Measuring and controlling device used for rotary steering drilling system and measuring and controlling method utilizing same

A technology of rotary steerable drilling and measurement and control device, which is applied to the automatic control system of drilling, drilling equipment, measurement, etc., and can solve the problems of not considering practical application feasibility, redundant design of processors, not considering and so on.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

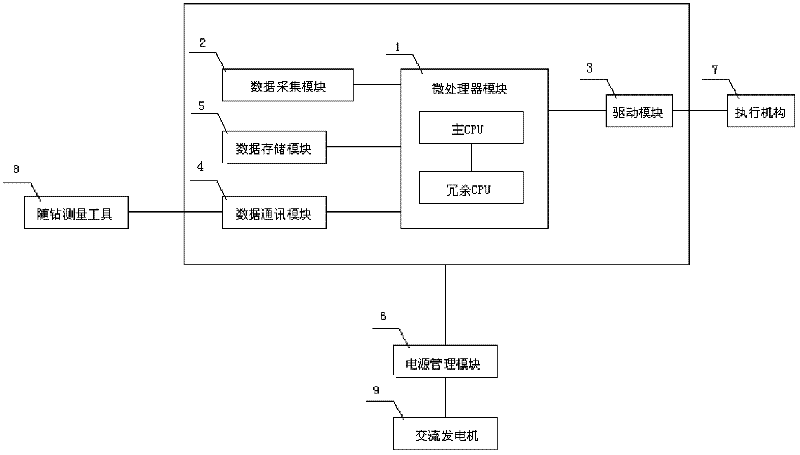

[0057] like figure 1 As shown, the measurement and control device proposed by the present invention includes several modules: a microprocessor module 1 , a data acquisition module 2 , a drive module 3 , a data communication module 4 , a data storage module 5 and a power management module 6 . The data acquisition module 2 , the drive module 3 , the data communication module 4 , and the data storage module 5 are all connected to the microprocessor module 1 .

[0058] One end of the data acquisition module 2 is connected to the pressure sensor, temperature sensor, displacement sensor, and accelerometer, and the other end is connected to the microprocessor module 1. The I / O interface on the processor module transmits to the microprocessor module.

[0059] One end of the drive module 3 is connected to the microprocessor module 1 and the other end is connected to the actuator 7 to receive information from the microprocessor module 1 and control the movement of the actuator 7 .

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com