Sorting and conveying track for batteries

A technology of conveying rails and batteries, applied in sorting and other directions, can solve the problems of low production efficiency, time-consuming and laborious, etc., and achieve the effect of high work efficiency and accurate sorting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

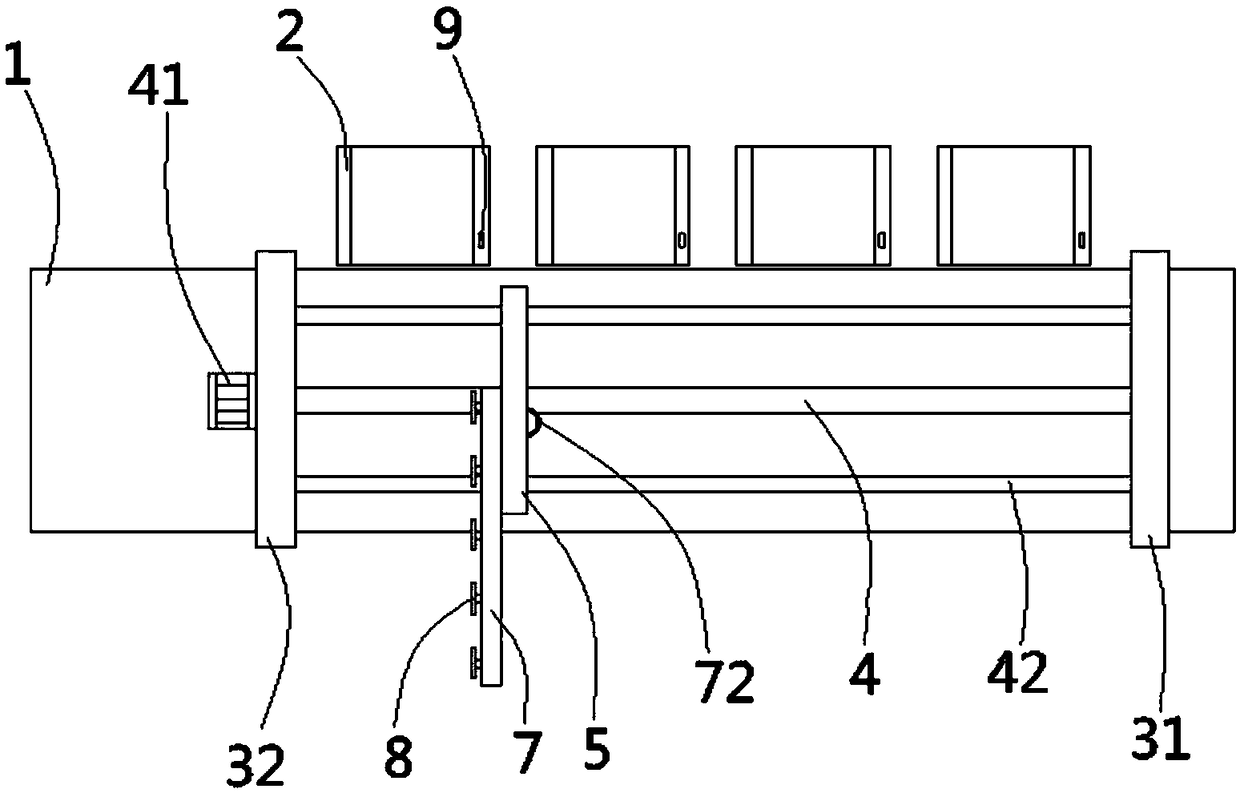

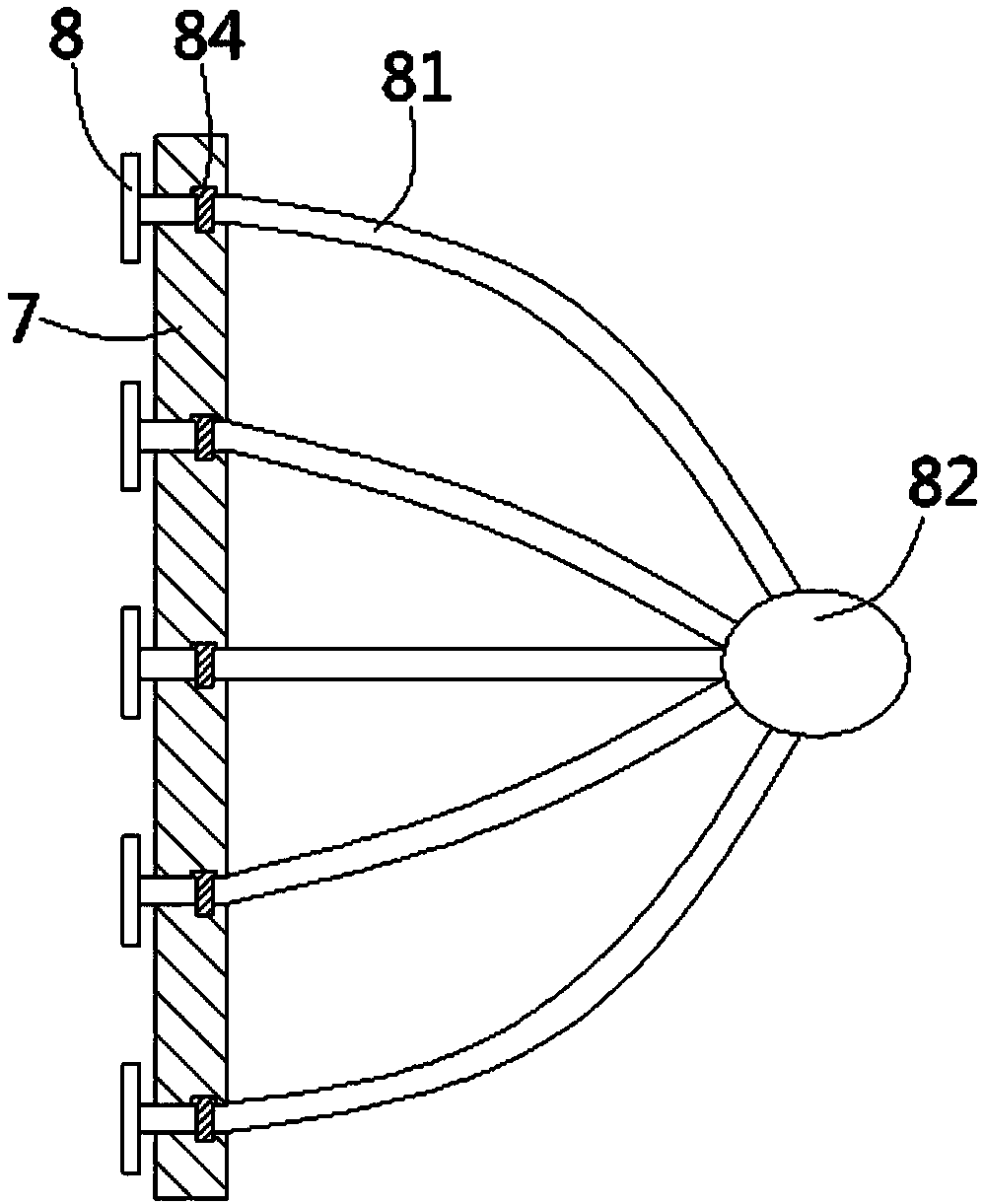

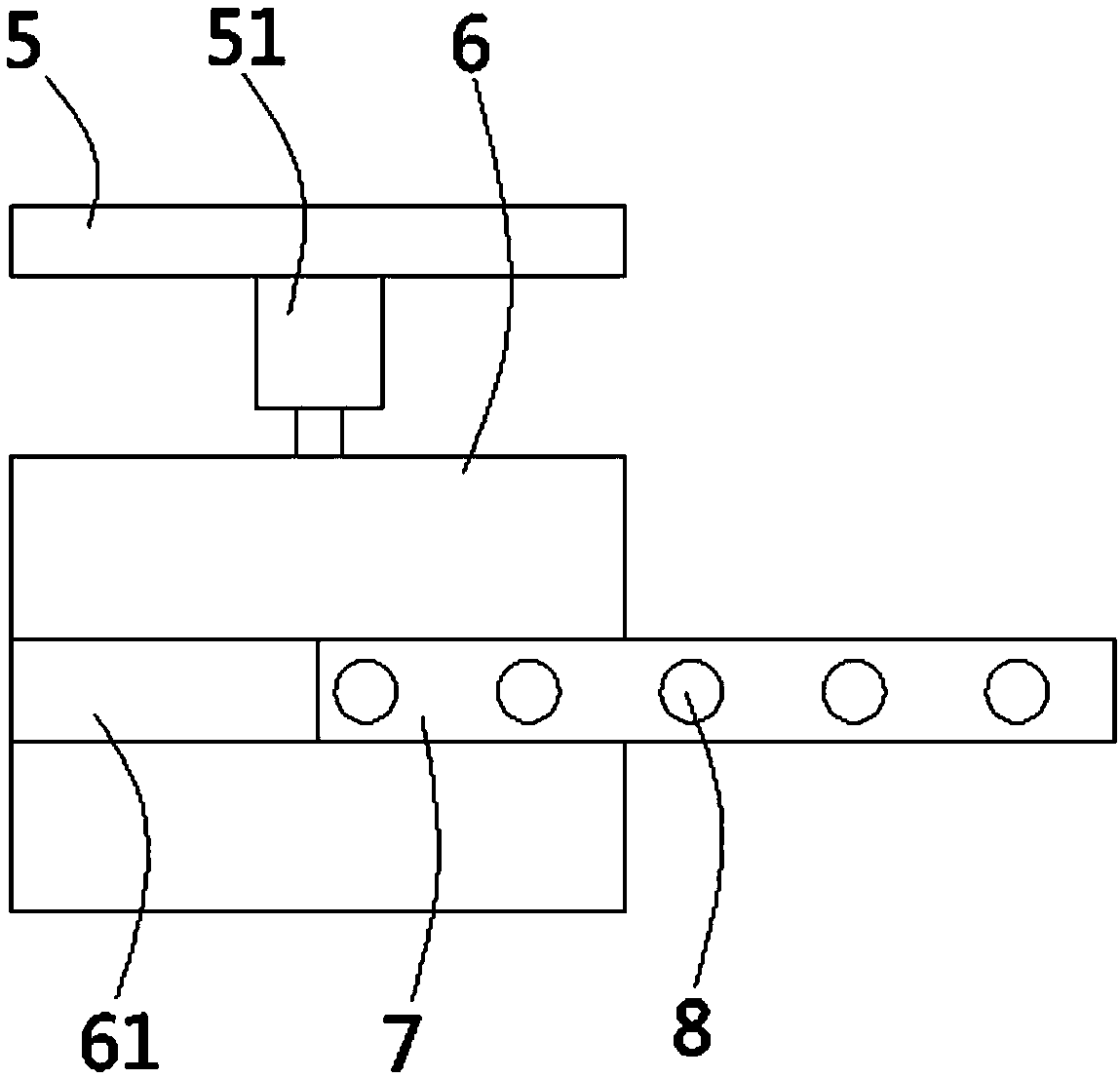

[0020] see figure 1 , image 3 , a battery sorting conveyor track according to the present invention, including a conveyor belt 1 connected to a sorting device (not shown), one side of the conveyor belt 1 is provided with several battery receivers for installing batteries of different grades Box 2, four battery receiving boxes 2 are arranged on one side of the conveyor belt 1, and the battery receiving boxes 2 are used to receive batteries of four grades respectively. There are first bracket 31 and second bracket 32 of "匚" type, one end of the screw rod 4 is hinged on the first bracket 31, and the other end is connected to the rotating shaft of the driving motor 41, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com