Unfolding method of circular cylinder wall and cylindrical surface during eccentric oblique intersection

A cylindrical surface and cylinder wall technology, applied in the field of transformer sheet metal processing, can solve the problem of raising the actual height of the seat cylinder wall, and achieve the effect of precise deployment, improving welding quality and ensuring the actual height

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The present invention will be further described through the embodiments below in conjunction with the accompanying drawings.

[0041] A method for unfolding in which a circular cylinder wall intersects with a cylindrical surface eccentrically and obliquely. For the interference of the cylindrical surface, it is necessary to shorten the axial length of the rectangular section of the cylinder wall so that the length is equal to the (axial) shortest distance from the mating side of the section to the flat end of the cylinder wall, so as to solve the interference between the cylinder wall and the cylindrical surface.

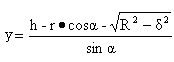

[0042] At the unfolding position θ, the distance from any point on the matching side of the section to the flat end of the cylinder wall is set to y, and the perpendicular distance from any point on the matching side of the section to the center line is set to r, and y is a function of r. according to Figure 1-Figure 3 The geometric relationship between the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com