Laying spreading method for composite material

A composite material and layering technology, applied in special data processing applications, instruments, electrical digital data processing, etc., can solve problems such as low efficiency, poor dimensional accuracy, and low material utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Now in conjunction with embodiment, accompanying drawing, the present invention will be further described:

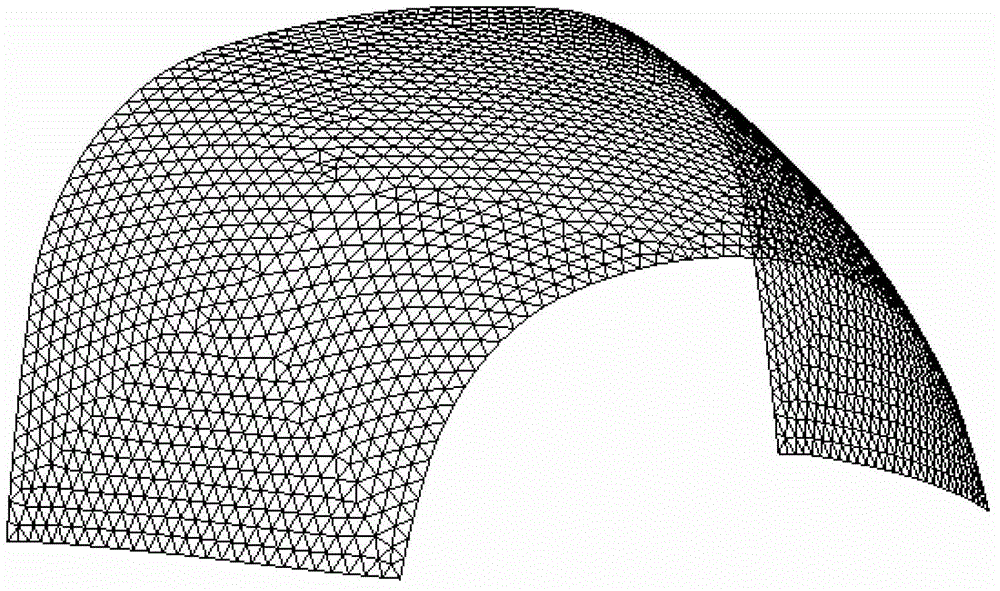

[0034] The surface to be unfolded is approximately represented by 3840 triangles connected by 2012 nodes (such as image 3 ), the composite material to be laid on the curved surface is a plain weave cloth, and the distance between any two warp fibers or weft fibers is 1mm. direction.

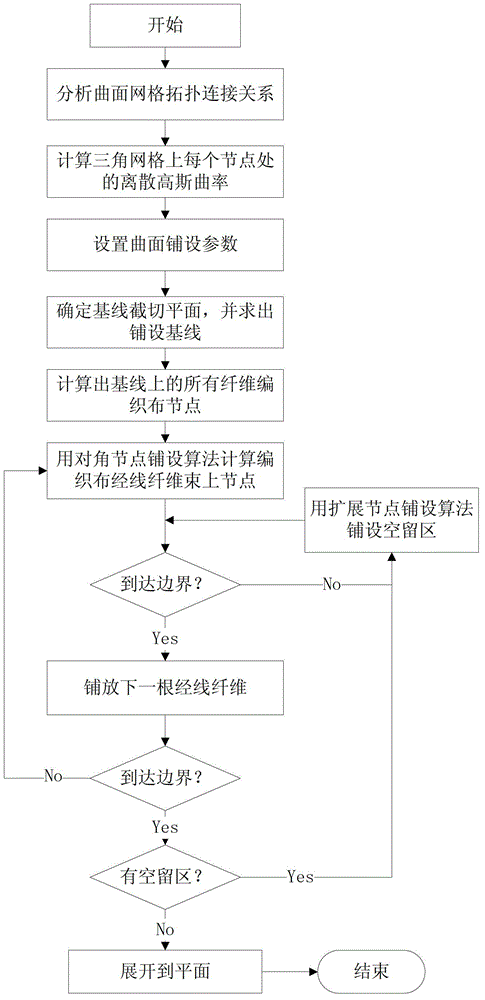

[0035] According to the present invention, its implementation process is as follows:

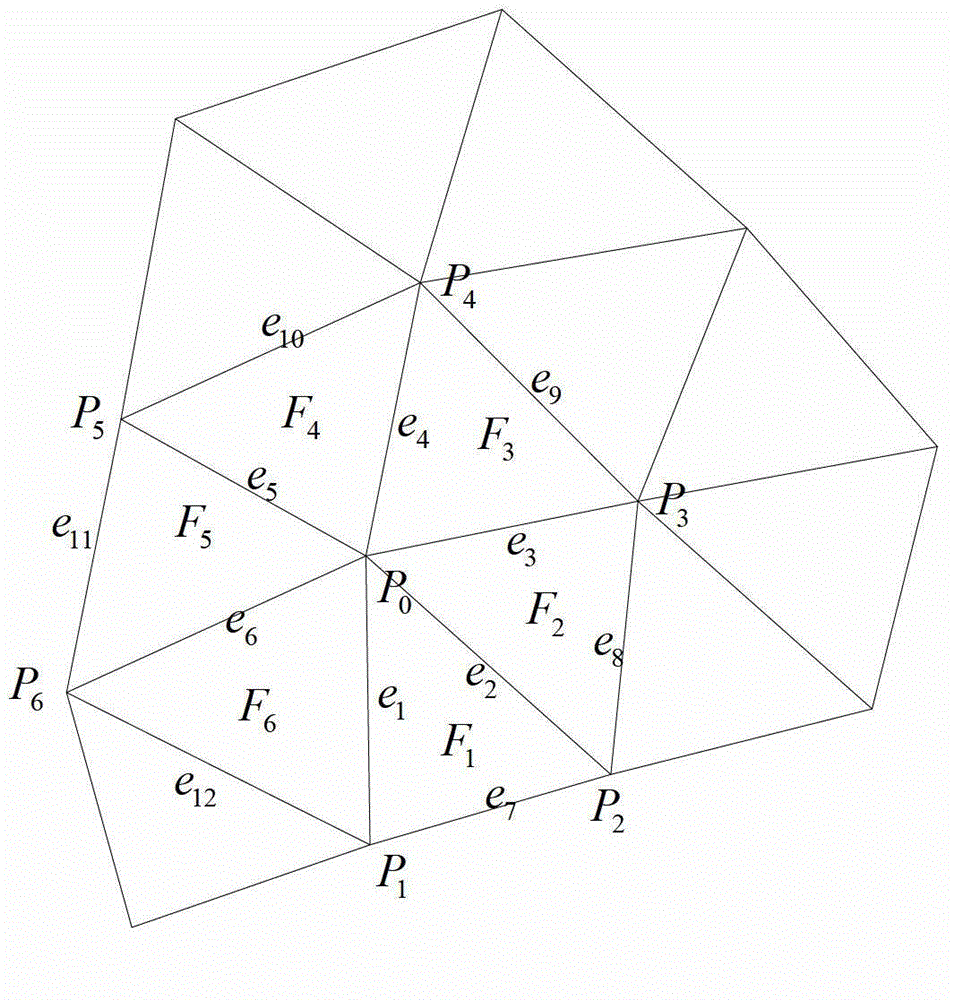

[0036] 1) Analyze the topological connection relationship of the triangular mesh, and the number of edges N can be obtained by Euler's theorem e =N p +N F -2=5850, such as Figure 4 , the triangle connection relationship of the mesh surface can be further analyzed to obtain the following topological connection relationship among nodes, edges and triangles:

[0037] a. Point P 0 The edge set Eset 0 {e 1 ,e 2 ,e 3 ,e 4 ,e 5 ,e 6}, ..., point P 2012 Edge set Eset 2011 {...};

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com