On-line defect detection system and method for thin bamboo strips based on machine vision

A machine vision and detection system technology, applied in the direction of instruments, measuring devices, scientific instruments, etc., can solve the problems of low detection efficiency and high labor cost, and achieve the improvement of detection accuracy, accurate sorting, and avoiding missed detection and false detection. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] Below in conjunction with accompanying drawing and embodiment and the present invention will be further described.

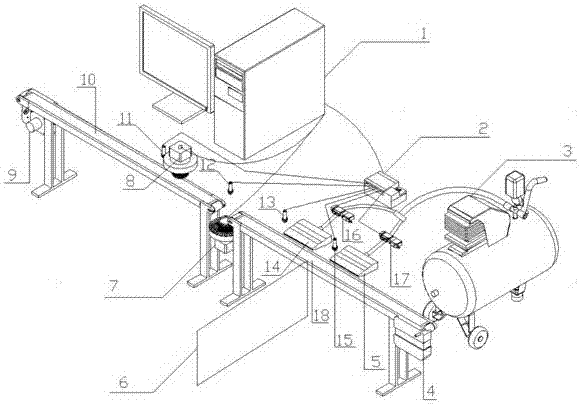

[0049] Such as figure 1As shown, the present invention includes an industrial PC 1, a PLC controller 2, an air pump 3, two solenoid valves 16,17, two air knives 14,5, an isolation plate 6, a line array camera 7, an area array camera 8, two A motor 9,4, two narrow conveyor belts 10,18, four photoelectric sensors 11,12,13,15;

[0050] The two narrow conveyor belts 10, 18 are arranged in a "line", and there is a gap between the two narrow conveyor belts 10, 18. A line-scan camera 7 for collecting images of the reverse side of the strips is installed below the gap, and the line-scan camera 7 is installed in a circular In the center of the light source, the first narrow conveyor belt 10 is driven to rotate by the first motor 9, and the second narrow conveyor belt 18 is driven to rotate by the second motor 4; The array camera 8 and the area array camera 8 are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com