Underwater gravel foundation bed laying device and method

A laying device and foundation bed technology, which is applied in the field of underwater gravel foundation bed laying devices, can solve problems such as low construction accuracy, correcting riprap pipes, and high cost, and achieve the effect of facilitating overall movement and ensuring accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

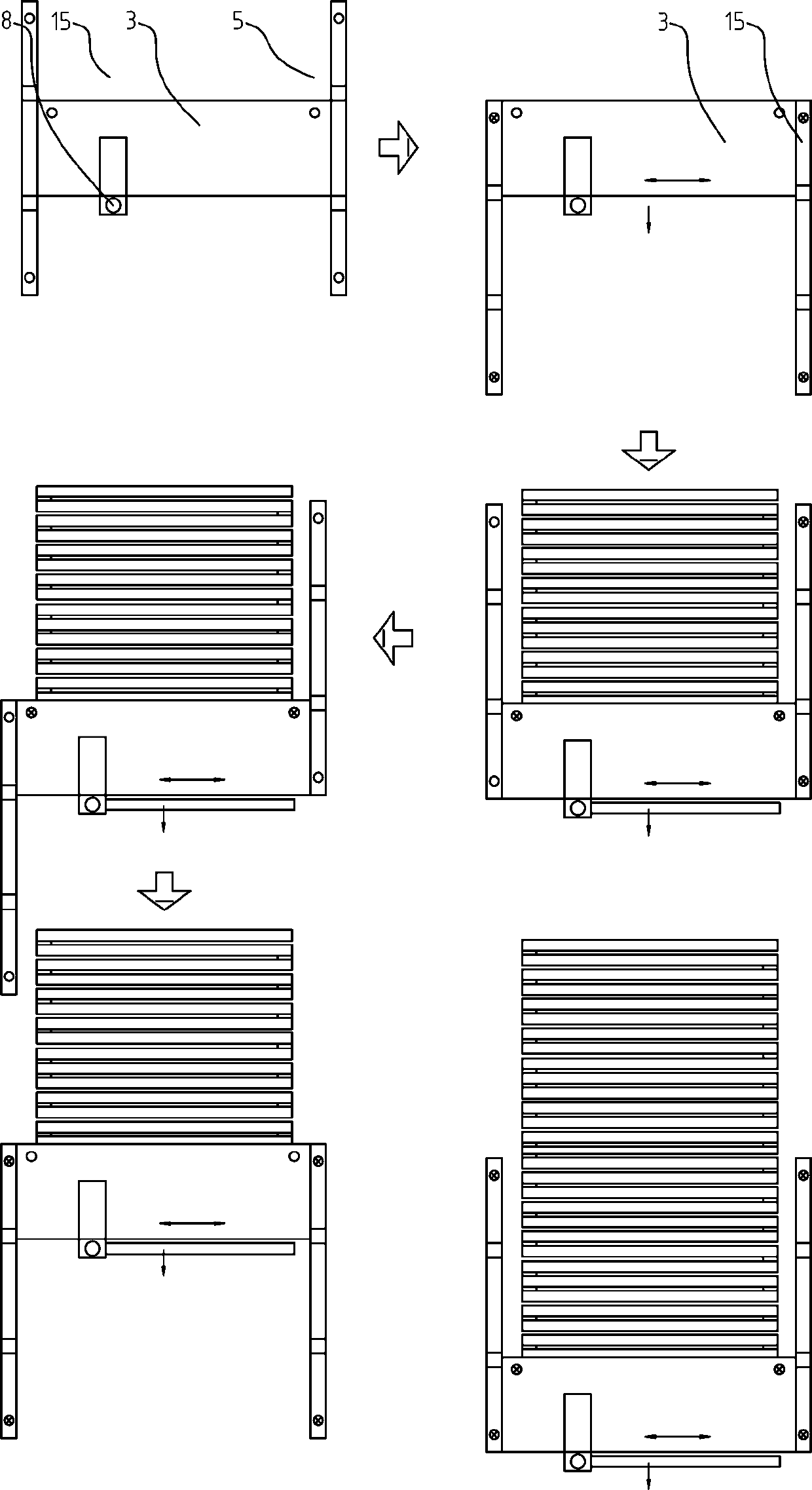

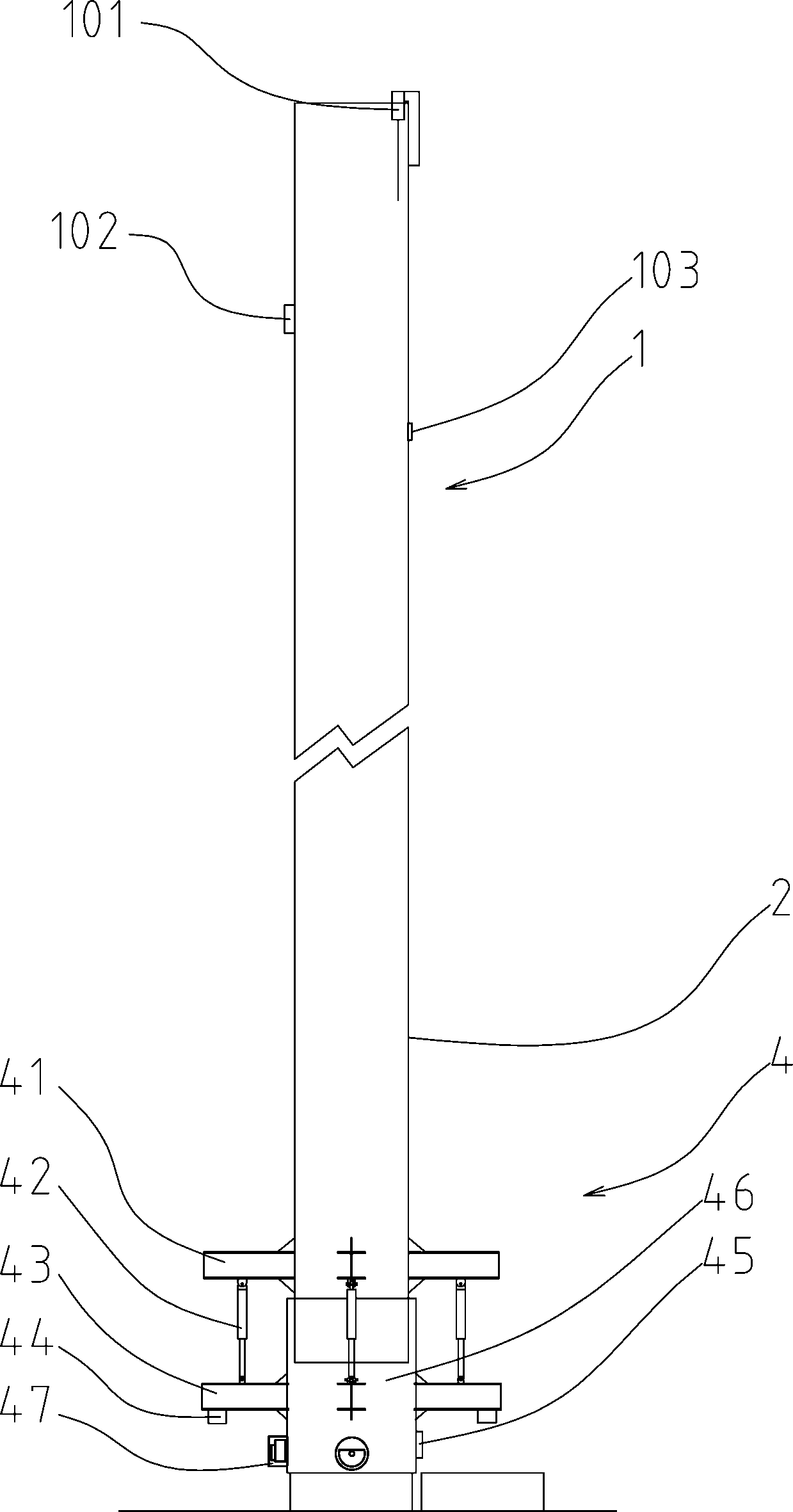

[0058] Such as Figure 1~4 Among them, an underwater gravel bed laying device includes a hull 3, on which a transport trolley 13 is arranged, and the transport trolley 13 is driven by a driving device to slide along the length direction of the hull 3, and on the transport trolley 13 is provided with a slide The top of the chute is provided with a feeding port 8, and the bottom of the chute is close to the bottom of the water; at least one conveyor belt for feeding the trolley 13 is also provided;

[0059] The position of hull 3 bow and stern is provided with buoyant tank slide rail 15, and buoyant tank slide rail 15 is slidably connected with hull, is provided with liftable positioning pile 5 on two buoyant tank slide rails 15 and hull 3;

[0060] Described pontoon slide rail 15 is folding structure, and the termination of pontoon slide rail 15 is folded on the side of hull 3 when moving, and during construction, the termination of pontoon slide rail 15 is launched. With this...

Embodiment 2

[0095] A method of using the above-mentioned underwater crushed stone bed laying device, comprising the following steps:

[0096] S1, the hull 3 moves to the design position, and uses GPS or Beidou system to locate the position of the chute on the horizontal plane;

[0097] The pontoon slide rail 15 is launched so that the hull 3 is positioned at the initial position of the pontoon slide rail 15; the positioning pile 5 on the pontoon slide rail 15 is driven into the bottom of the water;

[0098] S2. Control the elevation position of the discharge port at the bottom of the chute by adjusting the lift of the chute;

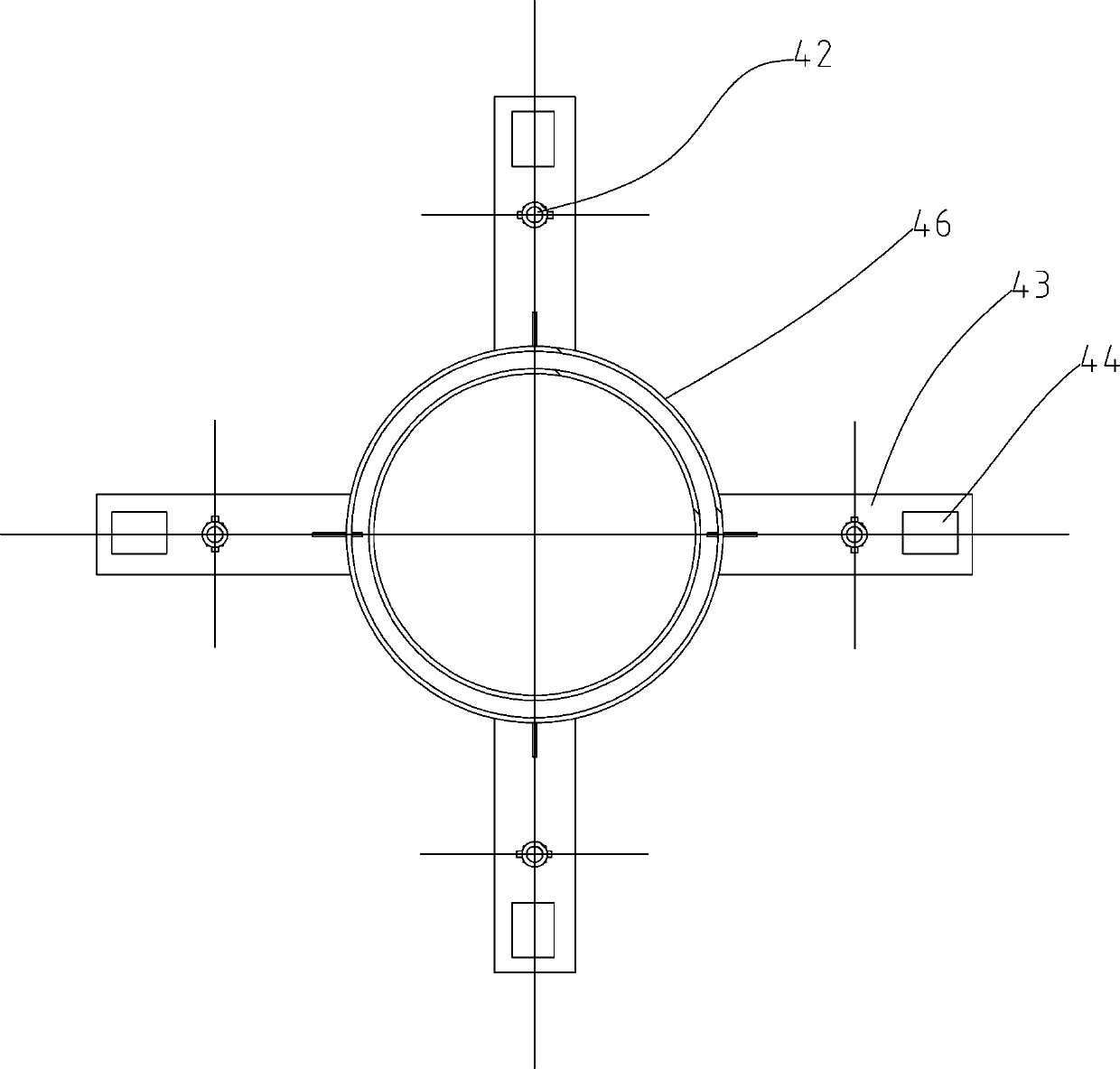

[0099] S3, the bottom of the chute is provided with a discharge opening adjustment device 4, and an inclination adjustment oil cylinder 42 is provided in the discharge opening adjustment device 4 to adjust the horizontality of the discharge opening at the lowermost end of the chute;

[0100] S4. Fill stones into the chute through the conveyor belt. When the stone r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com