Bamboo strip automatic detecting and sorting system and method

An automatic detection and sorting system technology, applied in sorting and other directions, can solve the problems of low production efficiency and high labor intensity, and achieve the effect of high production efficiency and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

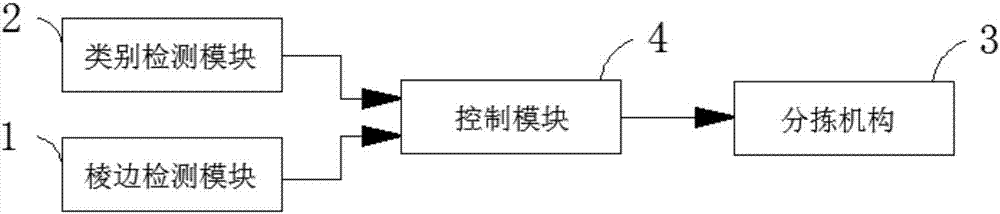

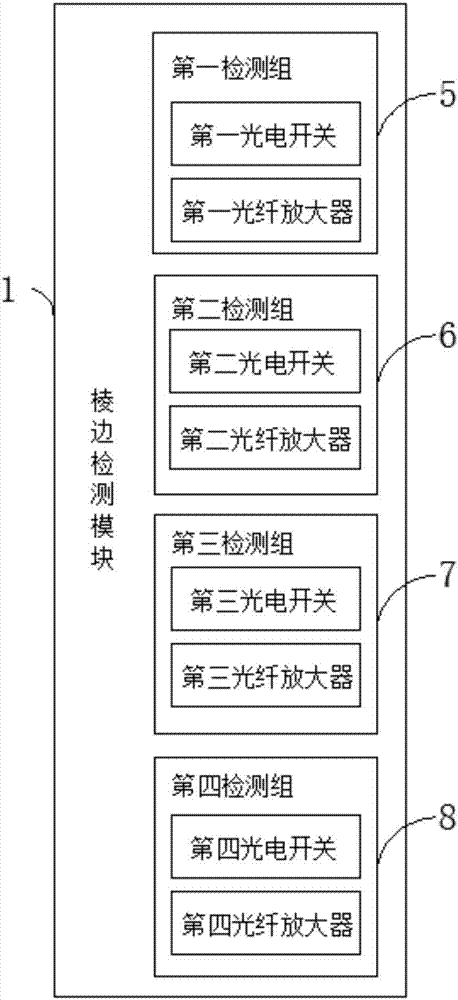

[0055] Such as figure 1 As shown, a kind of automatic detection and sorting system for bamboo strips includes an edge detection module 1, a category detection module 2, a sorting mechanism 3 and a control module 4, and the edge detection module 1, the category detection module 2 and the sorting module Mechanisms 3 are all connected to the control module 4 through lines;

[0056] The edge detection module 1 detects the integrity of the four edges of the bamboo strip in parallel in real time, and when it detects that there are defects in the four edges of the bamboo strip, it generates a defect signal and transmits it to the control module 4; When there is no defect in the four edges of the bamboo strip, a complete signal is generated and transmitted to the control module 4;

[0057] Described category detection module 2 carries out category detection to bamboo strip, generates category detection signal and transmits to control module 4;

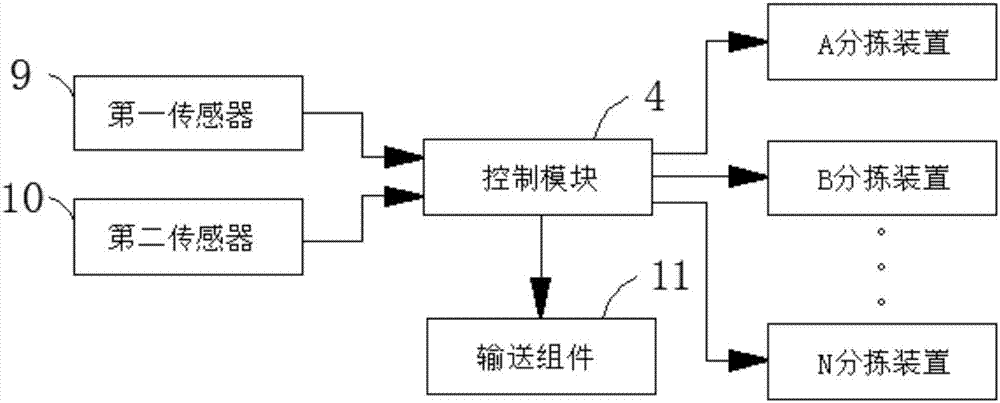

[0058] The control module 4 controls ...

Embodiment 2

[0070] Such as Figure 4 Shown, a kind of bamboo strip automatic detection sorting method is characterized in that, comprises the following steps:

[0071] Step S1. The edge detection module 1 detects the integrity of the four edges of the bamboo and wood strips side by side in real time. When it detects that there is a defect in the edges of the bamboo and wood strips, it generates a defect signal and transmits it to the control module 4; the control module 4 according to The defect signal controls the input and output device to transmit the bamboo strip to the outside; when it is detected that there is no defect in the edge of the bamboo strip, it generates a complete signal and transmits it to the control module 4; the control module 4 controls the input and output device according to the complete signal. The wooden strip is transmitted to the category detection module 2;

[0072] Step S2. The category detection module 2 detects the category of the bamboo and wood strips, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com