Device and method for sorting building waste

A technology for construction waste and materials, applied in the direction of sorting, etc., can solve the problems of undeveloped professional technology system, weak construction waste recycling technology, mixed light and heavy materials in winnowing method, so as to promote further transformation and upgrading and avoid environmental pollution and waste of resources, the effect of breaking through common bottlenecks

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] In order to further explain the technical solution of the present invention, the present invention will be described in detail below through specific examples.

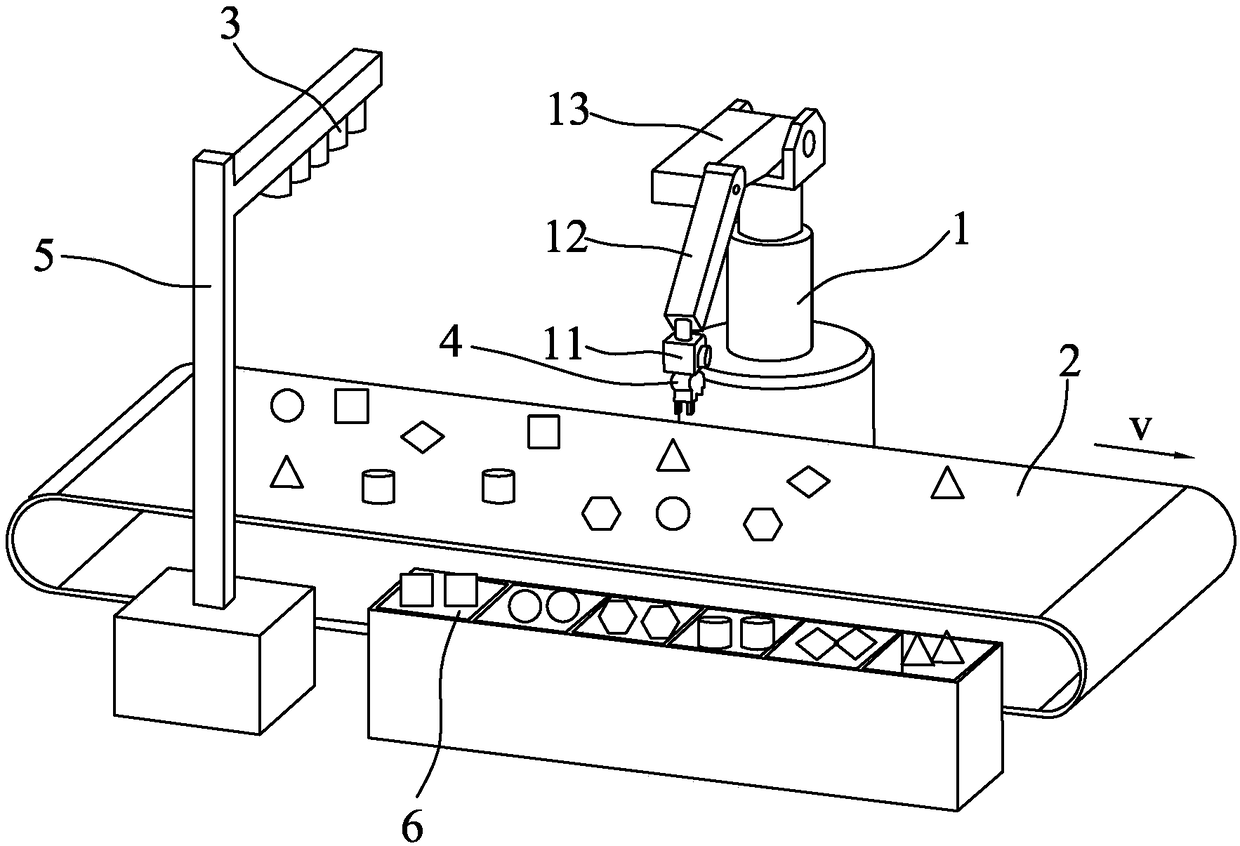

[0034] Such as figure 1 As shown, the present invention discloses a device for sorting construction waste, which includes a six-degree-of-freedom manipulator 1, a conveyor belt 2, a laser sensor 3 and a load cell 4, and the six-degree-of-freedom manipulator 1 is arranged on one side of the conveyor belt 2, such as As shown in the figure, the six-degree-of-freedom manipulator 1 includes a wrist arm part 11, a small arm part 12 and a big arm part 13, and a main control chip (not shown in the figure) is arranged in the six-degree-of-freedom manipulator 1, and the laser sensor It is arranged above the conveyor belt 2 and before the six-degree-of-freedom manipulator 1. As shown in the figure, in this embodiment, the laser sensor 3 is fixed above the conveyor belt 2 through a fixing frame 5. The laser sensor 5 is in ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com