Steel ball surface defect detection sorting equipment

A defect detection and steel ball technology, applied in sorting, optical testing defects/defects, chemical instruments and methods, etc., can solve the problems of false detection, high false detection rate and low efficiency of steel ball sorting equipment, to avoid The effect of missed detection and reduction of false detection rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

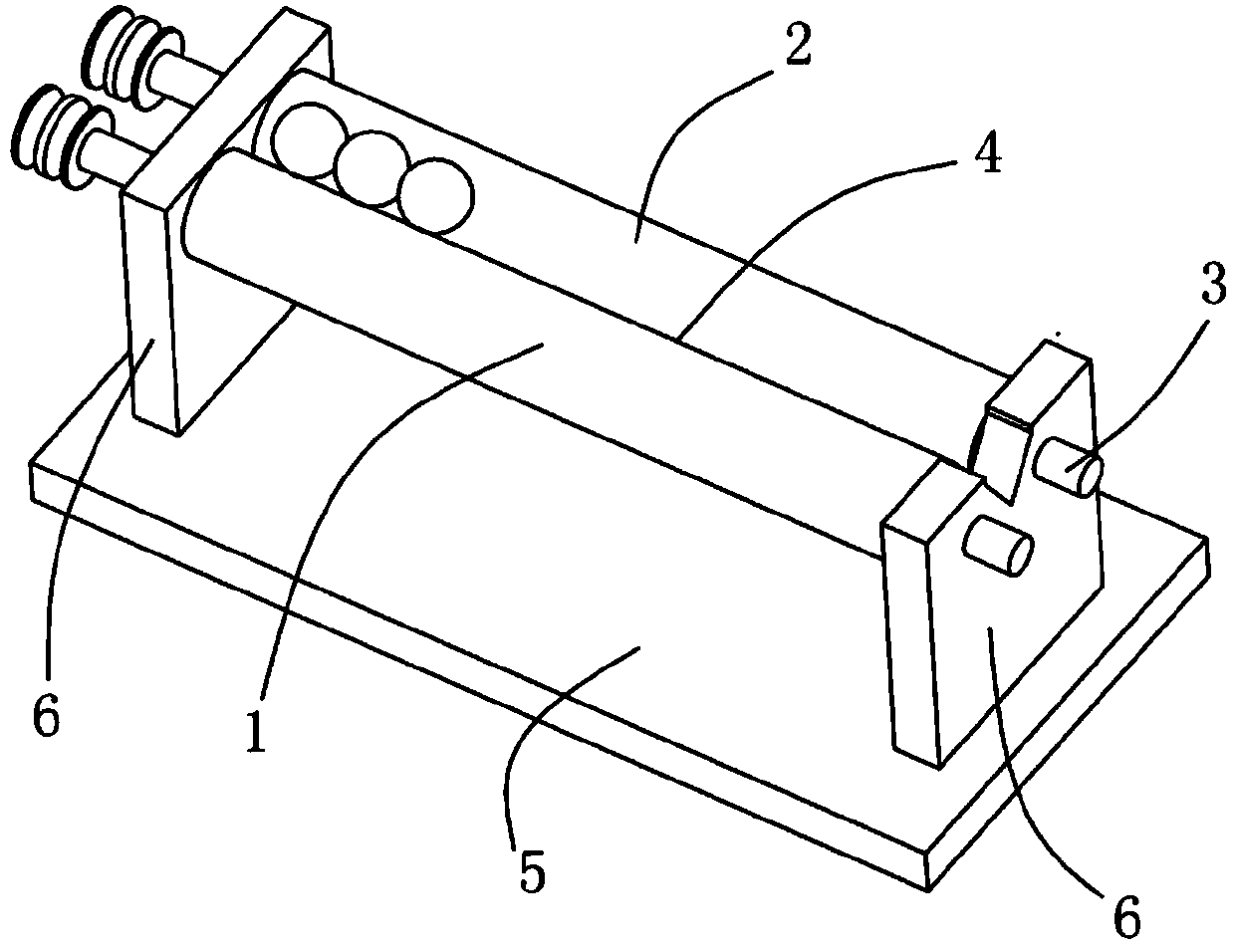

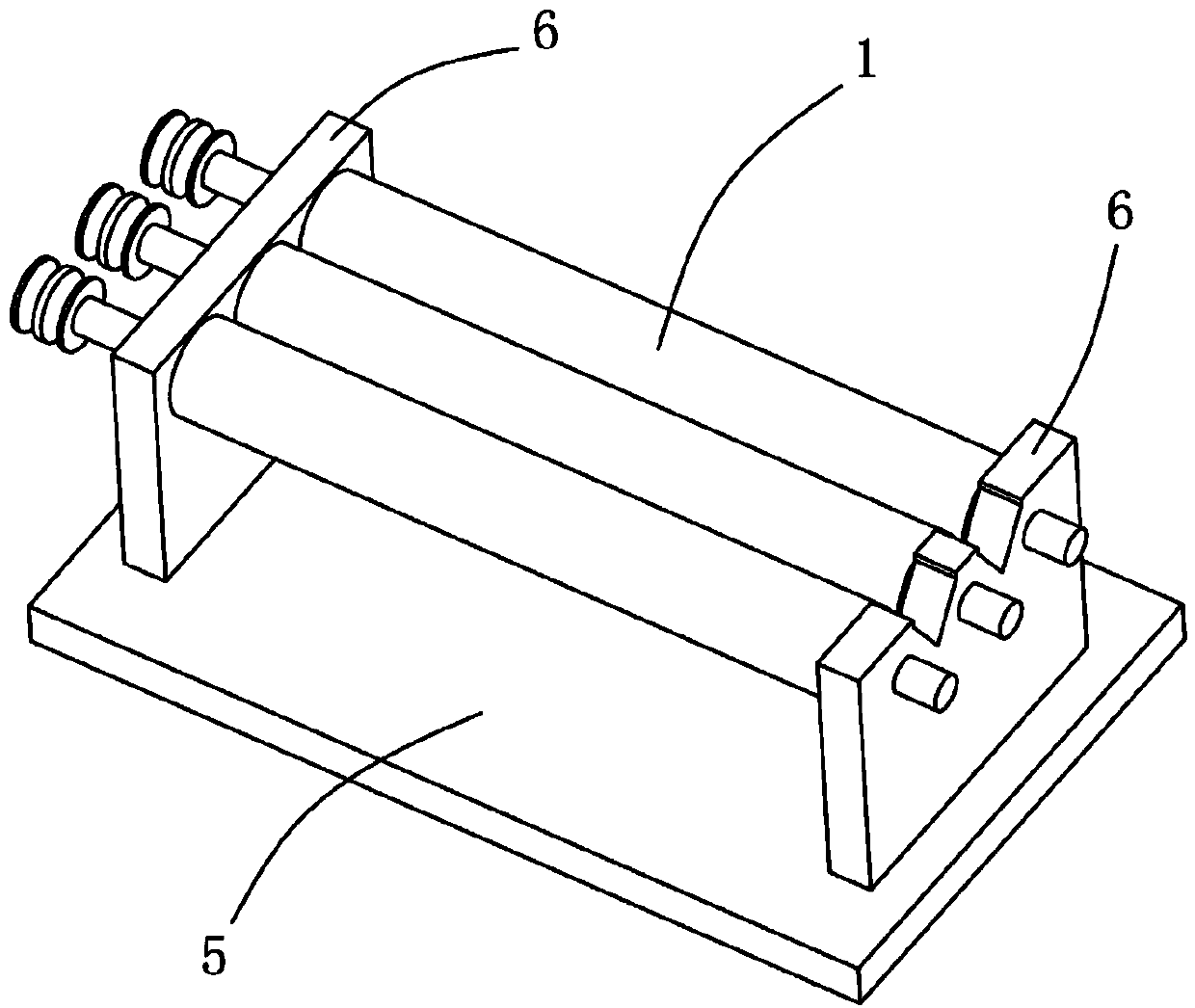

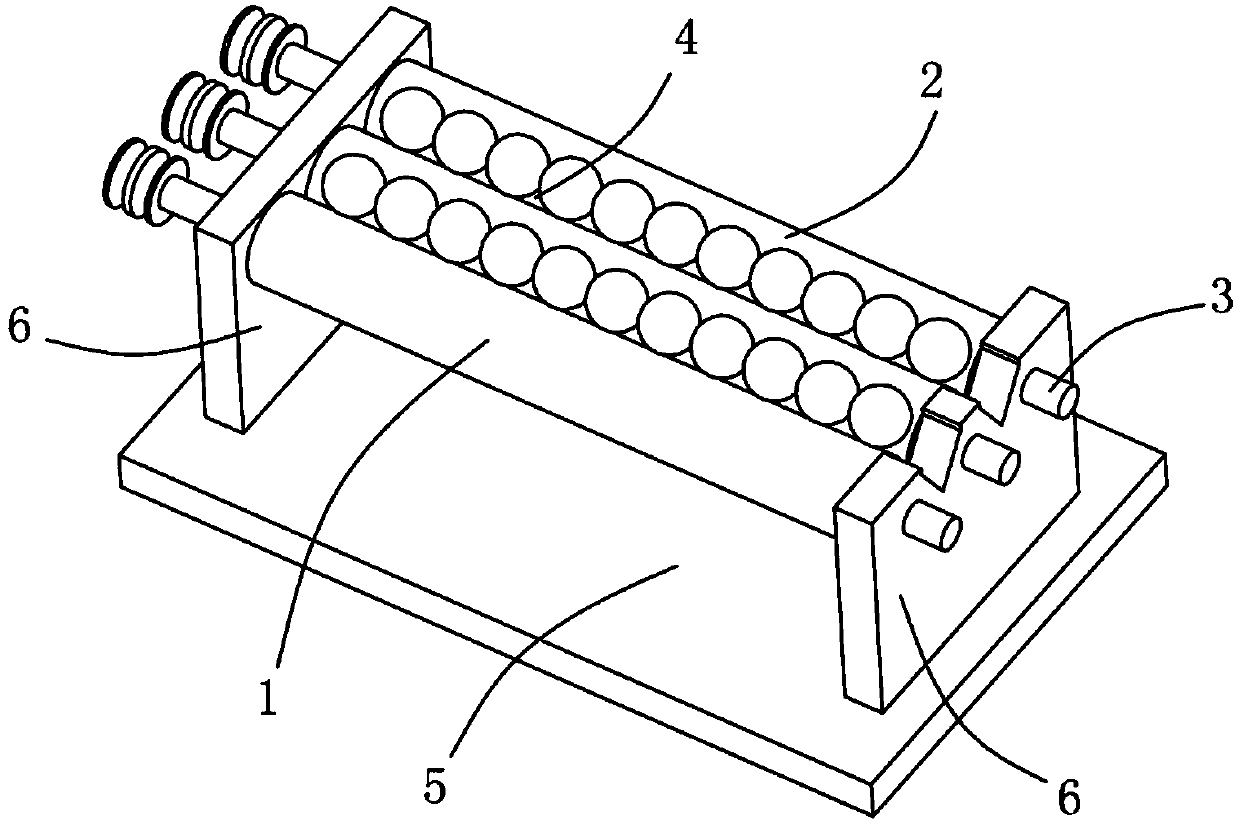

Embodiment 1

[0038] A steel ball surface defect detection and sorting device includes a steel ball size screening device, a steel ball surface unfolding device, a camera, a sorting device and a control module, and the camera and the sorting device are respectively connected to the control module. The steel ball entry end of the storage tank 4 of the steel ball surface unfolding device is connected with the qualified steel ball discharge end of the steel ball size screening device through the feeding channel, and the qualified steel balls screened by the steel ball size screening device are fed from the feeder. The channels enter the steel ball surface unfolding device one by one, the camera is arranged above the accommodating groove 4 of the steel ball surface developing device, and the sorting device is arranged at the steel ball roll-out end of the steel ball surface developing device's accommodating groove 4. The steel balls first pass through the steel ball size screening device to sele...

Embodiment 2

[0060] A steel ball surface defect detection and sorting device includes a steel ball surface cleaning device, a steel ball surface unfolding device, a camera, a sorting device and a control module, and the camera and the sorting device are respectively connected to the control module. The steel ball entry end of the storage tank 4 of the steel ball surface unfolding device is connected with the steel ball discharge end of the steel ball surface cleaning device through the feeding channel, and the steel balls cleaned by the steel ball surface cleaning device enter from the feeding channel one by one. The steel ball surface unfolding device, the camera is arranged above the accommodation groove 4 of the steel ball surface unfolding device, and the sorting device is arranged at the steel ball roll-out end of the steel ball surface unfolding device's accommodation groove 4. The steel ball first passes through the steel ball surface cleaning device for surface cleaning, and then th...

Embodiment 3

[0065] A steel ball surface defect detection and sorting device includes a steel ball size screening device, a steel ball surface cleaning device, a steel ball surface unfolding device, a camera, a sorting device and a control module, and the camera and the sorting device are respectively connected to the control module. The steel ball entering end of the spiral groove 18 of the steel ball surface cleaning device communicates with the second gap section L2 of the steel ball size screening device through the feeding channel, and the steel ball rolling end of the steel ball surface cleaning device spiral groove 18 is connected with the steel ball The accommodating tanks 4 of the spherical surface spreading device communicate with each other through feeding channels. The camera is arranged above the accommodating groove 4 of the steel ball surface developing device, and the sorting device is arranged at the steel ball rolling end of the accommodating groove 4 of the steel ball sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com