Unfolding device of steel ball sorting machine

A technology of sorting machines and steel balls, which is applied in sorting and other directions, can solve the problems of not being able to guarantee complete coverage of the steel ball surface, low detection efficiency, and short service life, so as to achieve accurate steel ball sorting, reduce motor loss, and prolong The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The following descriptions are only preferred embodiments of the present invention, and therefore do not limit the protection scope of the present invention.

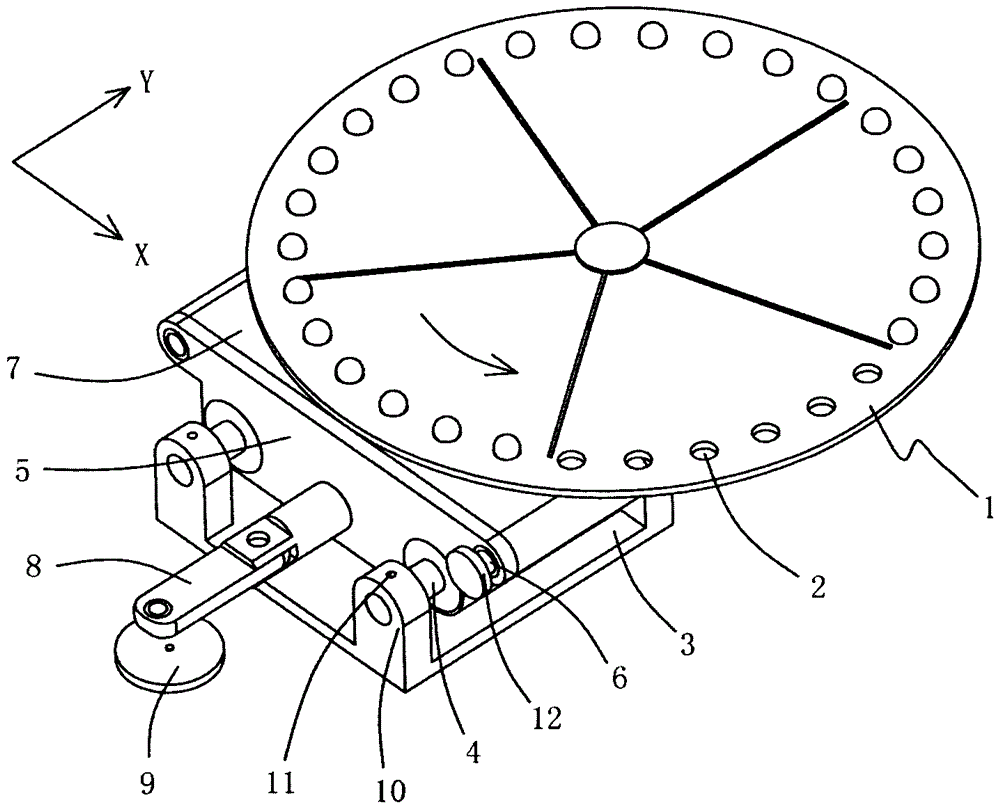

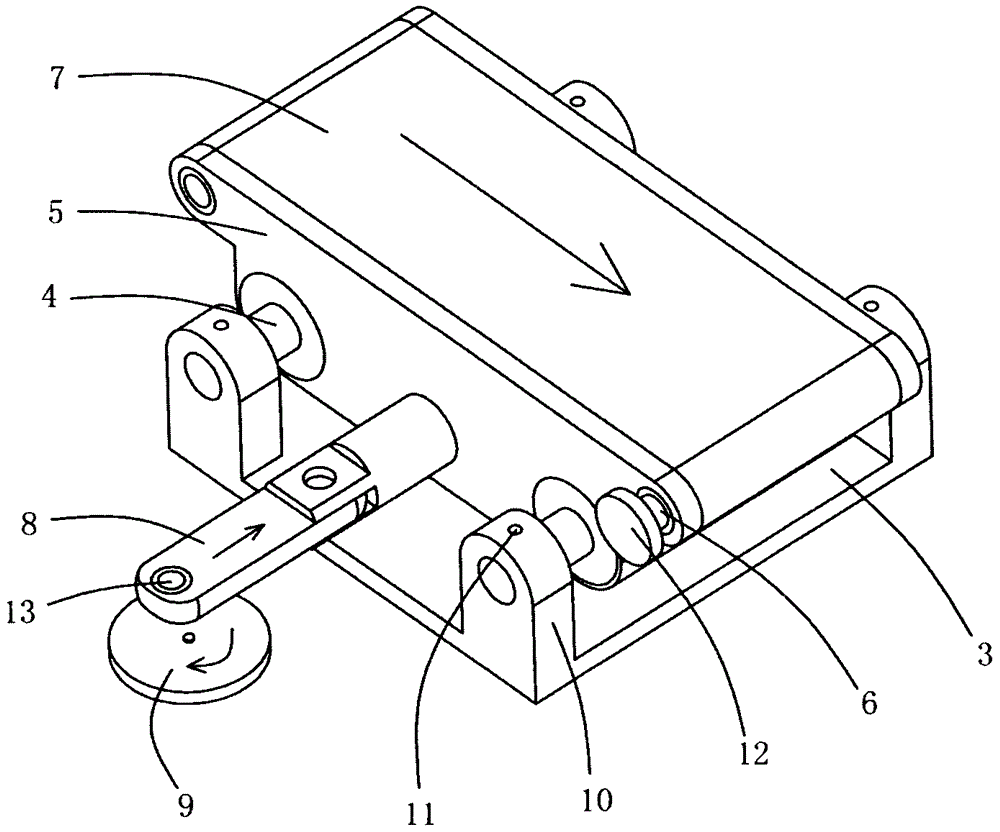

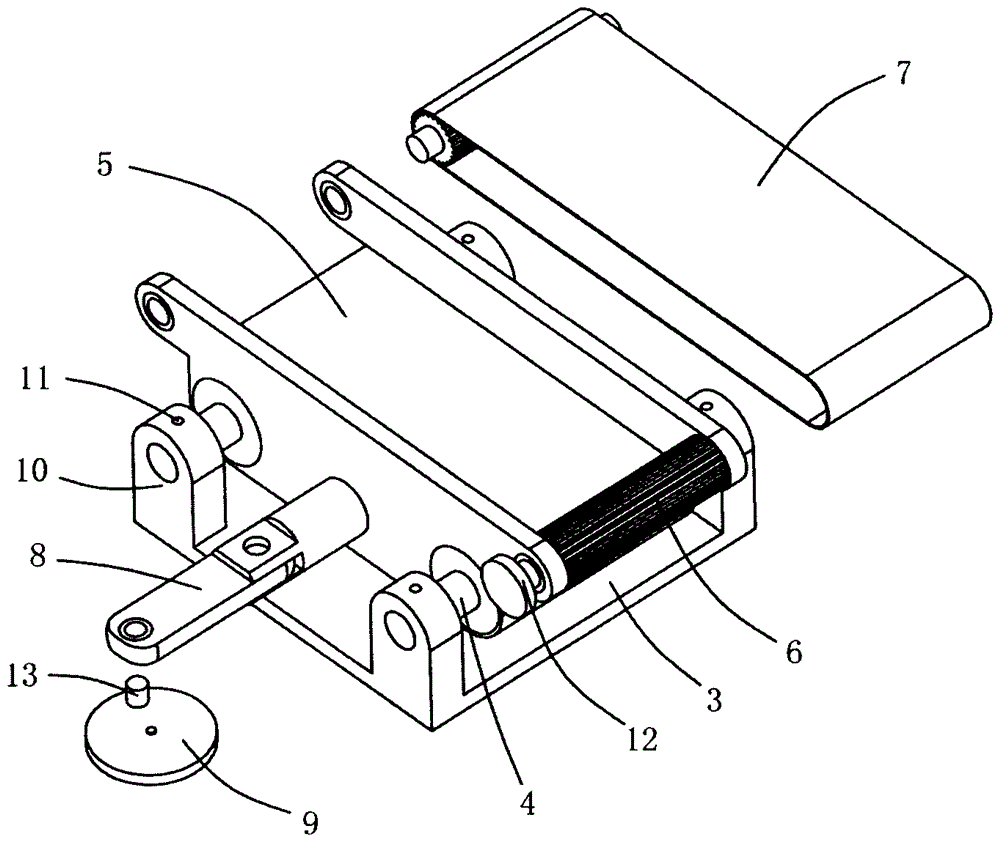

[0019] see Figure 1-Figure 3 , a steel ball sorting machine deployment device, including a feed tray 1, the feed tray 1 is provided with a number of detection chambers 2 for carrying steel balls, and also includes a mounting seat 3, the mounting seat 3 is provided with a slide rail 4, the slide The rail 4 is provided with a sliding seat 5, and the sliding seat 5 is provided with a friction belt 7 driven by the roller shaft 6. The friction belt 7 is located under the feed plate 1 and is used to drive the steel ball to roll in the detection chamber 2; it also includes a connecting rod 8. One end of the connecting rod 8 is hinged with the sliding seat 5, and the other end of the connecting rod 8 is eccentrically connected with the runner 9, and the runner 9 drives the sliding seat 5 to slide along the slide rail 4 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com