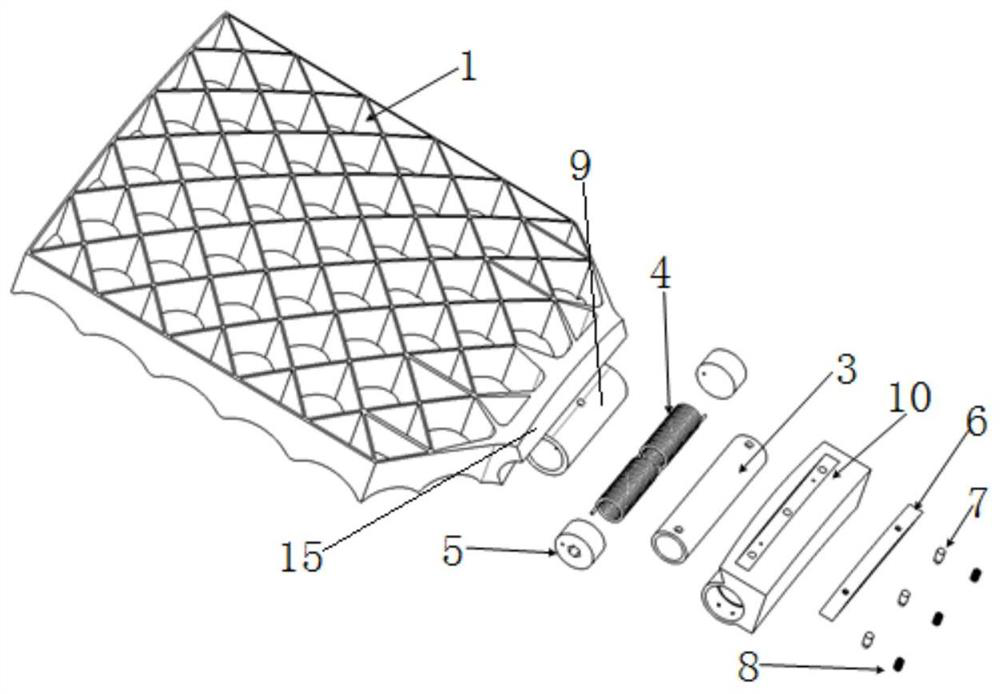

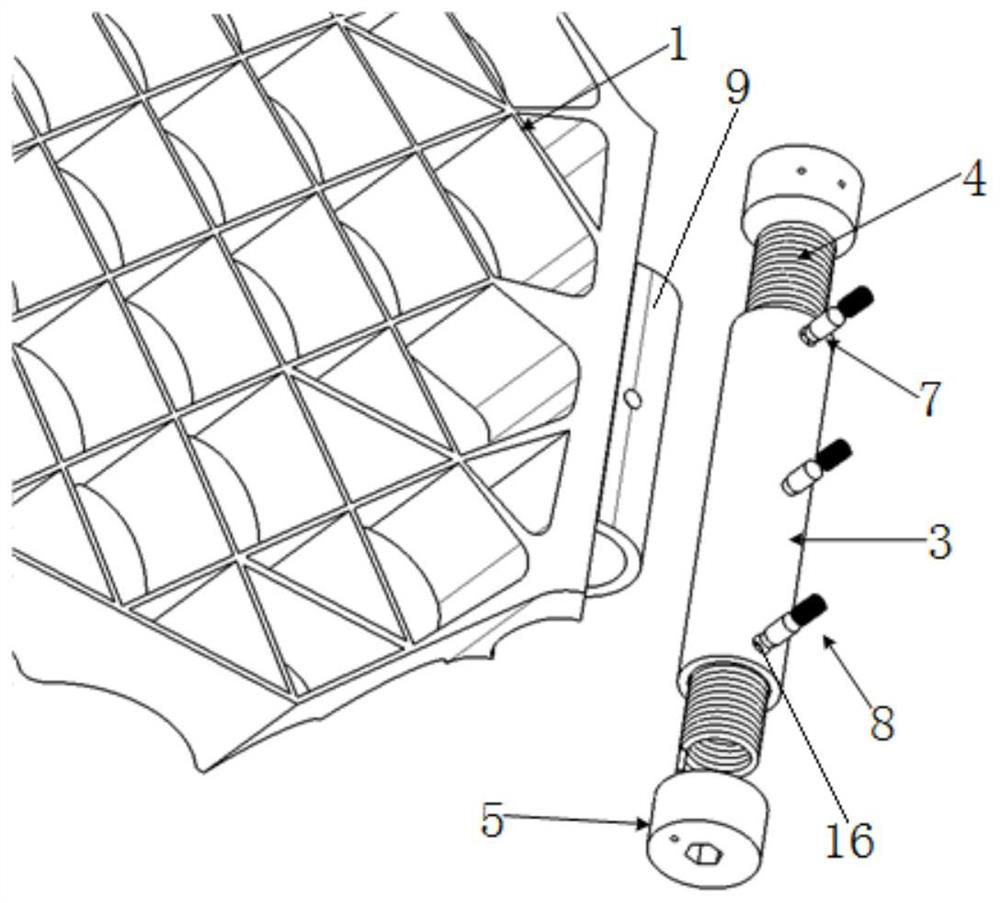

Grid rudder structure and rocket with same

PendingCN113267093APrevent over-rotationPrecise expansionSelf-propelled projectilesMechanical driveRocket

The invention relates to the technical field of aerospace, in particular to a grid rudder structure and a rocket with the same. The grid rudder structure comprises a grid rudder body; a mounting base, wherein a rotating shaft is fixedly connected with the grid rudder body and is rotatably connected with the mounting base; a torsion device, wherein one end of the torsion device is fixedly connected to the rotating shaft, the other end of the torsion device is fixedly connected to the mounting base, and when the grid rudder body needs to be unfolded, torsion force of the torsion device drives the grid rudder body to rotate relative to the mounting base along the rotating shaft; and a locking structure, wherein the locking structure is arranged on the mounting base and is suitable for being locked with the rotating shaft when the torsion device drives the grid rudder body to rotate in place. Through the arrangement of the torsion device, rotation driving of the grid rudder body can be achieved through the torsion force of the torsion device, through cooperation of the rotating shaft and the locking structure, when the grid rudder body rotates in place, locking of the locking structure on the rotating shaft is achieved, and due to the fact that mechanical driving unfolding and locking are adopted, the unfolding and locking reliability of the grid rudder body is improved.

Owner:BEIJING XINGJI RONGYAO SPACE TECH CO LTD +1

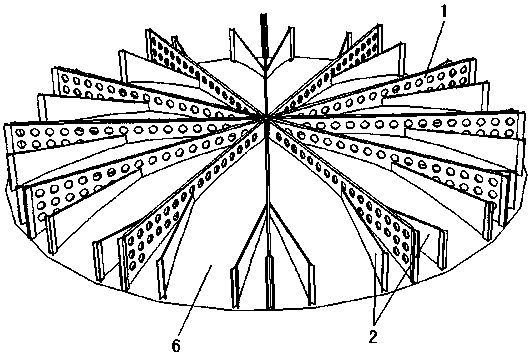

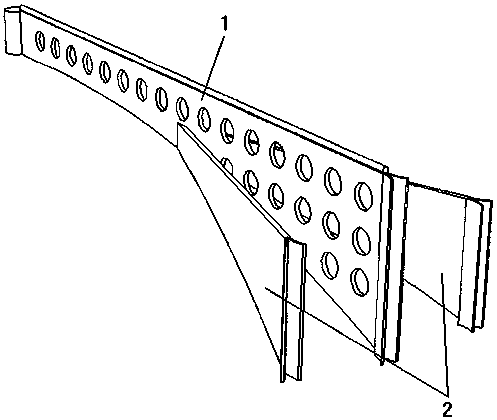

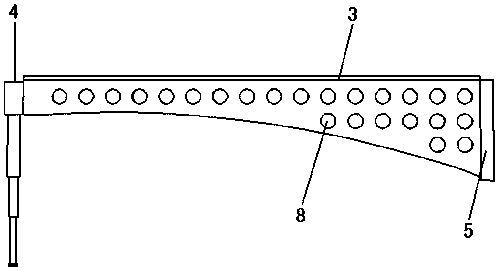

Expandable branching rib plate high-precision reflecting plane

ActiveCN107275795AIncreased out-of-plane bending stiffnessReduce local bucklingCollapsable antennas meansEngineeringParaboloid

The invention discloses an expandable branching rib plate high-precision reflecting plane, which comprises a center hub, main rib plates, auxiliary rib plates, positioning sheet-pressing springs, a paraboloid, a compressing belt, a waveguide rod and a feed source, and is characterized in that the upper side edge of each main rib plate is designed with dual straight pipes with an omega shape after being expanded, so that the out-plane bending rigidity is improved, and local buckling is substantially reduced. Each main rib plate is designed with the branched auxiliary rib plates, so that a defect of not satisfying an ideal paraboloid equation because of being away from a middle region is compensated, and the profile precision of a radial radiation rib plate antenna is improved. The lower side of the dual omega-shaped straight pipes is provided with the main rib plate with uniformly distributed circular holes, so that the structure mass can be effectively reduced, and the specific rigidity is improved. The positioning sheet-pressing springs drive expansion of the auxiliary rib plates and realize in-place expansion of the auxiliary rib plates at the same time.

Owner:HARBIN INST OF TECH

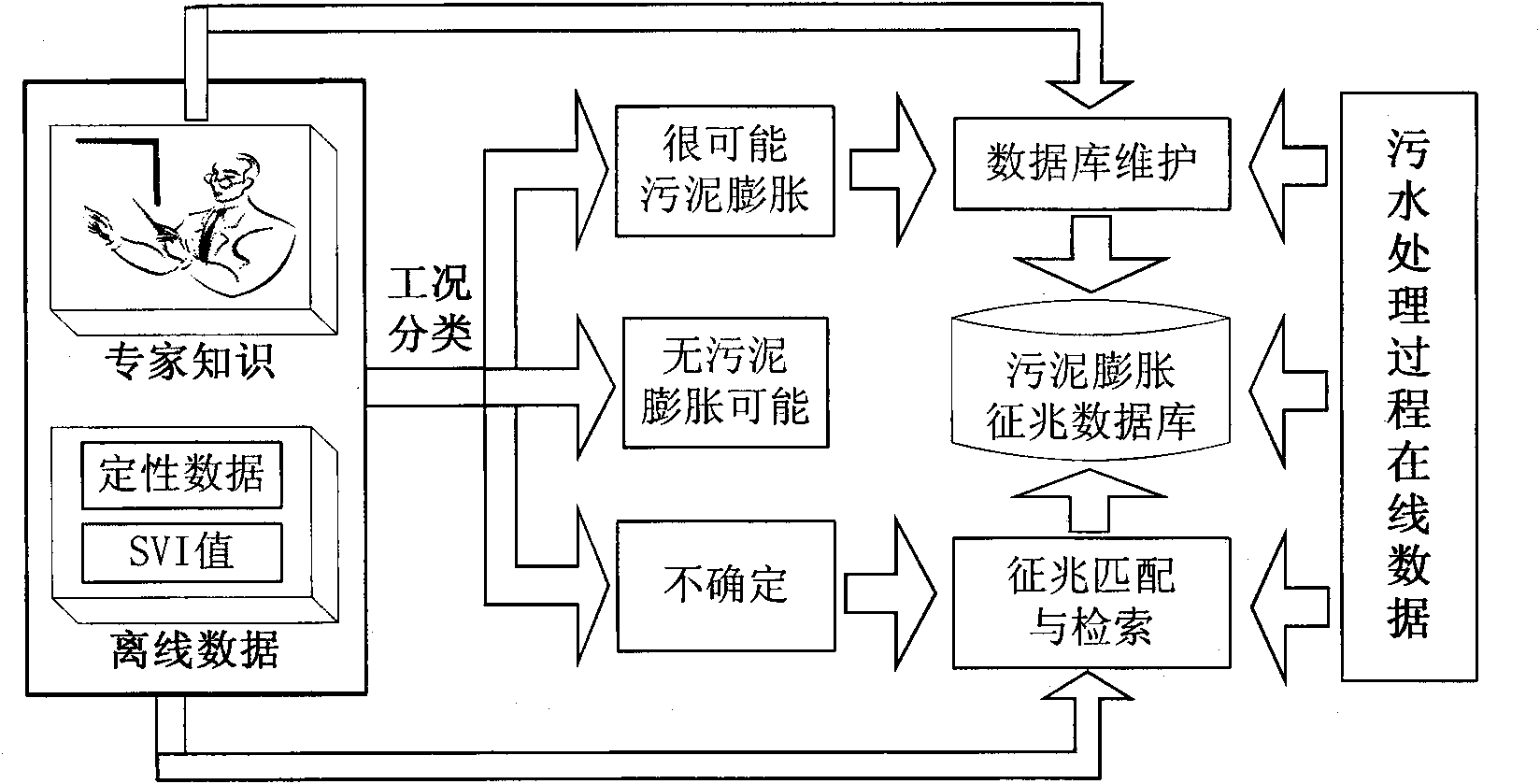

Sludge bulking predetermining method by activated sludge process in sewage treating process

InactiveCN101993146APrecise expansionAccurately identify swellingTreatment with anaerobic digestion processesSustainable biological treatmentWater treatment systemAutomatic control

The invention relates to a sludge bulking predetermining method by an activated sludge process in a sewage treating process, comprising the following steps: establishing a sludge bulking symptom database; analyzing key off-line data by means of the expert knowledge; simply classifying the current working condition; carrying out corresponding treatment aiming at different working conditions, wherein, the sludge bulking symptom database establishment comprises the primary data set collection; recording the stored process history data through an automatic control system to obtain the primary data set of the sludge bulking symptom database; determining the structure of the database and a sludge bulking symptom attribute; analyzing the sewage treating process data by means of the mastered expert knowledge; and utilizing on-line process data which can dynamically reflect the sludge bulking symptom information to serve as the sludge bulking symptom attribute. By combining the expert knowledge and a data drive method, the method of the invention has the advantages that qualitative data, quantitative data, the off-line data and the on-line data can be comprehensively analyzed, the sludge bulking can be accurately predetermined, the occurrence frequency of the sludge bulking is reduced, the safe and stable operation of a sewage treating system is ensured, and the system maintenance expense is lowered.

Owner:SHENYANG INST OF AUTOMATION - CHINESE ACAD OF SCI

Device and method for carefully settling a patient in a defined position

InactiveUS7716767B2Reduce thicknessSufficient mouldabilityStuffed mattressesSpring mattressesInternal pressureMedicine

The invention relates to a device and a method for the gentle placement of a patient in a defined position. In order to provide a device for the placement of patients which both allows gentle positioning and at the same time holds the patient in a defined position, the device according to the invention comprises a mattress having a surface able to adopt a flexible state, as a result of being subjected to a first control signal, and a rigid state, as a result of being subjected to a second control signal, a cushion which is filled with a fluid, rests on the mattress and comprises a flexible wall in the region of the patient or the body part of the patient resting on the cushion, and a fluid pump which is connected via a valve to the fluid in the cushion and via which the internal pressure and / or the internal volume of the cushion may be adjusted to a predetermined value.

Owner:BOHM STEPHAN +2

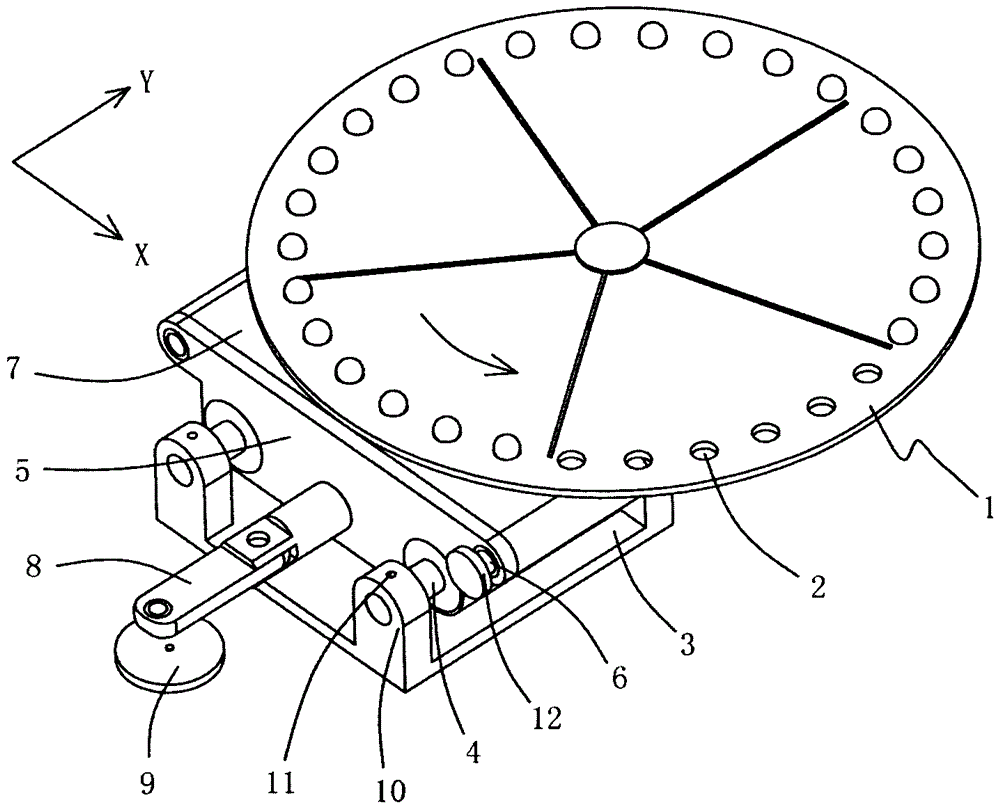

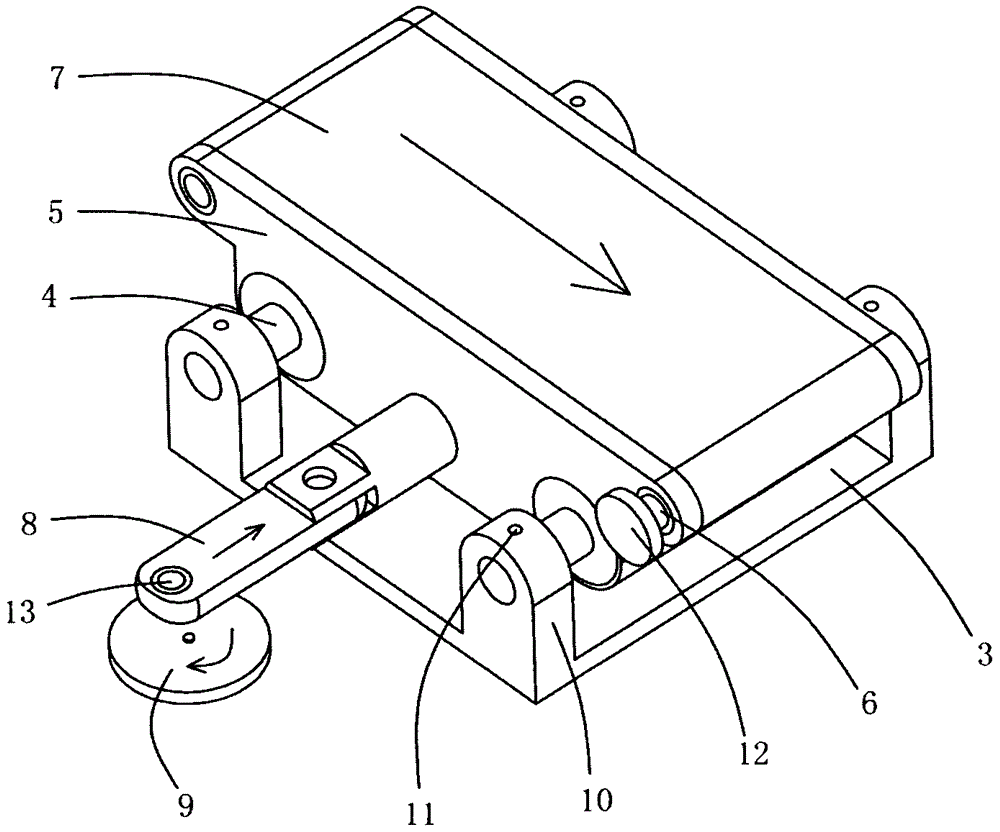

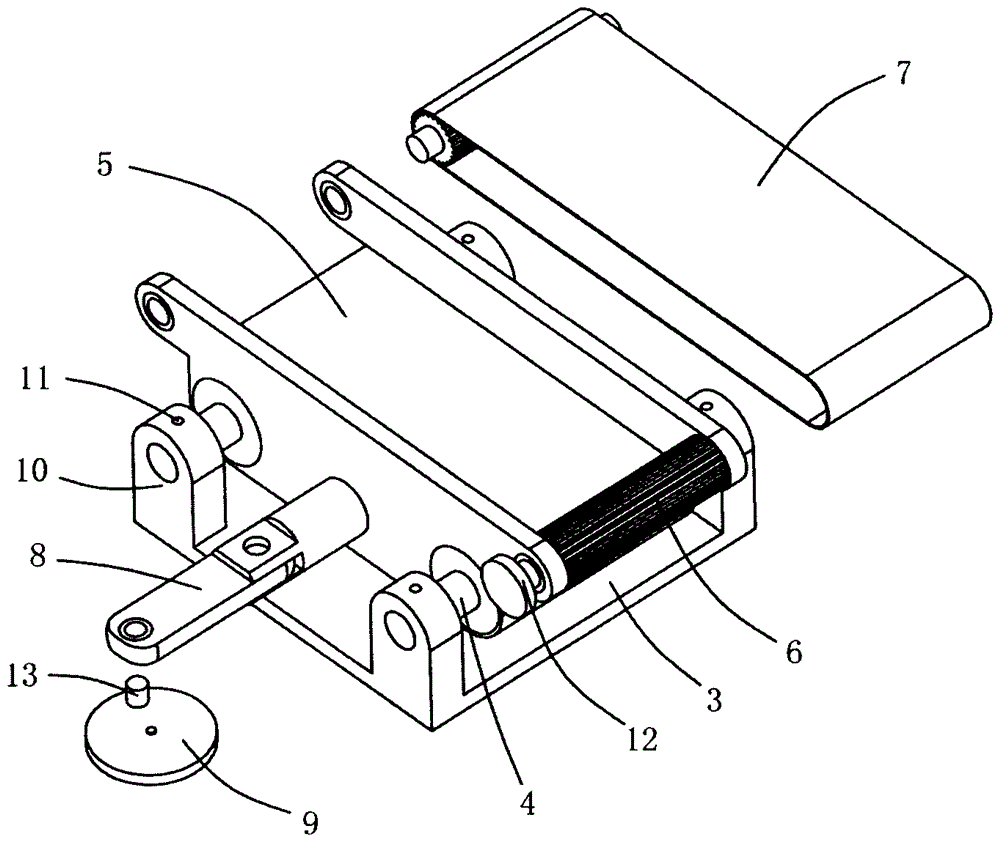

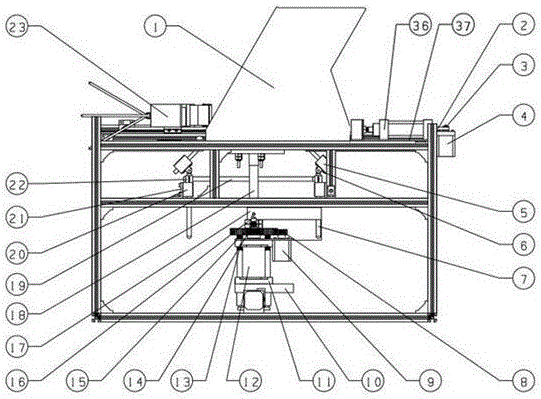

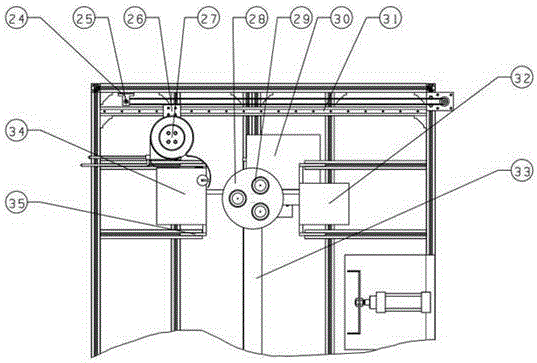

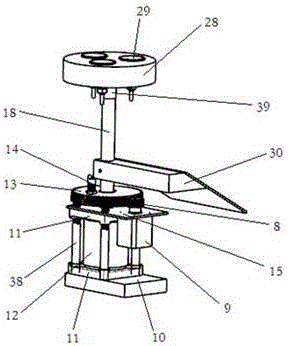

Unfolding device of steel ball sorting machine

The invention discloses an unfolding device of a steel ball sorting machine. The unfolding device comprises a feeding disc; and the feeding disc is provided with multiple detecting cavities for bearing steel balls. The unfolding device further comprises a mounting base; a slide rail is arranged on the mounting base; a slide base is arranged on the slide rail; and a friction belt driven by a roller shaft is arranged on the slide base, is positioned below the feeding disc, and is used for driving the steel balls to roll in the detecting cavities. The unfolding device further comprises a connecting rod; one end of the connecting rod is hinged to the slide base, and the other end of the connecting rod is eccentrically connected with a rotating wheel; the rotating wheel drives the slide base to slide along the slide rail through the connecting rod; and the conveying direction of the friction belt is orthogonal to the sliding direction of the slide base. The unfolding device adopts the rolling friction belt to drive the steel balls in the detecting cavities of the feeding disc to roll and unfold, can guarantee total unfolding of the steel balls, can guarantee total coverage of the surfaces of the steel balls by obtained images, is more precise in sorting of the steel balls, can feed the steel balls in batches through the feeding disc, improves the detecting efficiency, reduces the motor loss, and prolongs the motor service life.

Owner:NINGBO BAIJIABAI MEASUREMENT & CONTROL EQUIP

Minitype rudder face folding mechanism component

PendingCN110260727APrecise expansionGuaranteed locking accuracyProjectilesSpatial structureMechanical engineering

The invention relates to a minitype rudder face folding mechanism component. The minitype rudder face folding mechanism component comprises a rudder face and further comprises a double-twist spring, a taper pin, a spring and a positioning pin, wherein the two end portions of the double-twist spring are installed to a supporting pin correspondingly, the middle portion of the double-twist spring is installed on a pin shaft and a shaft sleeve, the installation end portion of the rudder face is installed inside a shaft hole of a rudder shaft through the pin shaft, the taper pin is connected with the spring, the double-twist spring is in close fit with the rudder face to make the rudder face be subjected to force of the spring all the time, and locking is jointly realized through double-twist spring expansion, spring compression and the positioning pin. The minitype rudder face folding mechanism component has the advantages that the minitype rudder face folding mechanism component is simple in structure and high in reliability, the spatial structure of the rudder shaft is utilized, a whole product is made to be small in structure, and the scheme of the minitype rudder face folding mechanism component is not only applicable to the minitype rudder face folding mechanism component and can be used on the product of the same type.

Owner:贵州航天控制技术有限公司

Full-automatic carton sealing machine structure and carton sealing method

The invention provides a full-automatic carton sealing machine structure. The structure comprises a carton obtaining device, a cylinder device, a bevel rotary table mechanism, ejector rod and turnover plate mechanisms and an adhesive sealing mechanism. The carton obtaining device comprises a carton collecting barrel and an elastic pressing plate, and the elastic pressing plate is arranged on one side of the carton collecting barrel which is arranged on the upper portion of a machine frame. A ball screw is arrange under an outlet of the carton collecting barrel, the whole bevel rotary table mechanism is mounted on the ball screw, the adhesive sealing mechanism is arranged opposite to the carton collecting barrel, and the adhesive sealing mechanism and the carton collecting barrel are located on the same plane. The ejector rod and turnover plate mechanisms are arranged on the two sides of the machine frame, a right turnover plate and a left turnover plate of the ejector rod and turnover plate mechanisms are flush with the bottom of the carton collecting barrel, an ejector rod body is vertically arranged on the lower portion of the corresponding turnover plate, the cylinder device is arranged on one side of the right turnover plate and comprises a cylinder body and a carrying plate, the cylinder body is arranged on the carrying plate, and the cylinder body is flush with the corresponding turnover plate. By means of the full-automatic carton sealing machine structure, the defects that an existing larger pipelined carton packaging machine is extremely large in occupied area, high in device cost and maintenance cost, complex in structure and operation, poor in start-stop flexibility and the like are overcome, the full-automatic carton sealing machine structure has the advantages that the comprehensive benefits of size, cost and efficiency can be optimized.

Owner:永丰余纸业(南京)有限公司

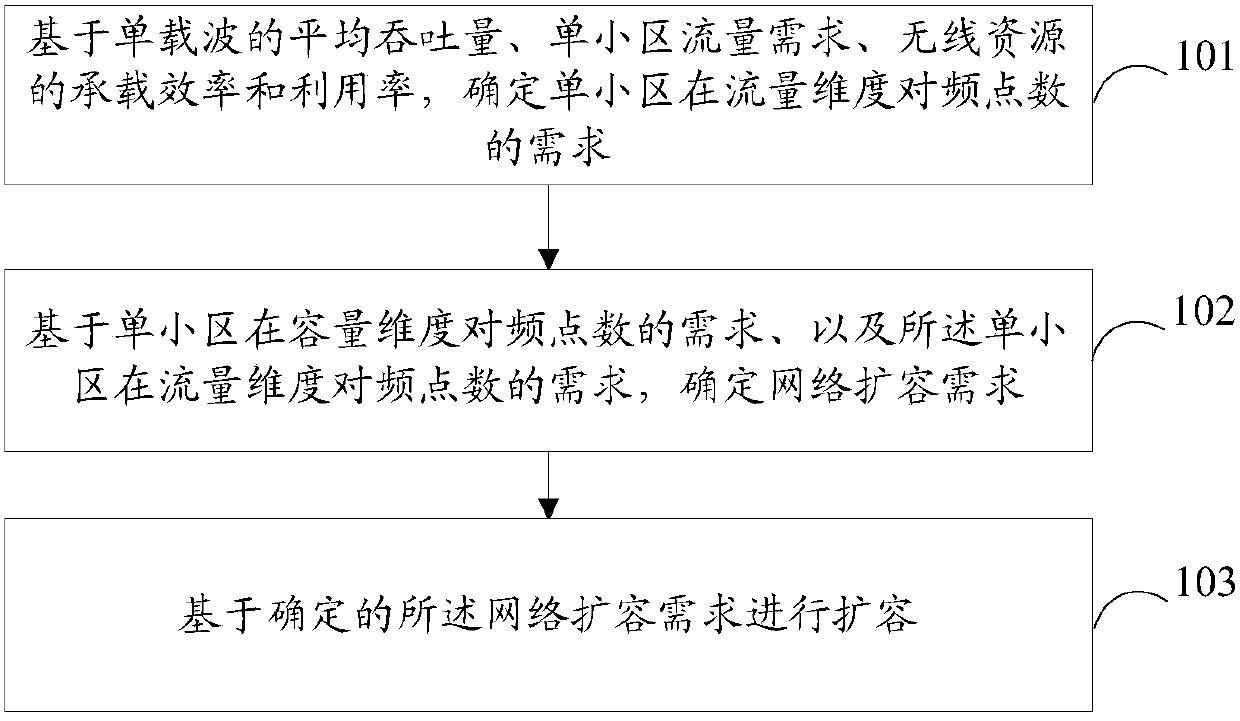

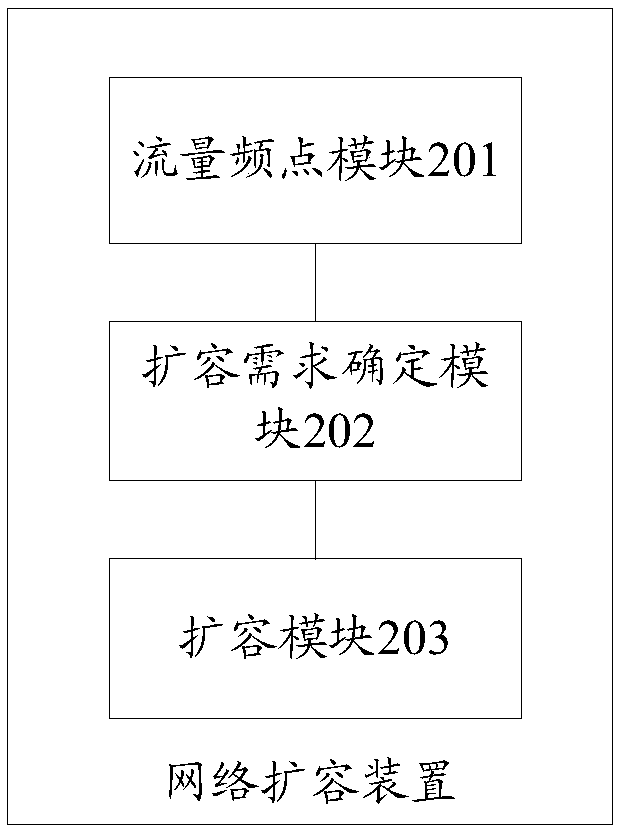

Network capacity expansion method and device and computer readable storage medium

ActiveCN110191473AGuaranteed business experiencePrecise expansionNetwork traffic/resource managementNetwork planningCarrier signalComputer science

The embodiment of the invention provides a network capacity expansion method and device and a computer readable storage medium, and the method comprises the steps: determining the requirement of a single cell for the number of frequency points in a flow dimension based on the average throughput of the single carrier, the flow requirement of the single cell and the bearing efficiency and utilization rate of wireless resources; determining a network expansion demand based on the demand of the single cell on the frequency point number in the capacity dimension and the demand of the single cell onthe frequency point number in the flow dimension; and carrying out capacity expansion based on the determined network capacity expansion demand.

Owner:CHINA MOBILE COMM LTD RES INST +1

Accessory for high voltage direct current energy cables

ActiveUS20180019582A1Enhanced electric field controlAvoid charge accumulationPlastic/resin/waxes insulatorsPower cables with screens/conductive layersElastomerHigh-voltage direct current

The present invention relates to an accessory for high-voltage direct-current (HVDC) energy cables comprising: at least one element made from a crosslinked elastomeric polymer material, and at least one scavenging layer comprising zeolite particles. The zeolite particles are able to scavenge, very efficiently and irreversibly, the by-products deriving from the cross-linking reaction, so as to avoid space charge accumulation in the element during the accessory lifespan. Moreover, the zeolite particles can prevent the crosslinking by-products present in the element of a non-degassed accessory from migrating towards the insulating layer of the energy cable on which the accessory is mounted.

Owner:PRYSMIAN SPA

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com