Floating-type underwater gravel base bed continuous leveling ship

A technology for leveling ships and crushing stones, applied in special-purpose ships, infrastructure engineering, ships, etc., can solve the problems of difficult to control leveling accuracy, correction of riprap pipes, slow positioning speed, etc., to increase the construction range, Improve construction efficiency and facilitate migration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

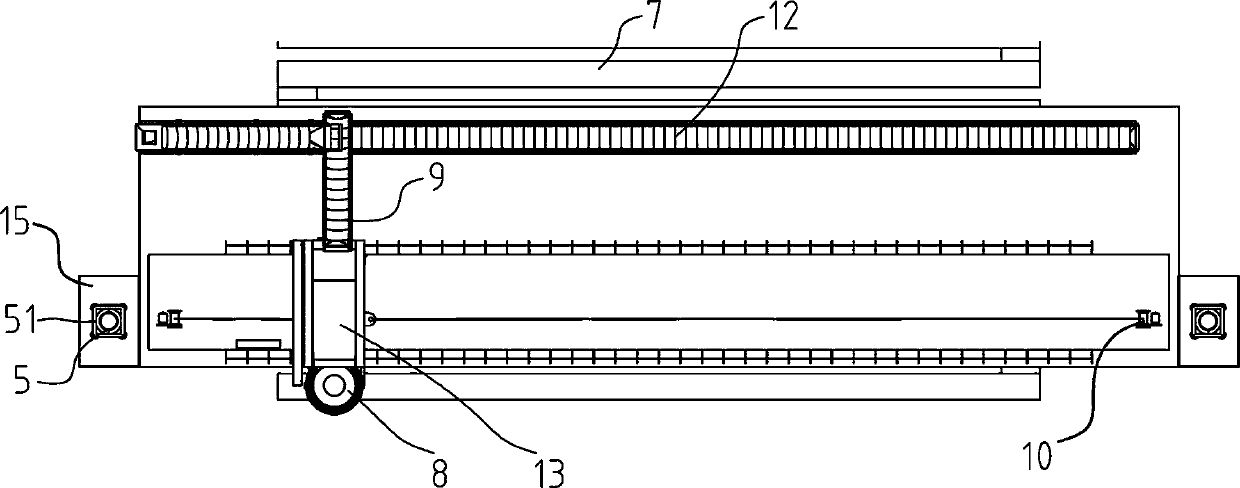

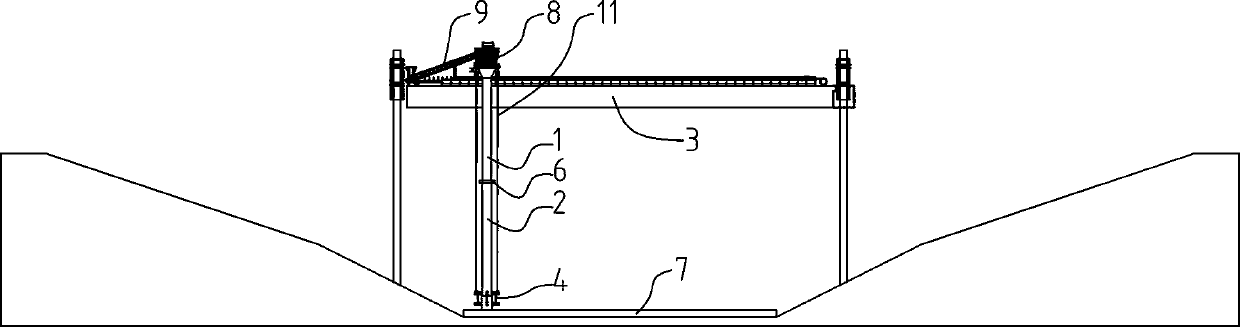

[0056] Such as Figure 1~3 Among them, a floating underwater gravel bed continuous leveling ship, including a hull 3, is provided with liftable positioning piles 5 at the bow and stern of the hull 3. The positioning piles 5 and the hull 3 are in a horizontal direction Sliding connection; positioning piles improve the stability of the hull during the construction process, can resist the horizontal force caused by the water flow and the shovel, and provide some supporting force to keep the draught of the hull at a certain level without load, that is, transport Changes brought about by the movement of the trolley 13 and the slide pipe.

[0057] There is also a transport trolley 13, which is driven by a driving device to slide along the length of the hull 3. A slide pipe is provided on the transport trolley 13, a feeding port 8 is provided at the top of the slide pipe, and the bottom end of the slide pipe is close to the water bottom;

[0058] There is also at least one conveyor belt f...

Embodiment 2

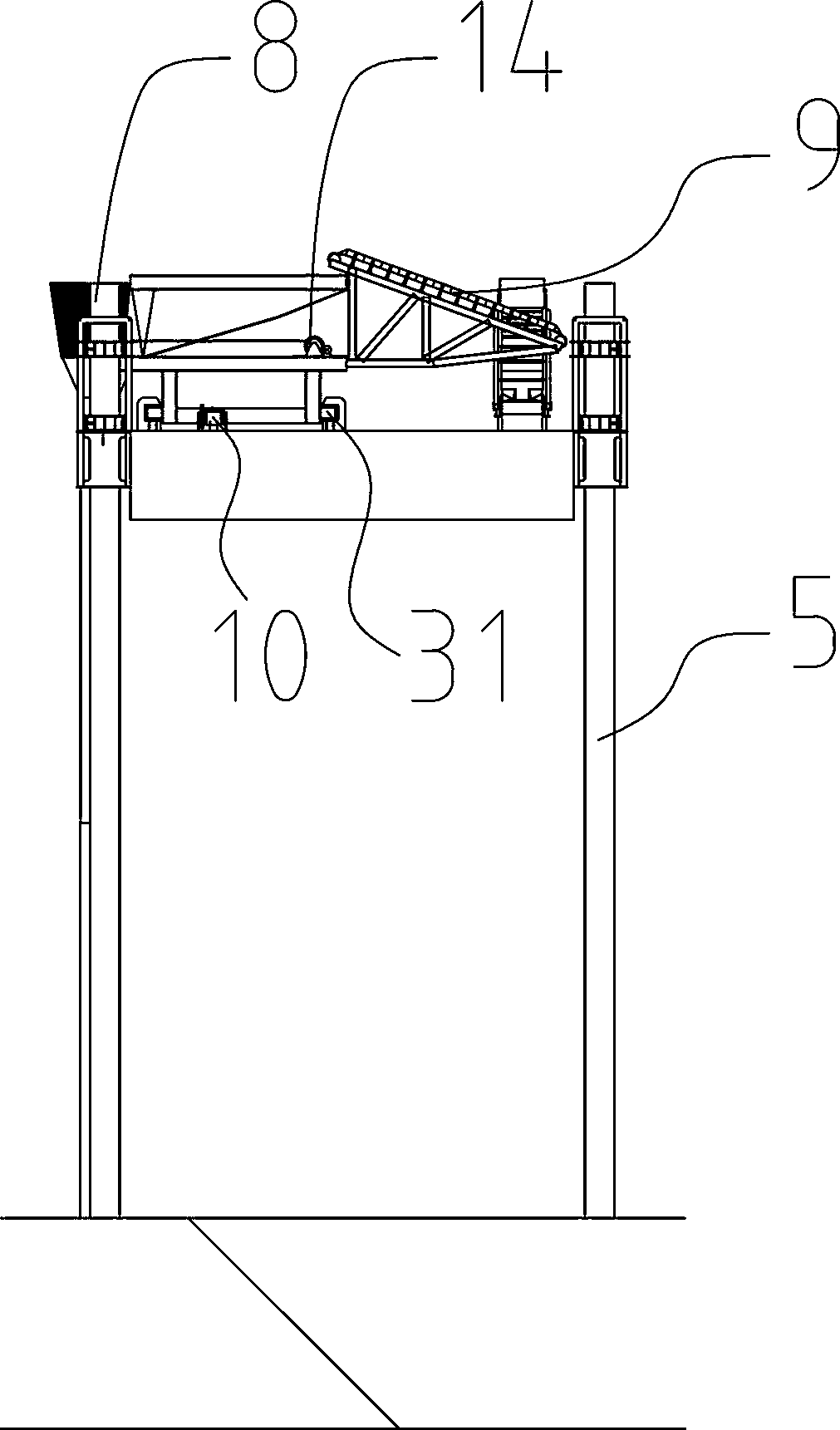

[0060] The preferred solution is Figure 4~7 In the above, the positioning pile 5 is arranged on the pontoon slide rail 15. At least two positioning pile locking devices 51 are provided near the two ends of the pontoon slide rail 15. The positioning pile 5 can be lifted and lowered on the positioning pile locking device. 51; the positioning pile locking device 51 is provided with a locking cylinder, the locking cylinder is connected with the compression block. The cross section of the positioning pile locking device 51 is a ring-shaped structure with an opening on the ring and a hinged compression block at the opening position. One end of the locking cylinder is hinged with the compression block, and the other end is connected with the ring structure. The expansion and contraction of the piston rod of the locking cylinder loosens or compresses the first slide tube 1. The construction method of lifting and driving the positioning pile 5 into the water is a technique commonly us...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com