Corn sorting machine

A sorting machine and corn technology, applied in the field of agricultural machinery, can solve the problems of unreachable corn non-staple food, consuming manpower and material resources, cumbersome sorting work, etc., and achieves the effects of compact structure, reduced power loss, and small occupied space.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Specific embodiments of the present invention are given below and described in conjunction with the accompanying drawings.

[0018] A corn sorting machine includes a feeding part, a sorting part and a sorting part.

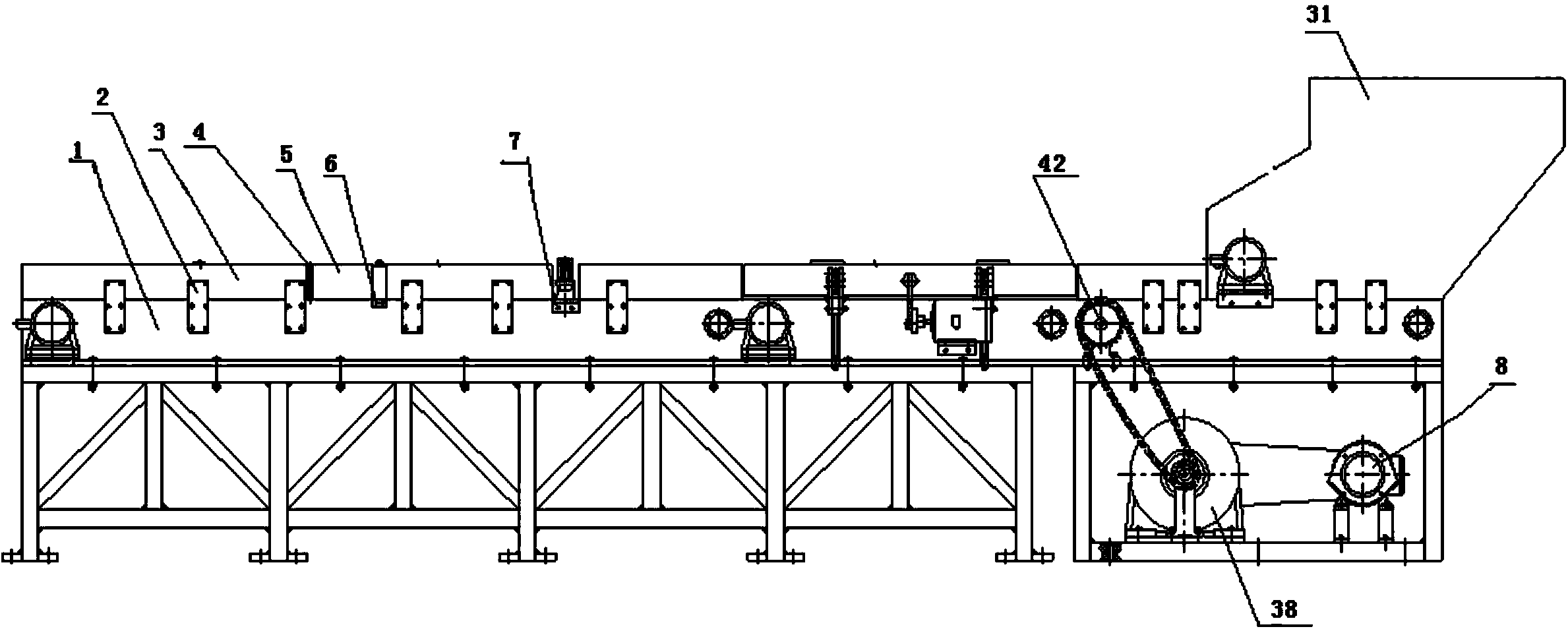

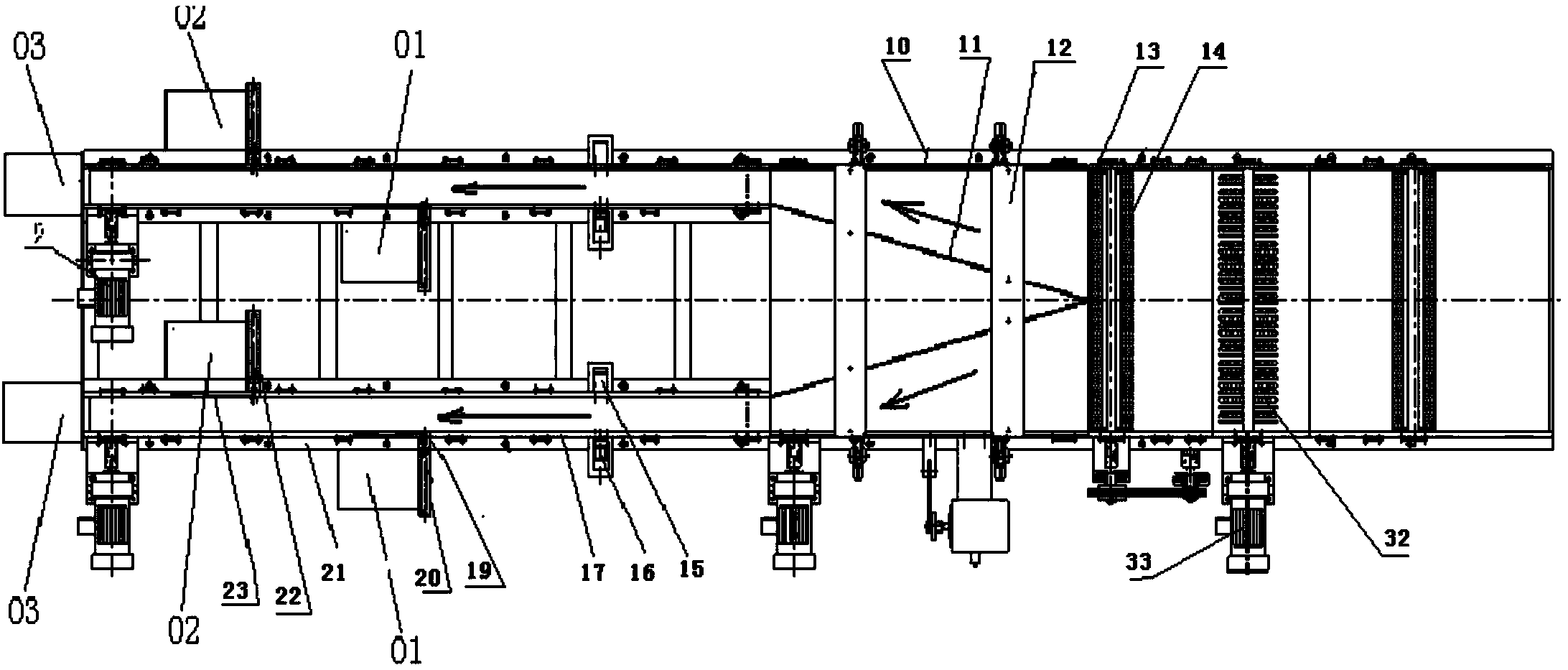

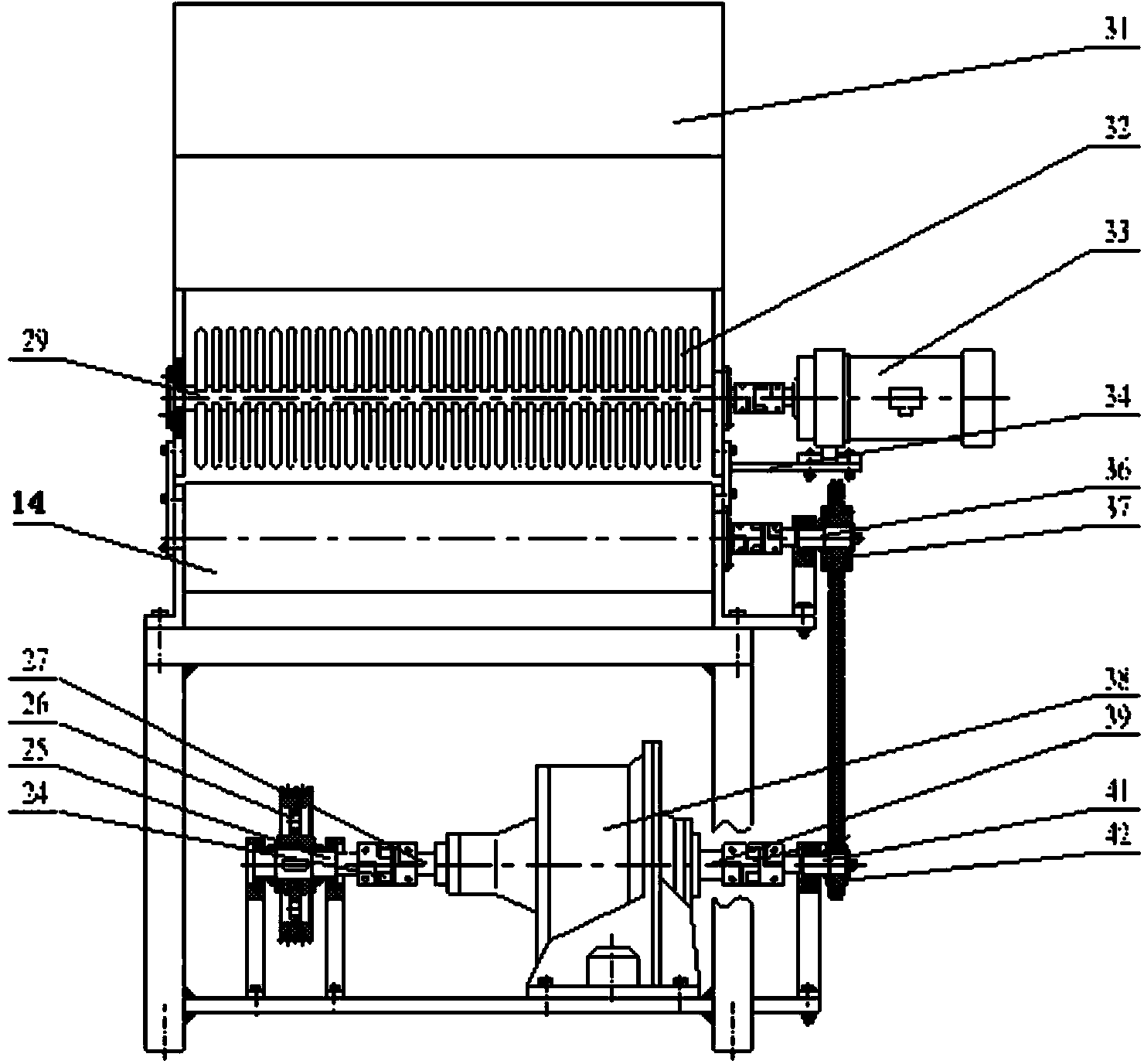

[0019] Such as figure 1 , 2 As shown in and 3, the feeding part includes two parts, the transmission system and the execution system; the transmission system uses the feeding motor 8 as the power source, and its output shaft is connected with the small pulley shaft by means of a plum blossom coupling, and the power is transmitted to The belt pulley 26 is passed to the input shaft 27 of the planetary gear reducer 38 via the large pulley shaft 25 and the quincunx coupling 24 . The output shaft 39 of the planetary gear reducer transmits power to the sprocket 42 by means of another quincunx coupling and the small sprocket shaft 41, and the large sprocket shaft 36 and the feeding drum 14 of the conveyor belt are also connected to each other by means of a quinc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com