Method for realizing sorting of textile bobbins based on machine vision

A bobbin sorting and machine vision technology, applied in the field of machinery, can solve the problems of waste of manpower, material and financial resources, robustness, flexibility, limited degree of intelligence, easy to judge errors, etc., to save labor costs, significantly Economic benefits and the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to describe the technical content of the present invention more clearly, further description will be given below in conjunction with specific embodiments.

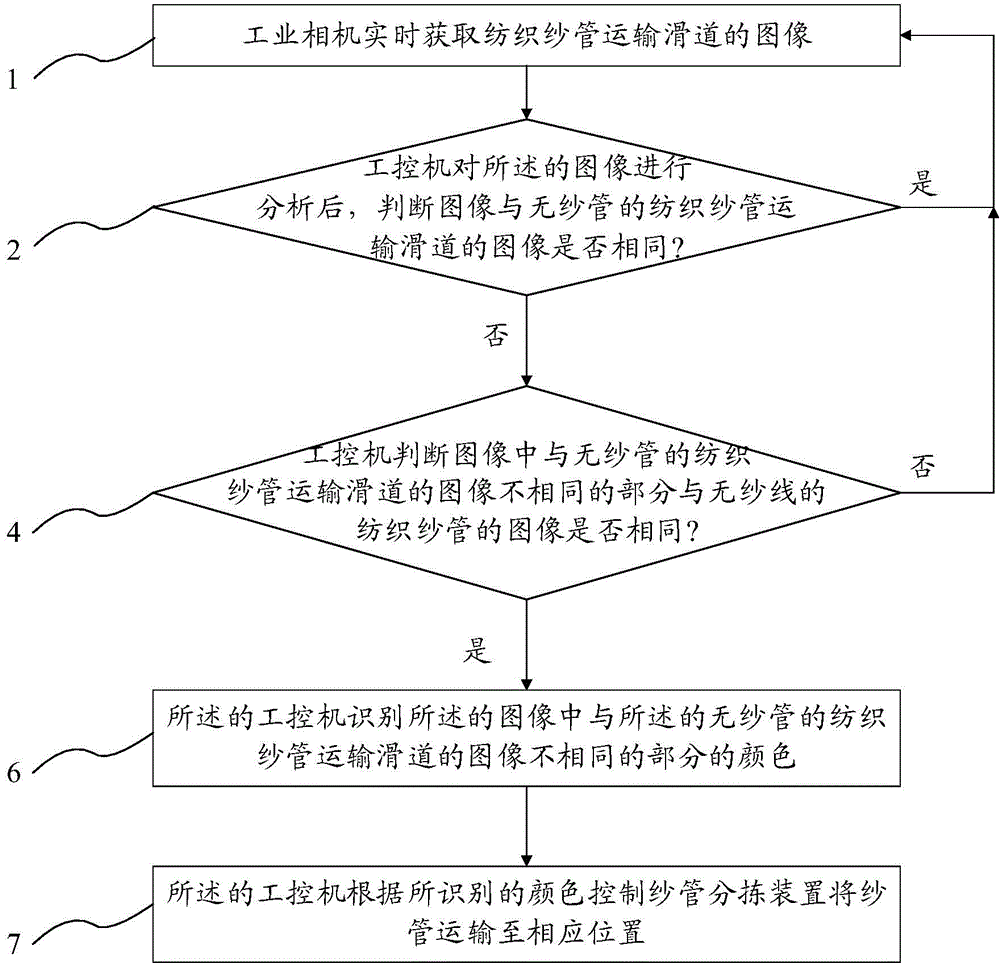

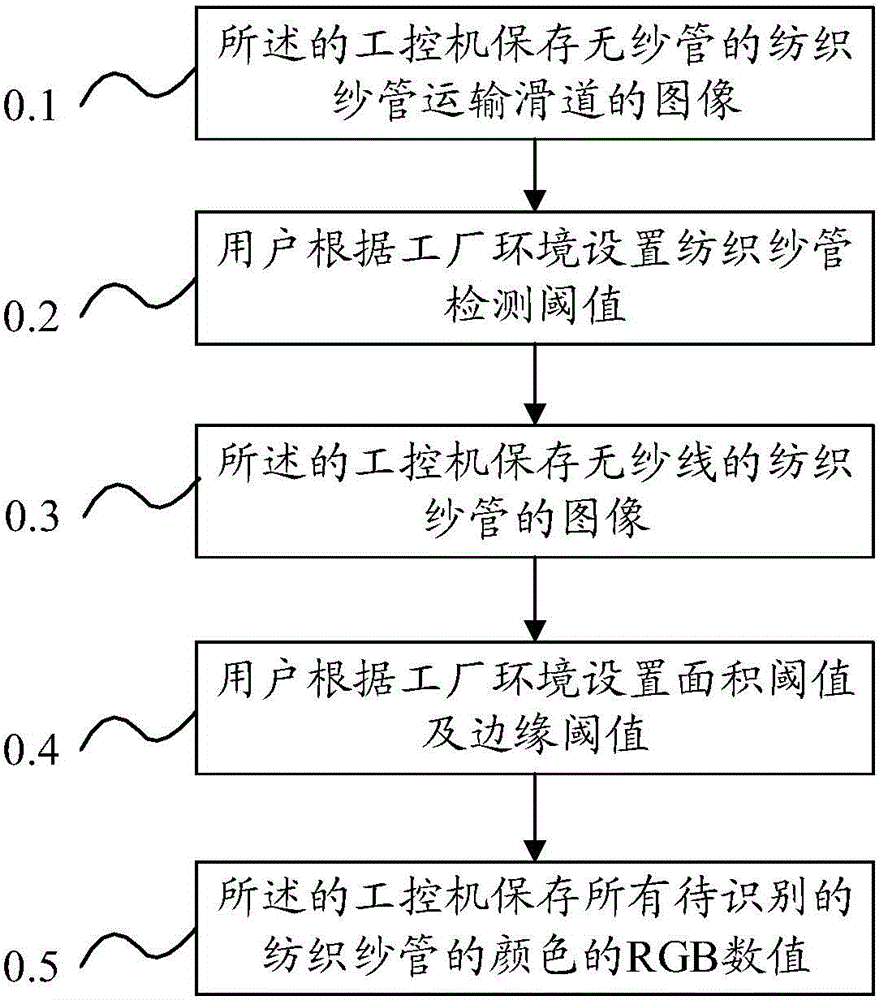

[0055] see Figure 1 to Figure 3As shown, the method for sorting textile bobbins based on machine vision of the present invention abandons the use of color-sensitive sensors in the prior art (color-sensitive sensors can only obtain color signals, but cannot process color signals) to identify textile bobbins and the color of the residual thread of the textile bobbins, the method for sorting the textile bobbins based on machine vision of the present invention can not only obtain the color information of the entire textile bobbins with pixel-level resolution, but also can obtain all pixel points of the textile bobbins Carry out algorithmic processing, realize various intelligent functions, and complete management tasks with better performance.

[0056] The method for realizing textile bobbin sorting based on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com