Patents

Literature

111results about How to "Sorting is accurate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

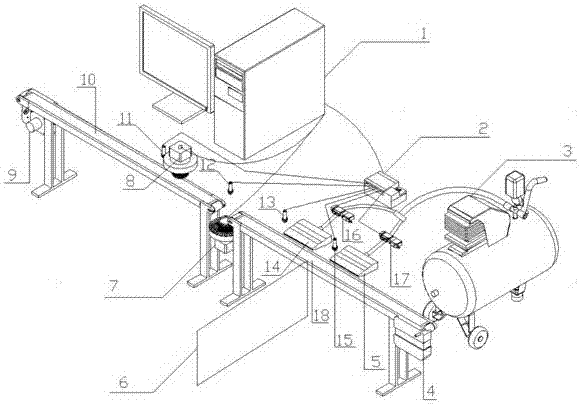

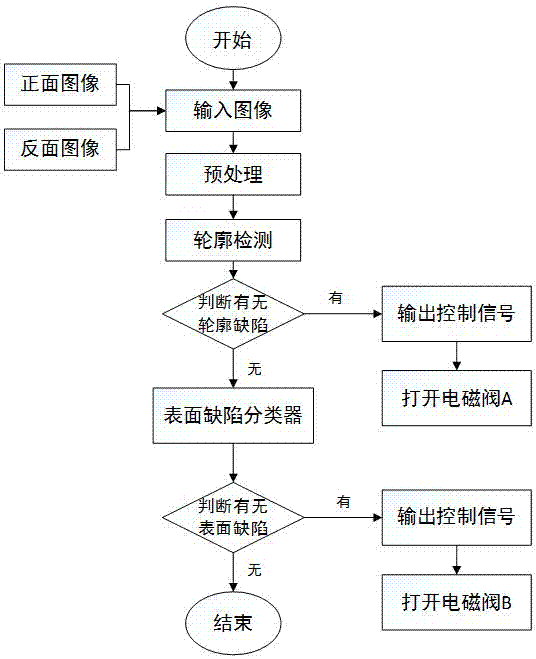

On-line defect detection system and method for thin bamboo strips based on machine vision

PendingCN107486415AAvoid the problem of missed detection and false detectionImprove detection accuracyMaterial analysis by optical meansSortingAir pumpAir knife

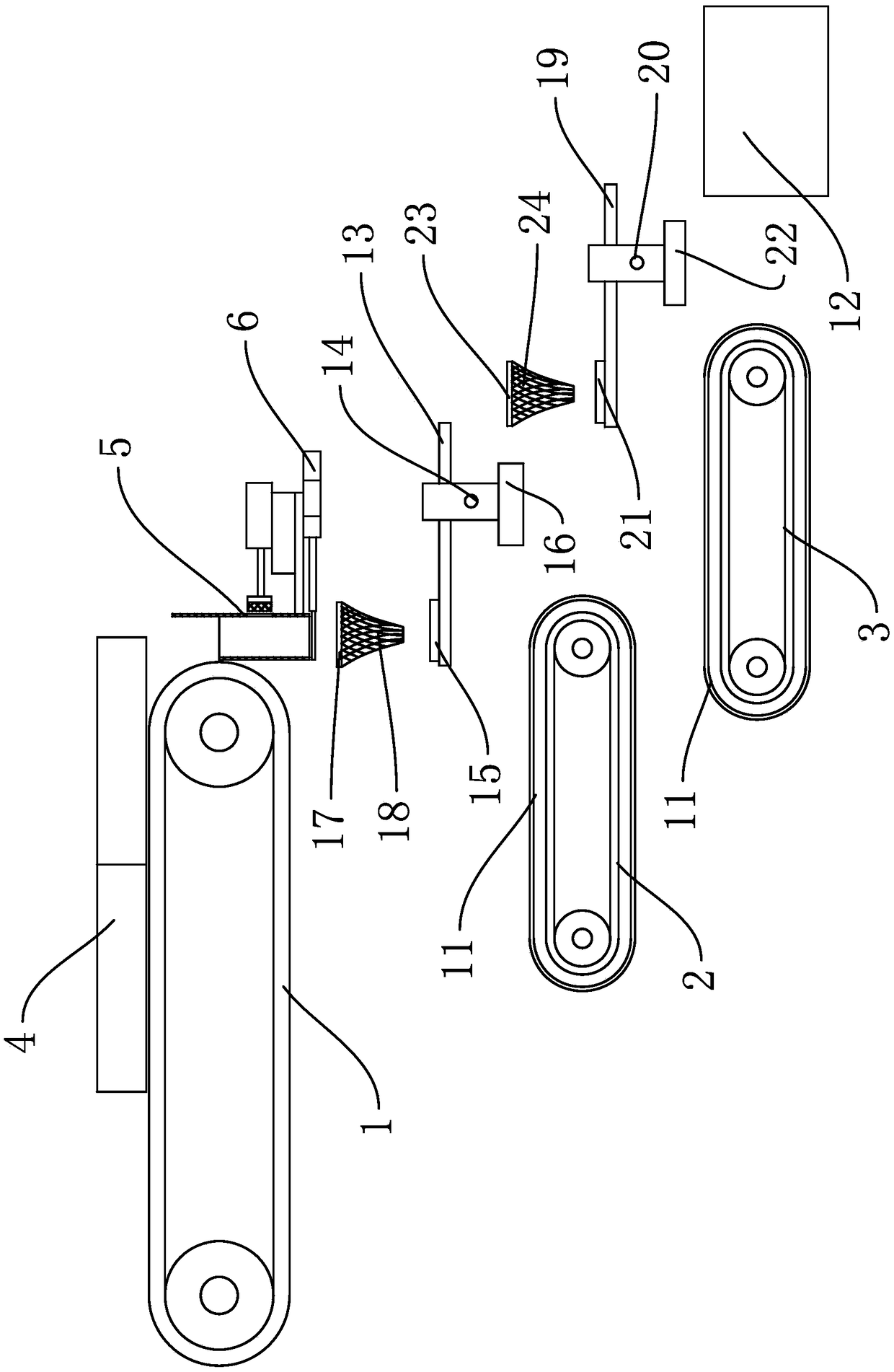

The invention discloses an on-line defect detection system and method for thin bamboo strips based on machine vision. The on-line defect detection system comprises an industrial personal computer, a PLC, an air pump, two electromagnetic valves, two air knives, an isolation board, a line-array camera, an area-array camera, two motors, two narrow conveyor belts and four photoelectric sensors, wherein the conveyor belts convey thin bamboo strips to the area-array camera and the line-array camera; front side and reverse side images of thin bamboo strips are collected, and the images are input into the industrial personal computer for image pretreatment; profile and surface defects are detected, so as to obtain three types of products, namely products with profile defects, products with surface defects and products without defects; the classification result is output to the PLC through a serial port, and the electromagnetic valves are controlled to be opened through the PLC, and products with profile defects and surface defects are removed; if no defect is detected, the PLC fails to actuate. According to the on-line defect detection system and method for thin bamboo strips based on machine vision, the problems of missing defection and false detection in manual detection are avoided, and the detection accuracy is improved; moreover, historical data is stored by utilizing a database, the querying is convenient, and the counting is accurate; and besides, the system has a clear structure and is simple in operation.

Owner:CHINA JILIANG UNIV

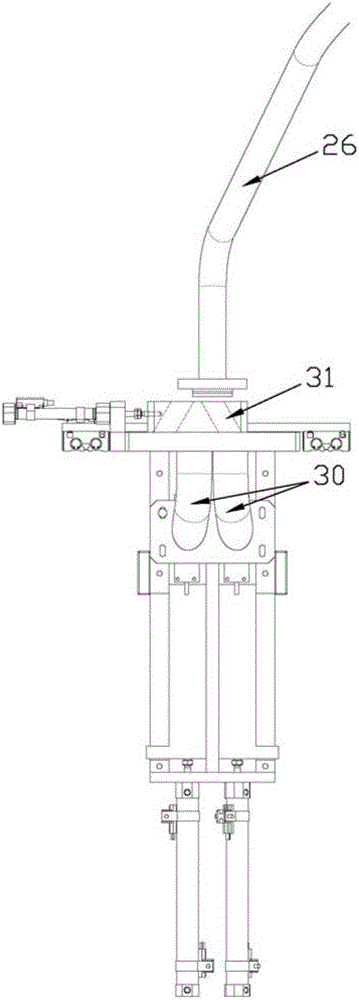

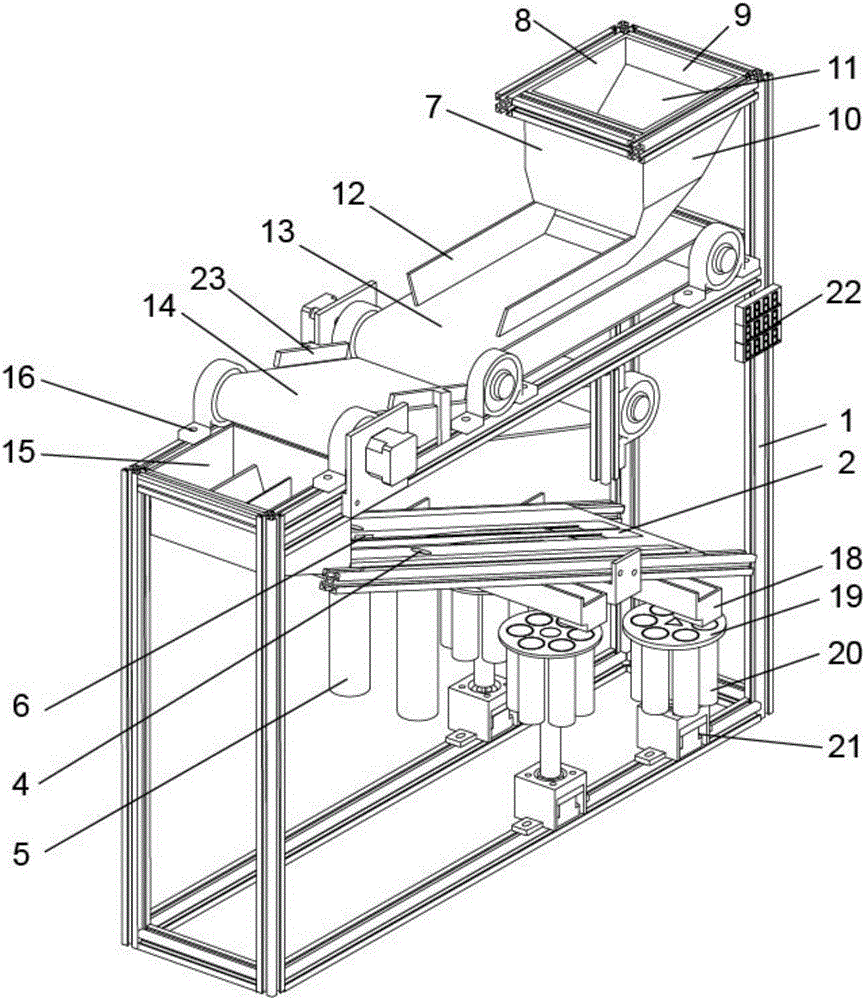

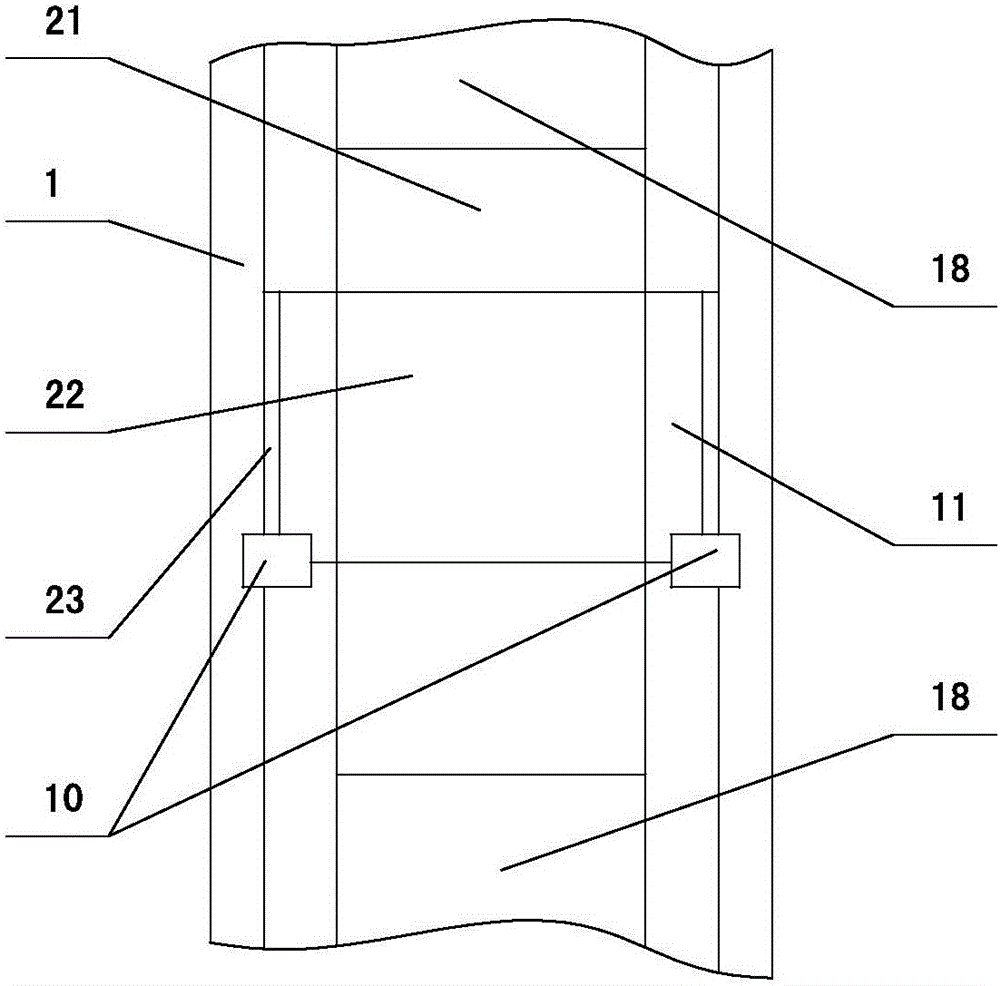

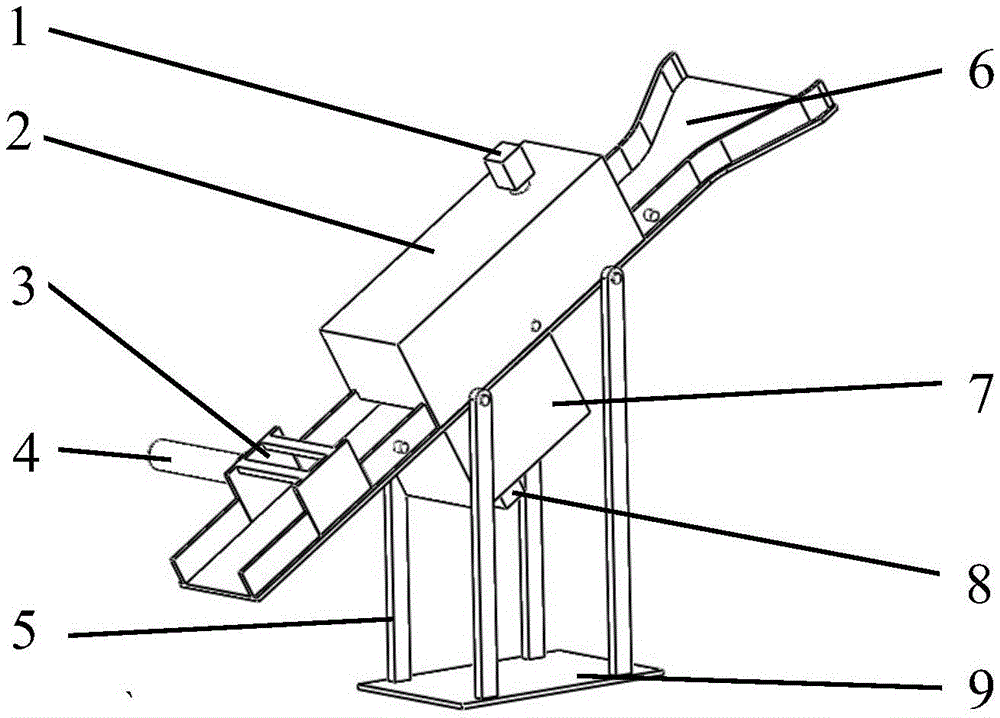

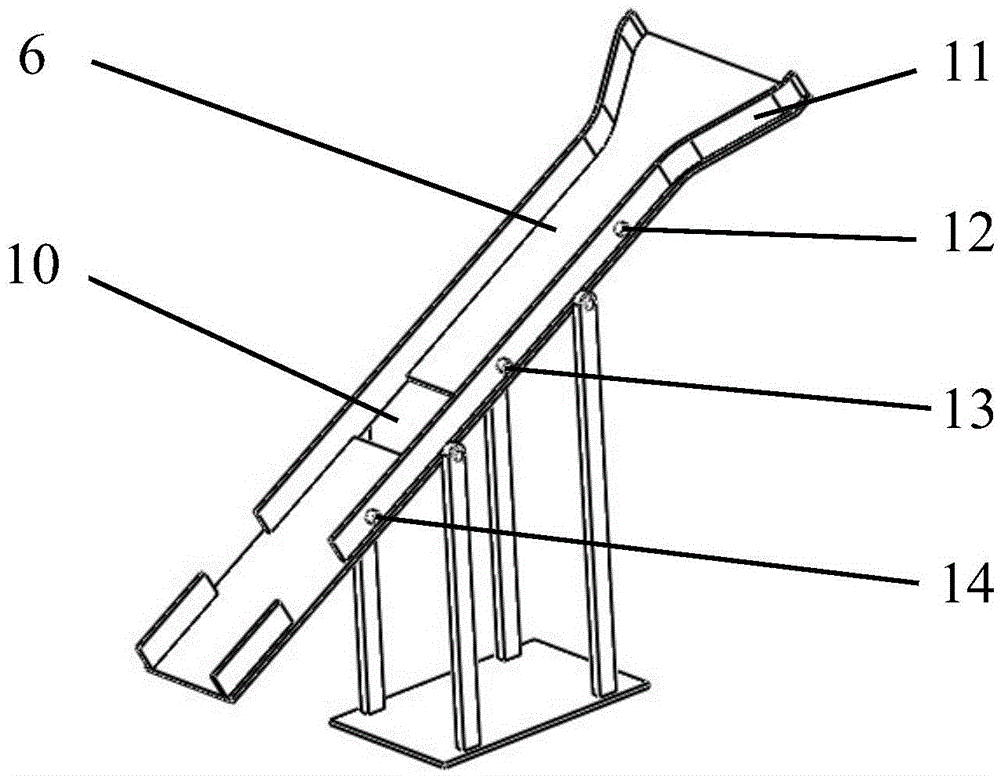

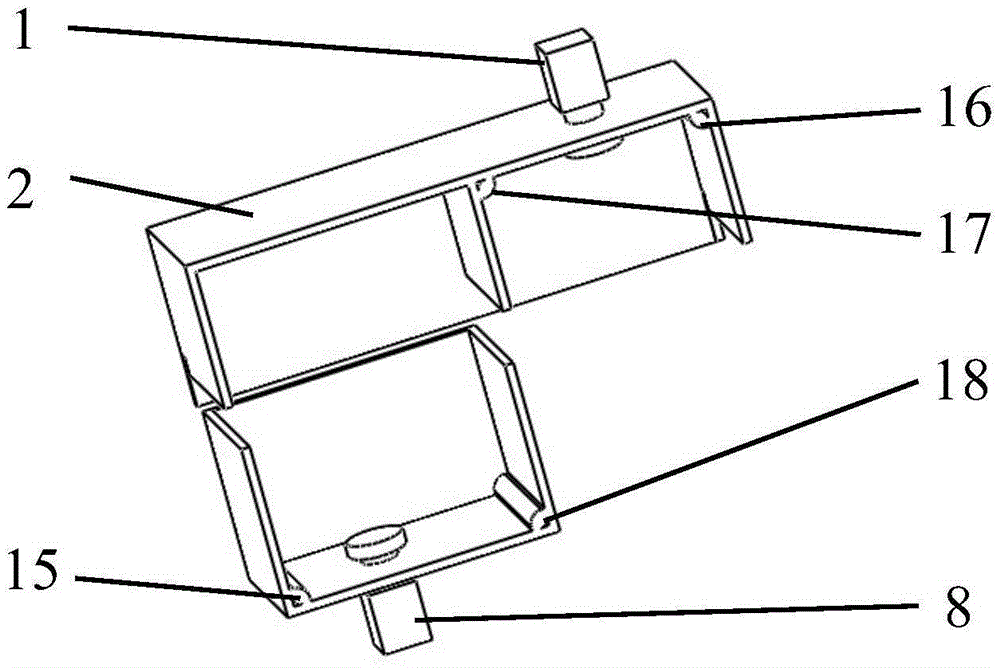

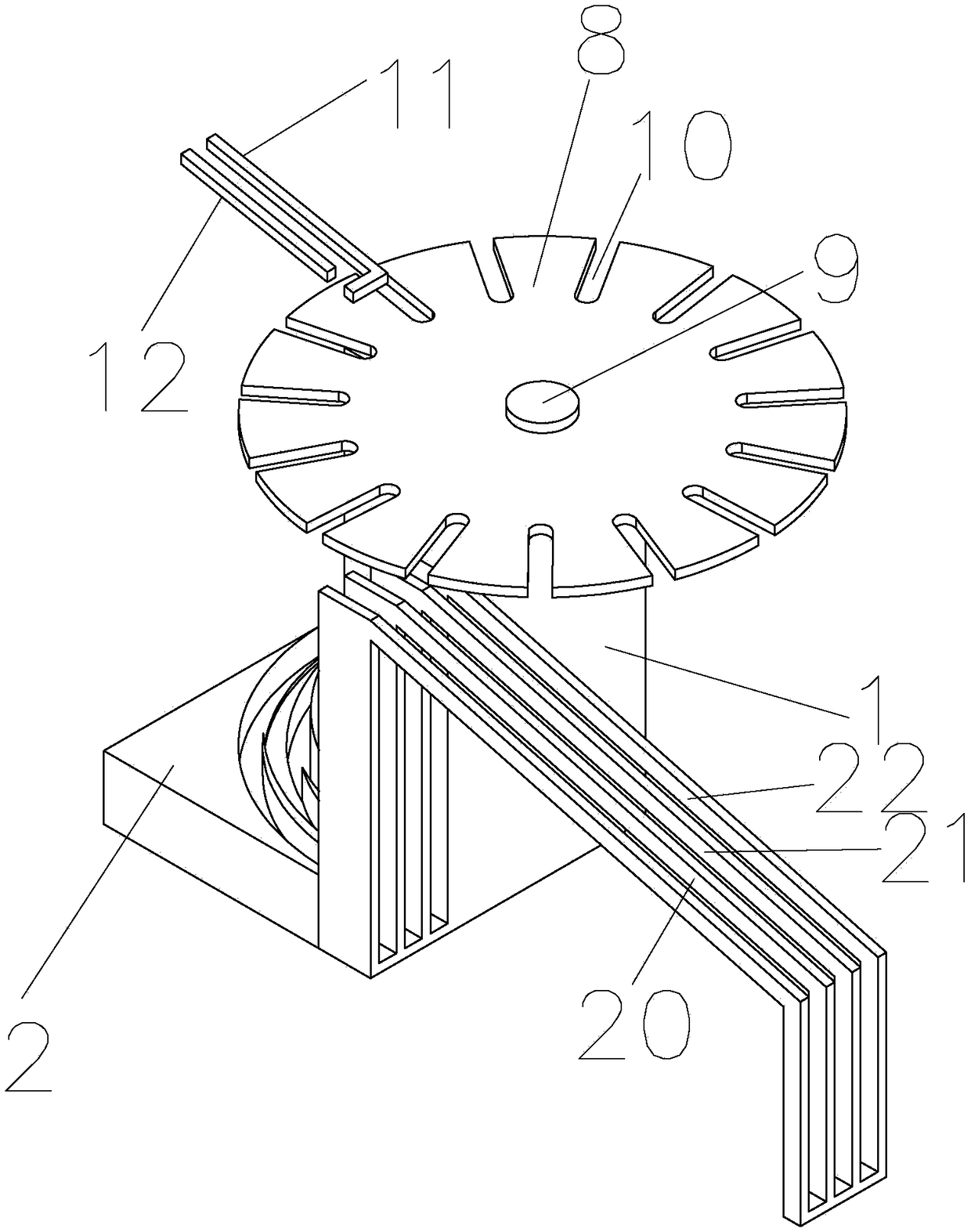

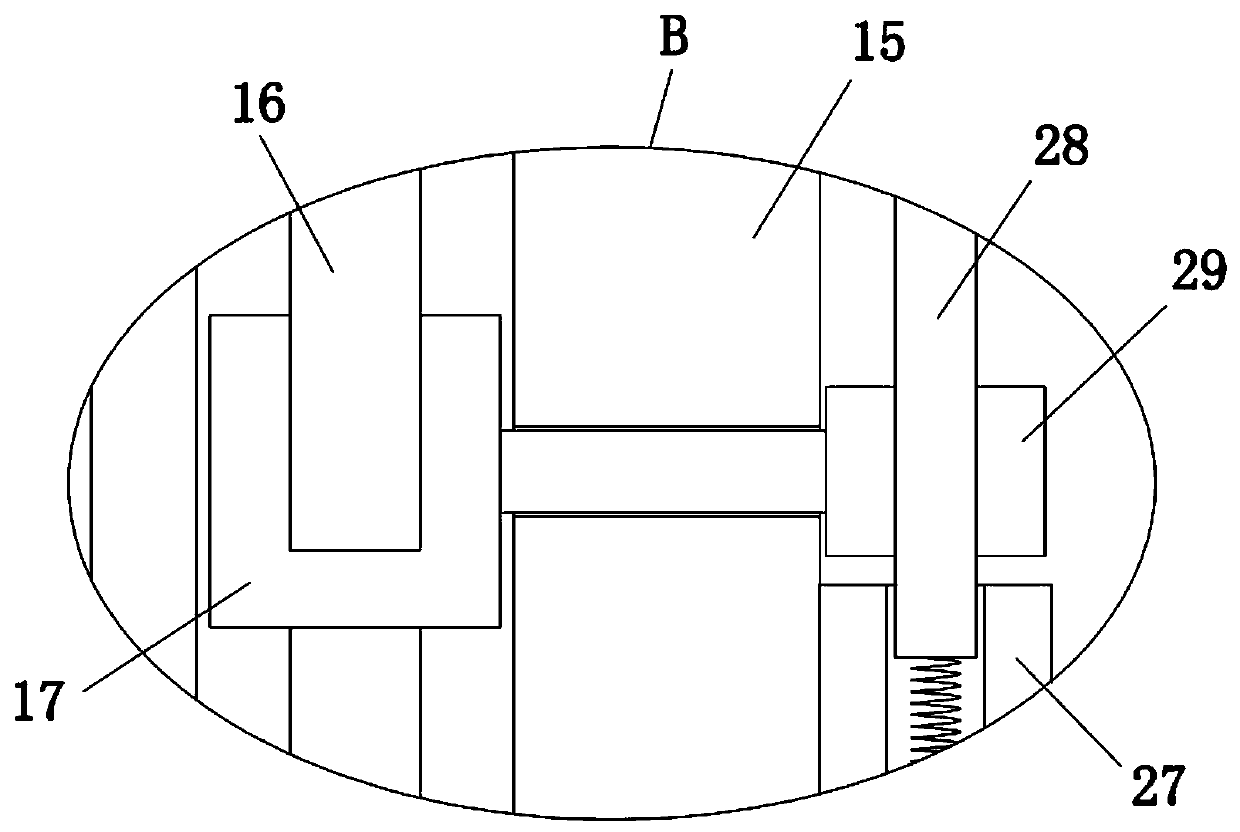

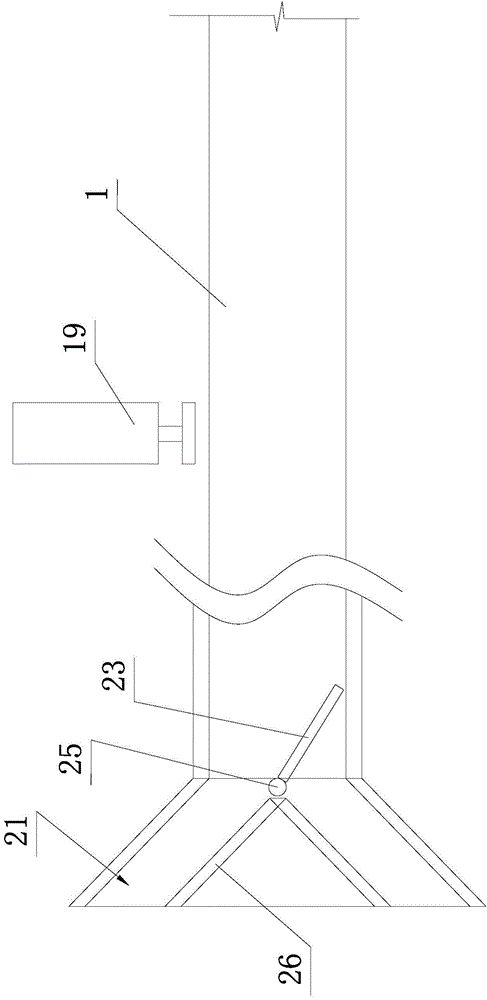

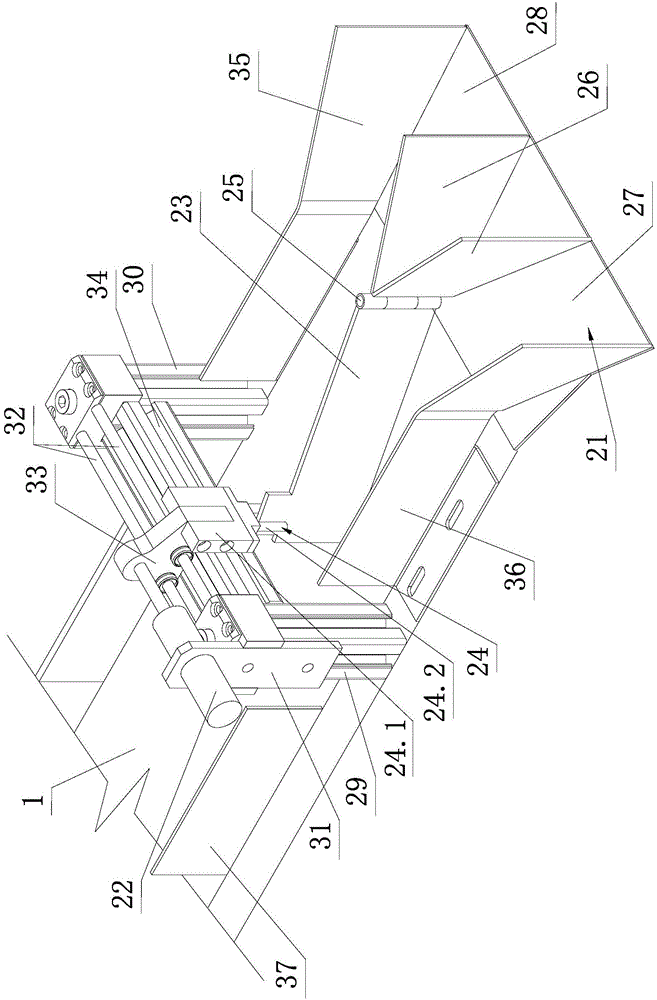

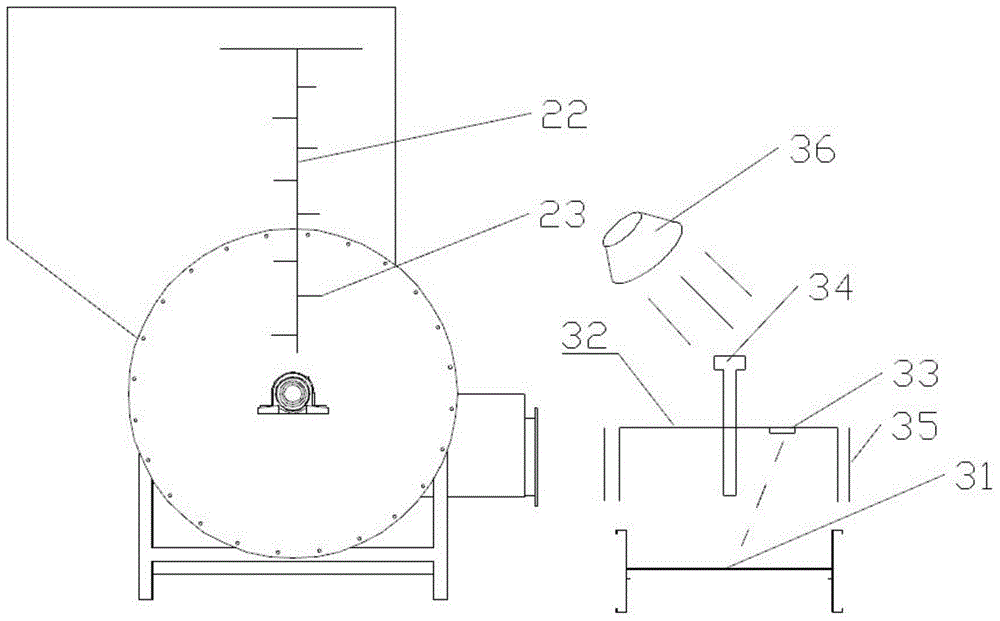

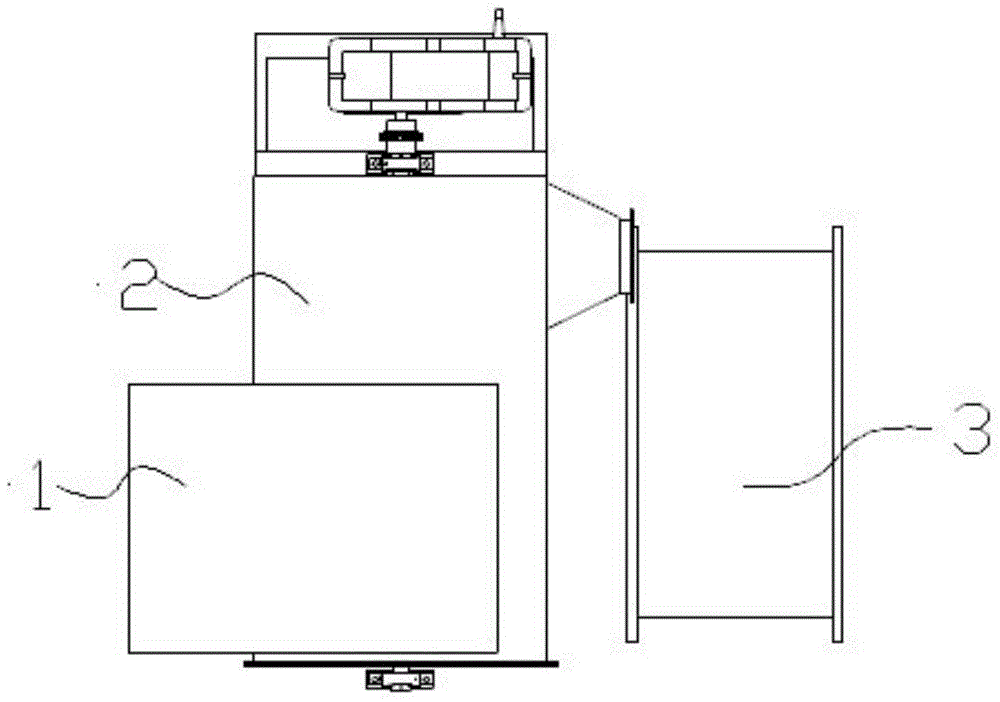

Sorting device and automatic seed slicing and sampling equipment

ActiveCN106217432ASorting is accurateWithdrawing sample devicesSortingEngineeringMechanical engineering

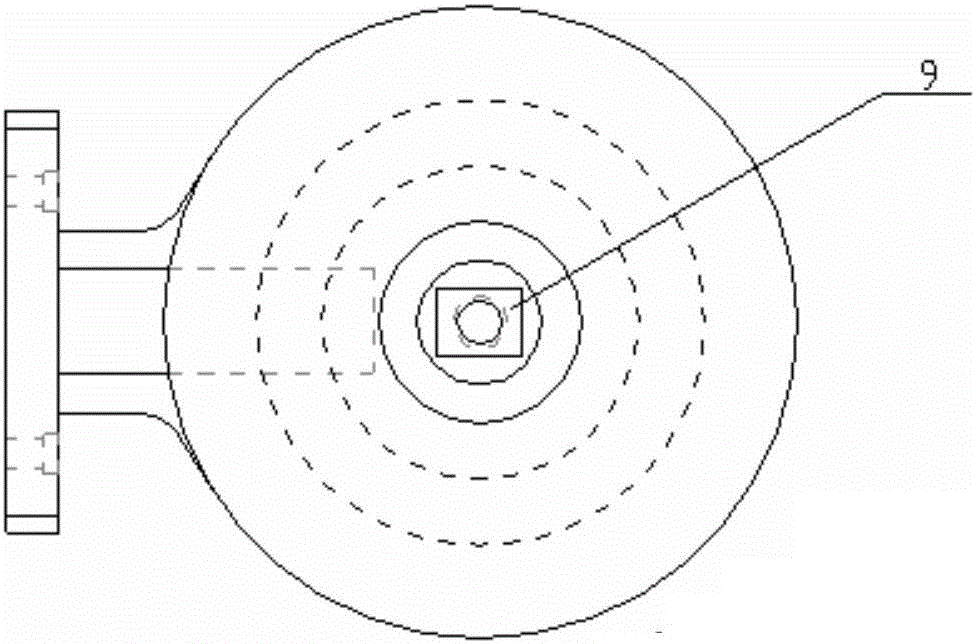

The invention relates to a sorting device. The sorting device comprises a storage hopper and a blanking guide pipe. The storage hopper is used for storing a certain number of seeds, and the bottom of the storage hopper is composed of a fixed disc. The fixed disc is arranged obliquely, an opening is formed in the edge area of the upper portion of the fixed disc, and the position of the opening is higher than the seeds stored in the storage hopper. One end of the blanking guide pipe communicates with the opening of the fixed disc, and the other end of the blanking guide pipe is directly or indirectly led to the position above a lifting platform. The sorting device is characterized in that a sorting rotary disc is further included; the sorting rotary disc is arranged at the bottom of the storage hopper and attached to the upper side of the fixed disc; a plurality of gaps are evenly distributed in the edge area of the sorting rotary disc along the perimeter; the sizes of the gaps are designed to meet the condition that only one seed is contained in each gap; and the sorting rotary disc can rotate in a stepping manner relative to the storage hopper, so that one gap always rotates to the position communicating with the opening of the fixed disc in an alignment manner. The invention further relates to automatic seed slicing and sampling equipment.

Owner:CHINA GOLDEN MARKER BEIJING BIOTECH CO LTD

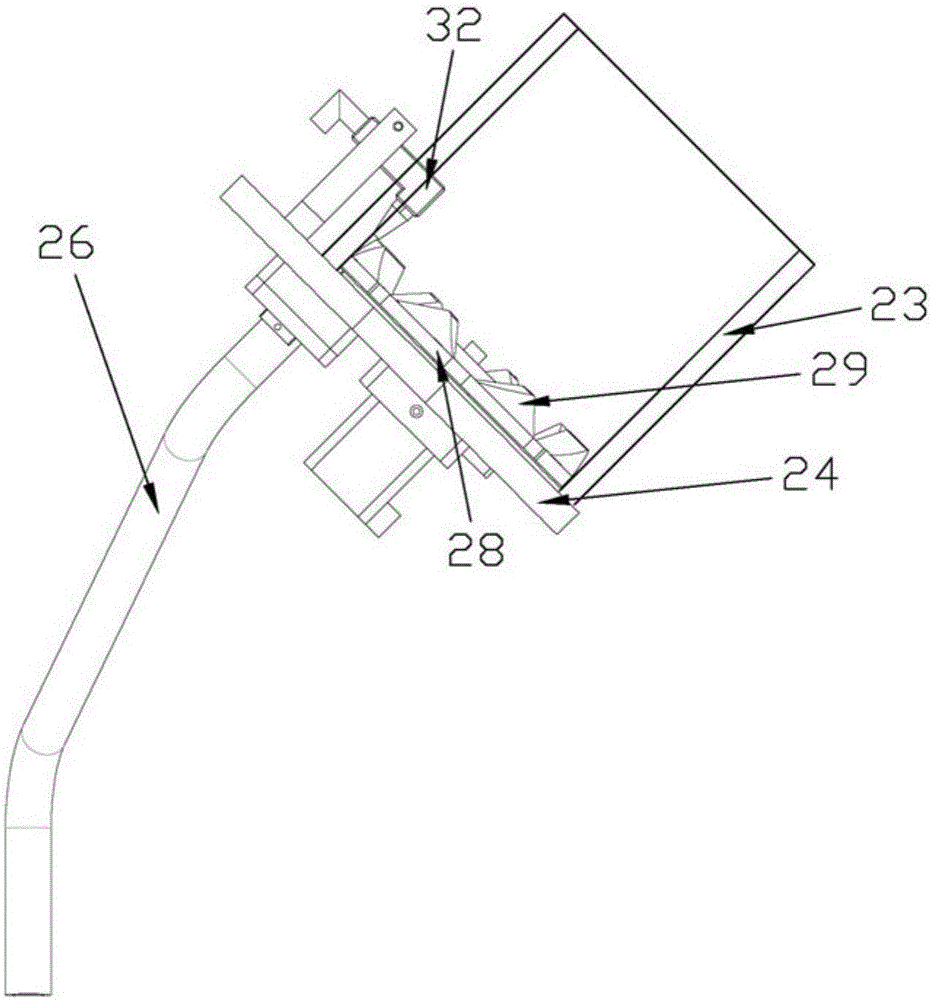

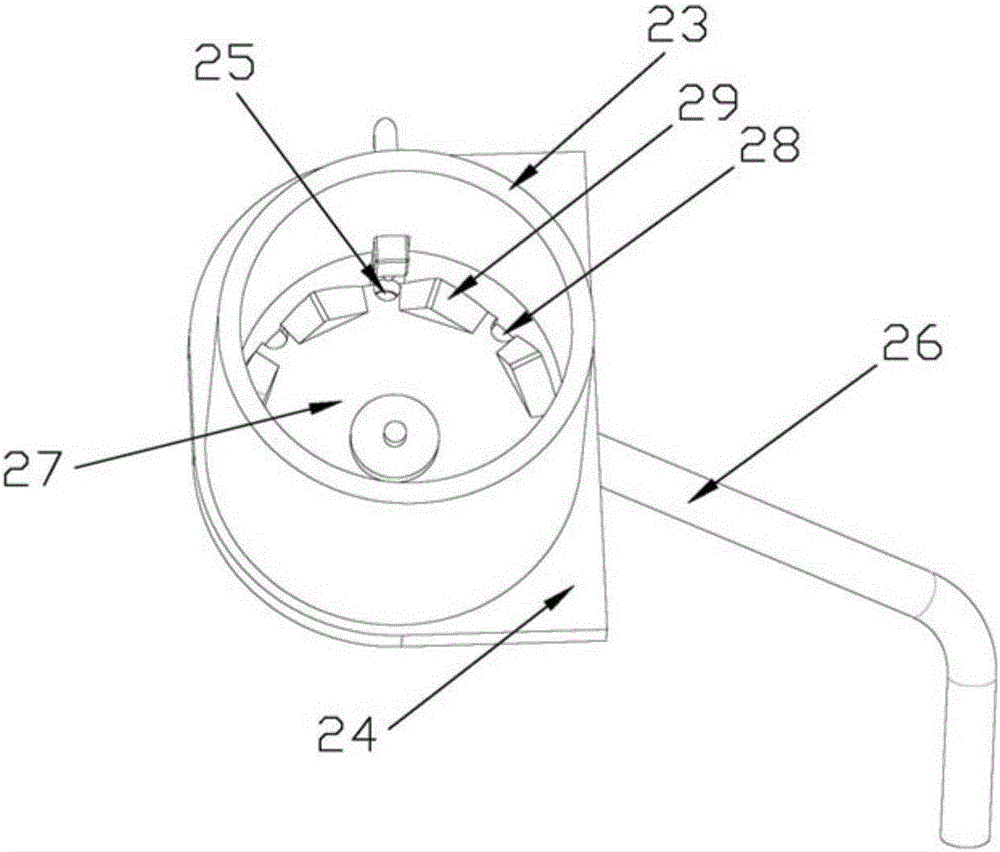

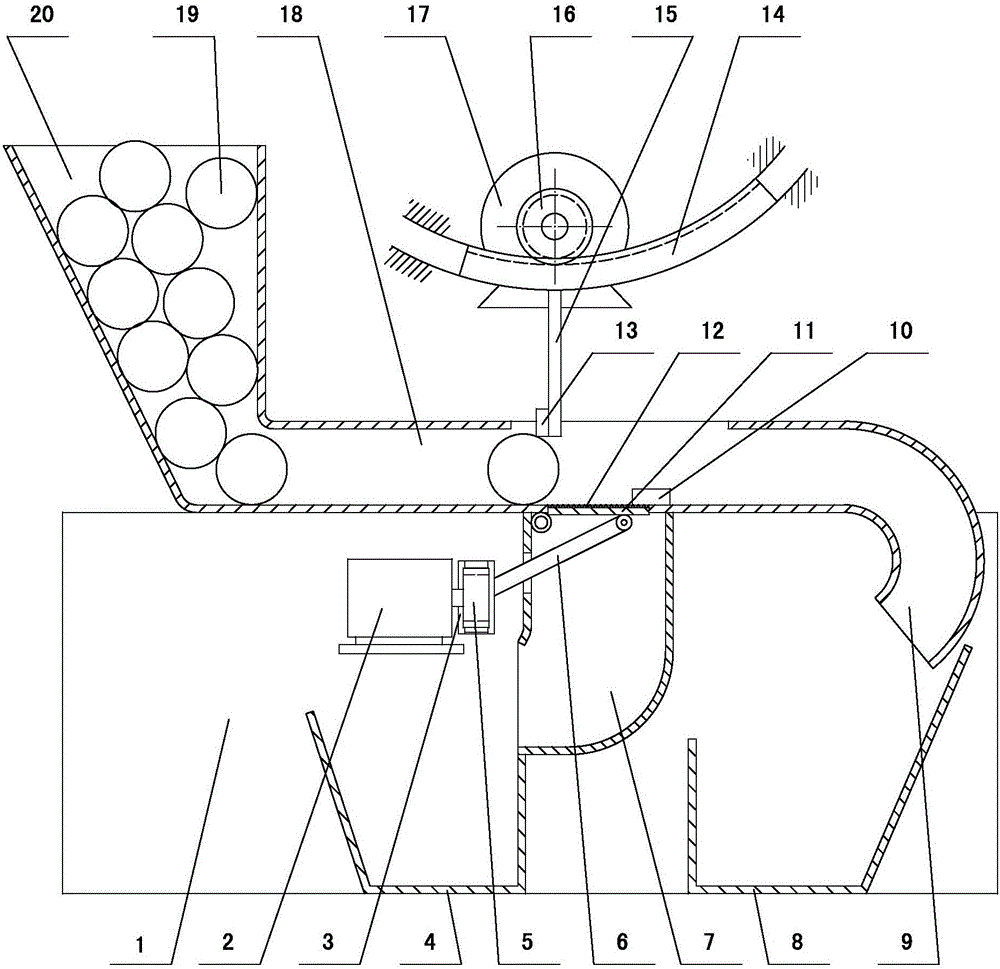

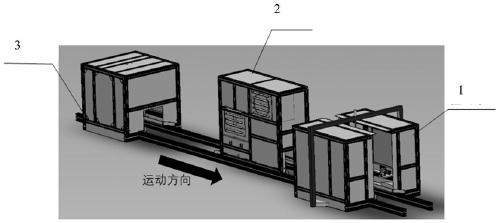

Steel ball surface defect detection sorting equipment

ActiveCN104190634AImprove fullyHigh false positive rateOptically investigating flaws/contaminationCleaning using toolsMetallurgySurface cleaning

The invention discloses steel ball surface defect detection sorting equipment. The steel ball surface defect detection sorting equipment comprises a steel ball size screening device, a steel ball surface cleaning device, a steel ball surface unfolding device, a camera, a sorting device and a control module, wherein the steel ball size screening device comprises two parallel rolling shafts; the steel ball surface cleaning device comprises a trapezoid rotary table and a rotary sleeve covering the rotary table; the steel ball surface unfolding device comprises at least two rolling bars, wherein a containing groove is formed between two adjacent rolling bars, and at least one rotatable rolling bar in the two adjacent rolling bars can be used for driving steel balls to roll in the containing groove in synchronism with the rolling bars. The equipment disclosed by the invention can screen out the out-of-size steel balls and can clean the surfaces of the steel balls so as to prevent the false detection caused by blots on the surfaces of the steel balls; in combination with the specific steel ball surface unfolding device, the steel ball surface defect detection storing equipment can rapidly and accurately sort the steel ball sizes and the steel ball surface defects, and the steel ball sorting efficiency is greatly promoted.

Owner:NINGBO BAIJIABAI MEASUREMENT & CONTROL EQUIP

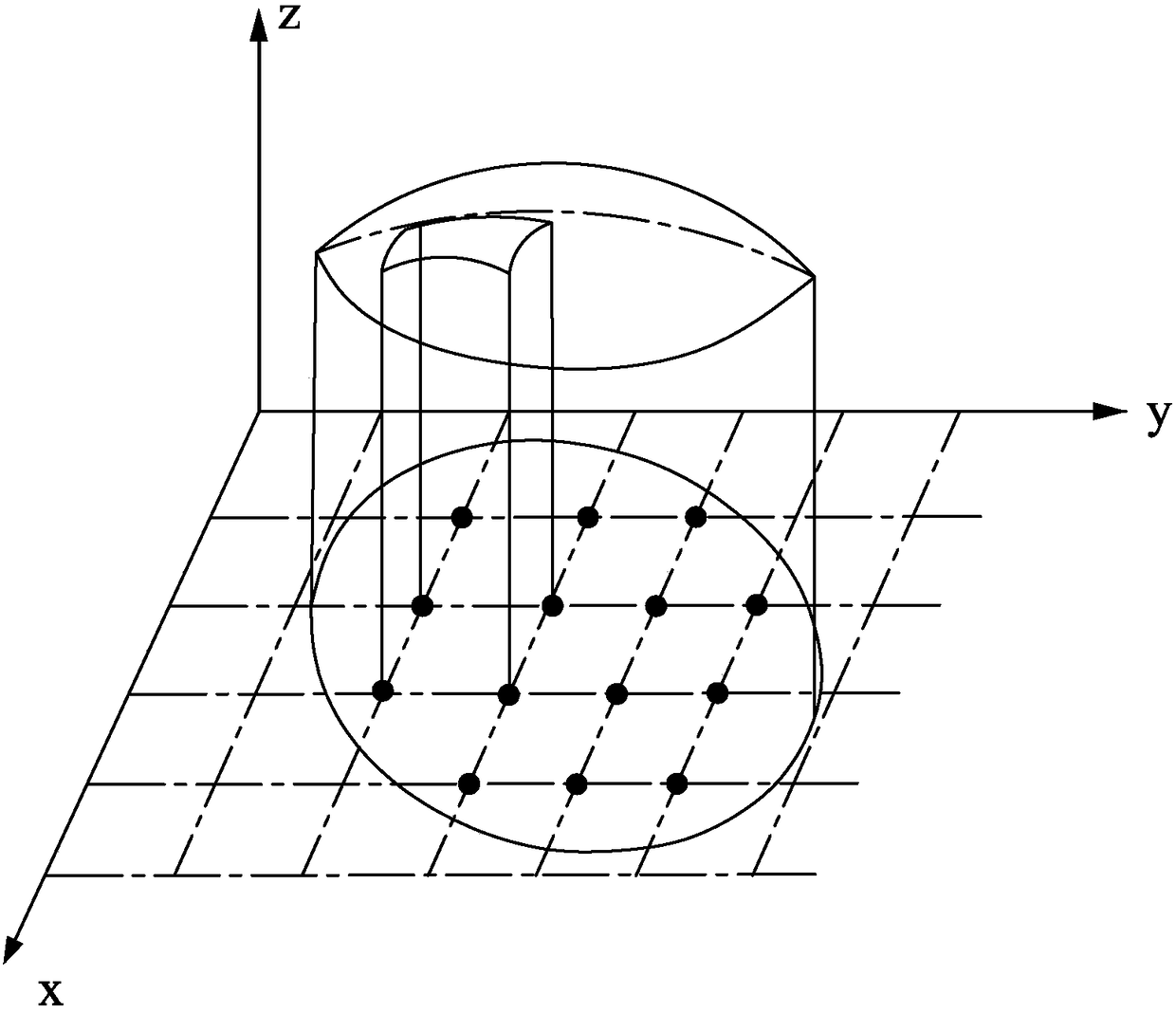

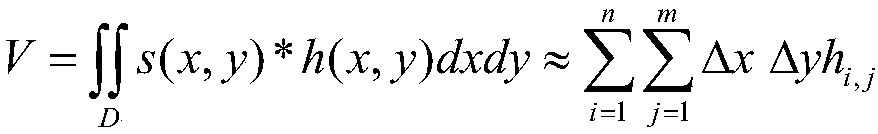

Device and method for sorting building waste

PendingCN108273761AAccurate sortingGuaranteed classification efficiencySortingMaterial typeIntelligent planning

The invention discloses a device and method for sorting building waste. The outline, position, height and other information of materials are obtained through a laser sensor on the basis of a six-freedom-degree mechanical arm, and then, in the process that the six-freedom-degree mechanical arm is guided to grab materials, a tension sensor on the six-freedom-degree mechanical arm is used for obtaining the grabbed material weight information. Finally, the material density can be roughly estimated by utilizing material weight information and space volume information, and accordingly the material type is judged. A density recognition method is adopted for accurately sorting the building waste, and the sorting error rate is greatly reduced; through intelligent planning of the motion path of thesix-freedom-degree mechanical arm, the coordinates of the materials can be rapidly positioned, the material sorting efficiency is guaranteed as well, accurate material sorting is achieved, the work efficiency is greatly improved, and the human resource is saved.

Owner:HUAQIAO UNIVERSITY +1

Multi-coin sorting and packing device

The invention relates to a multi-coin sorting and packing device. The multi-coin sorting and packing device includes a coin entrance container, a coin layered transmission mechanism, a coin authenticity check and sorting mechanism, coin counting and packing mechanisms and a control module which is connected with the coin layered transmission mechanism and the coin counting and packing mechanisms, wherein the coin entrance container, the coin layered transmission mechanism, the coin authenticity check and sorting mechanism and the coin counting and packing mechanisms are sequentially arranged from top to bottom; the coin authenticity check and sorting mechanism includes a plurality of coin sorting slope channels which are arranged obliquely, strong magnets and counterfeit coin collection tubes; the tops of the coin sorting slope channels are aligned with the exit of the coin layered transmission mechanism; counterfeit coin attraction slot holes are formed at side walls at the middle portions of the coin sorting slope channels; the strong magnets are arranged at the outer sides of the counterfeit coin attraction slot holes; the counterfeit coin collection tubes are aligned with the counterfeit coin attraction slot holes; a plurality of sorting slot holes of which the widths are increased progressively are formed at the bottoms of the coin sorting slope channels, wherein the sorting slot holes are distributed from top to bottom along the oblique direction of the coin sorting slope channels; a plurality of coin counting and packing mechanisms are adopted; and the coin counting and packing mechanisms are aligned with the sorting slot holes in various sizes. Compared with the prior art, the multi-coin sorting and packing device of the invention has the advantages of high simplicity, low manufacture cost, high efficiency, convenience and the like.

Owner:SHANGHAI UNIV OF ENG SCI

Automatic ball sorting machine

The invention discloses an automatic ball sorting machine. The automatic ball sorting machine comprises a machine frame, a charging barrel, a ball conveying pipe, a sorting device, a first material falling device and a second material falling device. The sorting device comprises a sensor, a baffle, an arc rack, a first gear and a first motor. An output shaft of the first motor drives the baffle to swing through engagement of the first gear and the arc rack. The lower end of the baffle is connected with the sensor. The distance between the sensing end and the bottom of the ball conveying pipe is equal to the diameter of balls. The first material falling device comprises a material falling plate, a first material falling pipeline, an oblique pulling rod, a sliding block, a second gear and a second motor. An output shaft of the second motor drives the material falling plate to overturn through engagement of the second gear and the rack and cooperation of the sliding block and the oblique pulling rod. By adopting the structure, manual sorting is replaced, the production efficiency is greatly improved, the sorting precision is higher, and operation is more convenient.

Owner:太仓吉井机械有限公司

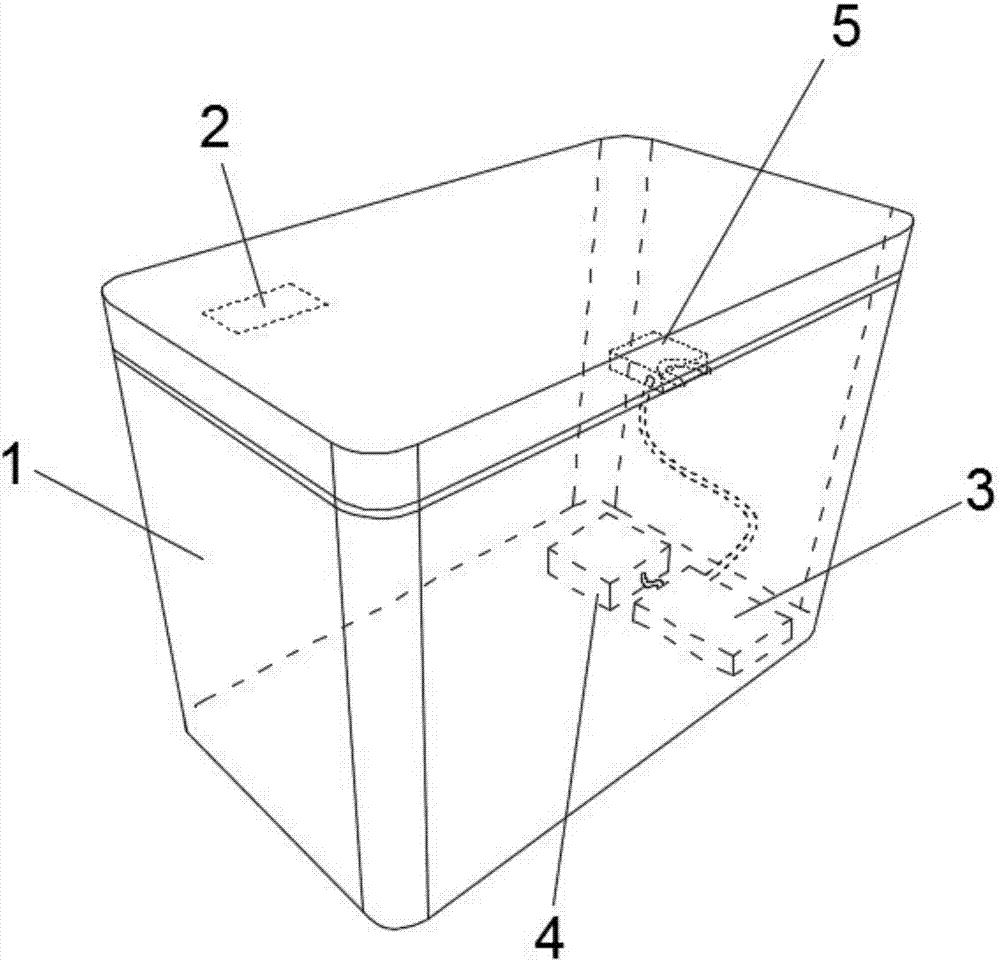

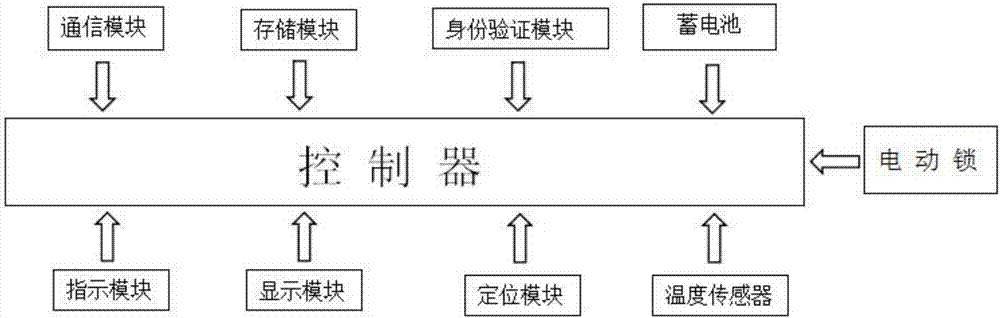

Intra-city intelligent logistics distribution management method and intelligent logistics heat insulation box

PendingCN107194653AThere will be no order confusionThe order was packed smoothlyDomestic cooling apparatusLighting and heating apparatusLogistics managementApproaches of management

The invention discloses an intelligent logistics incubator, which includes an incubator body, an RFID card, a controller, a communication module, a storage module, an identity verification module, a storage battery and an electric lock, wherein the RFID card, the controller, the communication module, the storage The module, identity verification module and storage battery are respectively set on or built into the heat preservation box, and the electric lock is set at the opening of the heat preservation box; the communication module, storage module, identity verification module, battery and electric lock are respectively connected to the controller. The invention also discloses an intra-city intelligent logistics distribution management method based on the above-mentioned intelligent logistics incubator, which realizes orderly, smooth, and fast processes such as order packaging, sorting, distribution, and sign-in, and realizes assembly line operations as a whole, with high efficiency and improved The accuracy and safety of goods delivery.

Owner:深圳市道嘉鲜科技有限公司

Intelligent production system for wattmeter

The invention discloses an intelligent production system for a wattmeter and solves the technical problems that the conventional electric energy meter calibration and warehouse management system is imperfect and only one type of wattmeter can be operated. The intelligent production system comprises a warehouse inlet / outlet delivery line, a warehouse system and a plurality of calibration systems, wherein the warehouse system comprises a three-dimensional meter library and a stacker for fetching the wattmeter from the three-dimensional meter library; and the intelligent production system is characterized in that: a production scheduling platform system transmits task instructions to the warehouse inlet / outlet delivery line, the warehouse system and the calibration systems; each calibration system comprises a calibrating main delivery line and a plurality of calibration units; and the three-dimensional meter library is lifted through the stacker and is butted with the warehouse inlet / outlet delivery line and the calibrating main delivery lines of various calibration systems respectively. By the system, a monitoring device is integrated, the safety is guaranteed, the system can be adjusted in real time, the whole set of system is operated in order, a plurality of types of wattmeters are warehoused and calibrated simultaneously without interference, and actual production requirements are met.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER +1

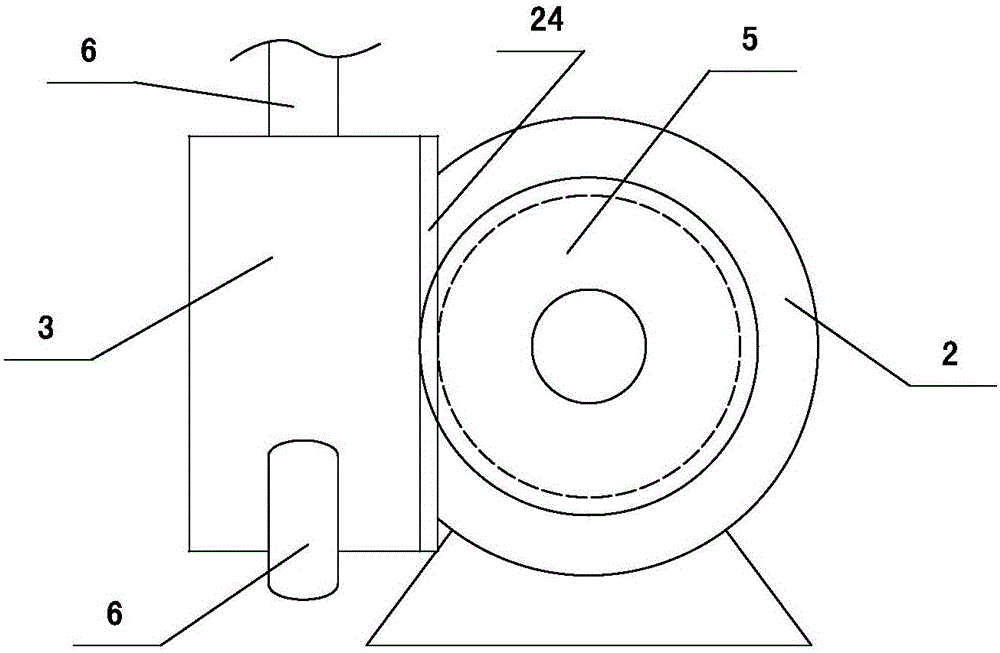

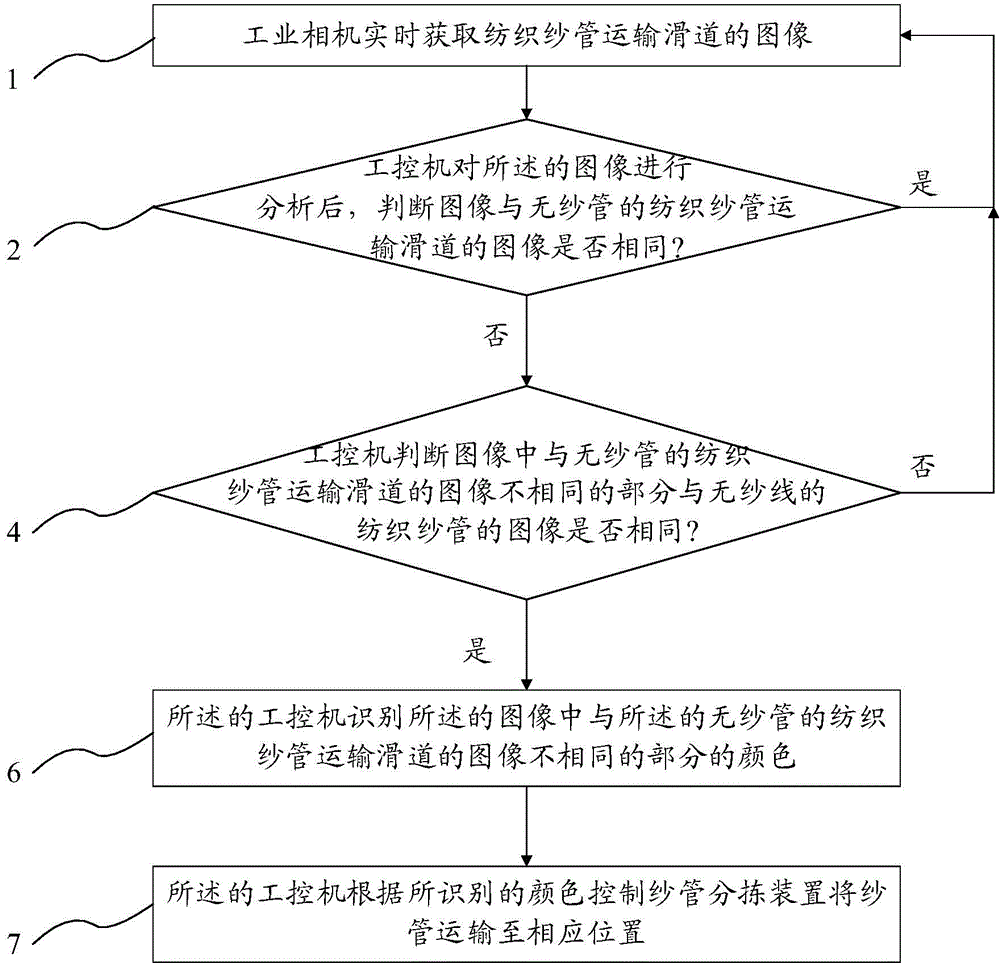

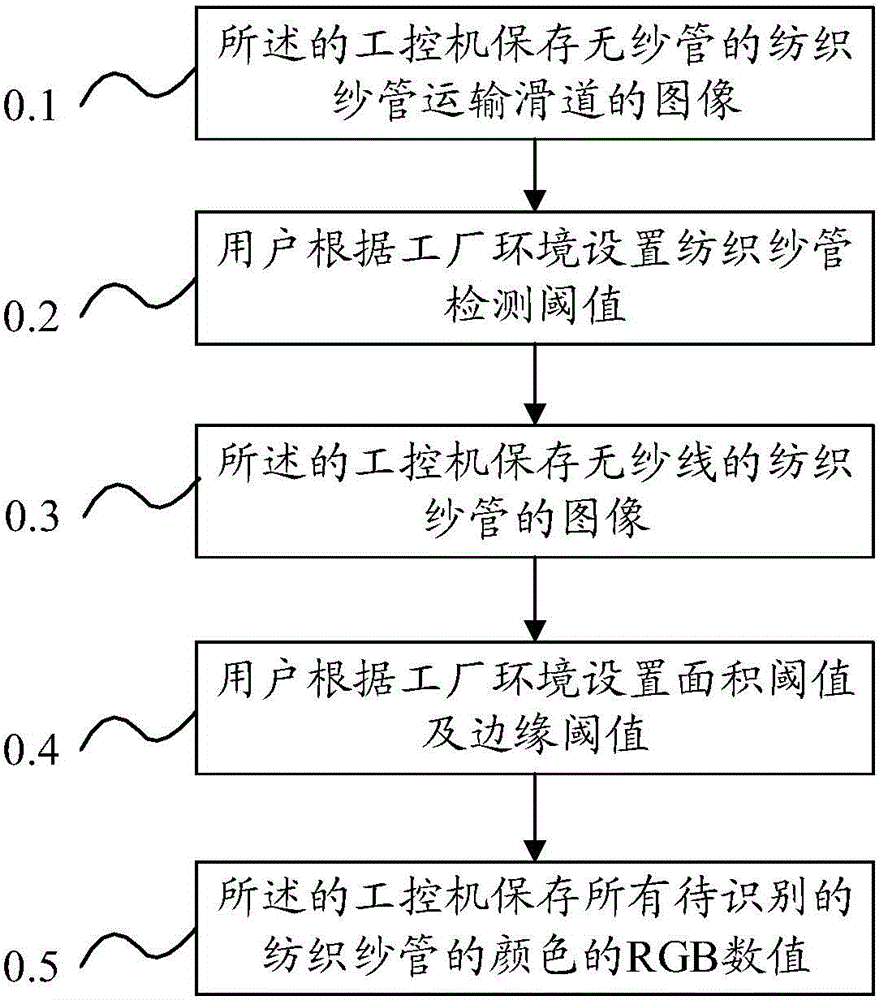

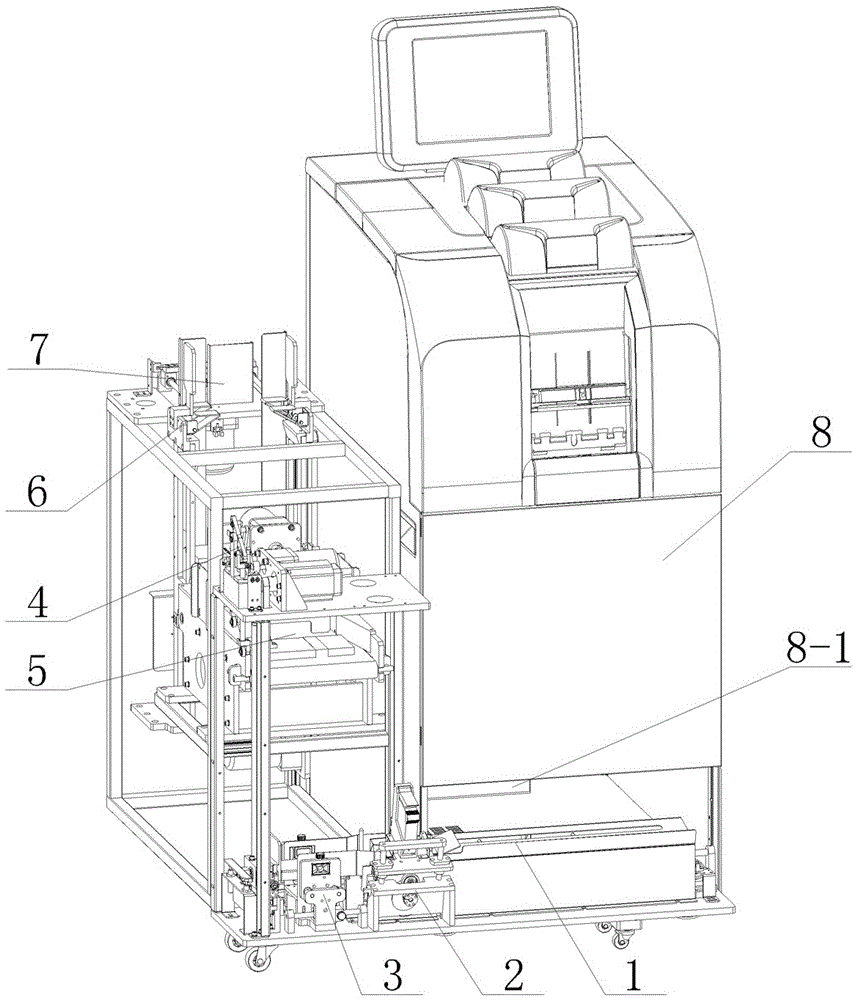

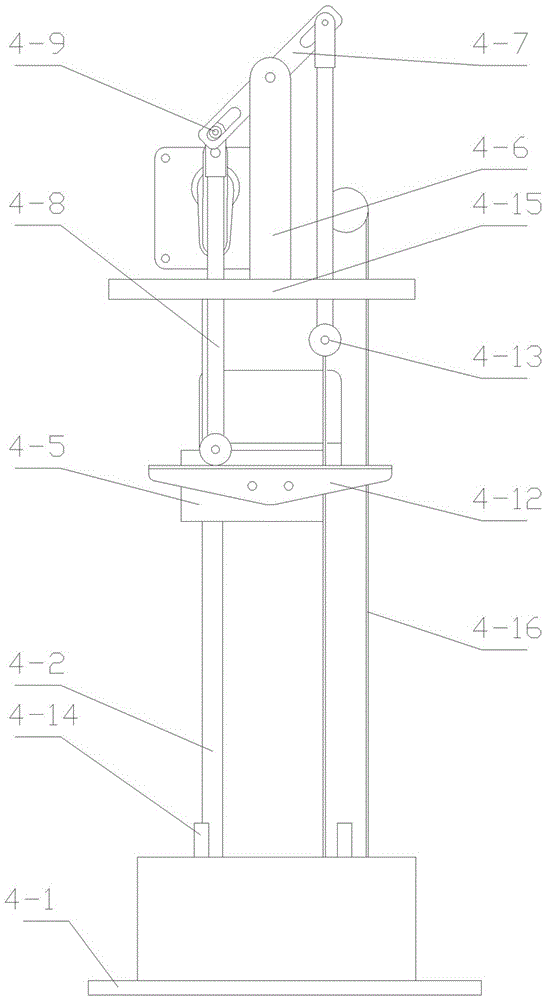

Method for realizing sorting of textile bobbins based on machine vision

A related method for realizing sorting of textile bobbins based on machine vision comprises an operation process and a debugging process; the operation process mainly comprises that an industrial camera acquires an image of a textile bobbin transportation slideway in real time, and an industrial control computer performs binary processing on the image of the textile bobbin transportation slideway, and performs bobbin existence recognition, bobbin yarn recognition, color recognition and textile bobbin end thickness recognition on the processed image, and puts the textile bobbins finishing recognition according to requirements; and the debugging process mainly comprises learning on correlated characteristics of the operation process. The method for realizing sorting of textile bobbins based on machine vision abandons a technical scheme of employing a color-sensitive sensor for sorting of textile bobbins in the prior art, realizes precise sorting of textile bobbins by utilizing machine vision, helps to improve the robustness, the flexibility and intelligentization for sorting of textile bobbins, improve production efficiency and save labor cost, and brings substantial economic benefit.

Owner:SHANGHAI WEIHONG ELECTRONICS TECH

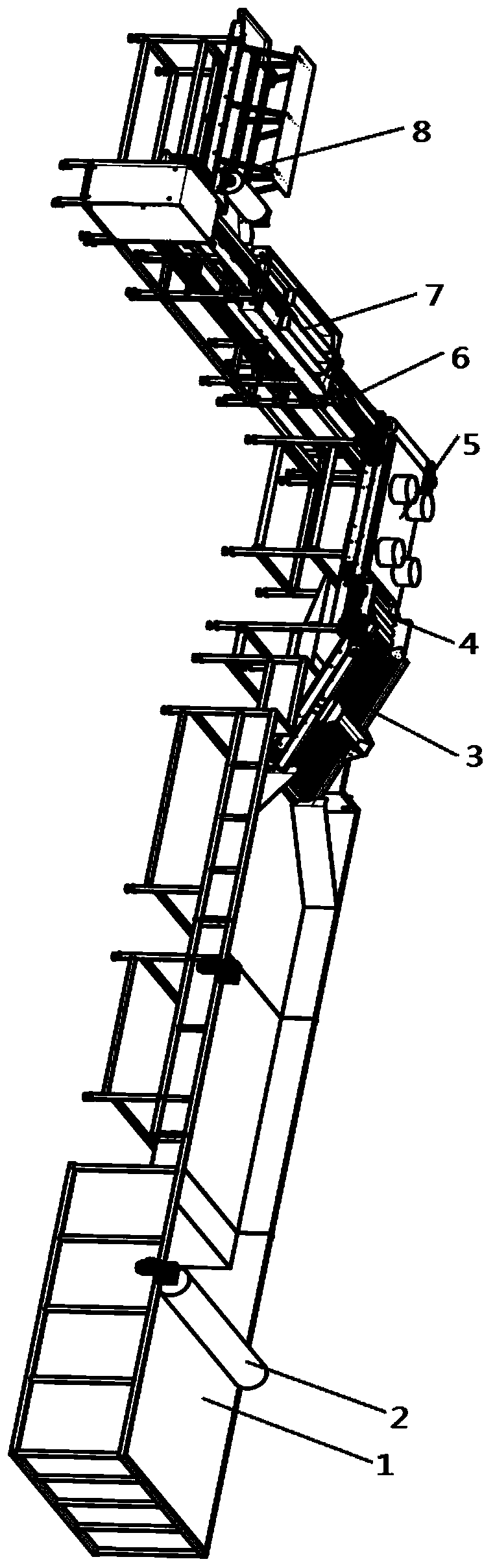

Clearing system integrated with bundling integrated processing apparatus

ActiveCN105825577AReduce complexityEasy follow-upCoin/currency accepting devicesEngineeringHandling system

The invention relates to a clearing system integrated with a bundling integrated processing apparatus. With the system, a technical problem that the labor intensity of the staff of the bank mechanism is high and the work efficiency is low because the existing clearing system is not integrated with a paper money integrated processing system can be solved. According to the technical scheme, the system comprises a clearing machine and a bundling integrated processing device connected with a cash outlet at the lower part of the clearing machine. The bundling integrated processing device includes a case and rack, a bundling inlet formed in the bottom of the case, a stack outlet arranged at the upper part of the case, a bundling lifting bidirectional overturning type sorting mechanism arranged in the case, a precise limiting type bundling conveying mechanism arranged between the bundling inlet and the bundling lifting bidirectional overturning type sorting mechanism, a printing mechanism, a stamping mechanism, and a bundling lifting stacking output mechanism arranged between a sorting output terminal of the bundling lifting bidirectional overturning type sorting mechanism and the stack outlet, wherein the printing mechanism and the stamping mechanism are arranged along the conveying direction of the precise limiting type bundling conveying mechanism. The system has advantages of simple structure and high integration degree.

Owner:HEBEI HUIJIN ELECTROMECHANICAL

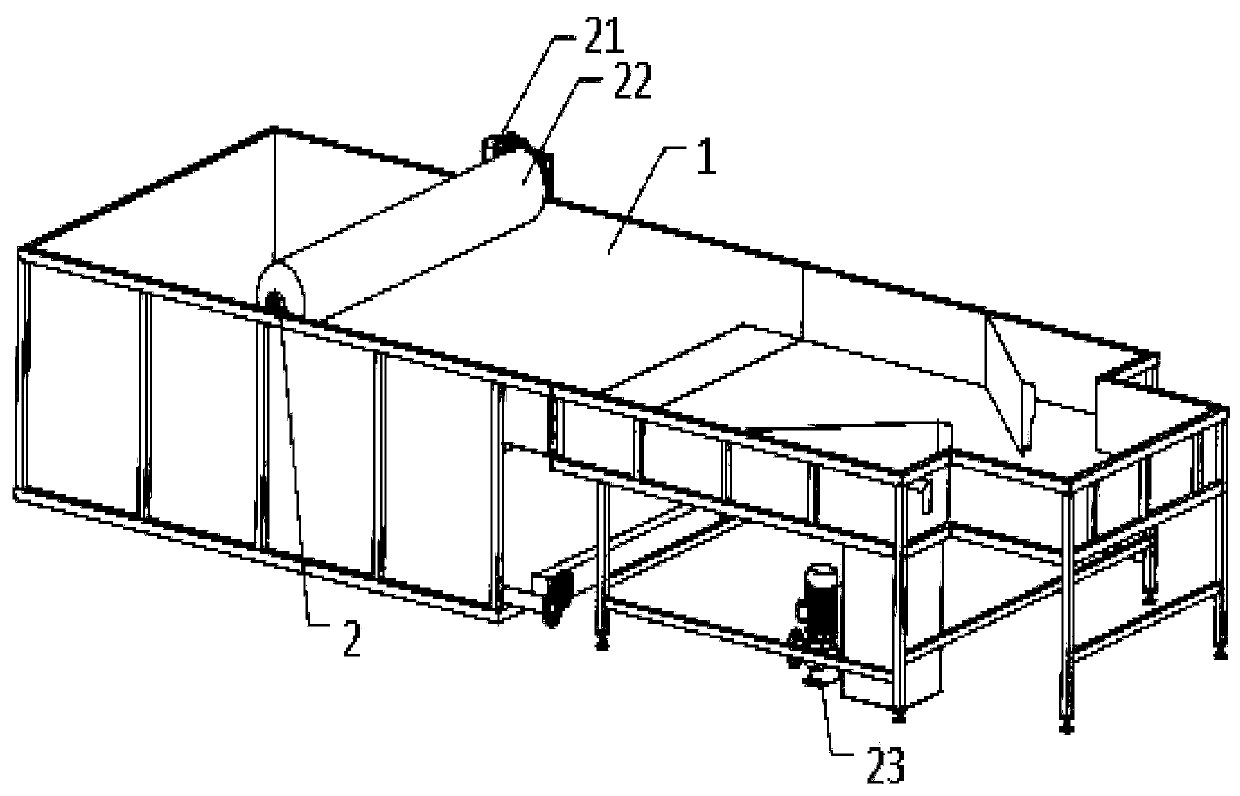

Image collecting and sorting device for tea bags

ActiveCN105457907ARealize online detectionSorting is accurateOptically investigating flaws/contaminationSortingAutomatic controlMachine vision

The invention discloses an image collecting and sorting device for tea bags. The image collecting and sorting device comprises a machine frame module, a sliding table module, a dark box module, an image collecting module and a sorting module. The machine frame module is formed by lap joint of four sectional bars different in length and a bottom plate and is used for supporting and fixing the whole device; the sliding table module comprises guide plates and a sliding table; the dark box module comprises an upper dark box shell, a lower dark box shell and LED lamps; the image collecting module comprises an upper camera, a lower camera, a PC and photoelectric sensors; the sorting module comprises a PLC, an air cylinder and a sorting push plate. According to the image collecting and sorting device, the machine vision technology and the automatic control technology are adopted, the tea bags can be accurately sorted at high speed, problems in packaging of the tea bags can be found easily, the labor intensity is greatly lowered, the production efficiency is improved, and the shortcomings of traditional manual sorting are overcome.

Owner:YIWU SCI & TECH INST CO LTD OF ZHEJIANG UNIV OF TECH

Corn sorting machine

InactiveCN103962311AAvoid accumulationCompact structureSortingProgrammable logic controllerReciprocating motion

The invention relates to a corn sorting machine capable of dividing corns into three sorts, namely corns with the lengths of less than or equal to 150 millimeters, corns with the lengths of more than 150 millimeters and smaller than 200 millimeters and corns with the lengths of more than or equal to 200 millimeters, according to the lengths of the corns. Three major parts, namely a feeding part, a division part and a sorting part, are arranged on a steel structural rack, and are driven by six motors respectively. In the feeding part, the corns fall on a conveyor belt driven by a driving system consisting of a belt transmission device, a planetary gear speed reducer and a chain transmission device after being arranged through arrangement rollers in a hopper. In the division part, a vibrating frame reciprocally moves by virtue of a crank-connecting rod mechanism driven by the motor to divide the corns into rows in a vibrating way. In the sorting part, double rows of parallel conveyor belts are adopted, and after the corns reach the detection range of a sensor, detected corn length signals are transmitted to a PLC (programmable logic controller), cylinders are further controlled to move, and a discharging baffle plate is further driven to realize the sorting of the corns. According to the corn sorting machine, the manual sorting can be replaced, so that the efficiency is improved by more than 10 times; the corn sorting machine is low in construction cost and convenient to operate.

Owner:HARBIN ENG UNIV

Sorting device special for long screw

The invention relates to a sorting device special for a long screw. The sorting device comprises a feeding module, a conveying module and a sorting module, the conveying module is connected to the upper side of the sorting module, and the feeding module is arranged on one side of the upper portion of the conveying module. The sorting device has few parts and is simple in structure and convenient to operate, manpower is greatly reduced, a lot of electric power is saved at the same time, energy is saved, the environment is protected, and the cost is reduced for enterprises. Through the design ofan adjustable sorting disc, long bolts different in standard can be well sorted precisely, qualified products are selected out, the sorting efficiency is improved, and the sorting accuracy is also improved at the same time.

Owner:NINGBO ZHENHAI YONGDING FASTENER

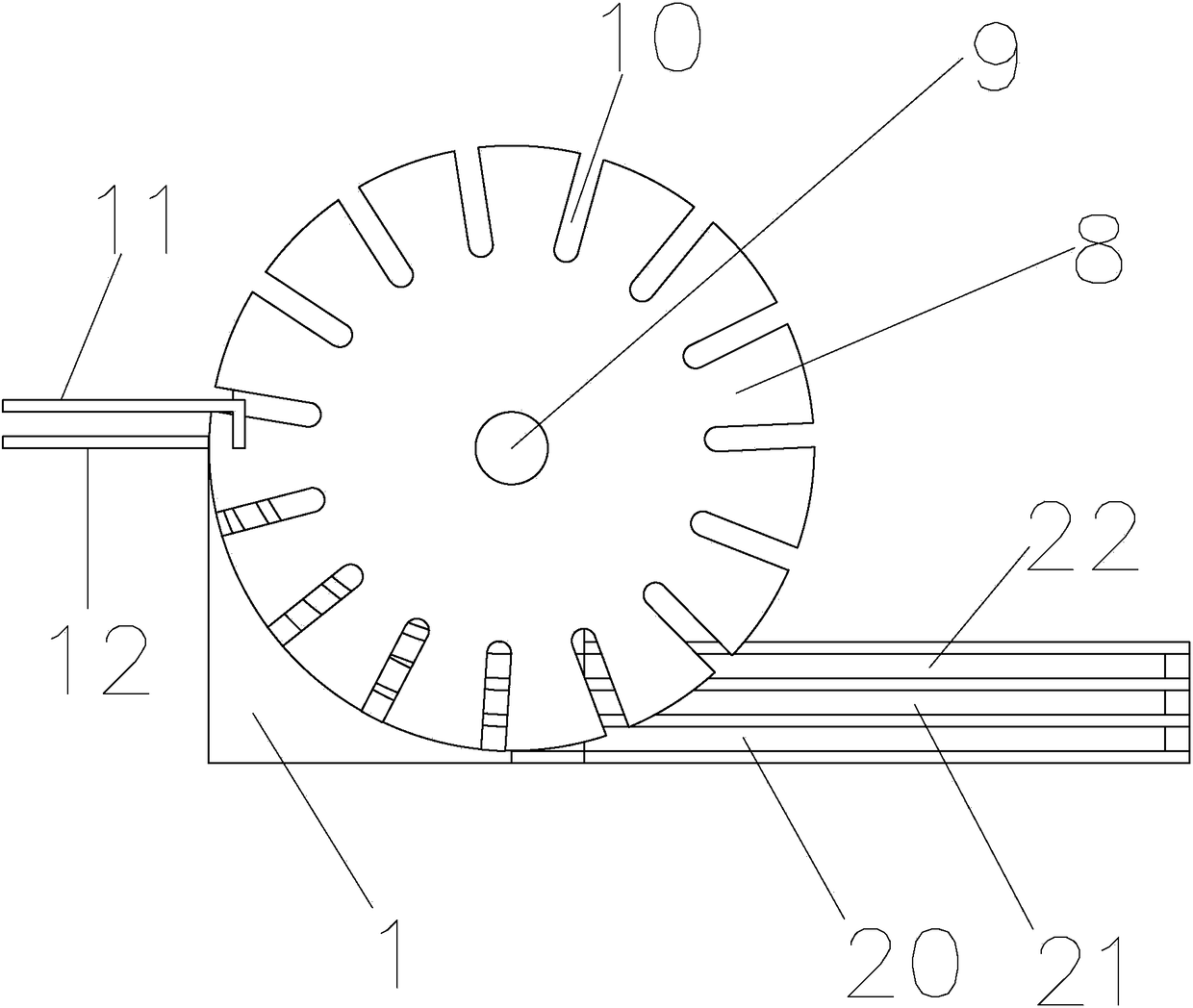

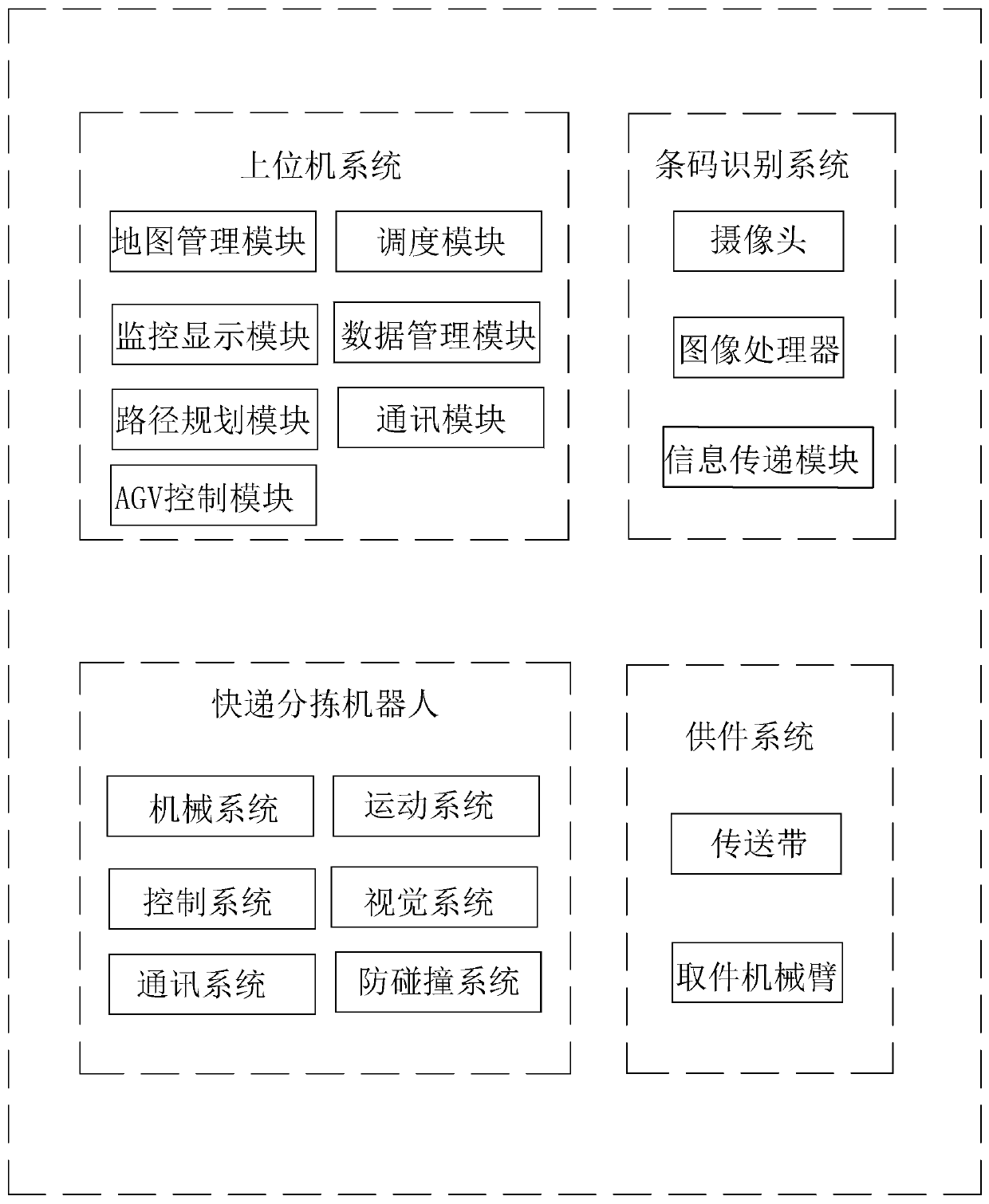

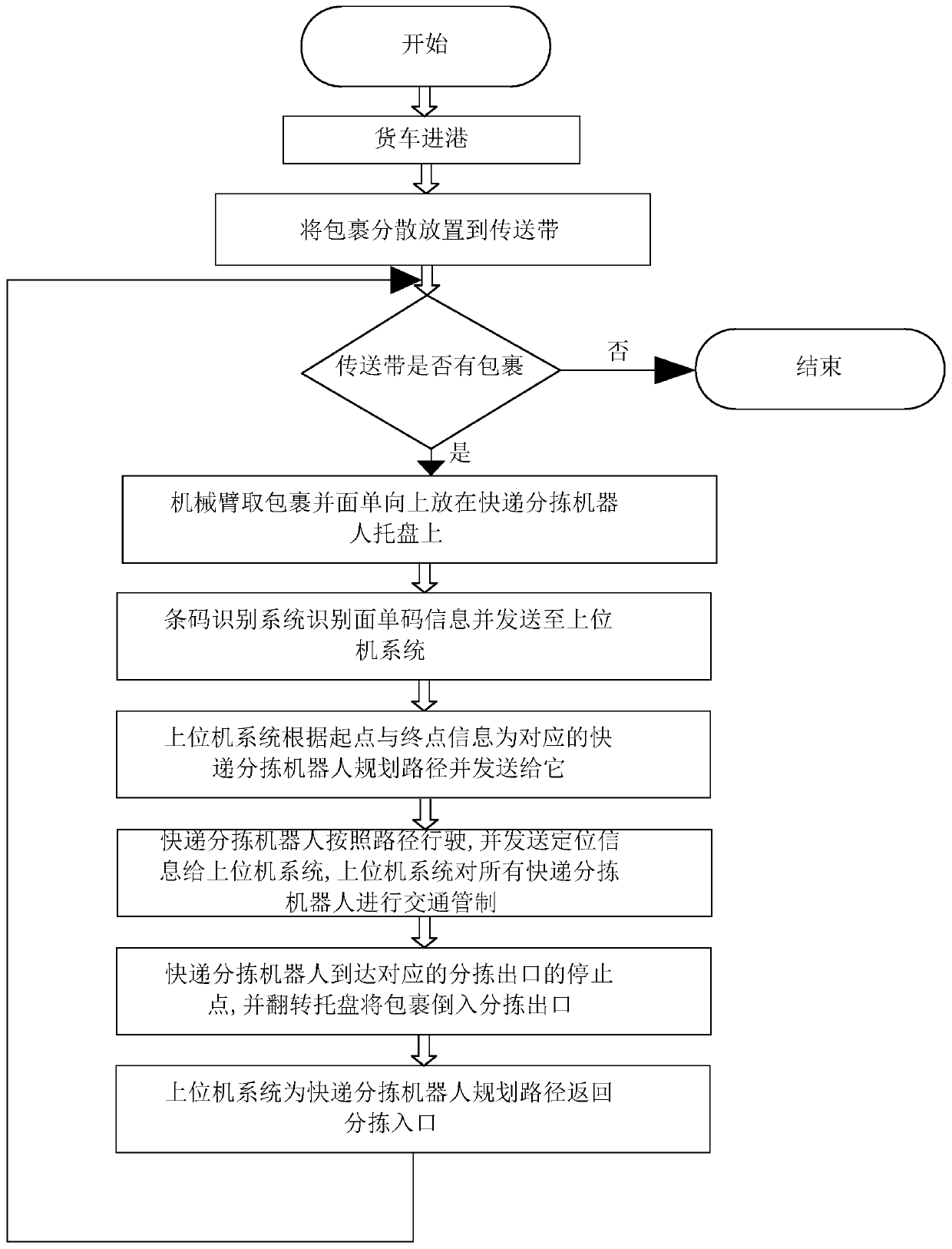

Logistics sorting system and sorting platform

InactiveCN110523645AImprove sorting efficiencySorting is accurateSortingLogistics managementPath network

The invention discloses a logistics sorting system and a sorting platform. The logistic sorting system comprises an upper computer system, an express sorting robot, an express supply system used for supplying express to the express sorting robot and a bar code recognition system used for scanning express sheet bar codes and sending information to the upper computer system, and the upper computer system comprises: a map management module used for building an electronic map model of a sorting site path network; a monitoring display module that is responsible for monitoring the motion state of the express sorting robot; a path planning module that is responsible for planning a path for the express sorting robot; an AGV control module that is responsible for managing and controlling the stateand action of the express sorting robot; a scheduling module that is responsible for allocating tasks to the express sorting robot; a data management module that is responsible for persisting system data to a database; and a communication module that is responsible for communication between the upper computer system and all the express sorting robots. The logistics sorting system has the effects of being accurate in sorting and high in sorting efficiency.

Owner:郑州佳和新供应链管理有限公司

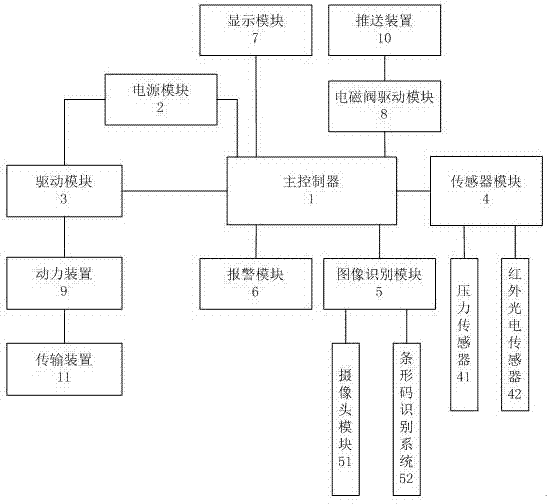

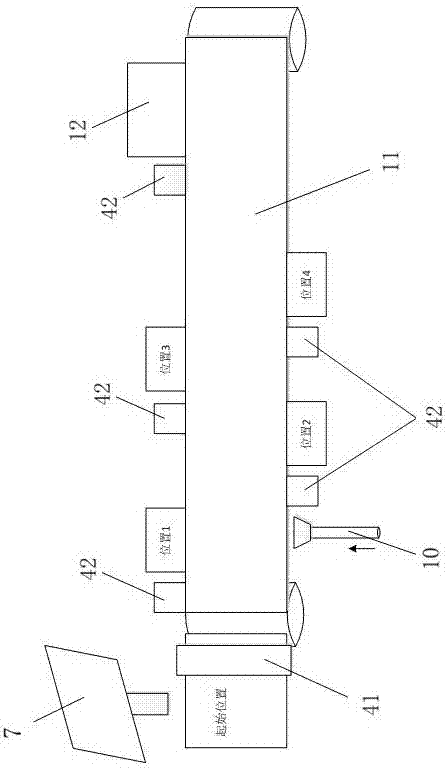

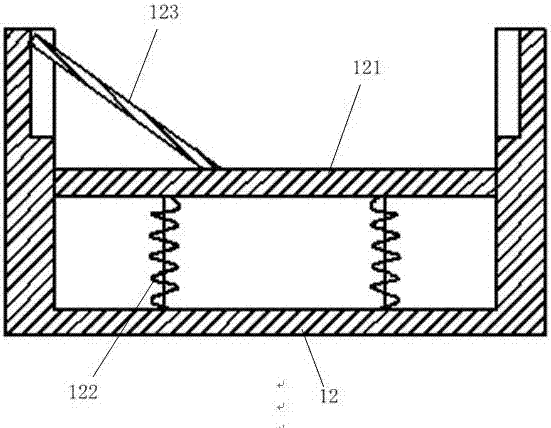

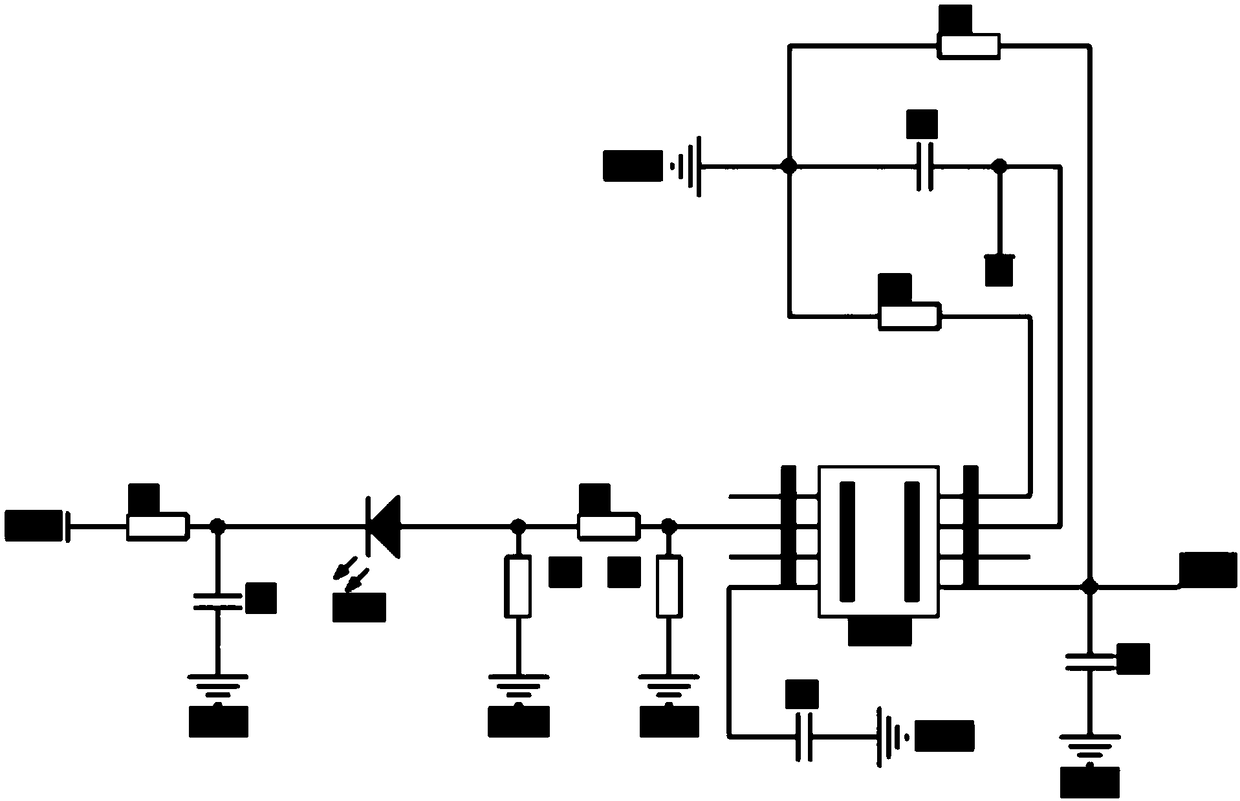

Intelligent sorting system for electronic commerce goods and implementation method

InactiveCN107168191AGood versatilityFast wayProgramme controlComputer controlMotor driveElectromagnetic valve

The invention belongs to the technical field of electronic commerce goods sorting, and provides an intelligent sorting system for electronic commerce goods. The intelligent sorting system comprises a main controller, a power supply module, a driving module, a sensor module, an image recognition module, an alarm module, a display module, an electromagnetic valve driving module, a power device, a pushing device and a transmitting device, wherein the main controller is connected with the power supply module, the driving module, the sensor module, the image recognition module, the alarm module, the display module, the electromagnetic valve driving module, the power device, the pushing device and the transmitting device. The technical scheme is applied to an intelligent sorting system in the field of electronic commerce, the goods are sorted accurately by taking different destinations as a condition under the premise of protecting the goods from being damaged in the sorting process by virtue of the modes such as a pressure sensing system and motor-driven transportation through image recognition, a sorting task is completed efficiently, and the intelligent sorting system replaces manpower to complete a task of goods waybill number scanning.

Owner:SHANGHAI UNIV OF ENG SCI

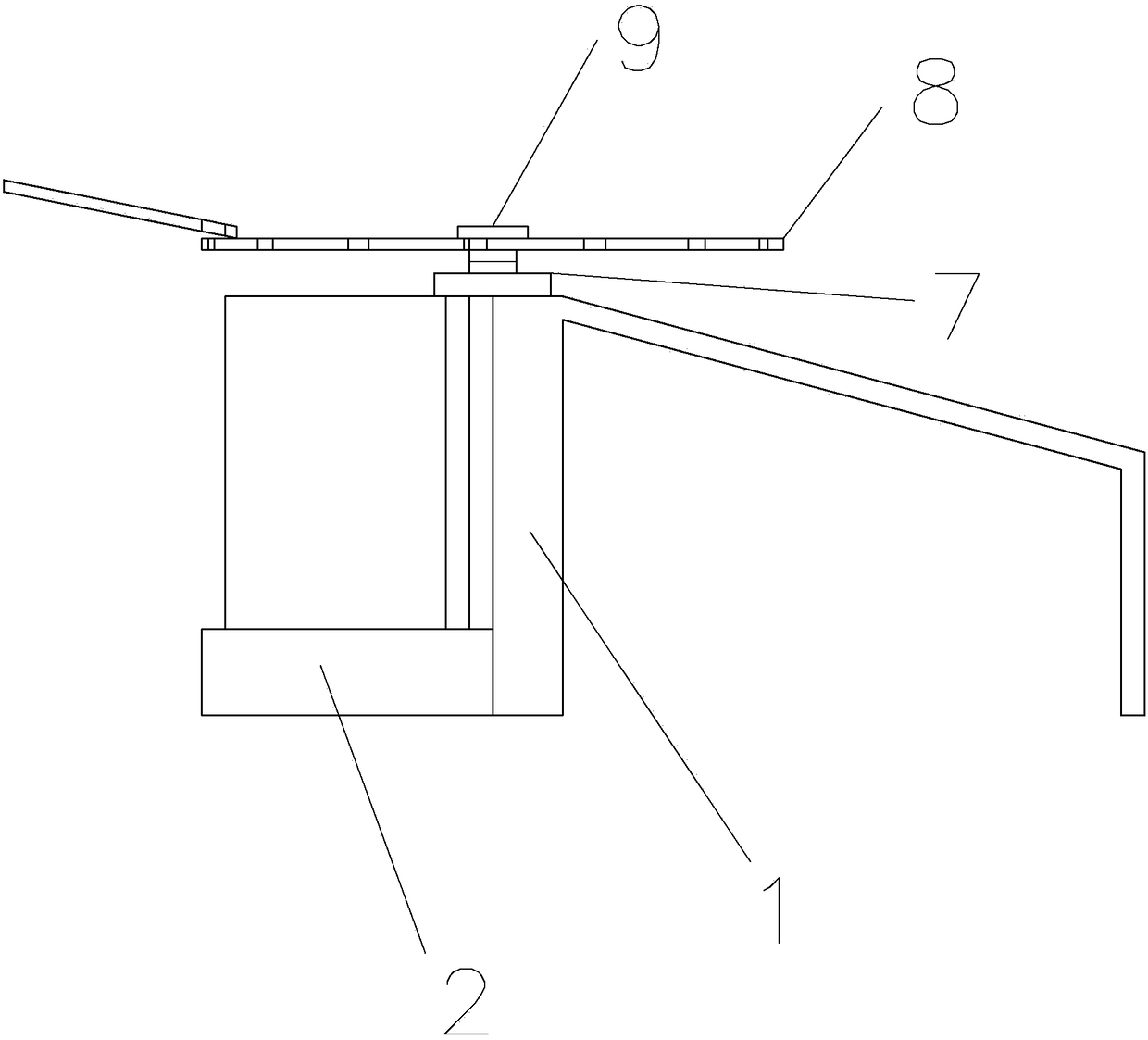

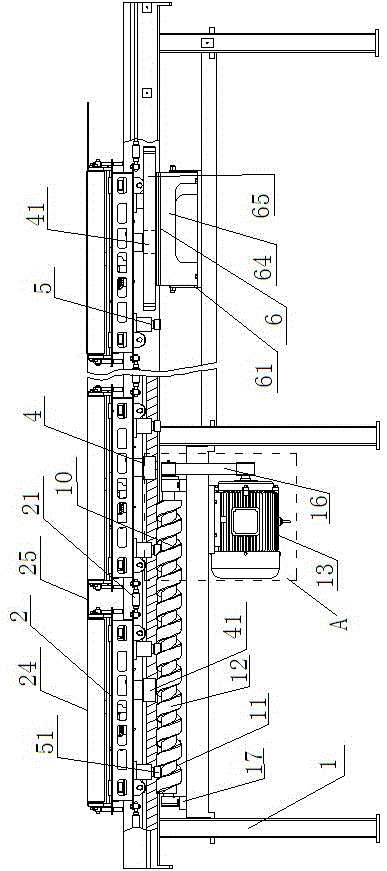

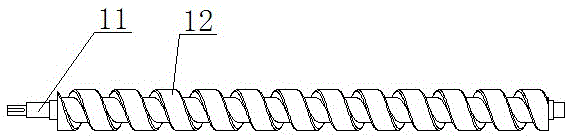

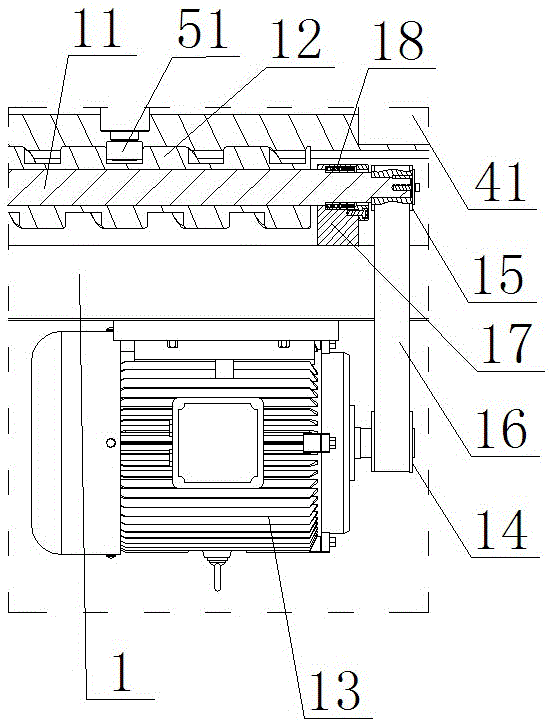

Express sorting machine comprising cam and worm for driving

The invention provides an express sorting machine comprising a cam and a worm for driving. The express sorting machine comprises a machine frame, trolleys and a trolley driving device. The trolleys and the trolley driving device are mounted on the machine frame. The trolley driving device controls advancing of the trolleys. The trolley driving device comprises the worm, the cam and a worm driving device. The cam is spirally fixed to the worm. Each trolley comprises a base, two side plates, a conveying belt, two roller devices, a conveying belt driving device and a transmission device, wherein the two side plates are fixed to the two sides of the base in parallel; the two ends of the two roller devices are connected with the two ends of the two side plates to form a rectangle; the conveying belt surrounds the outer sides of the two roller devices; the conveying belt driving device is mounted on the base and controls operation of the conveying belt; the transmission device is mounted on the base and connected with the trolley driving device. The express sorting machine is reasonable in structural design, good in conveying and transferring effect, safe, reliable, low in manufacturing cost, stable in goods conveying and accurate in sorting.

Owner:桐庐县富春江机电设备制造有限公司

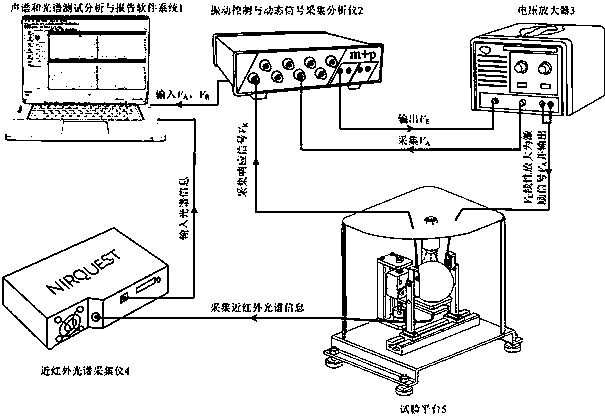

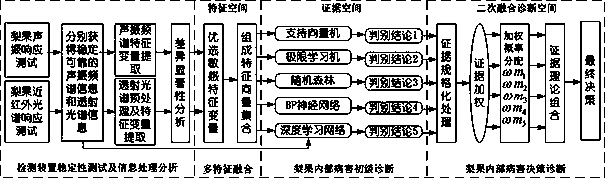

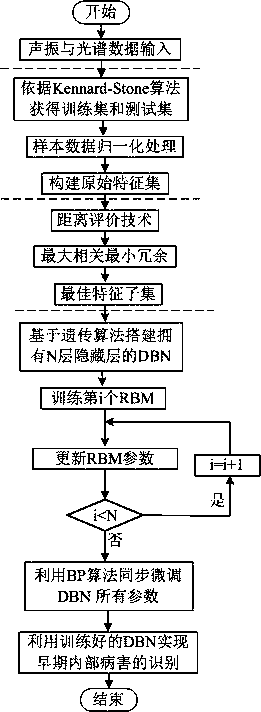

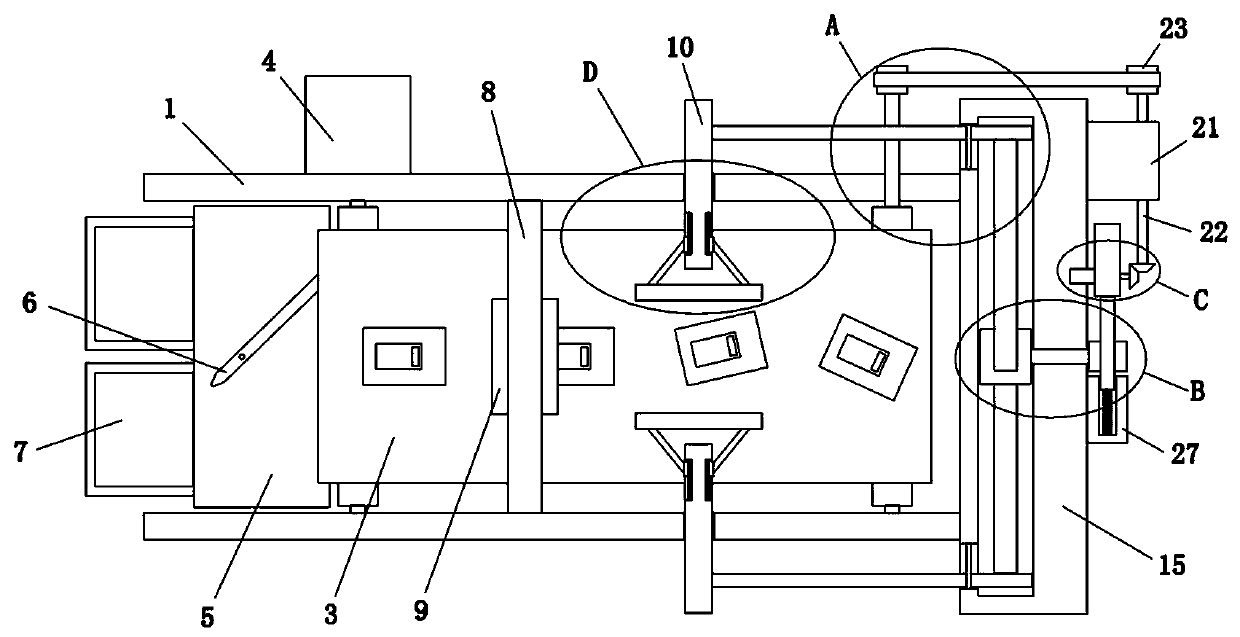

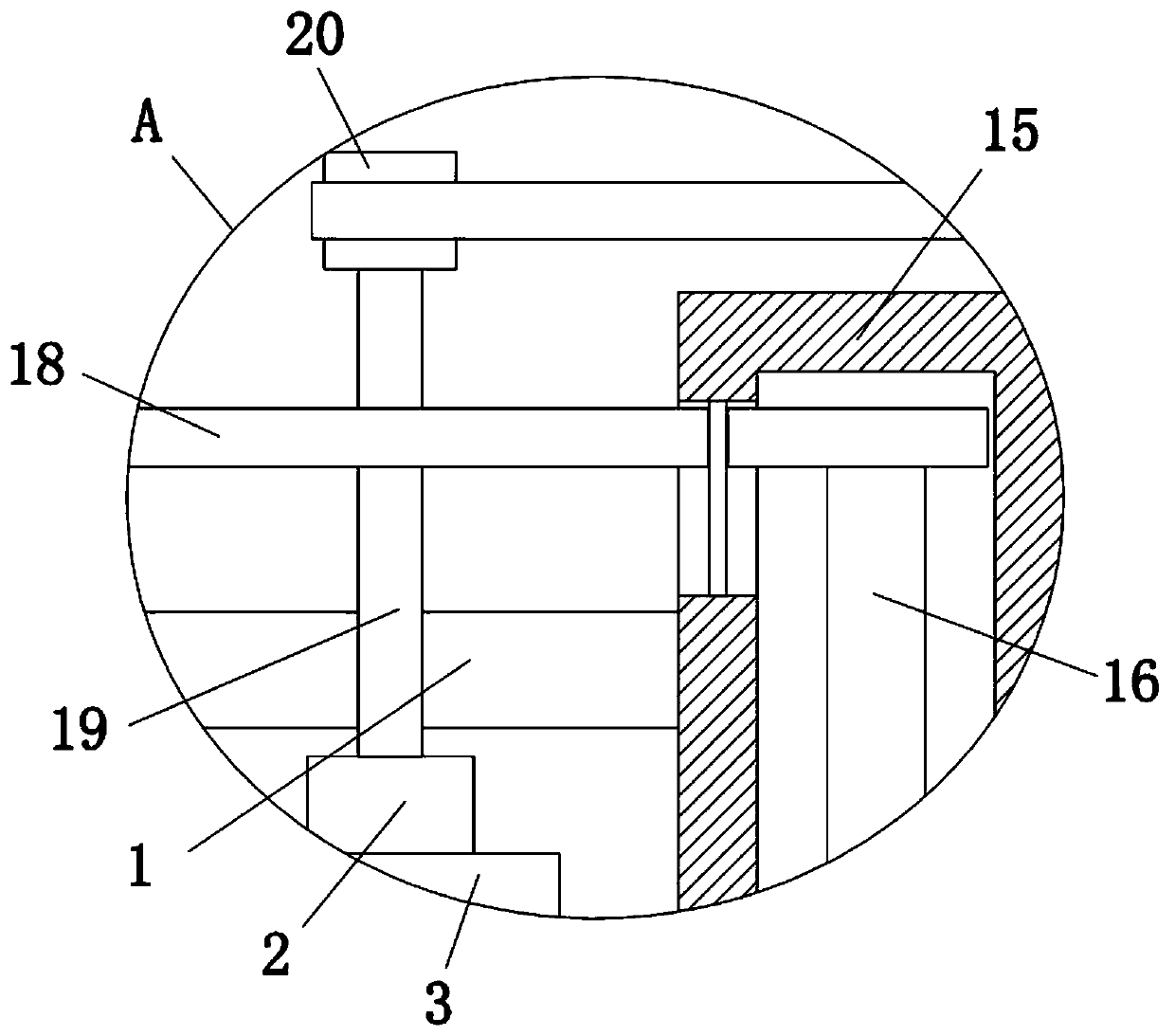

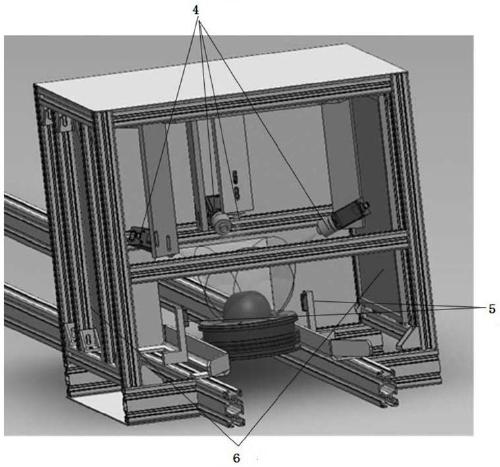

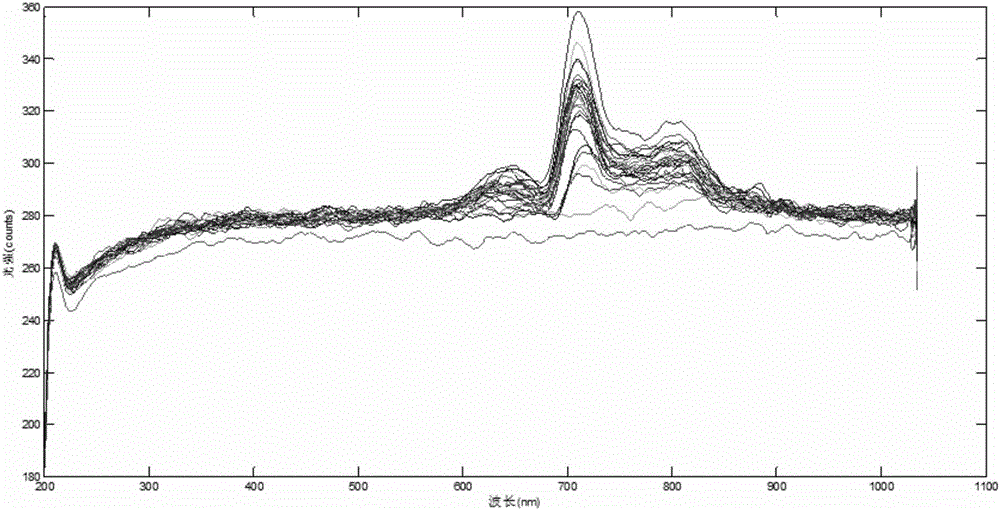

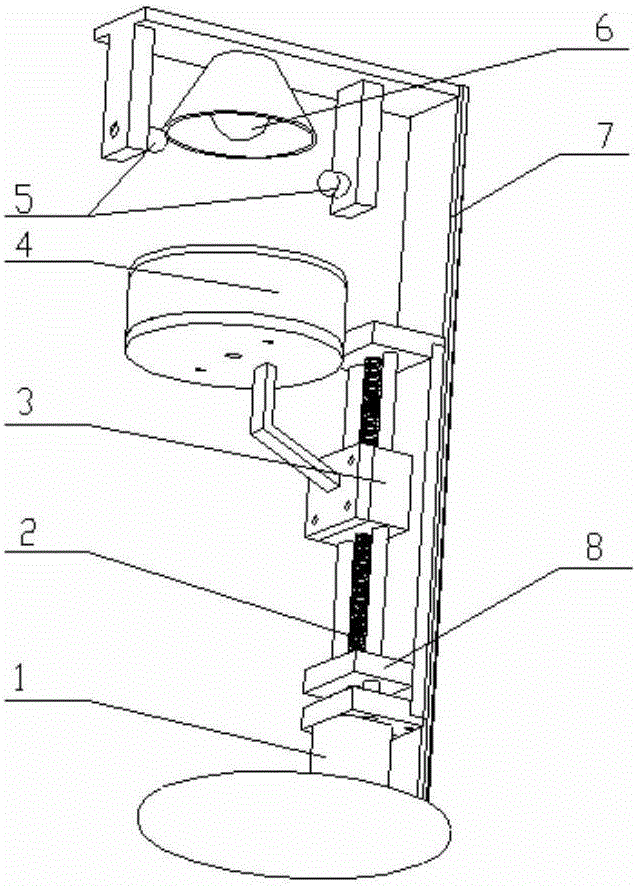

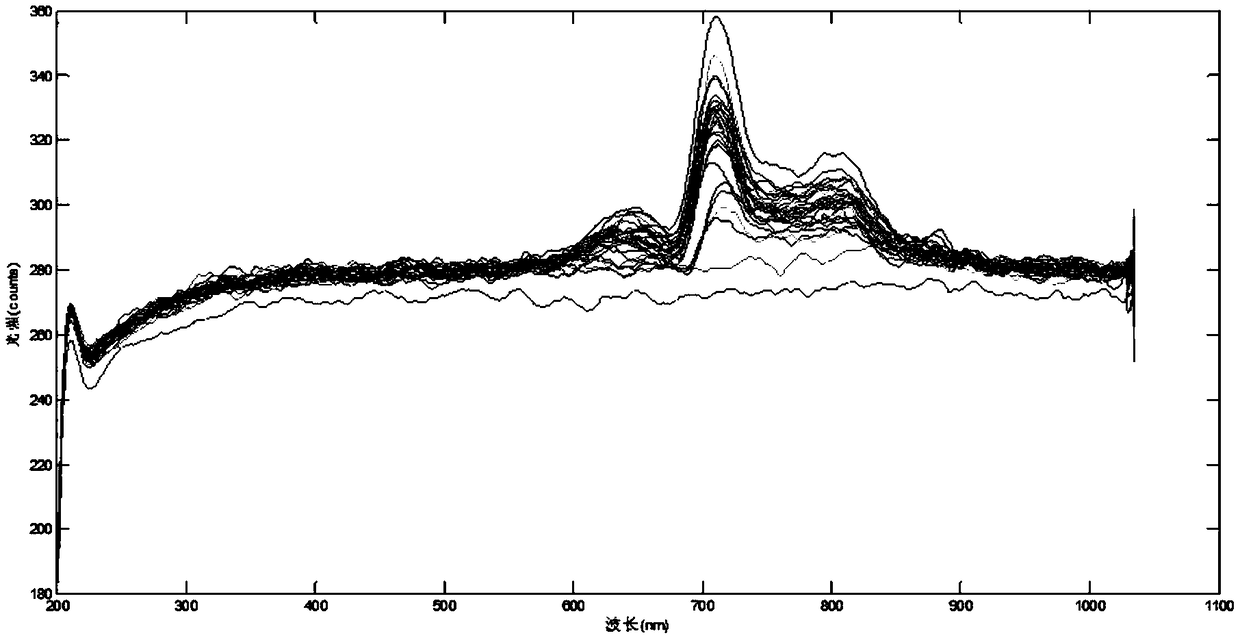

Nondestructive testing method and device for early-stage internal diseases of pears based on acoustic vibration multi-domain spectrum and near-infrared spectrum information fusion

ActiveCN111141836ASorting is accuratePrevent infestationMaterial analysis by optical meansProcessing detected response signalPEARDisease

The invention discloses a nondestructive testing method and device for early-stage internal diseases of pears based on acoustic vibration multi-domain spectrum and near-infrared spectrum information fusion. The detection method is characterized in that the acoustic vibration multi-domain spectrum and near-infrared transmission spectrum acquisition of early-stage disease pear fruits and healthy fruits is completed; an obtained original data set is subjected to preprocessing and feature extraction to construct an optimal feature set, then a discrimination model fusing acoustic vibration multi-domain spectrum features and transmission spectrum features is established by adopting a machine learning algorithm, and the accurate discrimination of the early-stage internal disease pear fruits is realized. By means of the mode, the method and device can rapidly and accurately detect the pears with early internal diseases, the early discovery of the internal diseases is achieved as much as possible, and the method and device have great significance in improving the commodity rate and market competitiveness of the pears and promoting rapid and healthy development of the pear industry.

Owner:SHIHEZI UNIVERSITY

Automatic sorting device for logistics post

InactiveCN110813763AIncrease buffer movement distanceEasy to captureSortingLogistics managementElectric machinery

The invention belongs to the field of automatic sorting devices, and particularly relates to an automatic sorting device for a logistics post. The automatic sorting device aims at solving the problemsthat an existing sorting device cannot automatically correct offset objects when the objects are conveyed, logistics information is difficult to capture when the objects are conveyed to the positionbelow a code scanner, and correct sorting cannot be achieved. According to the scheme, the automatic sorting device comprises two side plates, wherein conveying rollers are rotationally mounted on thesides, close to each other, of the two side plates; the two conveying rollers are meshed with the same conveying belt; a motor is fixedly connected to one side of each side plate; an output shaft ofeach motor is fixedly connected to the corresponding conveying roller; the same guide plate is fixedly mounted on the sides, close to each other, of the two side plates; a sorting plate is rotationally mounted at the top of the guide plate; and a motor is fixedly mounted at the bottom of the guide plate. The automatic sorting device is reasonable in structure and convenient to operate, the sortingdevice can automatically correct the offset objects when the objects are conveyed, the logistics information is conveniently and rapidly captured when the objects are conveyed to the position below the code scanner, and correct sorting can be achieved.

Owner:江苏云企供应链管理有限公司

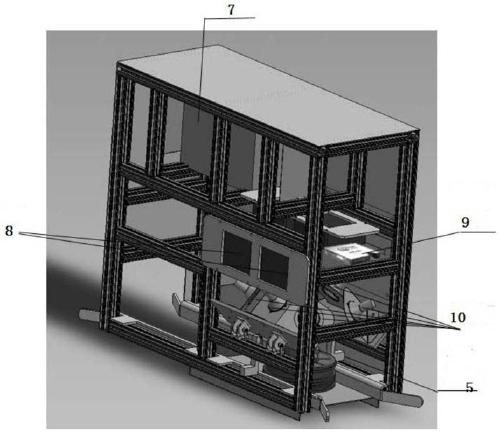

Online nondestructive testing method for internal and external quality of apples

ActiveCN111076670APrevent widespread infectionSorting is accurateOptically investigating flaws/contaminationUsing optical meansAgricultural engineeringImage manipulation

The invention relates to an online nondestructive testing method for internal and external quality of apples, wherein the method is applied to an online apple internal and external quality nondestructive testing system. The system comprises an apple external quality detection unit, an apple internal quality detection unit, a control and data processing unit and a fruit support. The control and data processing unit comprises an industrial personal computer. The apple external quality detection unit comprises an upper appearance detection unit and a lower appearance detection unit; the upper appearance detection unit, the apple internal quality detection unit and the lower appearance detection unit are sequentially fixed on fixing frames on the two sides of a conveying belt; the fruit support is arranged on the conveying belt and is used for placing apples; and the online apple internal and external quality nondestructive testing system is arranged in a black box. The apple diameter, coloring degree, surface defects, mildewed heart disease and sugar degree are detected by utilizing the machine vision and a visible light-near infrared transmission spectrum based on image processing, deep learning and spectral analysis technologies and thus the comprehensive, rapid and nondestructive detection theory and method for the internal and external quality of apples on a production line are realized.

Owner:北京京仪仪器仪表研究总院有限公司

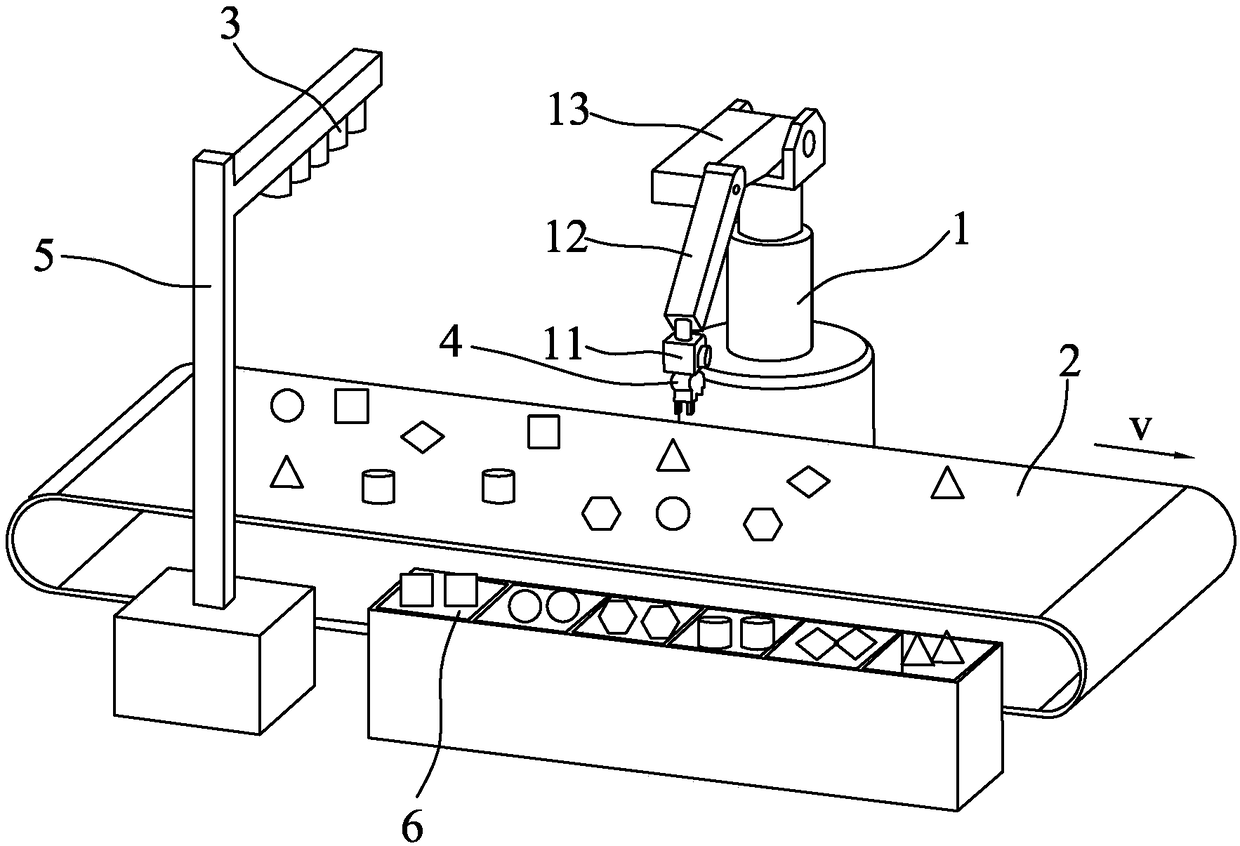

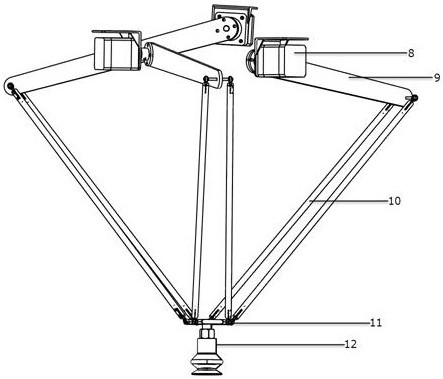

Parallel arm intelligent silkworm cocoon sorting robot and silkworm cocoon sorting method

The invention relates to a parallel arm intelligent silkworm cocoon sorting robot and a silkworm cocoon sorting method. The parallel arm intelligent silkworm cocoon sorting robot comprises a main control system, an image collecting device, a silkworm cocoon conveying system and a parallel arm sorting manipulator, and the collecting end of the image collecting device faces silkworm cocoons conveyed by the silkworm cocoon conveying system; and the execution tail end of the parallel arm sorting manipulator is located above the silkworm cocoon conveying system, and the image collecting device and the parallel arm sorting manipulator are both electrically connected with the control system. According to the parallel arm intelligent silkworm cocoon sorting robot, the parallel arm sorting manipulator is adopted, a negative pressure type suction cup is adopted, accurate silkworm cocoon grabbing is achieved, and secondary damage to silkworm cocoons is avoided; silkworm cocoon images are acquired through an upper camera and a lower camera, so that the recognition accuracy is improved; through a constructed silkworm cocoon classification CNN model based on deep learning, accurate and efficient identification and classification of the silkworm cocoons are realized; and the control system converts the position coordinates of the silkworm cocoons and drives the parallel arm manipulator to act to grab the silkworm cocoons, so that efficient and automatic sorting of the silkworm cocoons is realized.

Owner:SHANDONG AGRICULTURAL UNIVERSITY

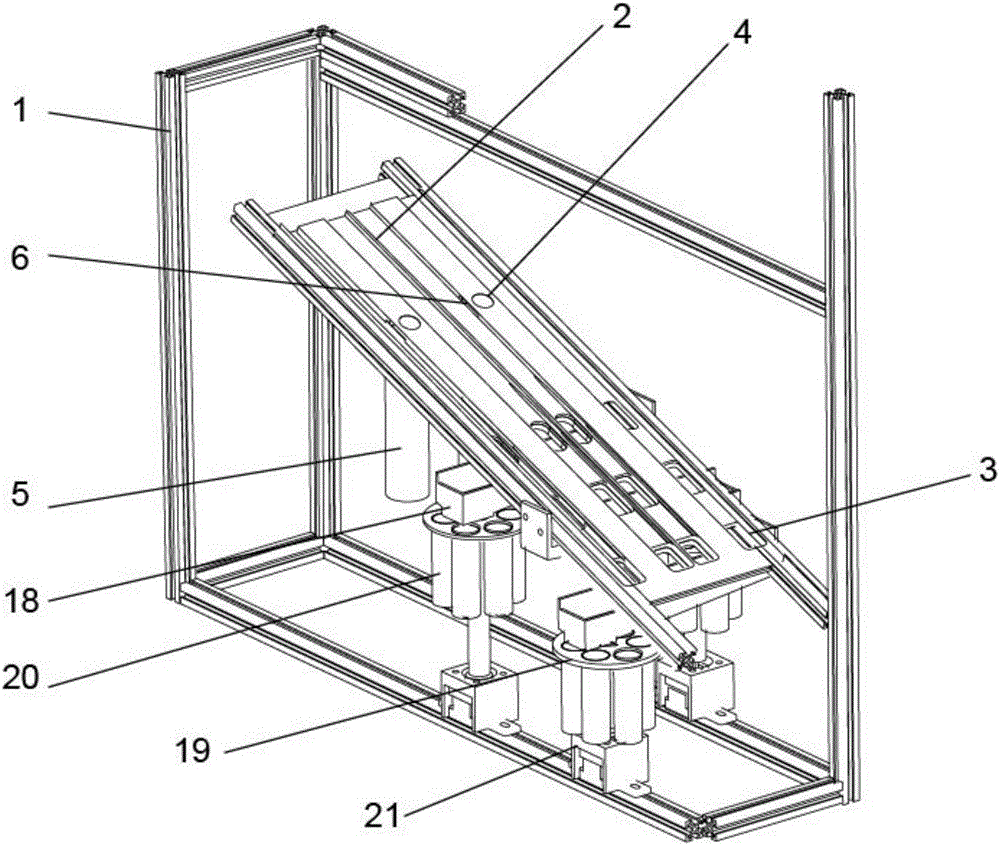

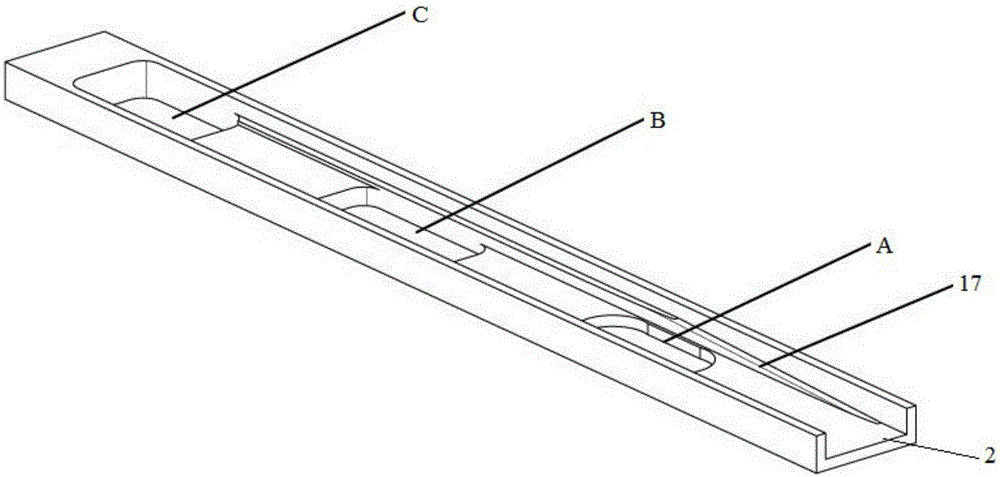

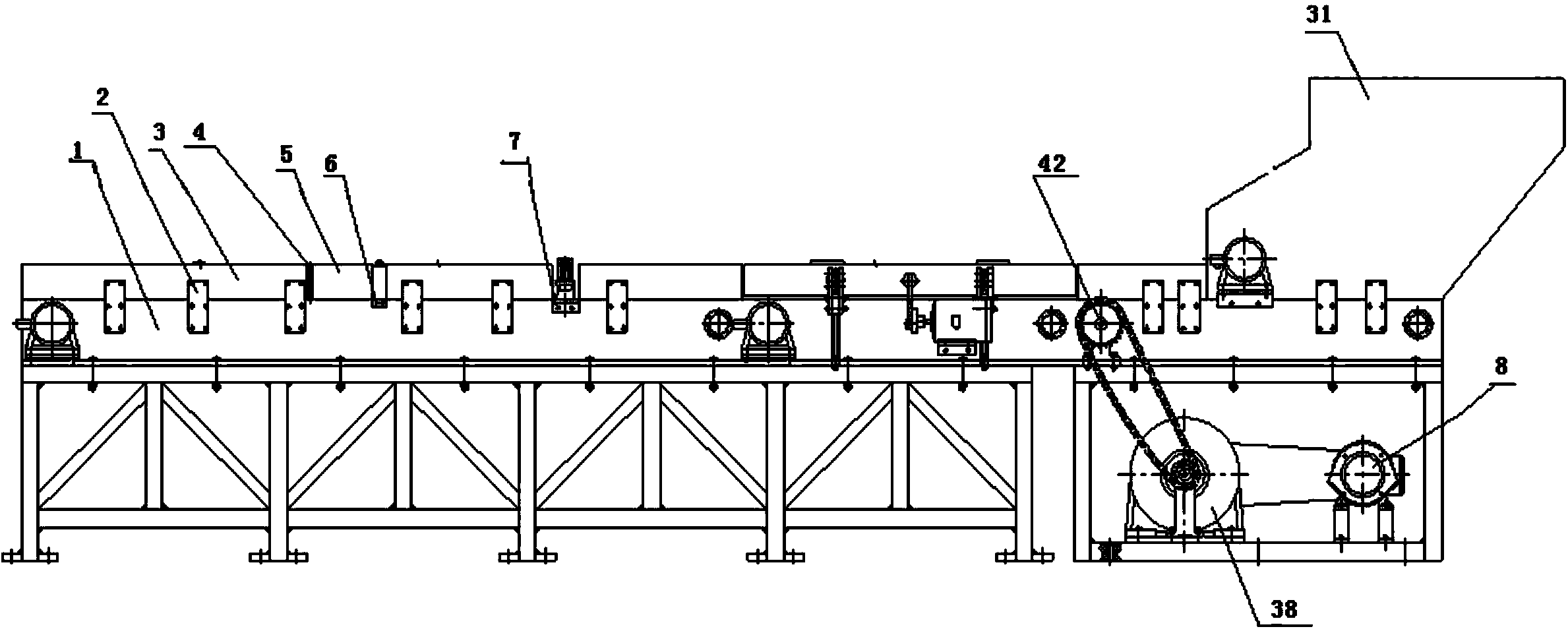

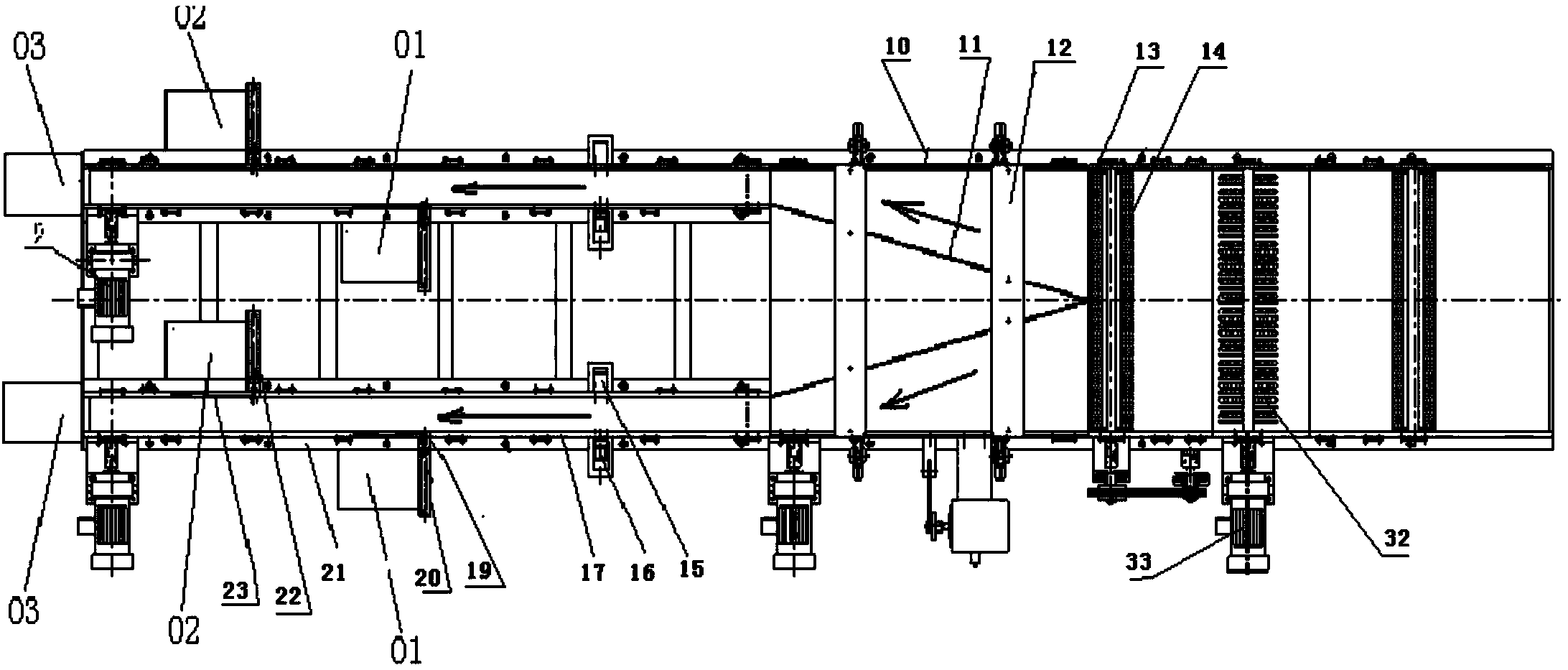

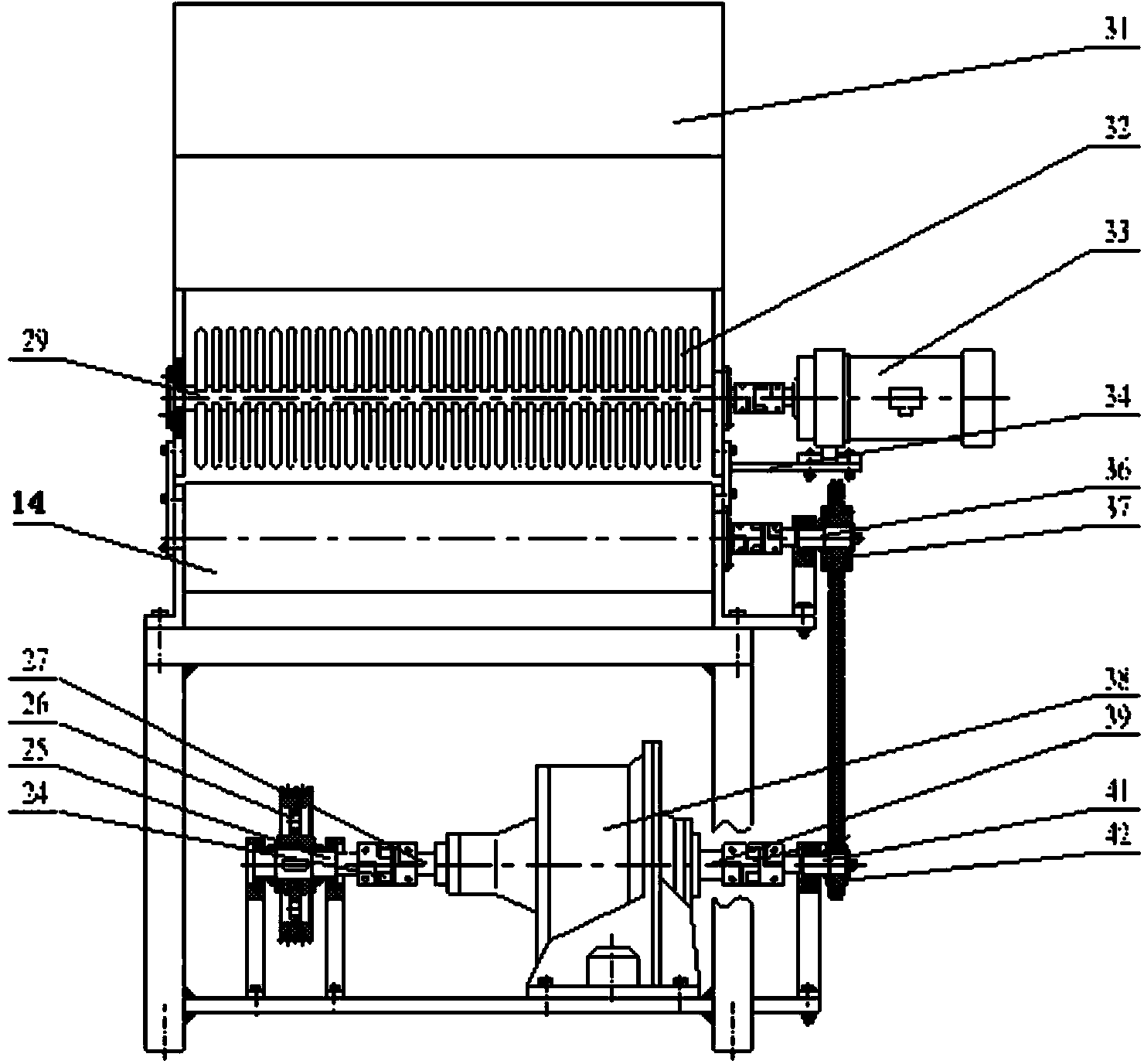

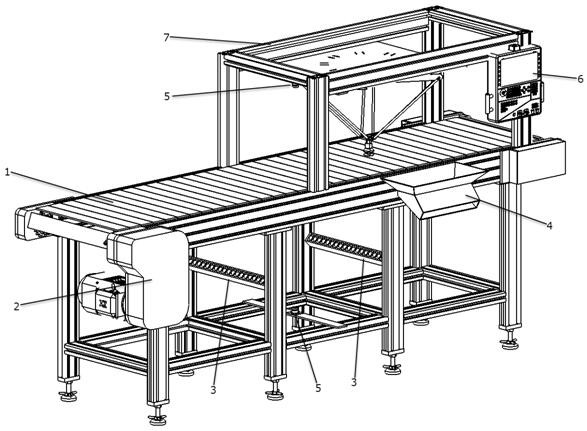

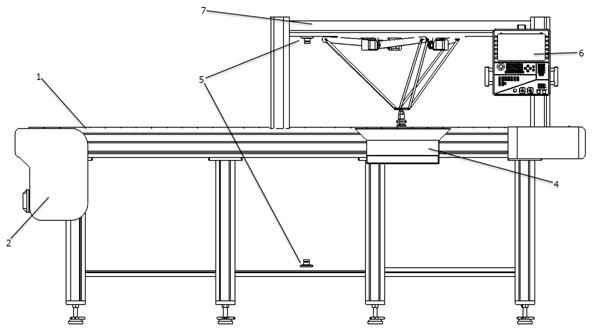

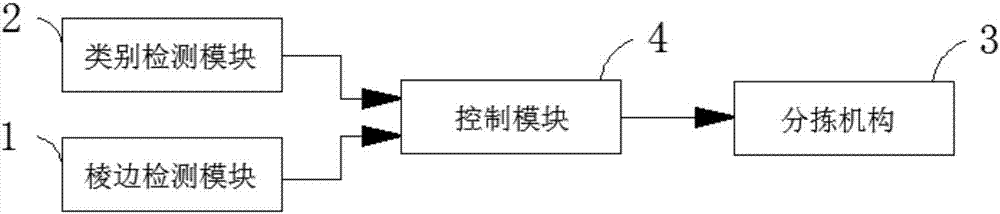

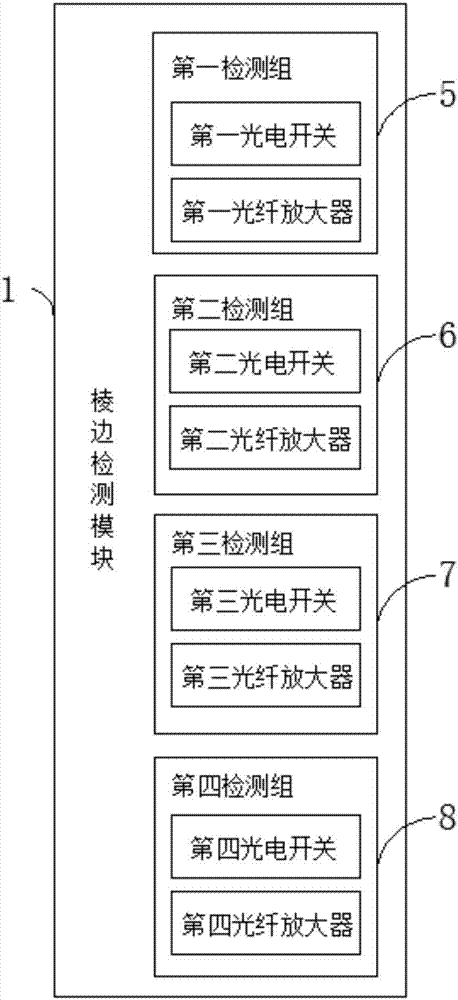

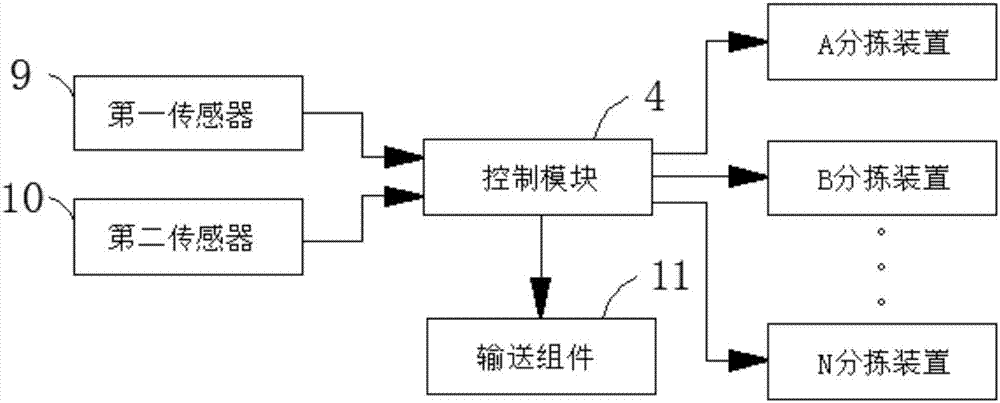

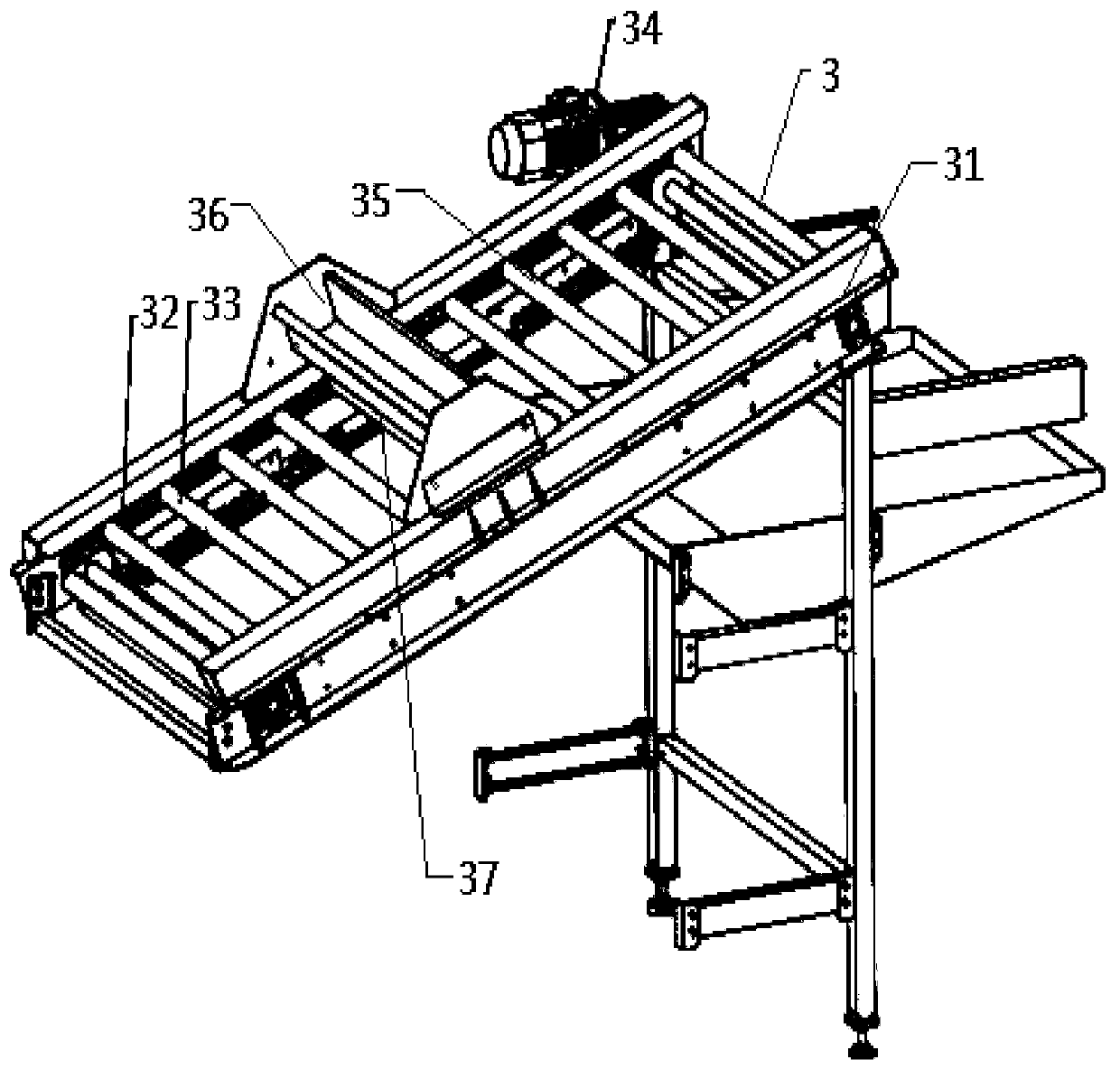

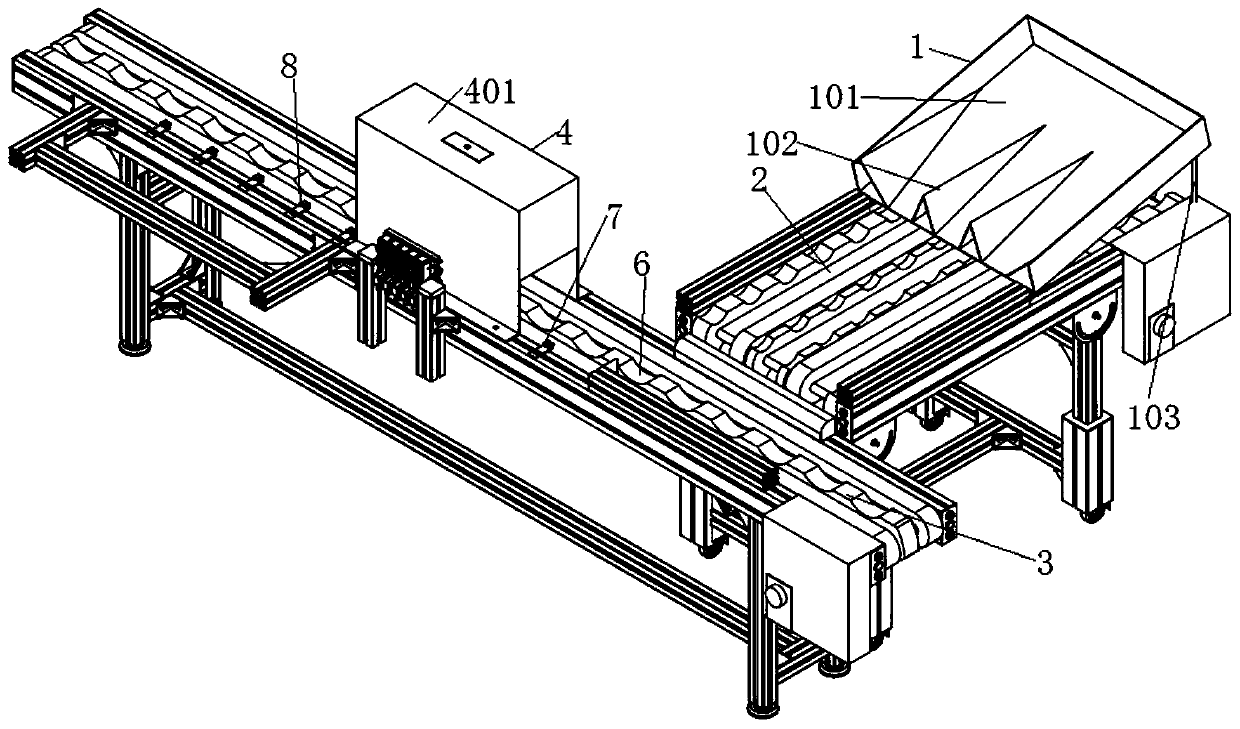

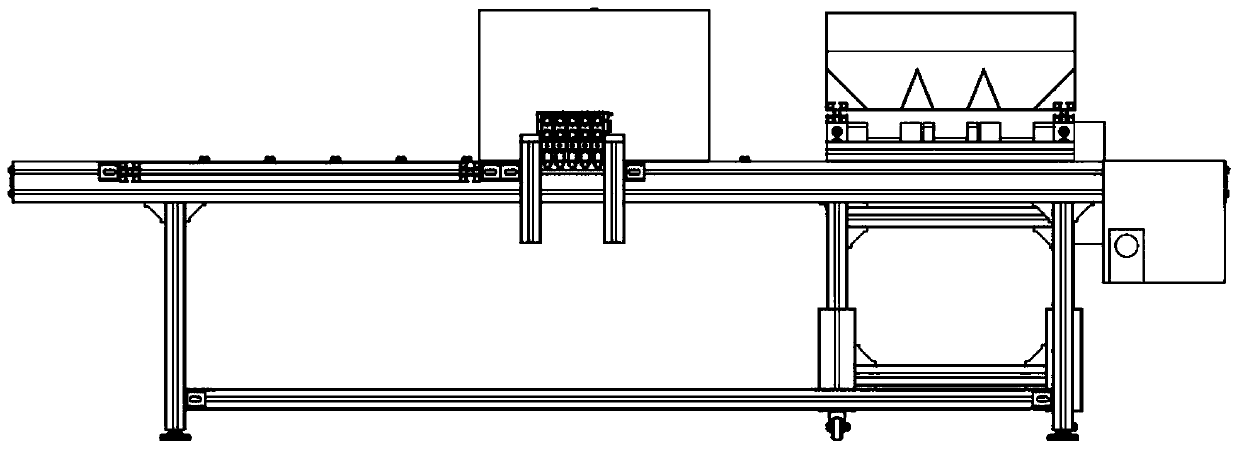

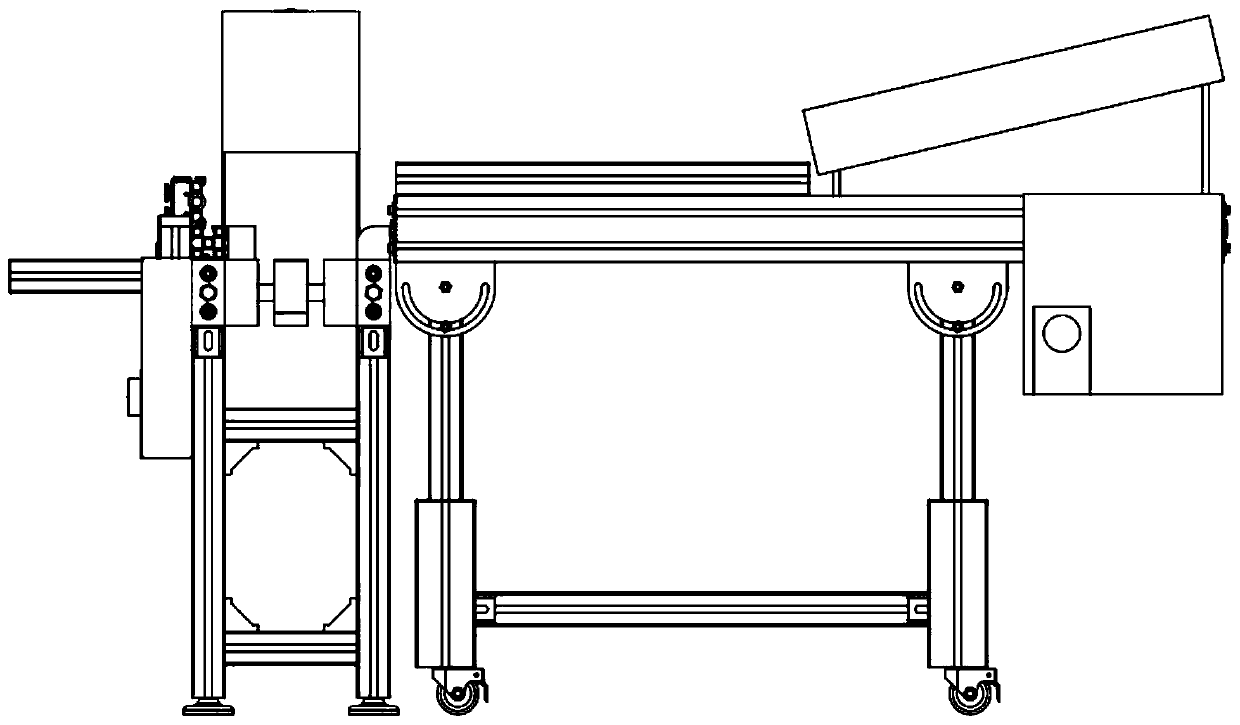

Bamboo strip automatic detecting and sorting system and method

ActiveCN106890798AImplement edge defect detectionReduce labor intensitySortingEngineeringFully automatic

The invention relates to a bamboo strip automatic detecting and sorting system and method. The system comprises a ridge detecting module, a class detecting module, a sorting mechanism and a control module. The ridge detecting module, the class detecting module and the sorting mechanism are connected with the control module through a line. Compared with the prior art, edge defect detection is carried out on bamboo strips, the bamboo strips are sorted and boxed, fully automatic bamboo strip sorting is achieved, the labor intensity is low, and the production efficiency is high.

Owner:ZIYUAN COUNTY DUOLISHI WOODWORKING MACHINERY

Apple moldy core discriminating model based on BP neural network of single-chip microcomputer and establishment method of model

ActiveCN105069504ASorting is accurateReduce morbidityPhysical realisationSpecial data processing applicationsMicrocontrollerDisease

The invention relates to an apple moldy core discriminating model based on BP neural network of a single-chip microcomputer. A formula of the model is M=-0.8350*y1-2.6581*y2+0.9930*y3, and when M is lower than 0, a moldy core exists in an apple. The invention also provides an establishment method and principle of the model. Establishment of the model completely relies on the obtained voltage value and diameter of the apple and software and hardware design of core devices including LED, MSP430 processor and photodiode, detection equipment is mini and low in cost, the detection precision is high, apples with diseases can be timely and accurately sorted when the apples are warehoused, the moldy core pathogen is prevented from invasion in large area, the incidence of disease is effectively reduced in the apple storage process, the model and method are characterized by low cost, simple operation, stable and reliable operation and high disease discrimination precision, the method can be used to grade apples in the production line, and the method can be also applied to rapid lossless quality detection of other fruits.

Owner:NORTHWEST A & F UNIV

Crocus sativus production and processing method

ActiveCN109479656AIncrease productionImprove qualitySeed and root treatmentBulb cultivationCold treatmentLesser florican

The invention belongs to the technical field of crocus sativus cultivation and provides a crocus sativus production and processing method. The method is characterized by including steps: S1, selectinghealthy and plump crocus sativus bulbs lighter than 1g in weight, subjecting to cold treatment at 4-10 DEG C for 4-6 weeks, removing integuments, flushing with water for 1-5h, sterilizing, flushing for 3-5 times, and absorbing moisture to dry for standby application; S2, transplanting the crocus sativus bulbs outdoors in November in the last year, burying the bulbs underground by 8-10cm until thebulbs appear in May in the next year, digging out the crocus sativus bulbs, and placing in a shade place for 10 days; S3, from the early June to the late June, sequentially arranging the crocus sativus bulbs on a double-layer net rack according to two grades by a sorting device. The crocus sativus production and processing method has the advantage of high crocus sativus yield.

Owner:JIAXING VOCATIONAL TECHN COLLEGE

Detection and sorting apparatus of automobile shock absorber bases

ActiveCN104964818APrevent accidental dropQuick checkMachine part testingUsing optical meansCylinder blockEngineering

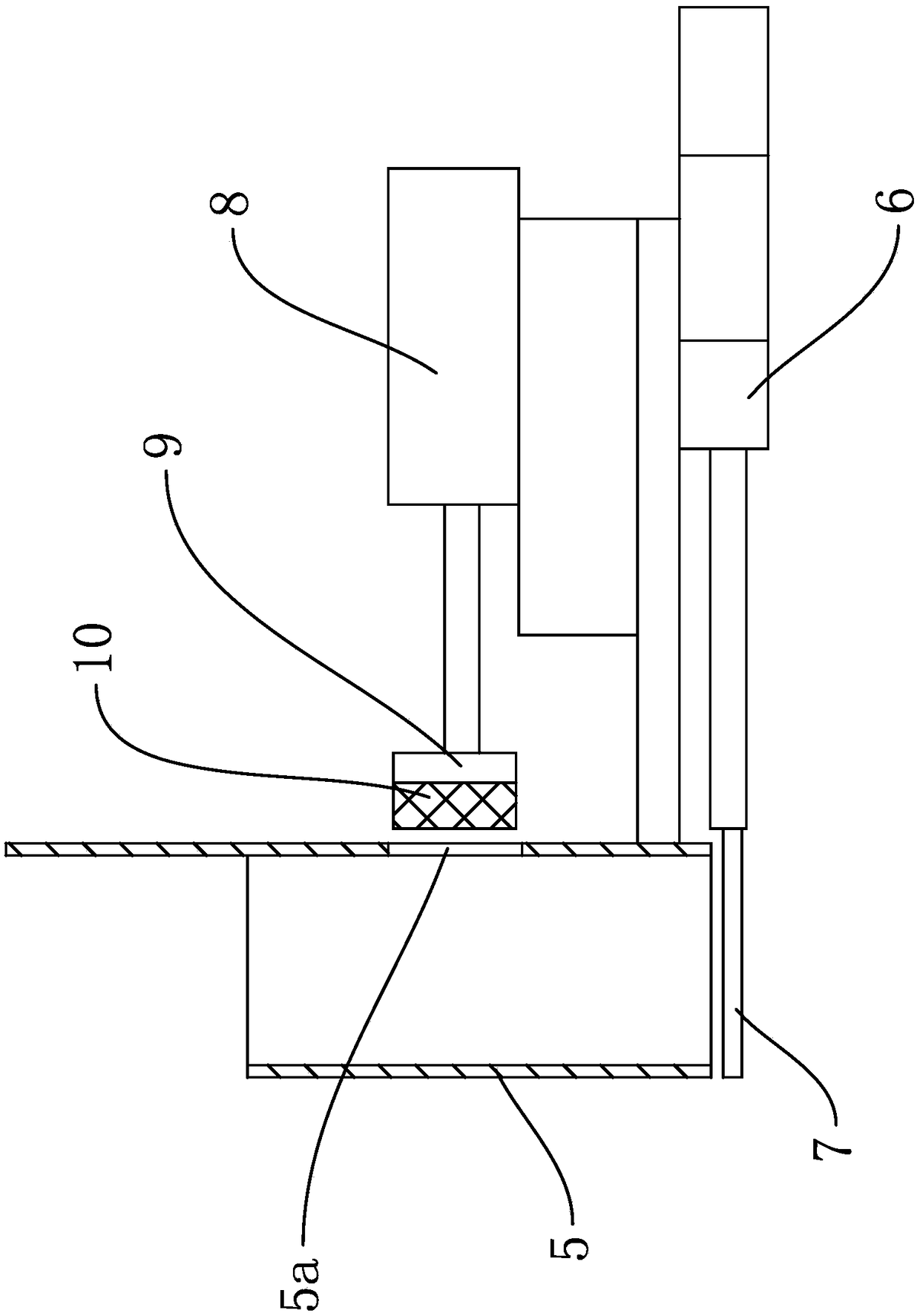

The invention discloses a detection and sorting apparatus of automobile shock absorber bases. The detection and sorting apparatus includes a conveyor belt (1), a detection device and a sorting device; the detection device comprises a detection driving cylinder (3); a small detection head (5) is fixed to the piston rod of the detection driving cylinder (3); the small detection head (5) is provided with a lower radial protruding ring (6); the piston rod of the detection driving cylinder (3) is sleeved with a large detection head (7) and a pressure spring (8); the large detection head (7) is provided with an upper radial protruding ring (9); the large detection head (7) abuts against the lower radial protruding ring (6) under the action of the pressure spring (8); the sorting device comprises a discharging hopper, a sorting support, a sorting driving cylinder, a swing plate and a displacement sensor; the cylinder body of the sorting cylinder is fixed on the sorting support; and the piston rod of the sorting driving cylinder is connected with a shifting fork; the swing plate is hinged to the discharging hopper; and the front end of the swing plate is inserted into the shifting fork. The apparatus of the invention has the advantages of high speed, high accuracy, low labor intensity and high efficiency.

Owner:NINGBO PREMIUM AUTOMOTIVE PARTS

Sorting equipment for weighed products

InactiveCN111438072AReasonable structurePrecise and reliable controlSortingFood treatmentAutomatic controlEnvironmental geology

The invention discloses sorting equipment for weighed products. The equipment comprises a water tank, a cleaning mechanism, a wiping mechanism, an air drying mechanism, a belt conveying mechanism, a weighing and sorting mechanism, a boxing and conveying mechanism and a control system. The control system comprises a data acquisition module, a 5G transmission module, a data analysis module and a final problem product processing module. Comprehensive automatic control over the cleaning and sorting process is achieved; a main body structure of the equipment is reasonable, modular design is adopted, control is accurate and reliable, and efficient, accurate and damage-free sorting of fruits is achieved; and meanwhile, a control module ensures that agricultural products to be sold do not containdamaged and rotten agricultural products, and the agricultural products can be graded. Meanwhile, data uploaded by the data acquisition module is used for enriching samples, so that the accuracy of artificial intelligence identification and classification is further enhanced; and cloud intelligent decision has the advantages that the cost can be saved, meanwhile, a database, an identification algorithm and a model can be shared to form an Internet of Things sorting system, and tracing is carried out by utilizing a block chain technology.

Owner:山东省烟台苹果大数据有限公司 +1

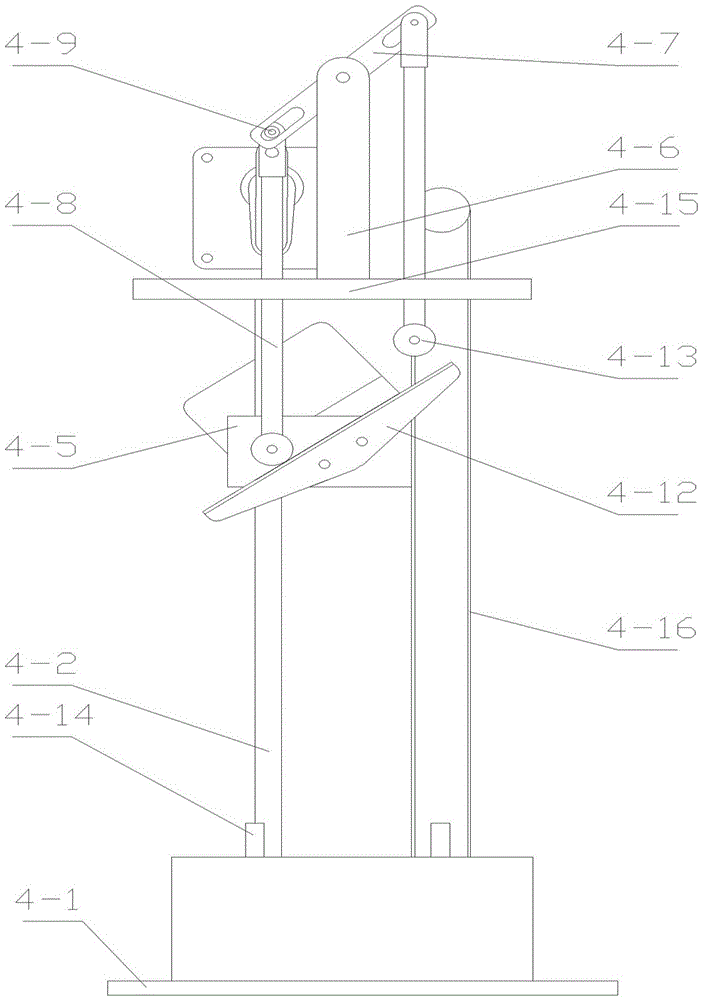

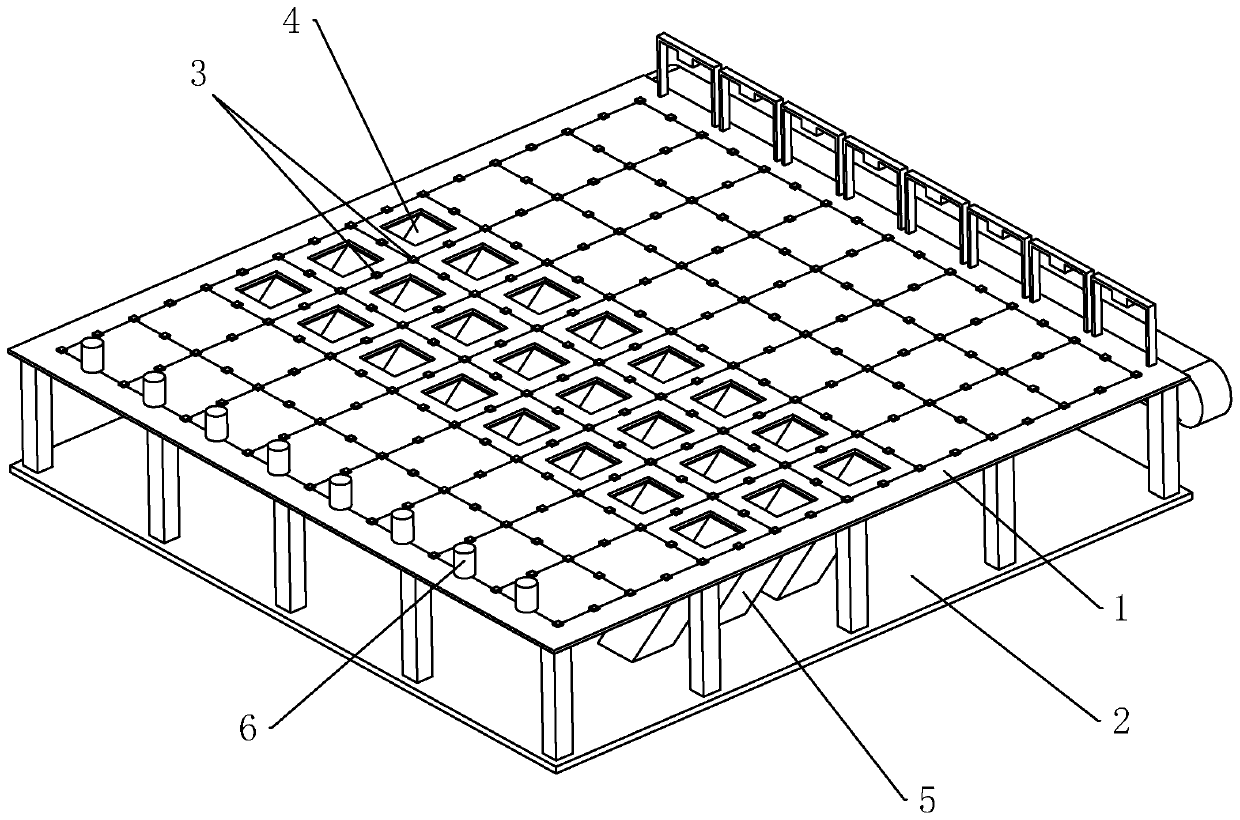

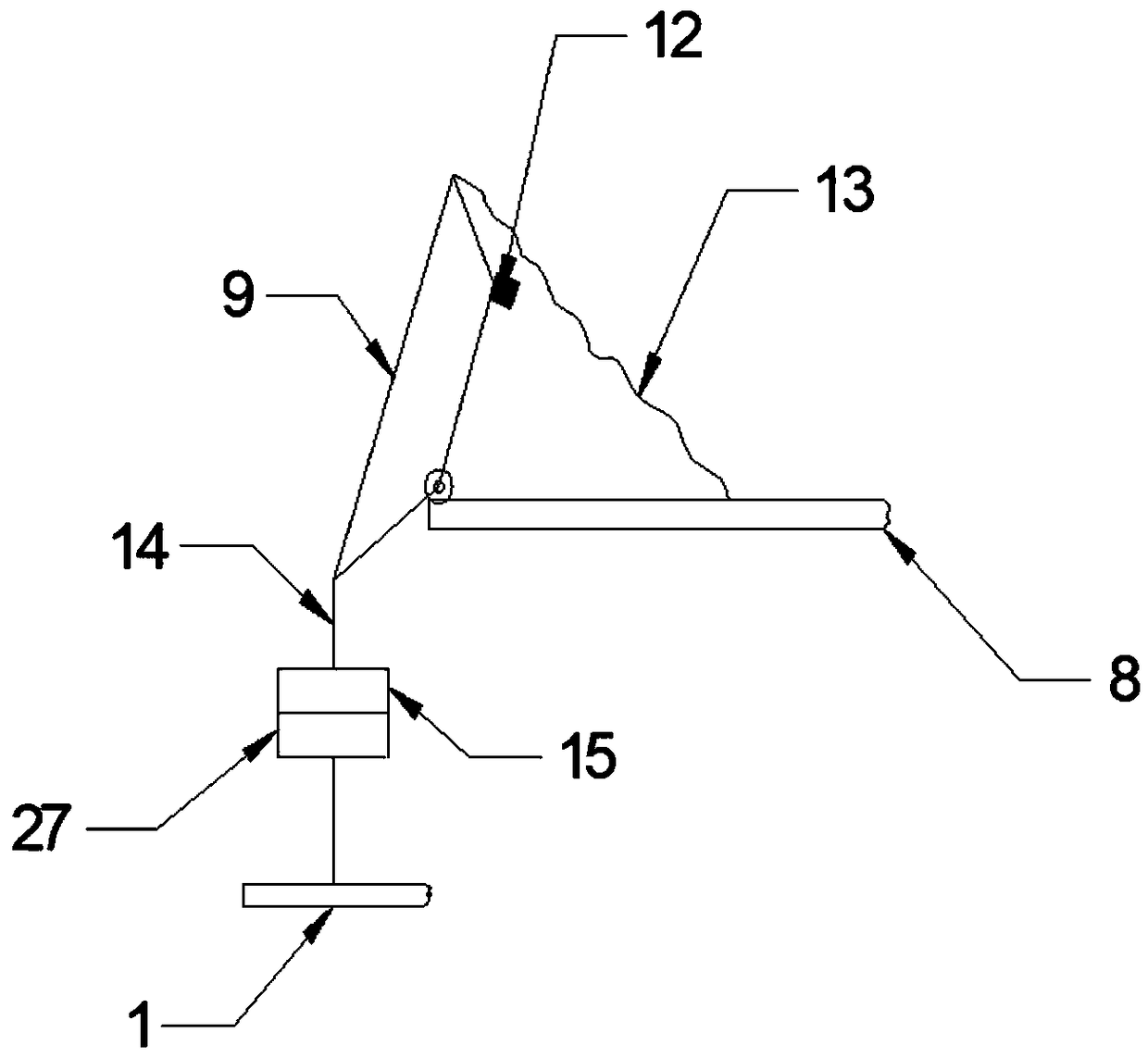

Multi-station rapid automatic detecting and sorting apple mould core device and method

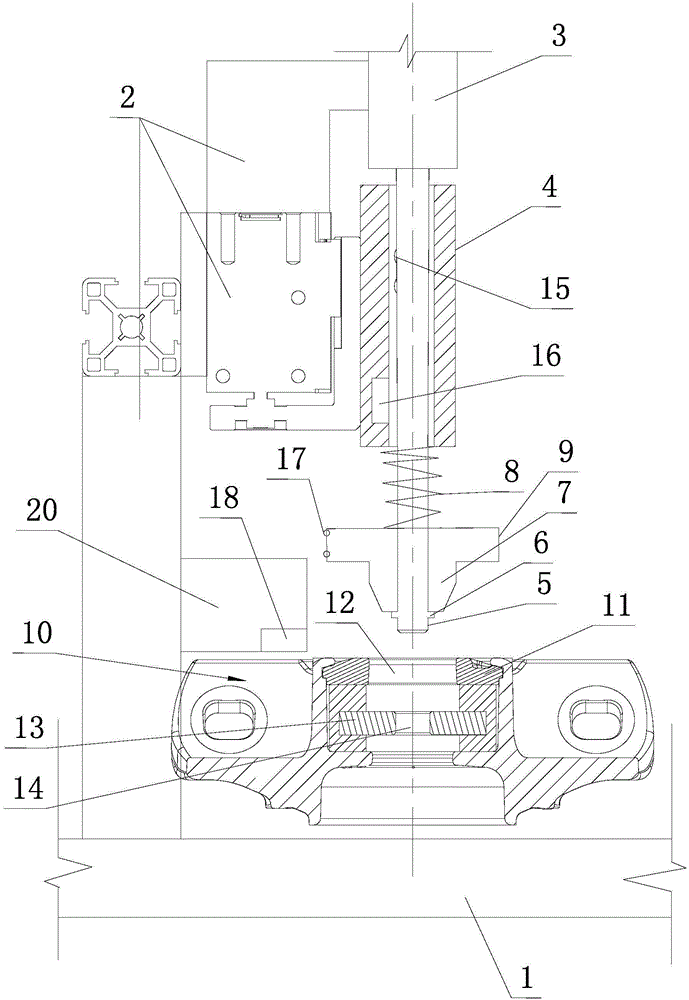

The invention discloses a multi-station rapid automatic detecting and sorting apple mould core device and method. The device comprises a rotary table support, a circular base is arranged at the lowestend of the support, a stepping motor is arranged at the upper middle portion of the base, a secondary speed reducer is connected to the upper surface of the stepping motor, the secondary speed reducer and the support are connected into a pan-tilt, a pan-tilt support is connected to the exterior of the pan-tilt, the support is fixed to the base, the middle of the pan-tilt is connected to the rotary table through the pan-tilt support, detection positions are arranged on the rotary table, a station for installing an apply tray is arranged on each detection position, and an ultrasonic sensor is arranged at the upper surface of one end of each apply tray; a light source is arranged at the other end of each apply tray, and a photoelectric sensor is arranged below each apply tray. The whole rapid automatic detecting and sorting process for the apple mould core is achieved.

Owner:NORTHWEST A & F UNIV

Apple sorting device and sorting method thereof

The invention discloses an apple sorting device and a sorting method thereof. The apple sorting device comprises a flexible loading device, a feeding conveyor belt, a sorting conveyor belt, an image recognition device and a sorting mechanism, wherein the flexible loading device is arranged on the feeding conveyor belt; the feeding conveyor belt is perpendicularly arranged at the feeding end of thesorting conveyor belt and is higher than the sorting conveyor belt; the sorting mechanism and the image recognition device are arranged on the sorting conveyor belt; and the sorting mechanism is located in the rear of the image recognition device. According to the apple sorting device and the sorting method thereof provided by the invention, through the flexible loading device, apples can be non-destructively added into the feeding conveyor belt; through the feeding conveyor belt, the apples are separately conveyed to the sorting conveyor belt; and through the image recognition device on thesorting conveyor belt, the apples in various grades are recognized and are conveyed to corresponding classification positions so as to be sorted into respective classification boxes, so that the graded apples are quickly sorted, and the classified applies are appropriate in size, similar in color, and accurate in grading.

Owner:GUIZHOU UNIV

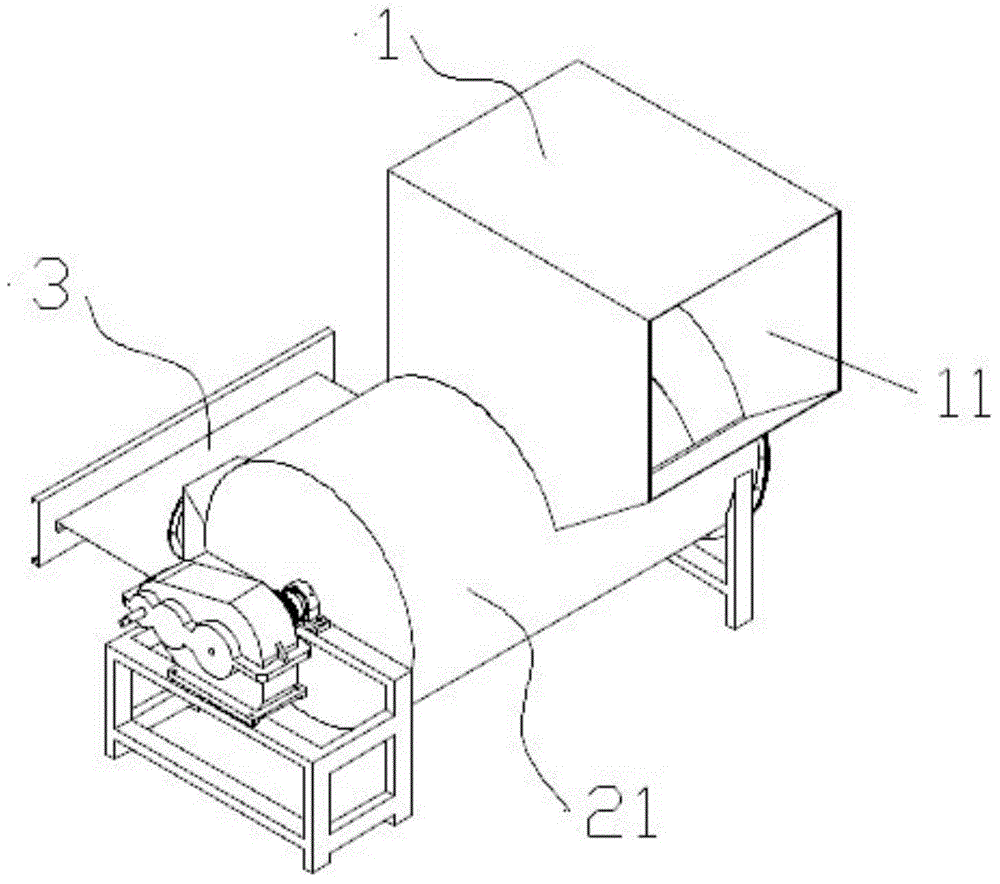

Intelligent crushing and sorting machine

InactiveCN104669465ASuitable for extractionHigh degree of intelligencePlastic recyclingSortingOptical pickupOptical property

The invention provides an intelligent crushing and sorting machine, which comprises a crushing device, a primary sorting device and an intelligent sorting device. The intelligent sorting device is added and comprises a conveyer belt which is connected with the primary sorting device; sealing devices are arranged on two sides of the conveyer belt and above the conveyer belt; and an optical pickup recognition device is arranged above the conveyer belt, so that impurities in foam fragments show different optical characteristics to be recognized under ray illumination. The optical pickup recognition device is electrically connected with an intelligent pickup manipulator for picking up impurities in the foam fragments. The intelligent crushing and sorting machine is high in intelligent degree, high in efficiency, high in accuracy and suitable for extraction of impurities in foam recovery.

Owner:高伟

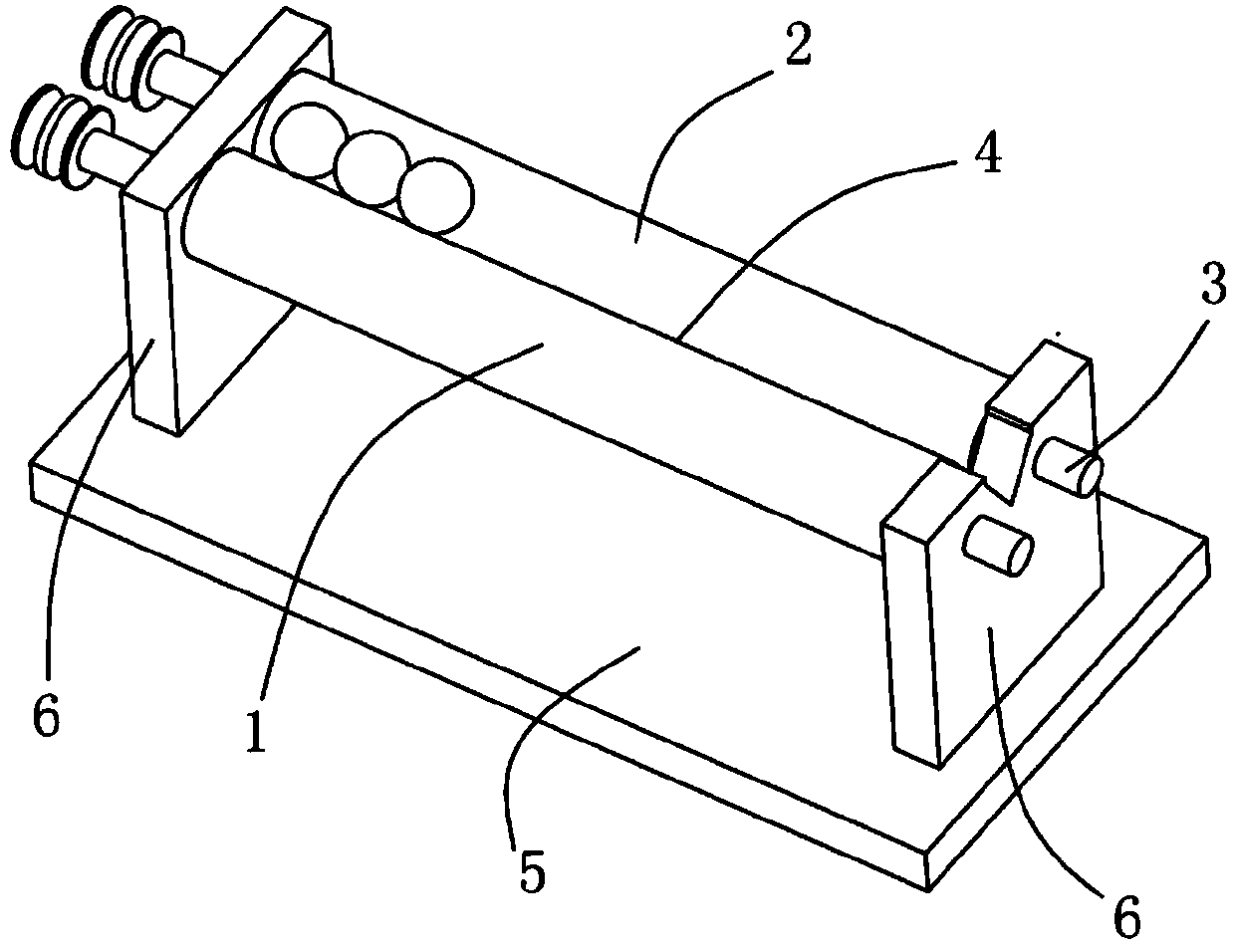

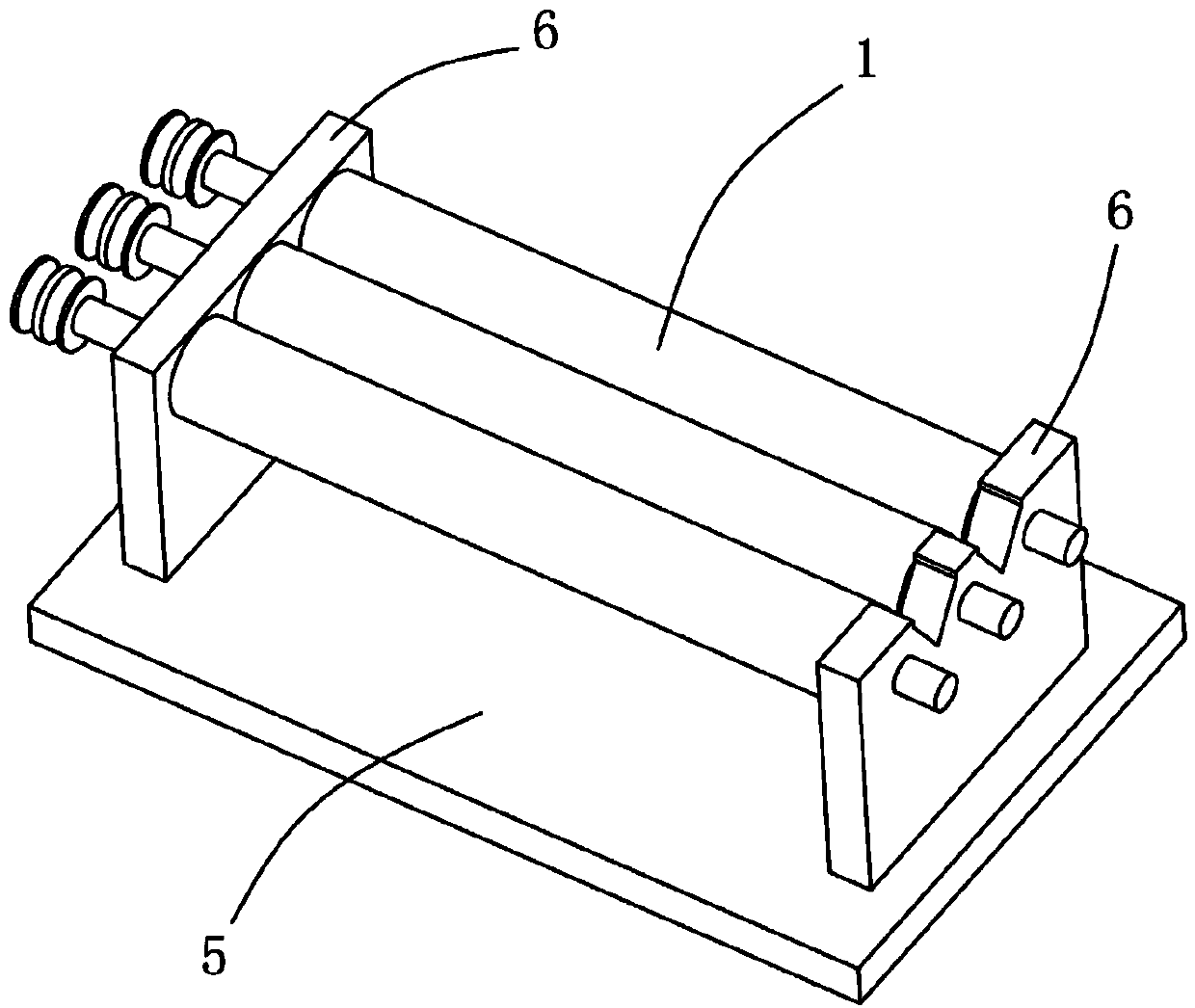

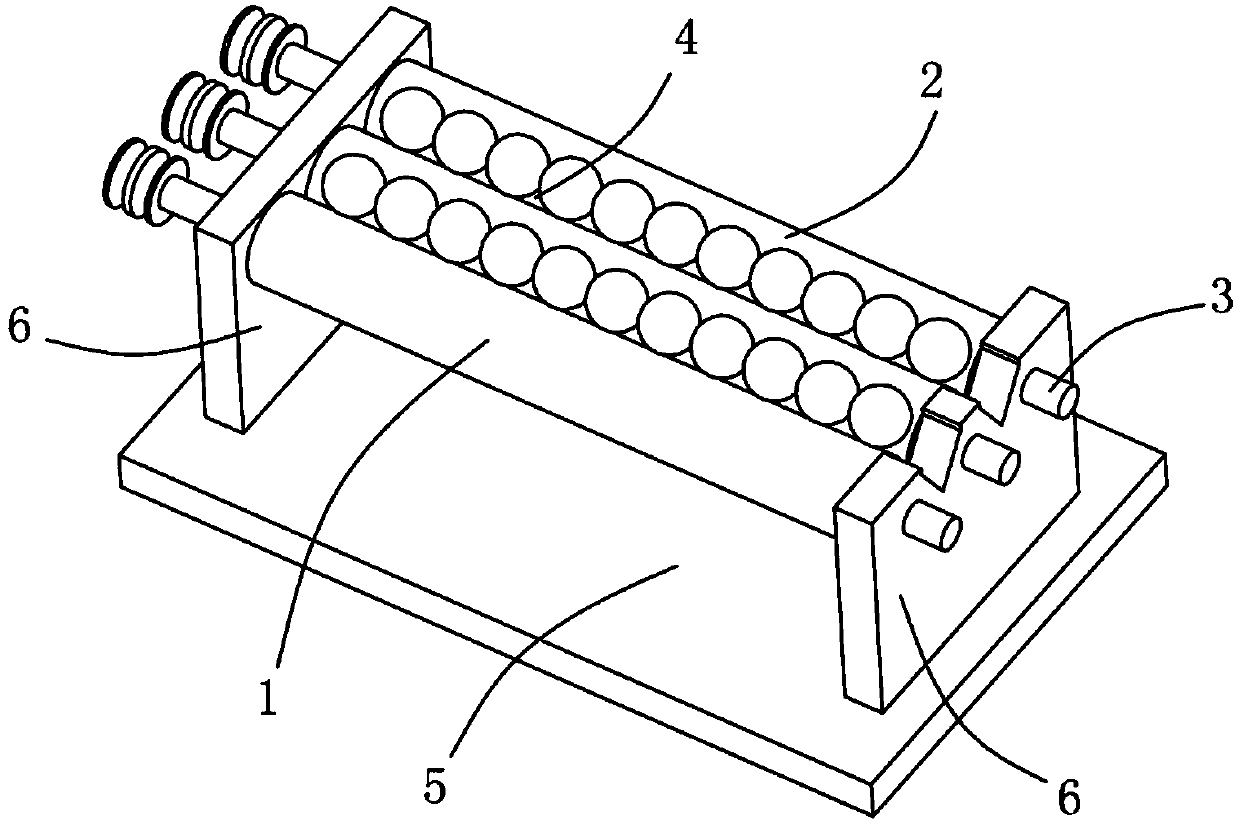

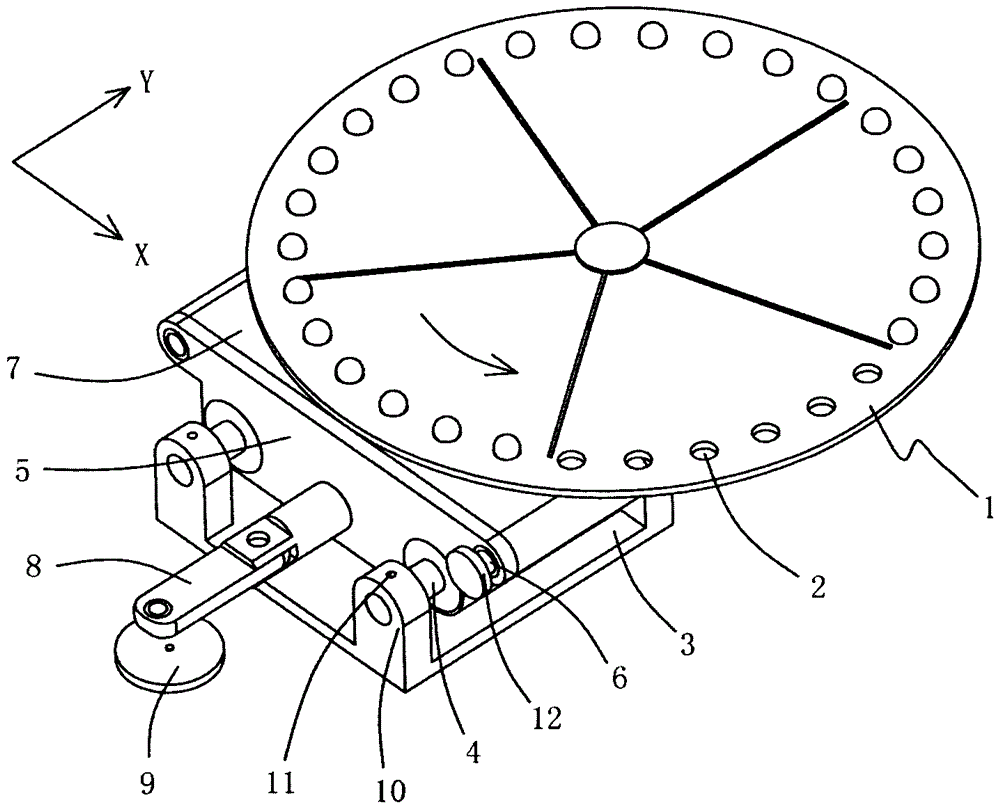

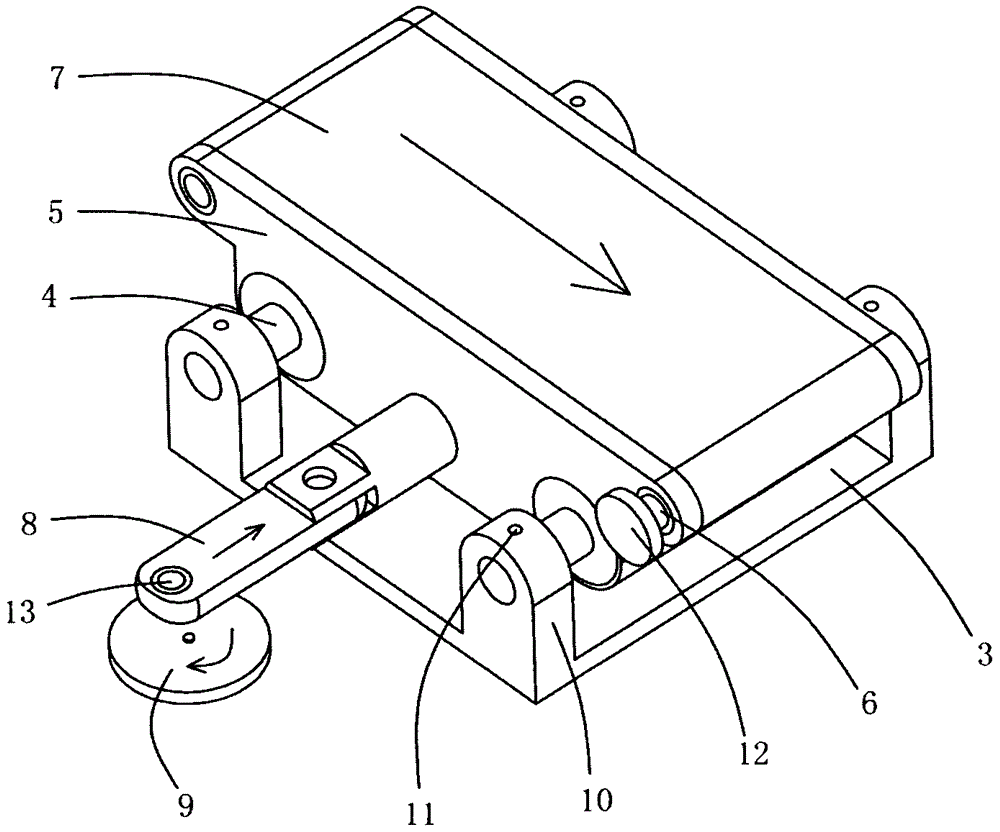

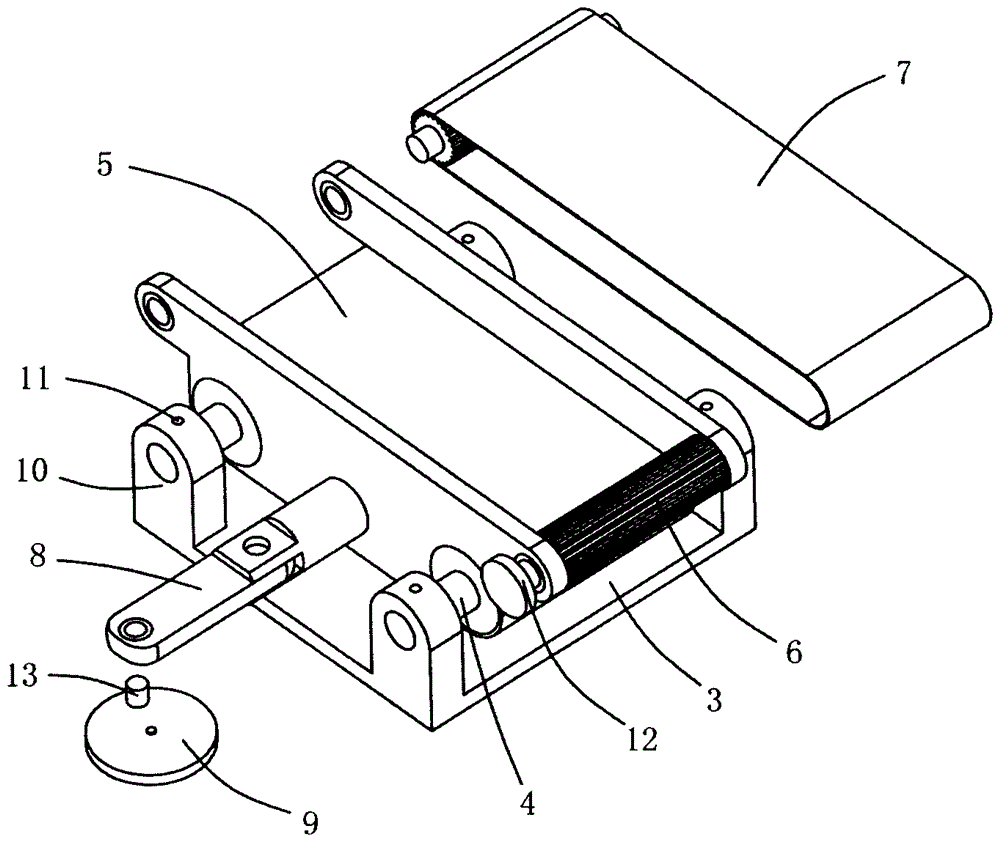

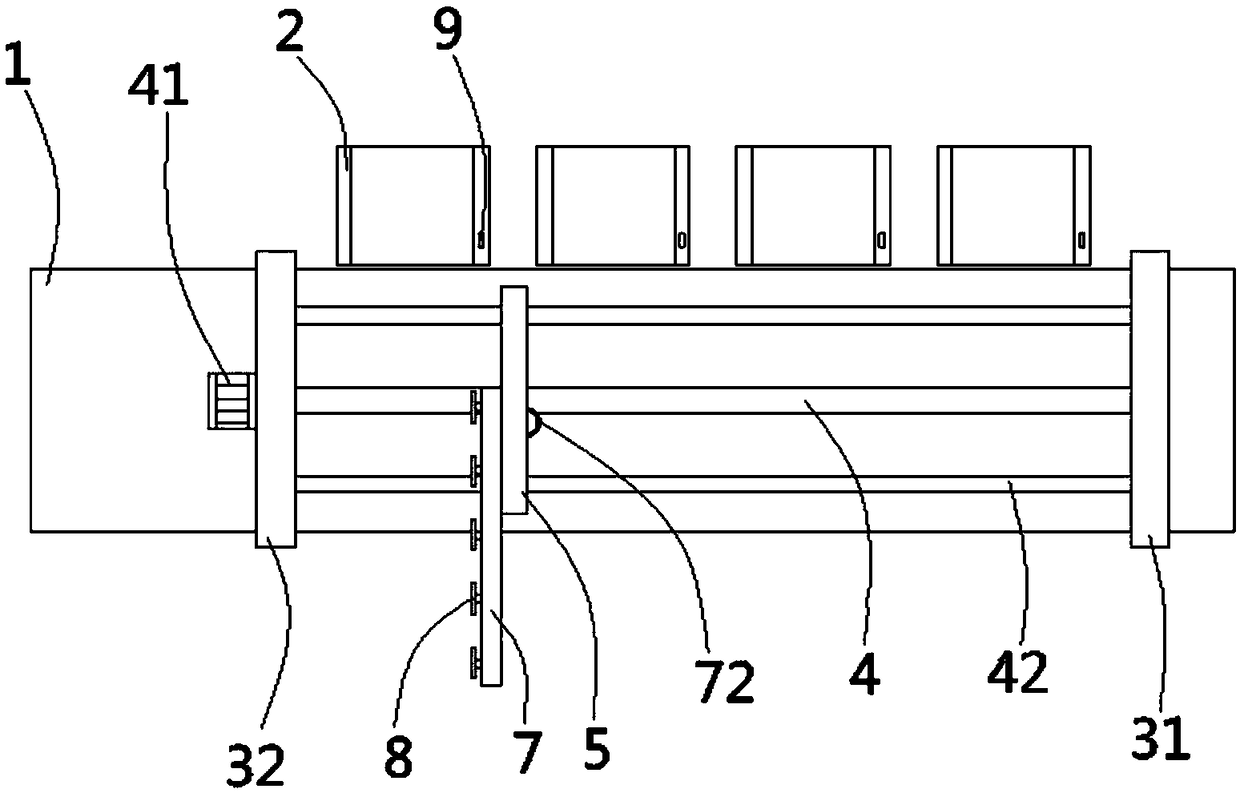

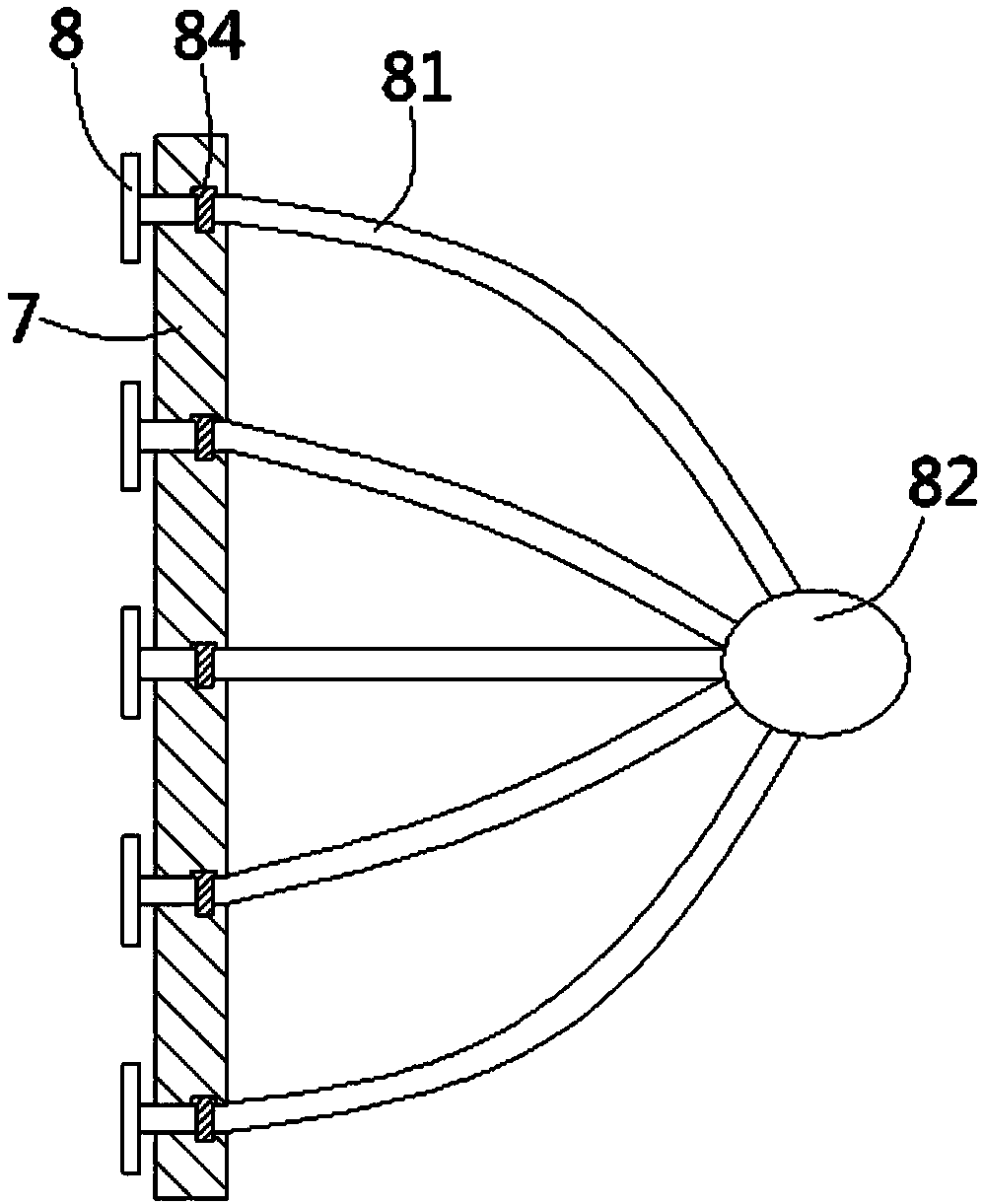

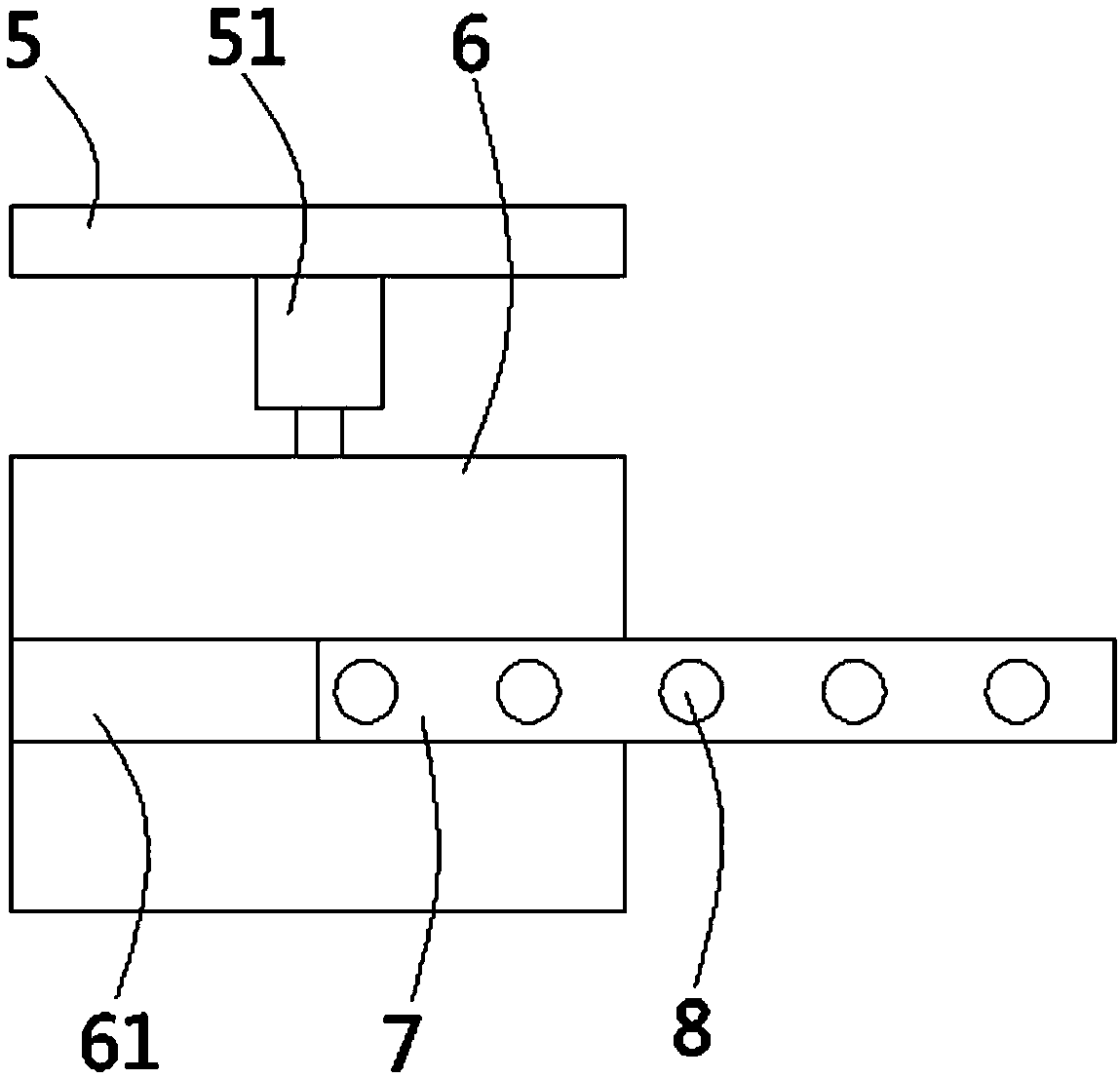

Unfolding device of steel ball sorting machine

The invention discloses an unfolding device of a steel ball sorting machine. The unfolding device comprises a feeding disc; and the feeding disc is provided with multiple detecting cavities for bearing steel balls. The unfolding device further comprises a mounting base; a slide rail is arranged on the mounting base; a slide base is arranged on the slide rail; and a friction belt driven by a roller shaft is arranged on the slide base, is positioned below the feeding disc, and is used for driving the steel balls to roll in the detecting cavities. The unfolding device further comprises a connecting rod; one end of the connecting rod is hinged to the slide base, and the other end of the connecting rod is eccentrically connected with a rotating wheel; the rotating wheel drives the slide base to slide along the slide rail through the connecting rod; and the conveying direction of the friction belt is orthogonal to the sliding direction of the slide base. The unfolding device adopts the rolling friction belt to drive the steel balls in the detecting cavities of the feeding disc to roll and unfold, can guarantee total unfolding of the steel balls, can guarantee total coverage of the surfaces of the steel balls by obtained images, is more precise in sorting of the steel balls, can feed the steel balls in batches through the feeding disc, improves the detecting efficiency, reduces the motor loss, and prolongs the motor service life.

Owner:NINGBO BAIJIABAI MEASUREMENT & CONTROL EQUIP

Sorting and conveying track for batteries

The invention discloses a sorting and conveying track for batteries. The sorting and conveying track for batteries comprises a conveyor belt connected to sorting equipment, a battery receiving box isarranged on one side of the conveyor belt, a first bracket and a second bracket are separately arranged on the conveyor belt, one end of a screw is hinged to the first bracket, and the other end of the screw is connected to a rotary shaft of a driving motor, a movable plate is in threaded connection with the screw, a lifting air cylinder is fixed to the movable plate, a baffle is fixed to a pistonrod of the lifting air cylinder, a moving plate is inserted onto the back end surface of the baffle, a rack is formed on the front end surface of the moving plate, the rack is meshed with a gear, thegear is connected with the rotary shaft of the motor, a plurality of suction discs which are spaced at an equal interval are arranged on the back end surface of the moving plate, the suction discs are separately connected with a vacuum gas source through pipelines, electromagnetic valves are separately arranged on the pipelines of the suction discs, and the driving motor, the lifting air cylinder, the motor and the electromagnetic valves are electrically connected with a controller connected to the sorting equipment. The sorting and conveying track is precise in sorting and high in work efficiency, and can achieve an assembly line.

Owner:东莞市广荣电子制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com