Patents

Literature

57 results about "Full sample" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

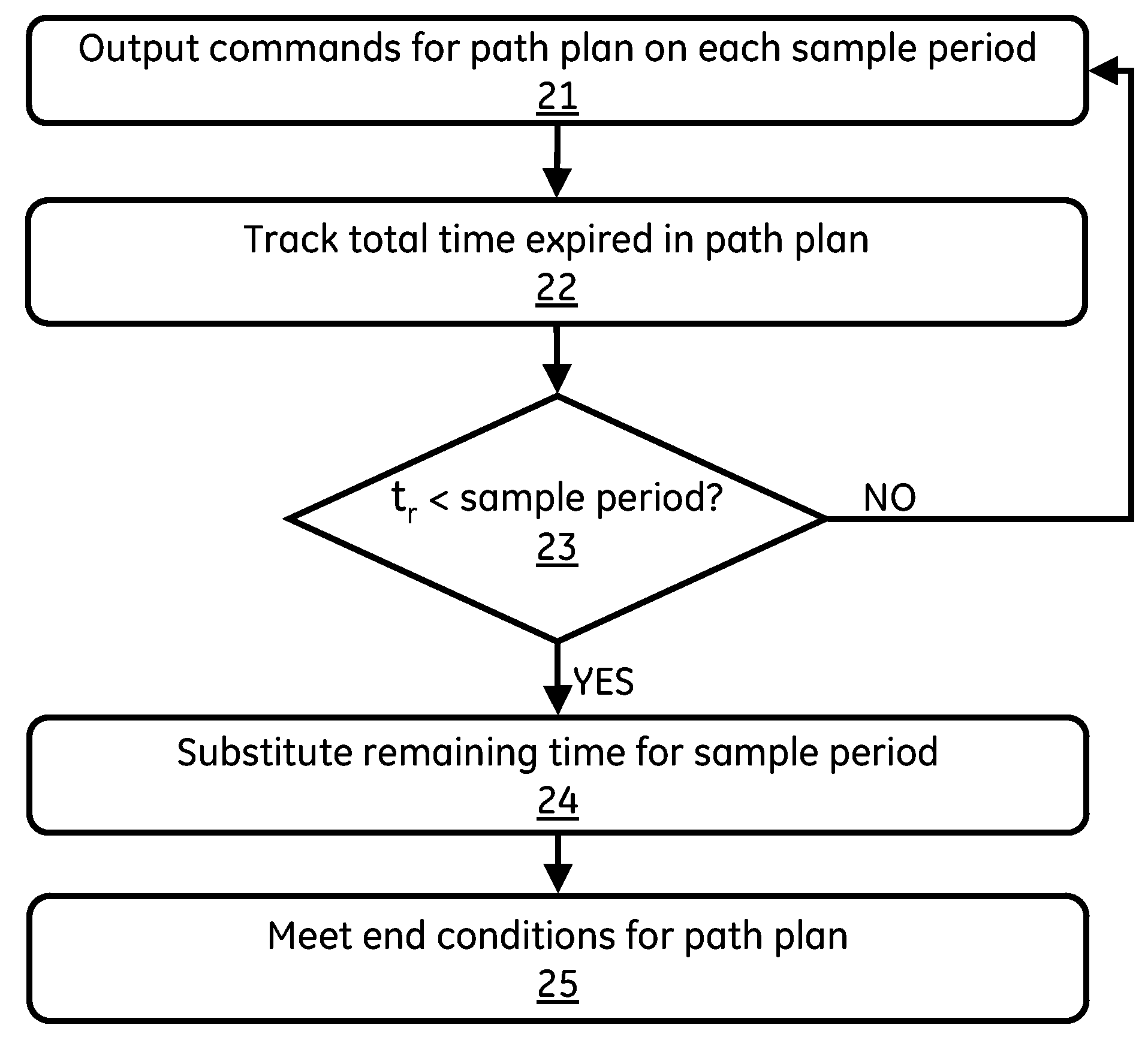

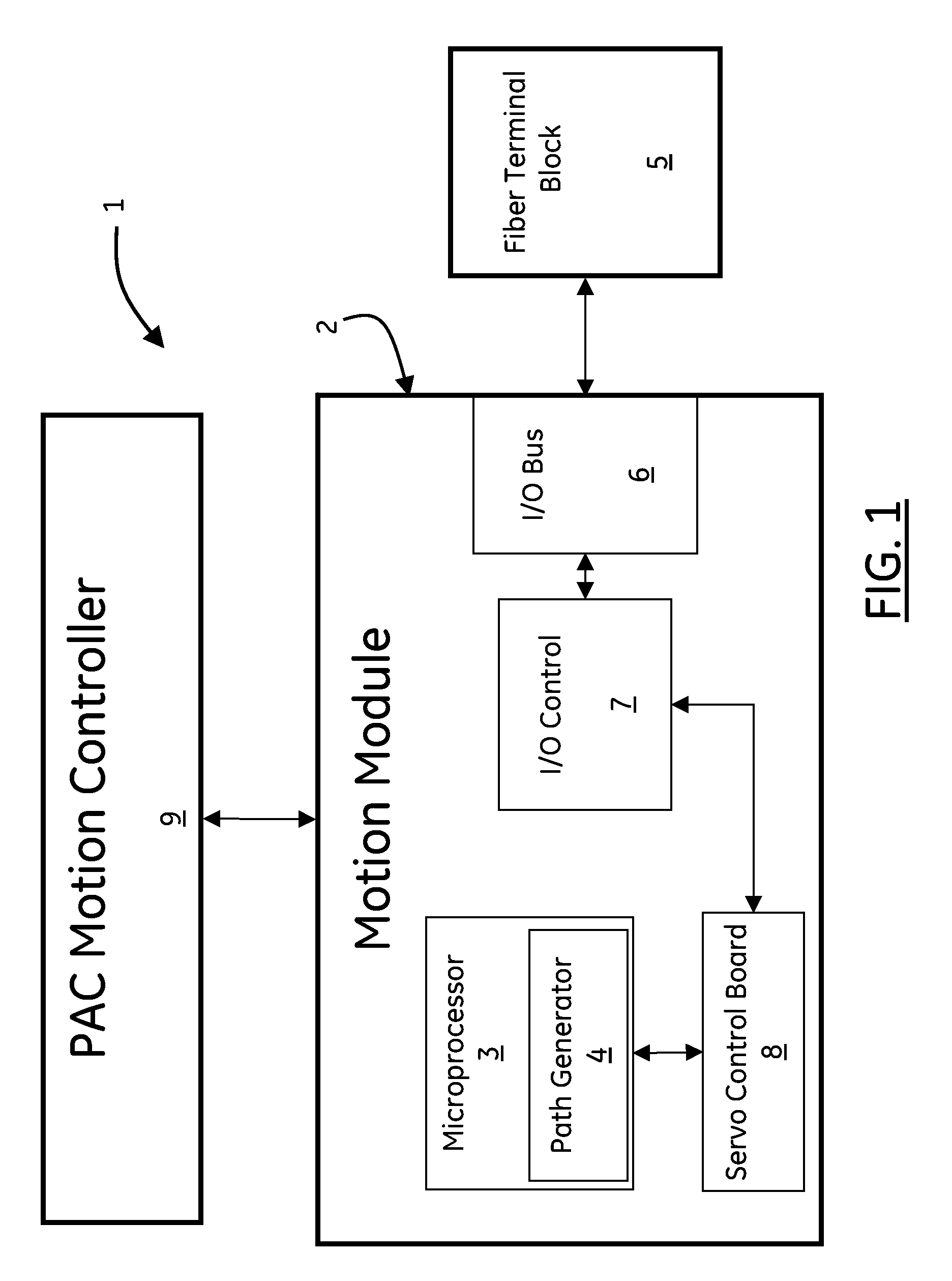

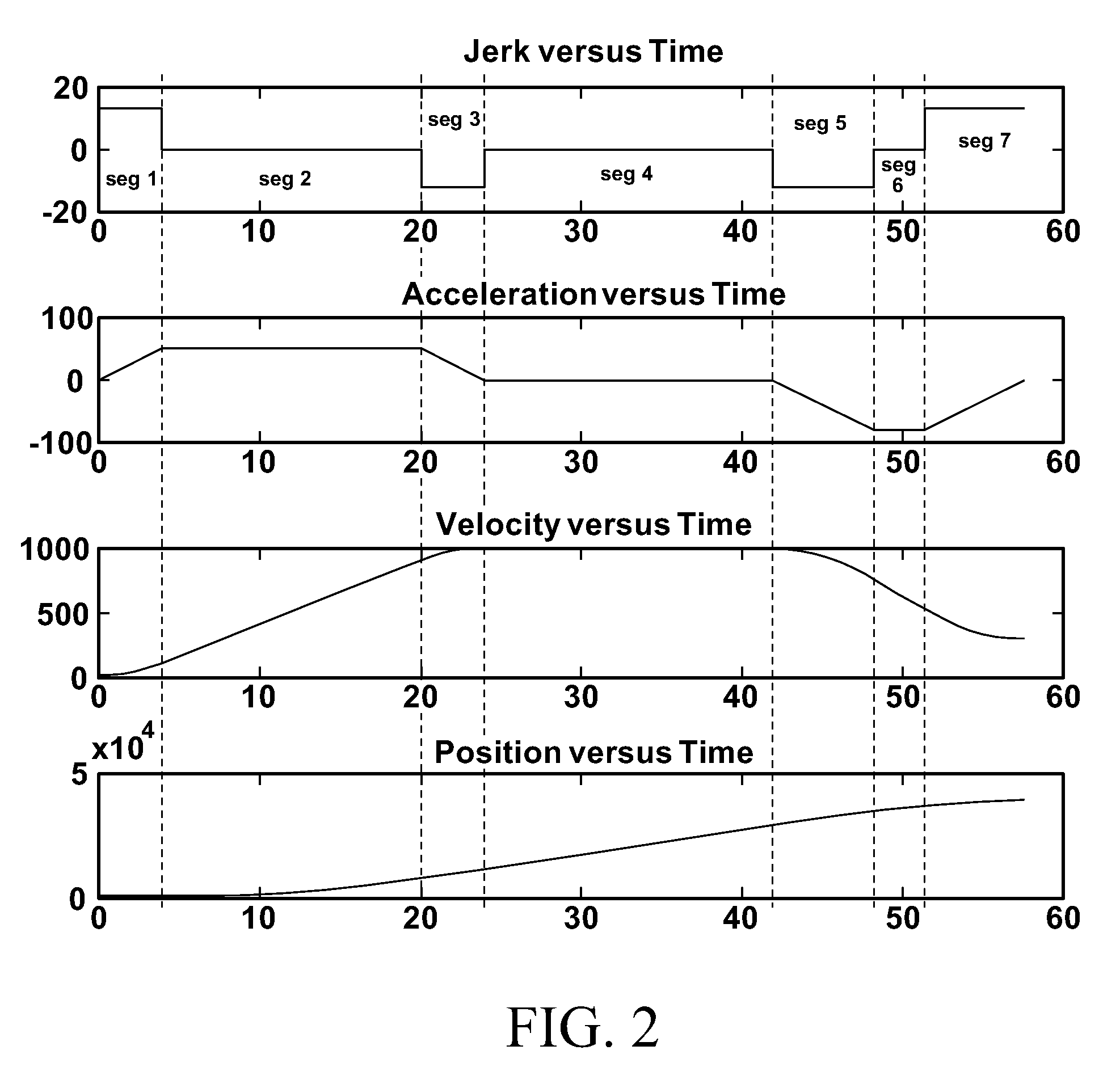

Method and system for meeting end conditions in a motion control system

ActiveUS8050800B2Sampled-variable control systemsProgramme-controlled manipulatorProgram planningControl system

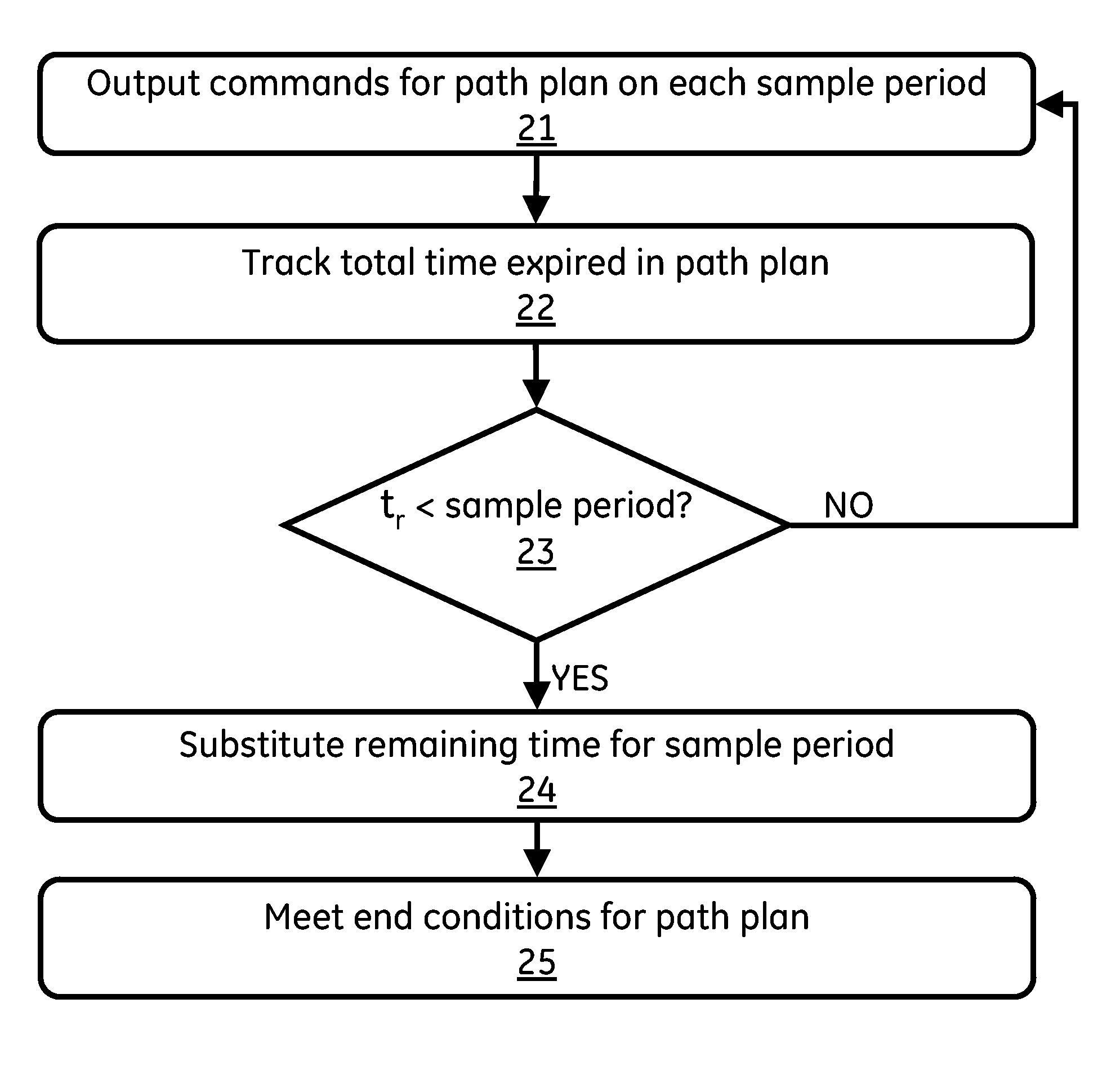

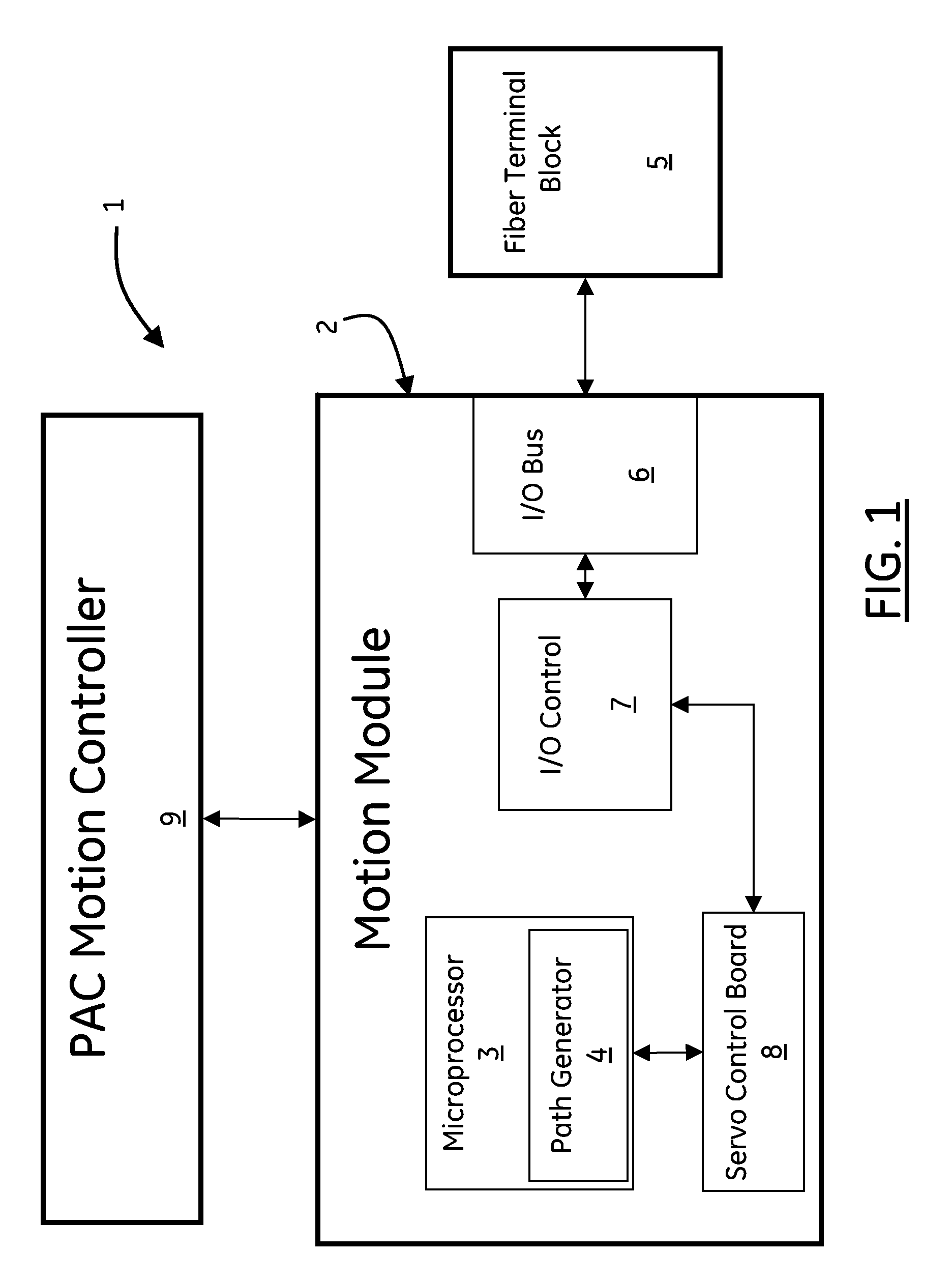

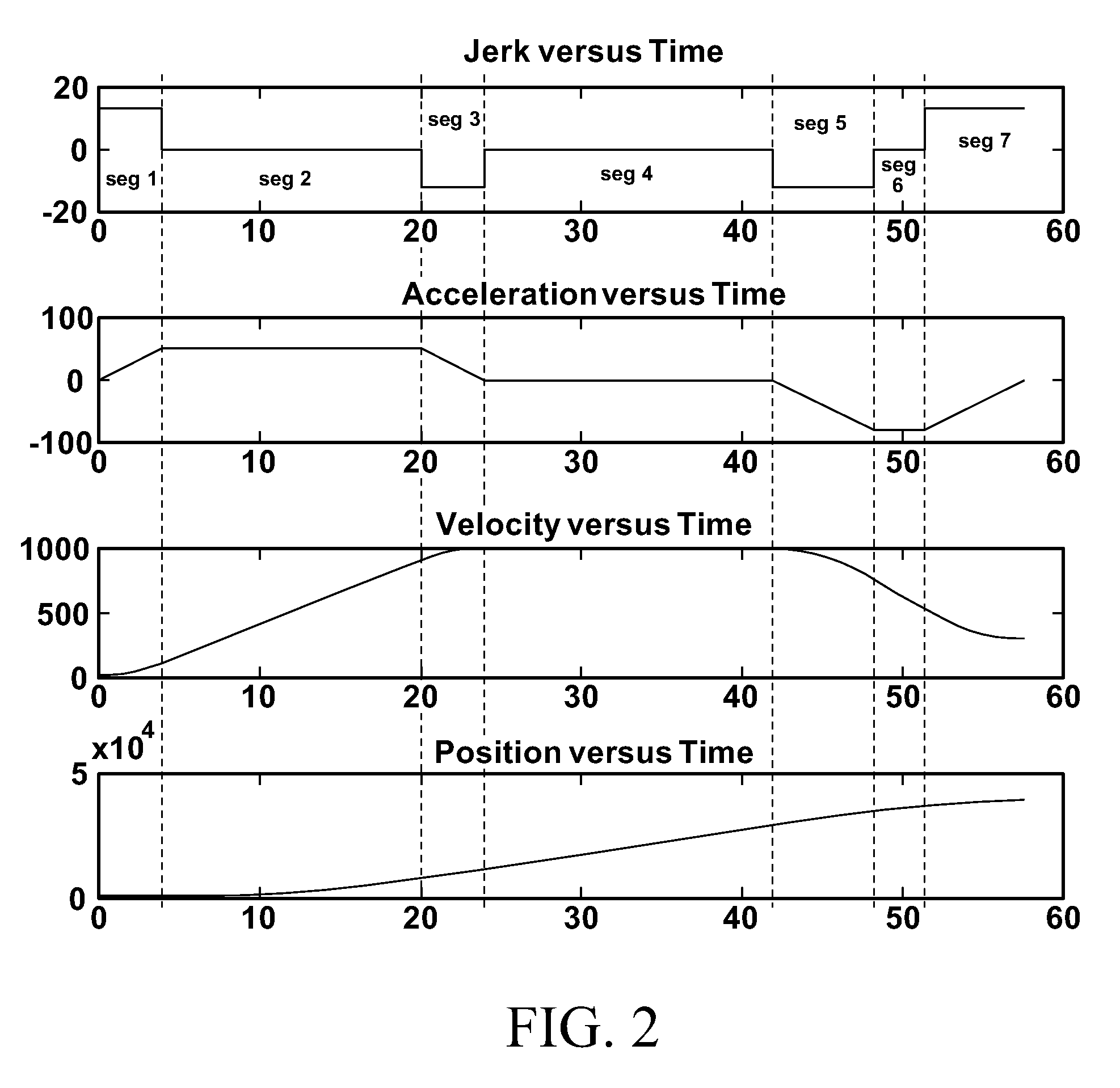

One embodiment of a system and method for meeting end conditions of a path plan utilizing a path generator that continuously generates commands for a path plan while tracking the total time expired in the path plan. The path generator computes the time remaining in the path plan and substitutes the remaining time for the length of the final sample period in the path plan when the length of the remaining time is less than the length of a full sample period.

Owner:INTELLIGENT PLATFORMS LLC

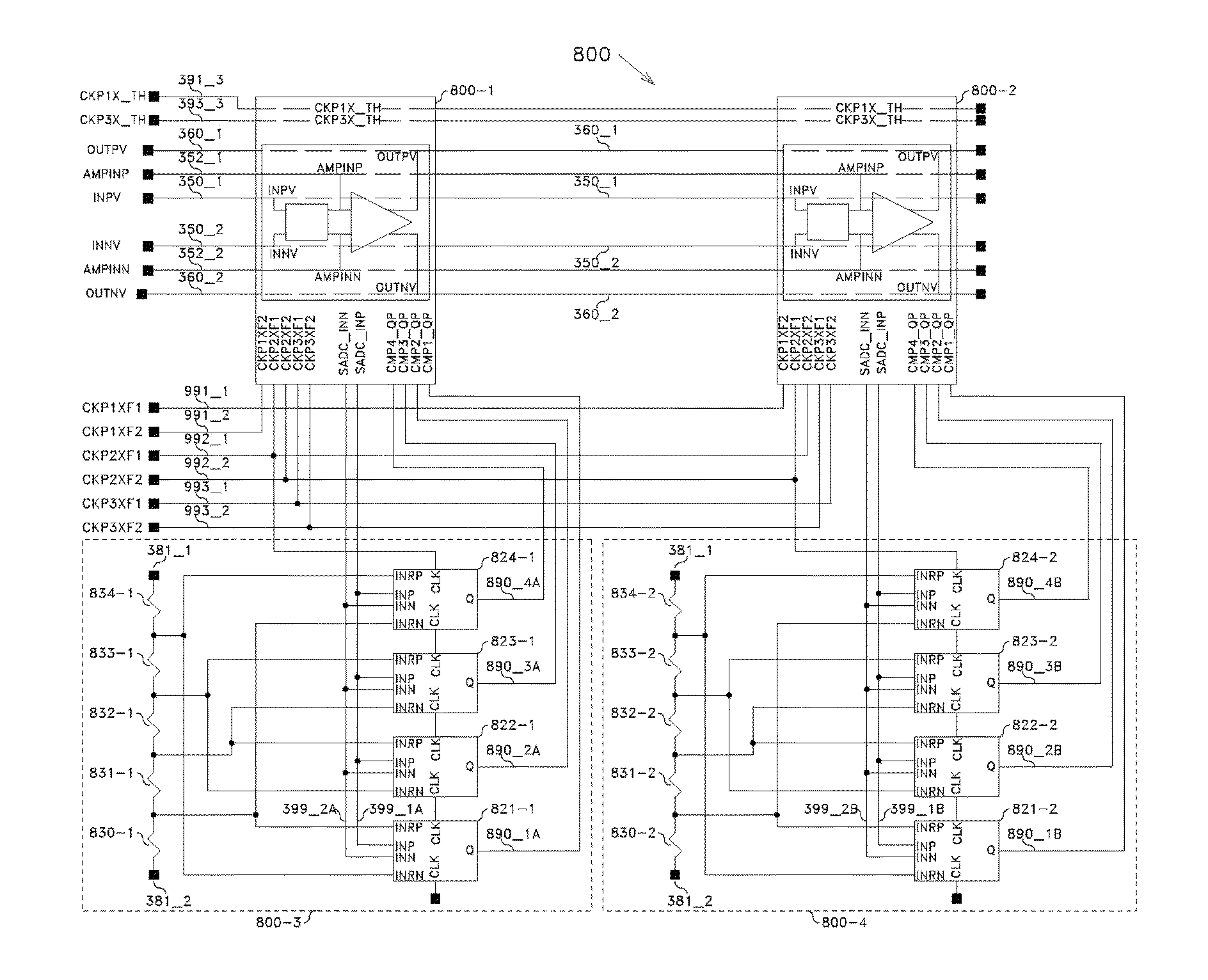

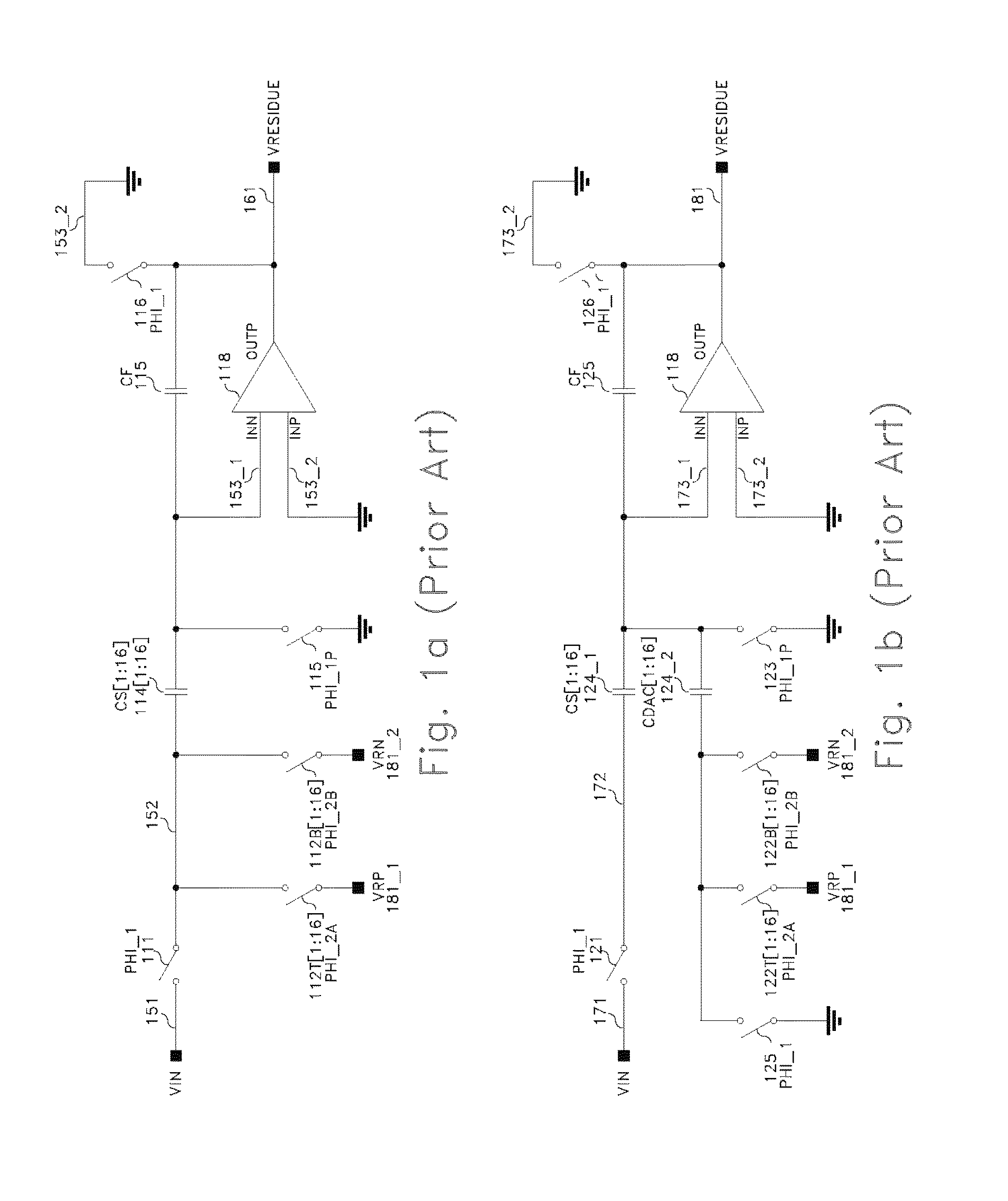

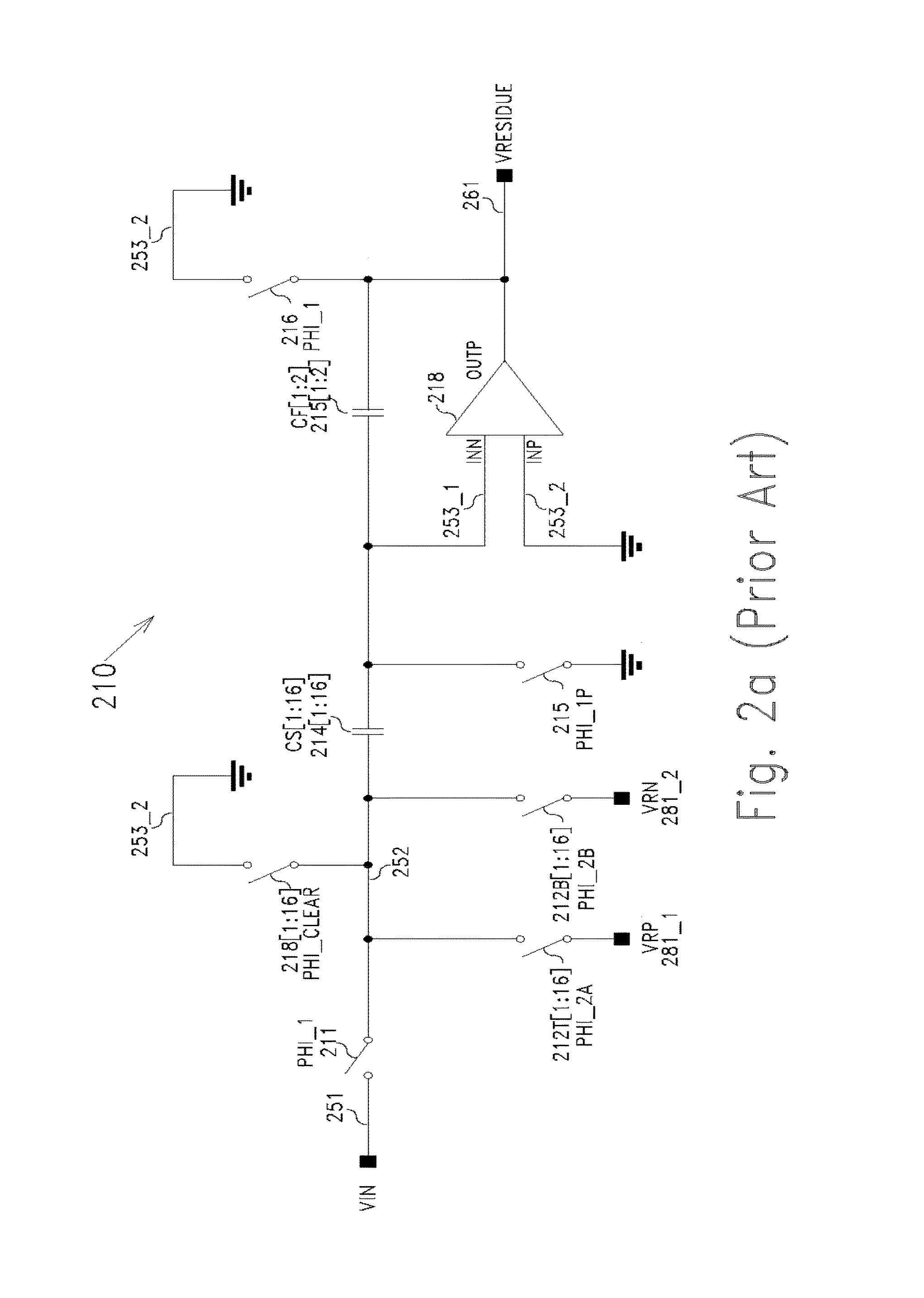

ADC first stage combining both sample-hold and ADC first stage analog-to-digital conversion functions

ActiveUS8604962B1Analogue/digital conversionElectric signal transmission systemsCapacitanceEngineering

A first stage circuit for a pipeline ADC first stage combines the functions of an input sample-and-hold-plus-amplifier (SHA) stage, and the functions of the first analog-to-digital conversion stage of an ADC, including a multiplying DAC (MDAC), stage-flash ADC (SFADC) comparators, and residue opamp (RAMP). The ADC first stage is duplicated, inputs and outputs are connected, and an autozero circuit using a switched-capacitor filter feedback loop controls the RAMP bias circuitry to reduce 1 / f noise and DC offsets. The sampling capacitors may be connected to the ADC input for one full sample clock time period and are disconnected from the analog input period before connecting the sampling capacitors to an amplifier voltage output or voltage reference, thereby sampling the input and allowing sufficient time for the SFADC comparators to resolve and control the MDAC capacitor settings with a low metastability error rate.

Owner:LEWYN CONSULTING

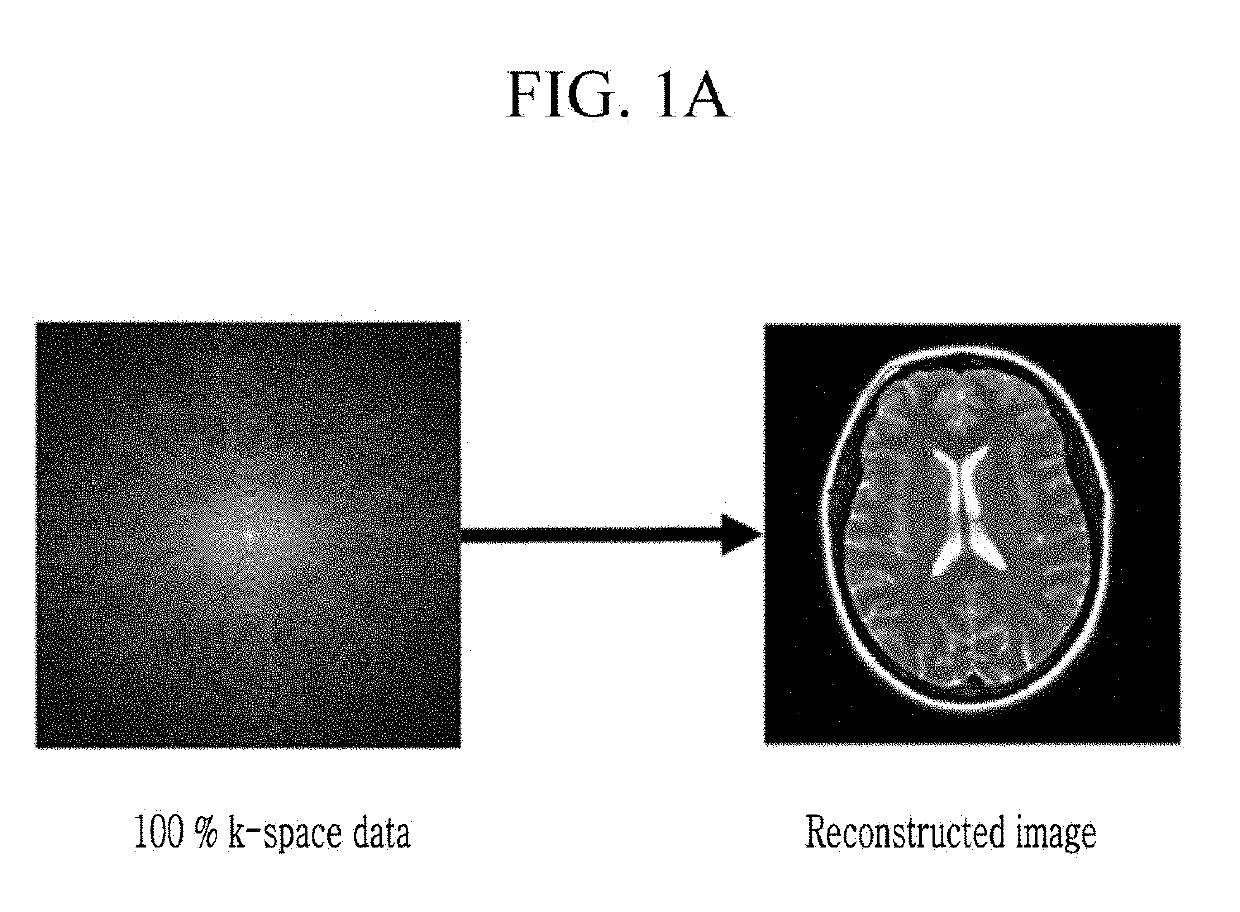

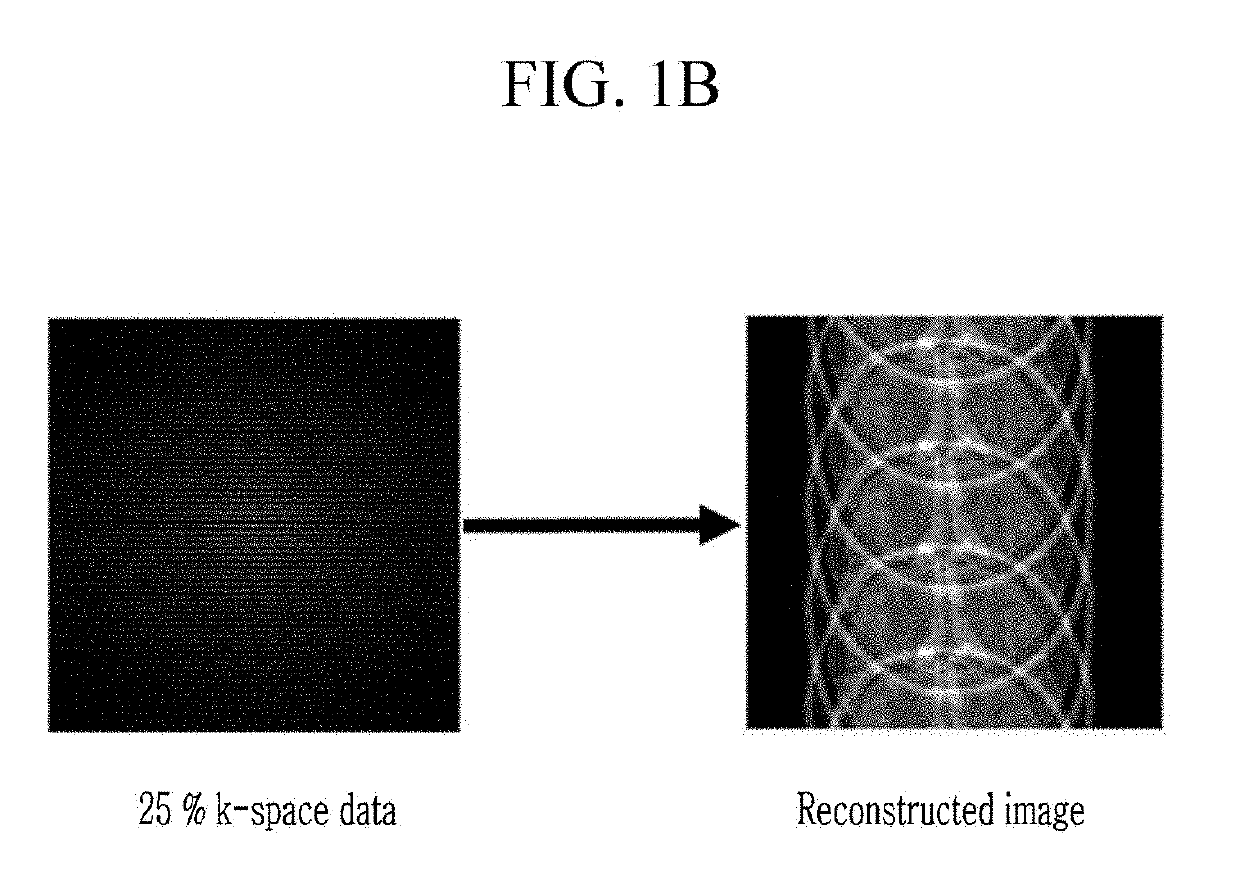

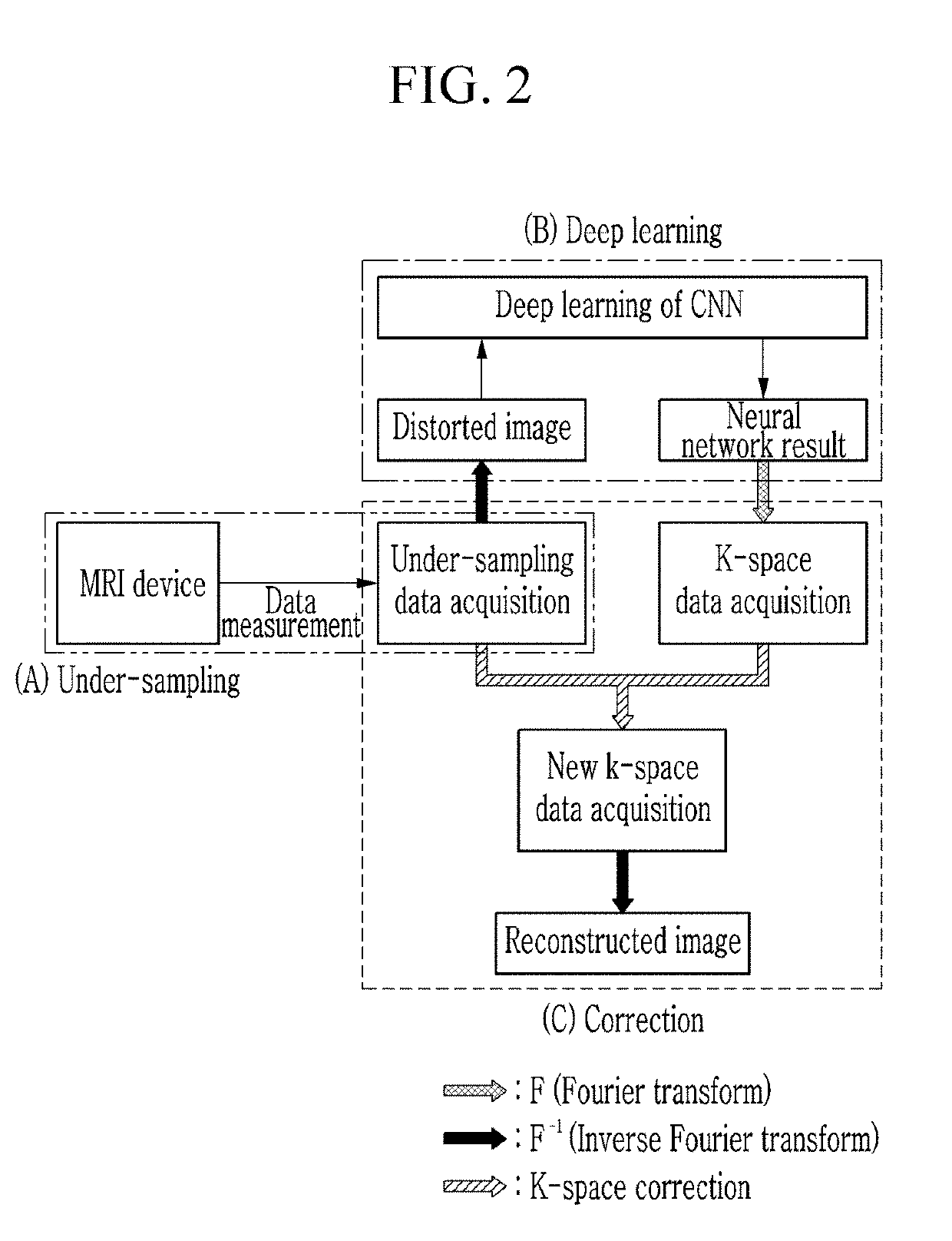

Apparatus and method for reconstructing magnetic resonance image using learning, and under-sampling apparatus method and recording medium thereof

ActiveUS20190101605A1High quality reconstructionReduced imaging timeImage enhancementImage analysisResonanceFull sample

An under-sampling apparatus for MR image reconstruction by using machine learning and a method thereof, an MR image reconstruction device by using machine learning and a method thereof, and a recoding medium thereof are disclosed. The disclosed under-smapling apparatus includes: a setting portion that sets a region corresponding to a center of the k-space image as a first region and remaining regions as a second region; and an under-sampling portion that full-samples the first region and under-samples the second region, wherein in the under-sampling performed in the second region, lines are selected at regular intervals and then only the selected line is full-sampled. According to the under-sampling apparatus, a high-resolution MR image can be acquired while reducing imaing time.

Owner:IND ACADEMIC CORP FOUND YONSEI UNIV

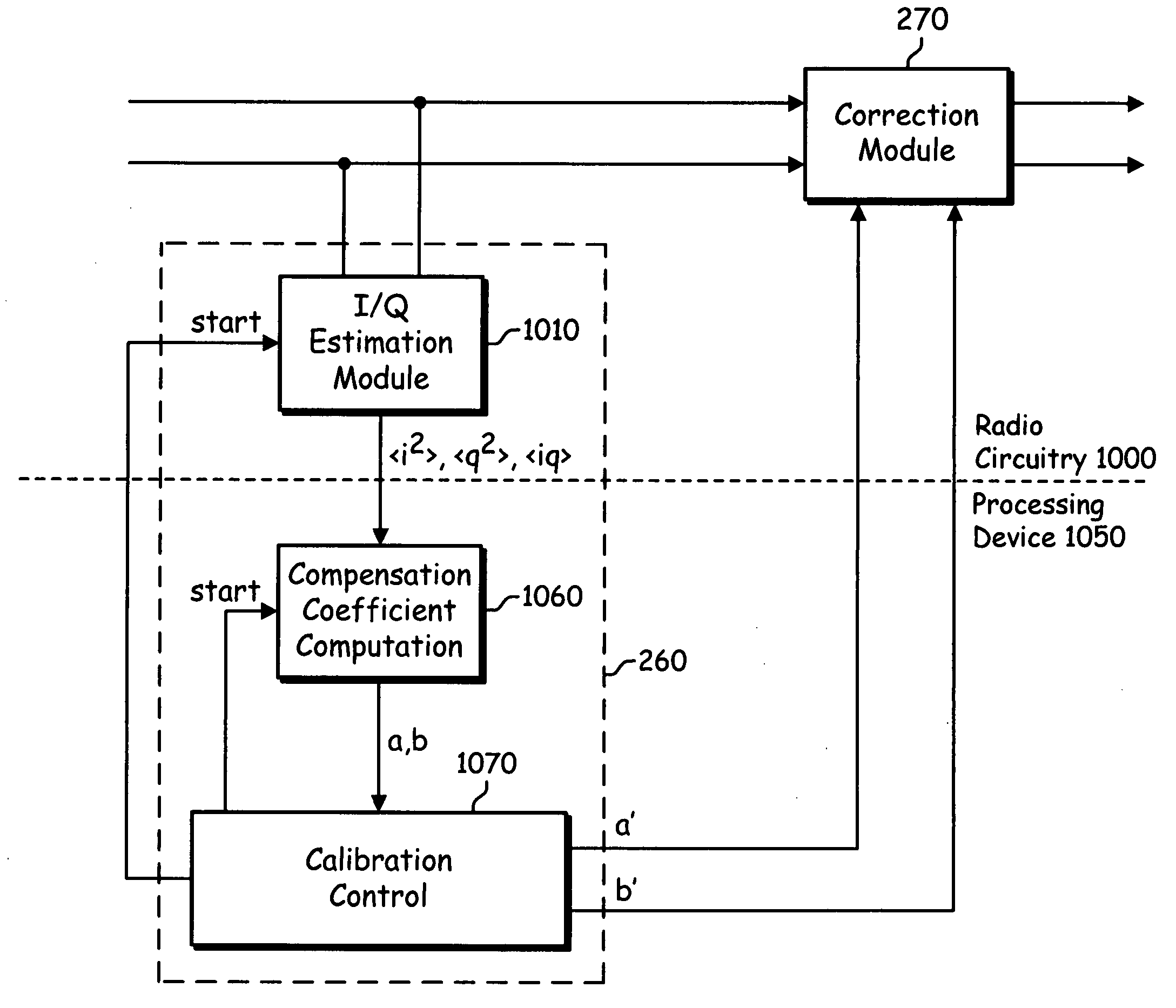

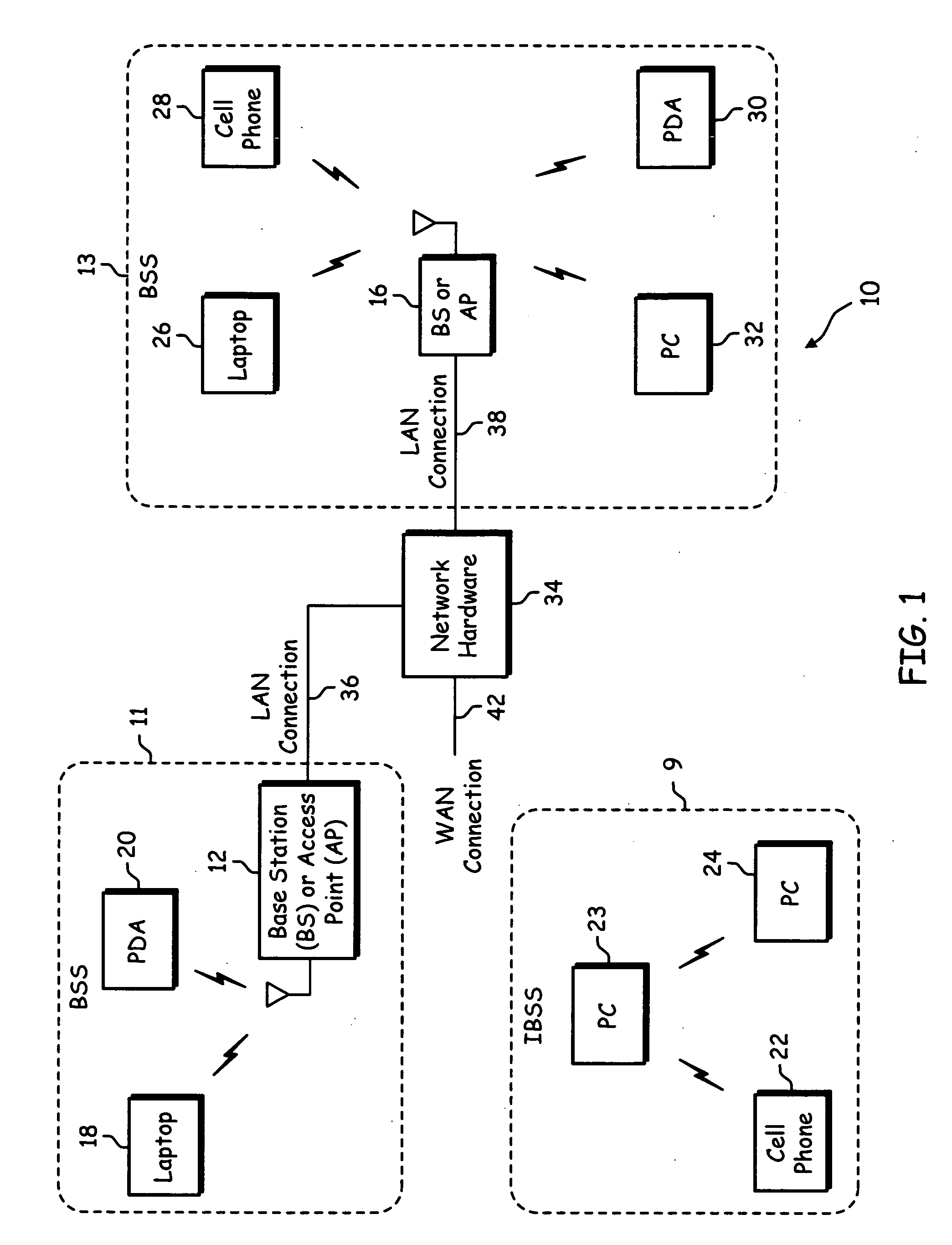

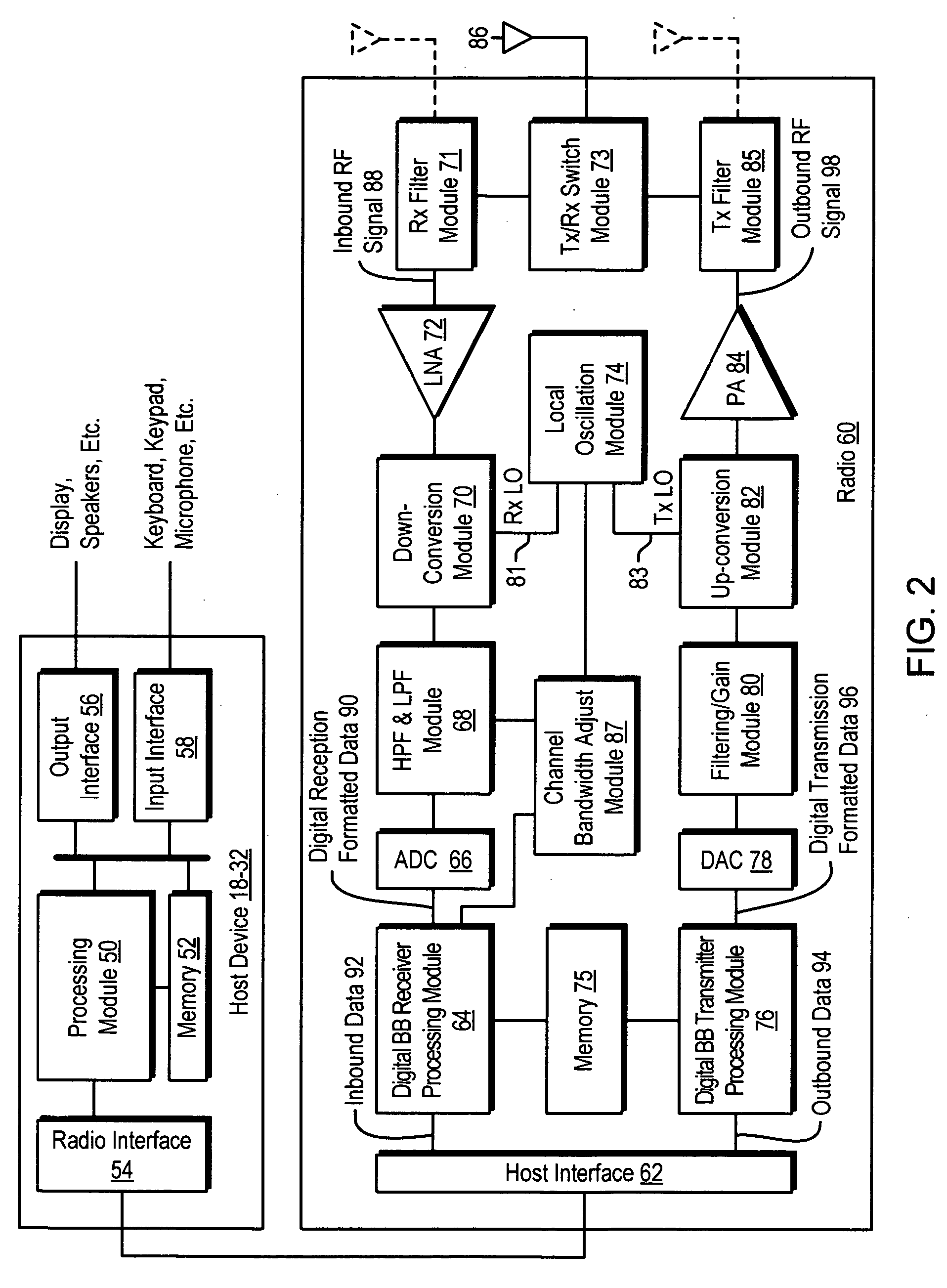

Receiver IQ imbalance calibration

InactiveUS20070025474A1Resonant circuit tuningPhase-modulated carrier systemsRadio receiverRadio reception

A calibration device for use in a radio receiver enables receiver self-calibration and self-correction of inbound RF signals. The calibration device includes an estimation module for receiving a sample digital packet and calculating imbalance parameters as a function of a portion of the sample digital packet. The calibration device further includes a correction module for applying the imbalance parameters to a received digital packet of an inbound RF signal to produce a corrected digital packet. The received digital packet may be a portion of the sample digital packet, the complete sample digital packet or a new packet.

Owner:AVAGO TECH WIRELESS IP SINGAPORE PTE

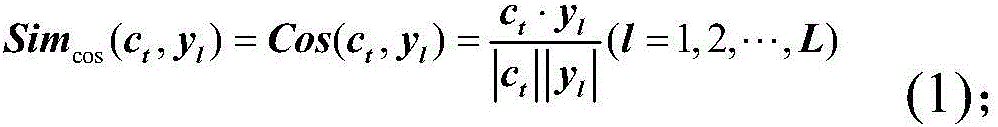

Power distribution network space load prediction method taking region and load property dual differences into consideration

The invention relates to a power distribution network space load prediction method taking region and load property dual differences into consideration. A conventional space load prediction method does not take influences exerted by regional differences, sample types and quality on load density into consideration, and the applicability is not sufficient. First of all, a full-sample space taking the regional differences into consideration is established, and then, a typical sample is screened by verifying and carefully choosing a load through a typical daily load curve. A region where the load is disposed is clustered through weighted Euclidean distance tolerance, afterwards, a subsample space matching is carried out, a type which the sample belongs to is determined, load density of a plot to be measured is predicted by use of an SVM algorithm, and a total future load amount of the plot is calculated through the load density. The load prediction precision is quite high, and the application is facilitated.

Owner:STATE GRID ZHEJIANG ELECTRIC POWER COMPANY ECONOMIC TECHN INST +1

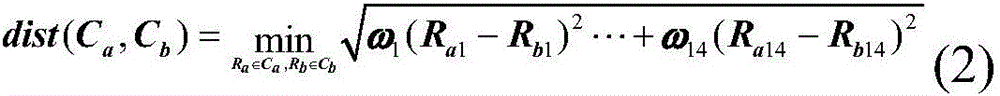

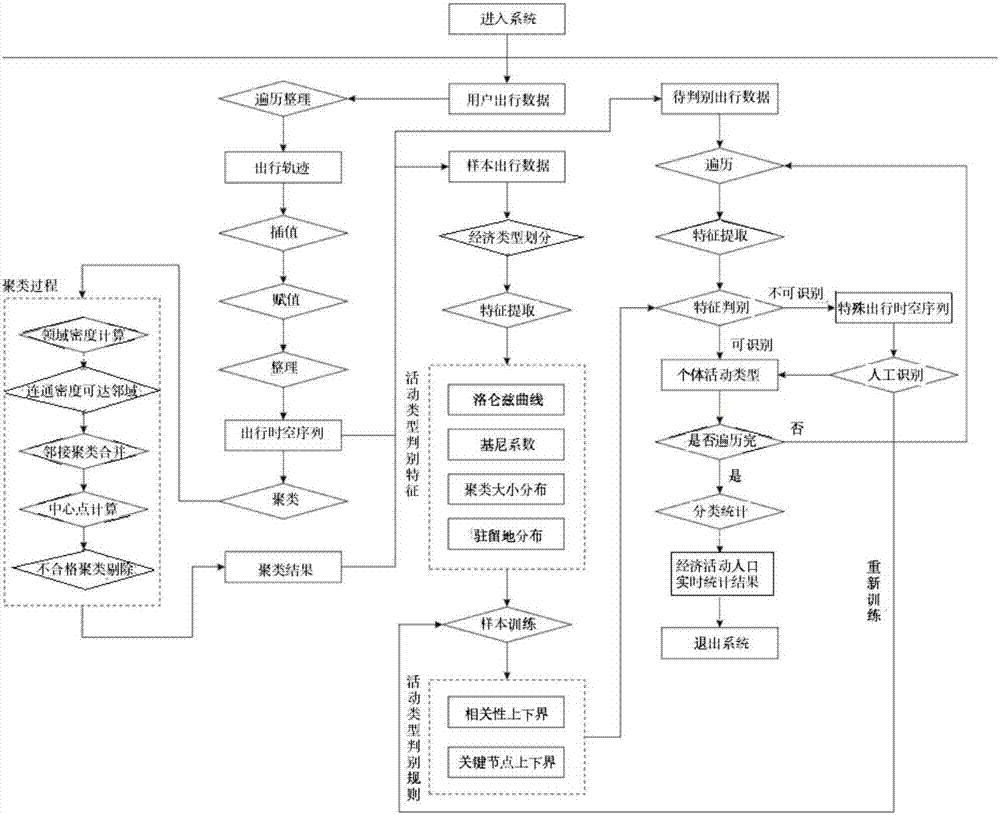

Method for identifying an economically active population based on big data

ActiveCN107977673AGet goodLow costCharacter and pattern recognitionLocation information based serviceTime rangeNODAL

The invention provides a method for identifying an economically active population based on big data. The method comprises by using an active data set (namely a communication record between the individual mobile terminal and a fixed position sensor) of an individual mobile terminal within a specified time range and space range, constituting an individual travel trajectory, interpolating the traveltrajectory to expand nodes, and establishing an individual travel trajectory; dividing an individual travel space into a plurality of regions by a spatial clustering method and extracting long-term resident places of the regions; selecting and training the travel trajectory of the sample individual, obtaining the spatial distribution characteristics and related parameters of the travel activitiesof various economically active populations; analyzing the full-sample data to identify economically active population in the sample; finally sampling a fixed proportion for expansion to obtain the real-time economically active population.

Owner:上海世脉信息科技有限公司 +1

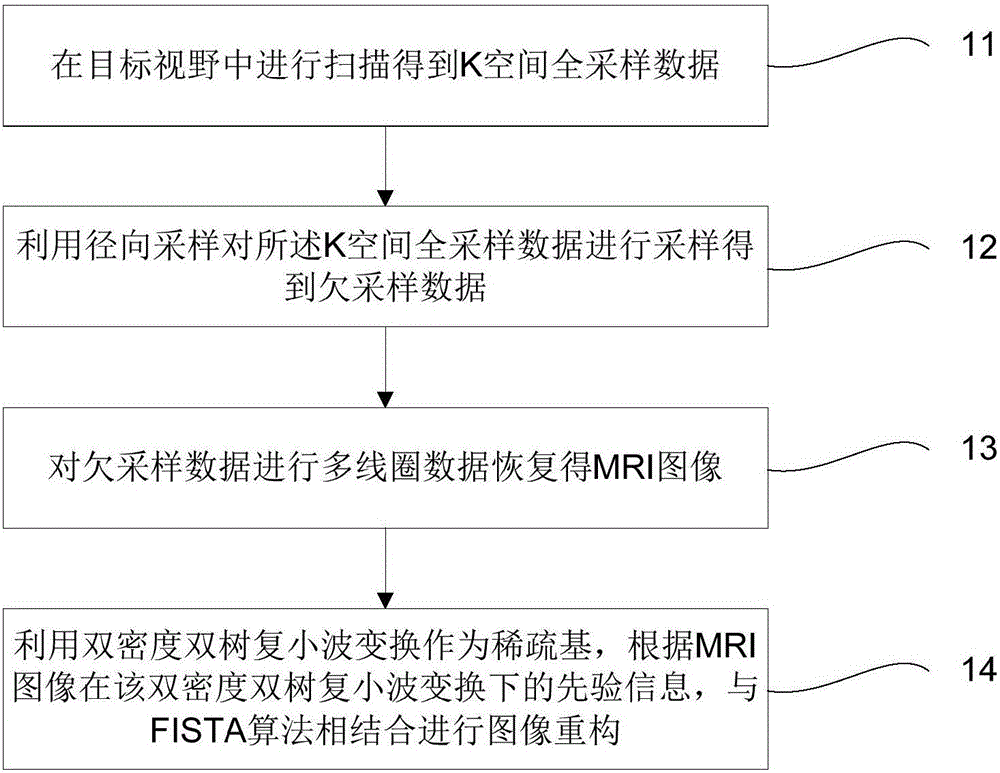

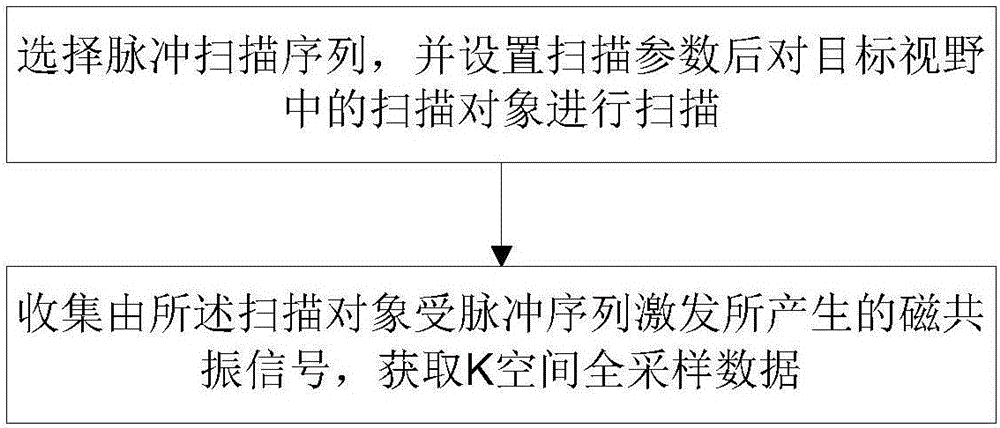

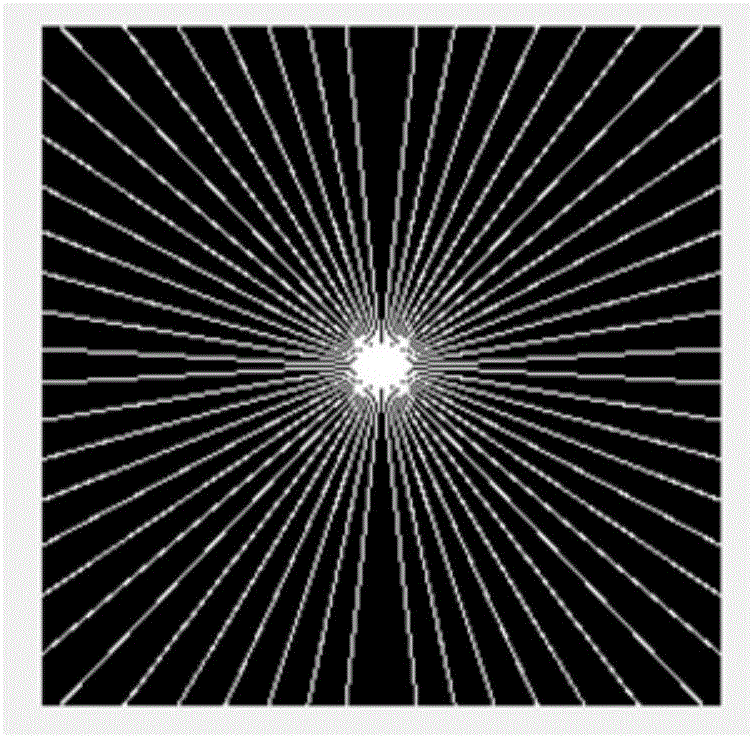

Fast and precise MRI (Magnetic Resonance Imaging) reconstruction method

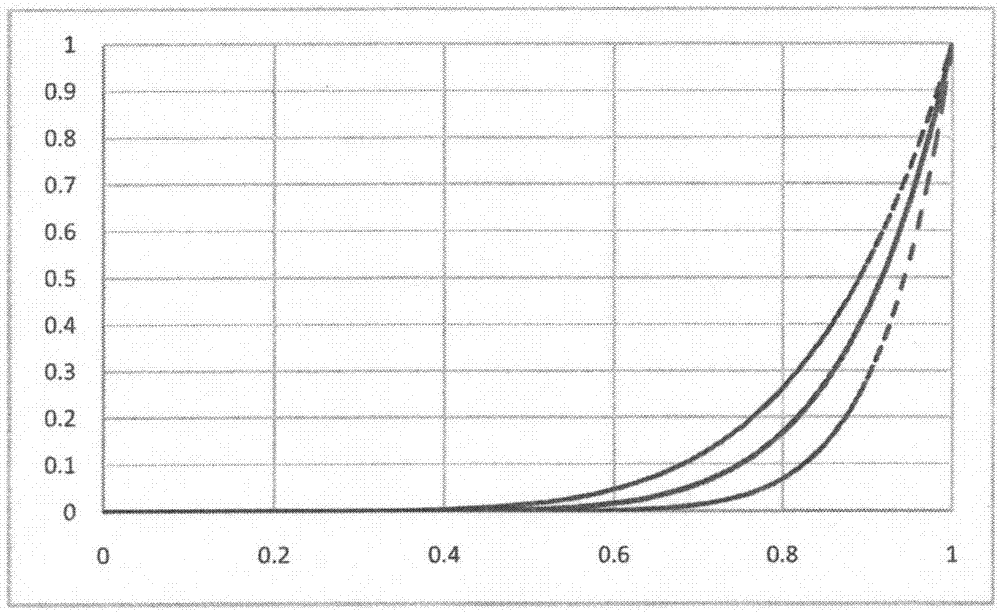

ActiveCN106485764AGood direction propertyReduce sensitivityReconstruction from projectionImage generationPattern recognitionVisual field loss

The invention discloses a fast and precise MRI (Magnetic Resonance Imaging) reconstruction method. The method comprises steps: scanning is carried out in a target visual field to obtain K space full sampling data; the K space full sampling data are sampled by using radial sampling to obtain under sampling data; the under sampling data are subjected to multi-loop data recovery to obtain an MRI image; and double-density dual-tree complex wavelet transform is used as a sparse basis, and according to the priori information of the MRI image under the double-density dual-tree complex wavelet transform, an FISTA algorithm is combined for image reconstruction. The reconstruction method can better depict image details and information, and the quality of the recovered image is improved.

Owner:UNIV OF SCI & TECH OF CHINA

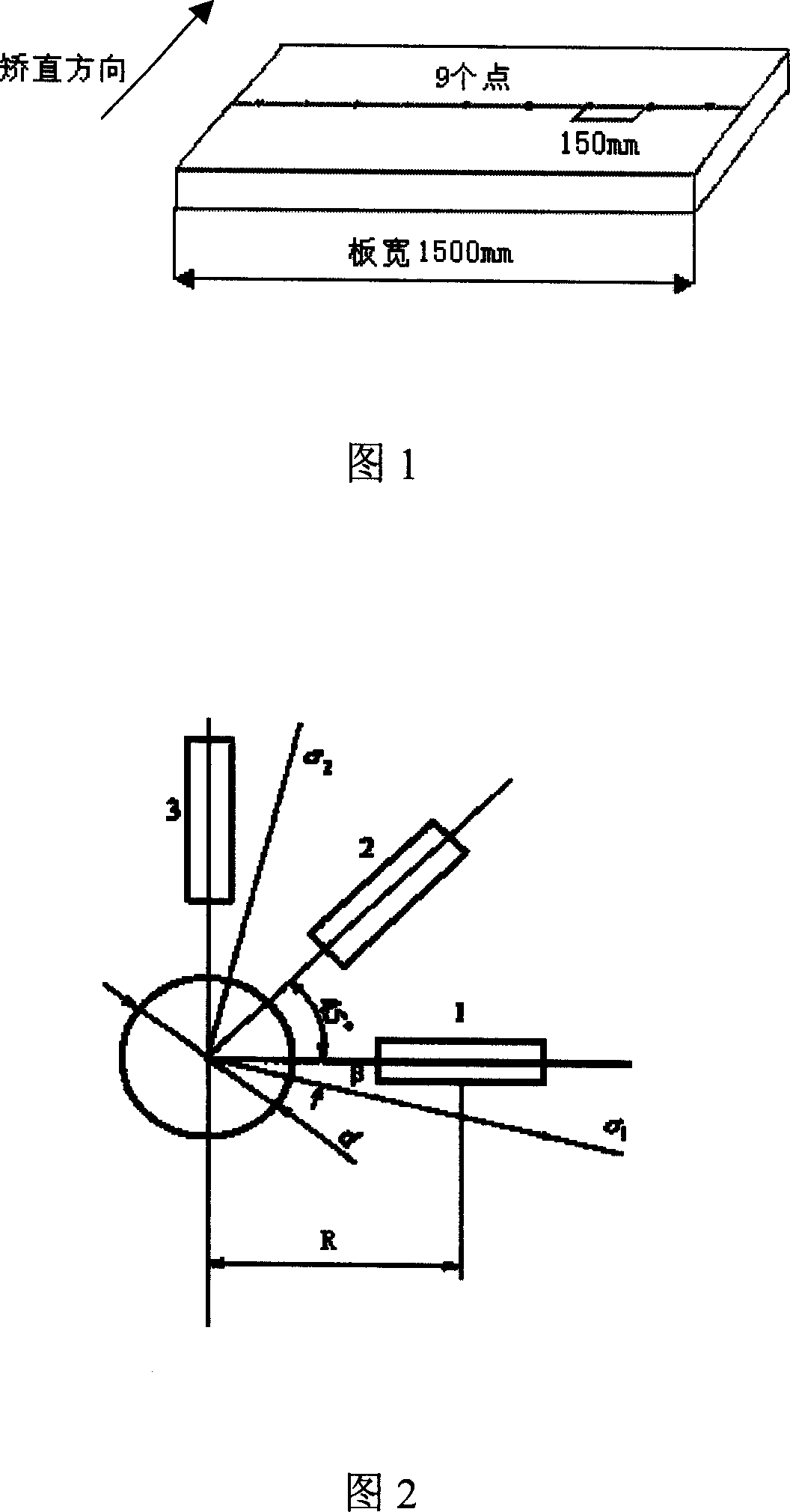

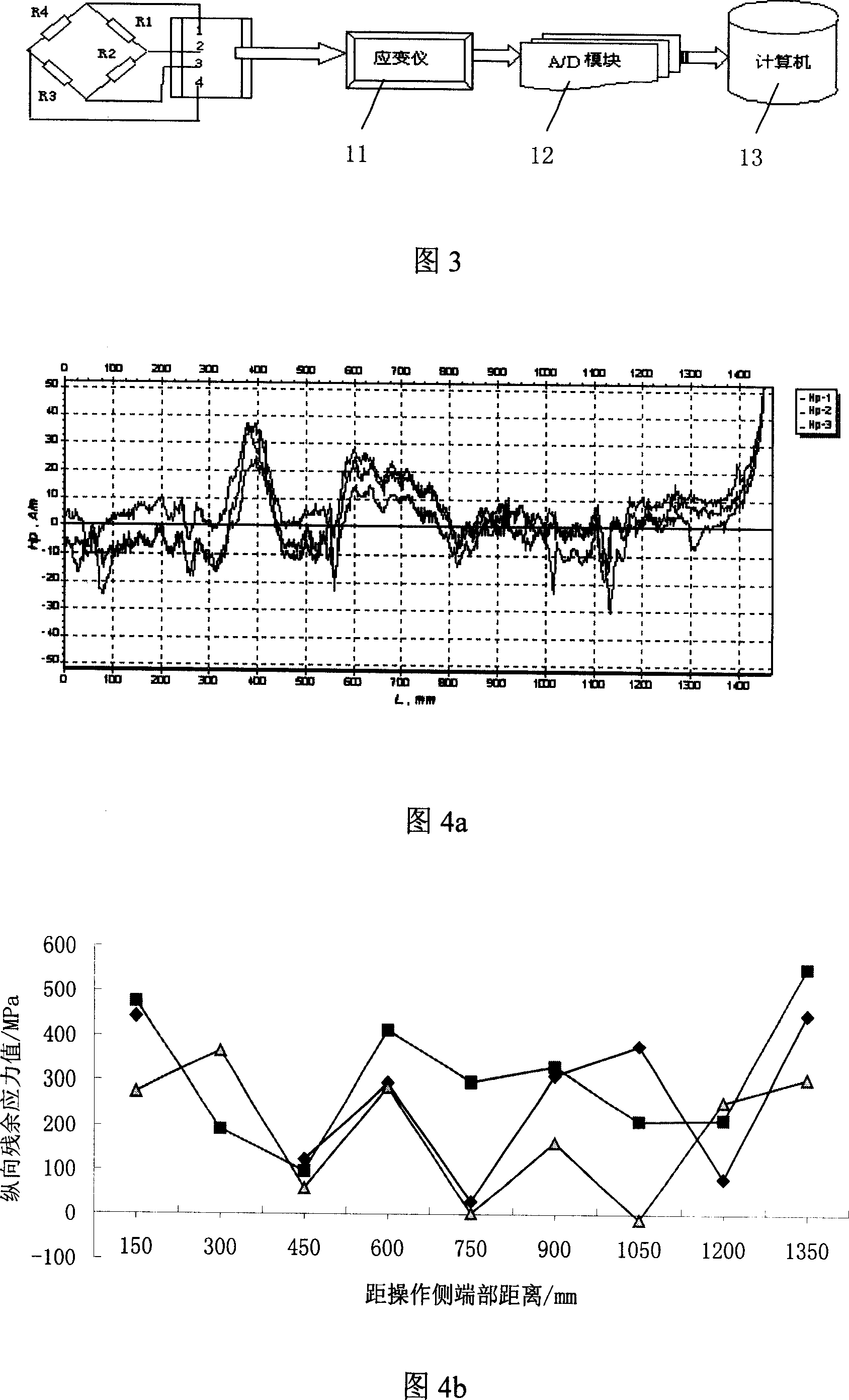

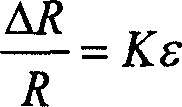

Method for detecting residual strain of thermal-continuous-rolled high-strength steel plate

InactiveCN1979161AHigh sensitivityEasy to measure from a distanceForce measurement using piezo-resistive materialsTesting metalsResidual strainElectrical resistance and conductance

The invention relates to a measuring method for testing hot continuous rolling dead-hard steel board residual stress. It uses electric resistance strain gauge to take measuring to residual stress of the sample and calculating the value, analyzing the distribution of the full sample residual stress. The method has stable reliability, accurate result, and could rapidly measure hot continuous rolling dead-hard steel board residual stress. It supplies theory foundation and technology support for hot continuous rolling dead-hard steel board, and improves the quality of the product.

Owner:BAOSHAN IRON & STEEL CO LTD +1

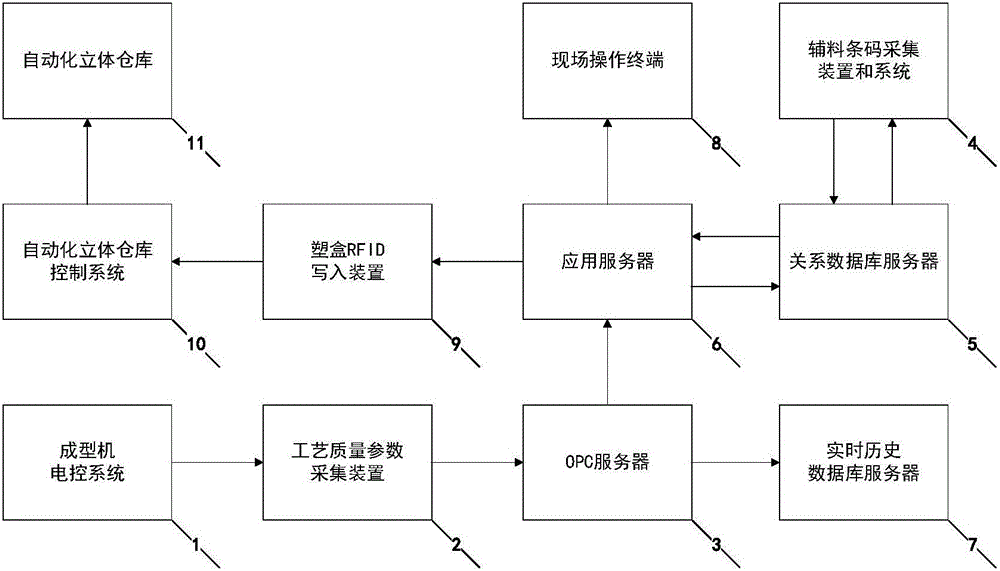

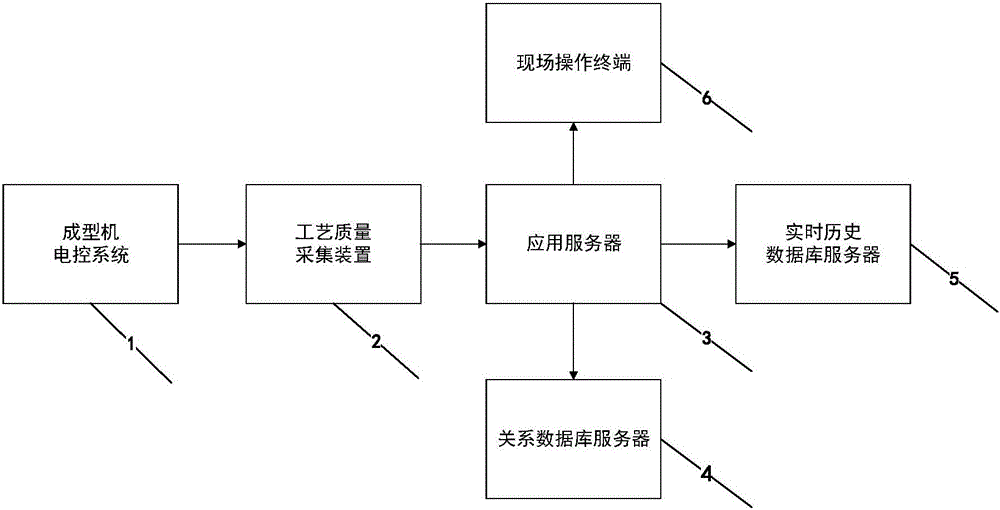

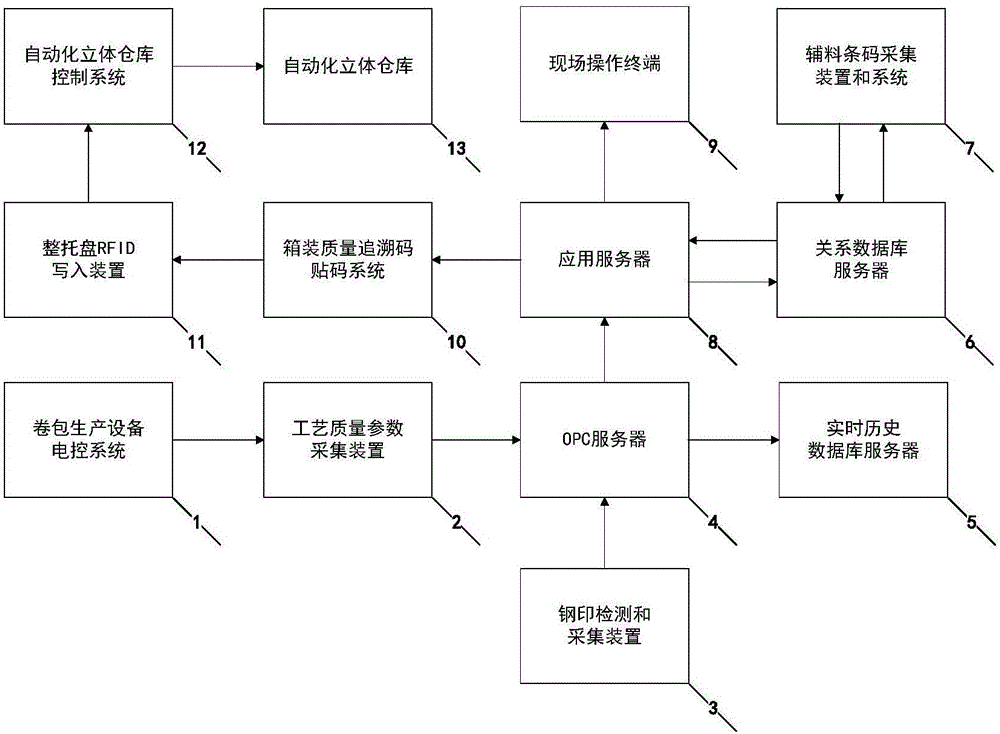

Filter stick forming process quality analyzing and tracing system

ActiveCN105760555AAvoid quality anomaliesReduce complexityRelational databasesCo-operative working arrangementsProcess qualityOLE for Process Control

The invention relates to a filter stick forming process quality analyzing and tracing system. The system consists of a forming machine electric control system, a process quality parameter acquisition device, an OPC (OLE for Process Control) server, an auxiliary material bar code acquisition device and system, a relationship database server, an application server, a real-time history database server, a field operation terminal, a plastic box RFID (Radio Frequency Identification Devices) writing device, an automation three-dimensional warehouse control system, an automation three-dimensional warehouse and PROFINET industrial Ethernet. According to the filter stick forming process quality analyzing and tracing system, process quality parameters in an equipment production process are acquired in real time through the process quality parameter acquisition device, and real-time monitoring and feedback of the change situations, adjustment situations and abnormal situations of the process quality parameters in a filter bar production process are realized according to a process quality standard of filter bars through an analysis model based on big data and a full-sample statistics technology. Recurrence of quality anomalies is avoided; a delivery command is sent to the automation three-dimensional warehouse control system specific to quality anomalies found through analysis, so that the manual tracing complexity is lowered greatly.

Owner:CHINA TOBACCO ZHEJIANG IND

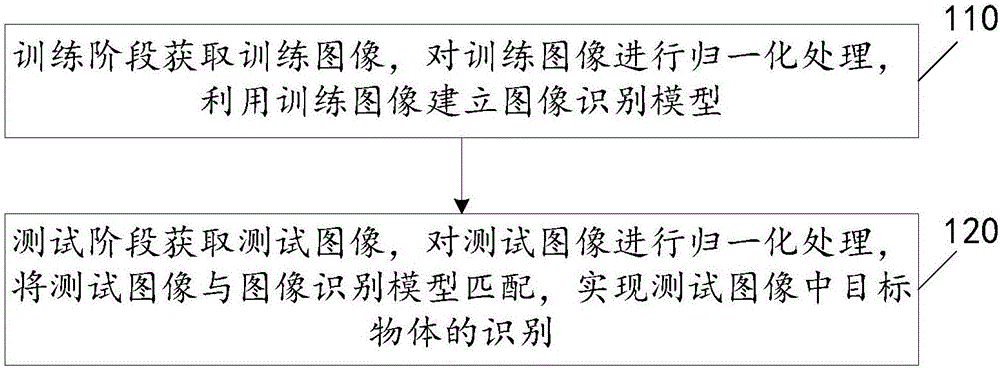

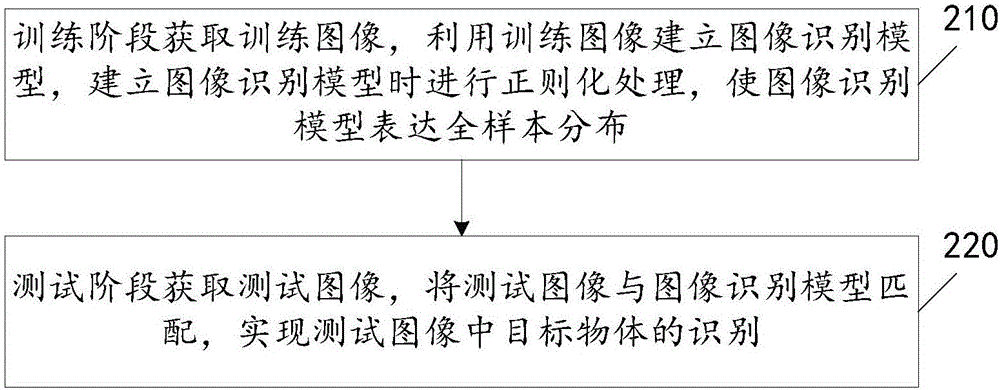

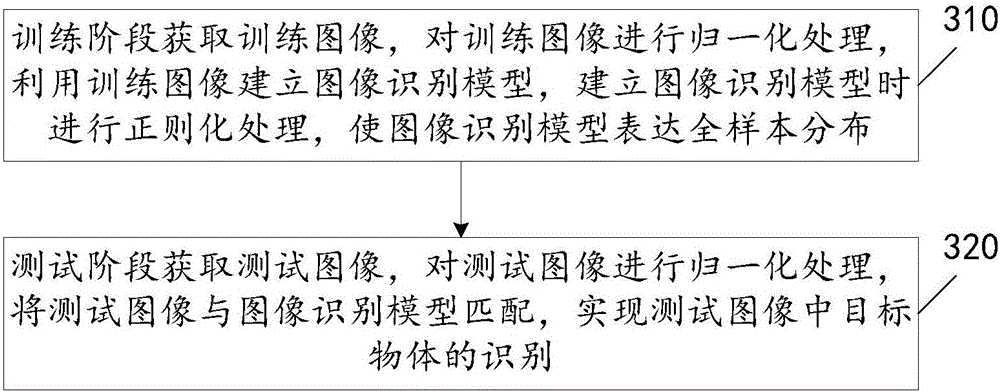

Method and system of identifying target object in image, and method and system of identifying food in refrigerator

InactiveCN106529427AAchieve consistencyThe test effect is goodCharacter and pattern recognitionRefrigerated temperatureFull sample

The invention relates to a method and system of identifying a target object in an image, and a method and system of identifying food in a refrigerator. The method of identifying a target object in an image includes the steps: acquiring a training image, utilizing the training image to establish an image identification model; and acquiring a test image, matching the test image with the image identification model, and realizing identification of a target object in the test image, wherein performing normalization processing on the acquired training image and the acquired test image, and mapping the training image and the test image to a unified space; and / or performing regularization processing during the process of establishing the image identification model to enable the image identification model to express full sample distribution. The method of identifying a target object in an image enables expression on the test data of the image identification model to approach to the expression on the training data as possible, thus realizing consistency of image identification and improving image identification accuracy.

Owner:HEFEI MIDEA INTELLIGENT TECH CO LTD

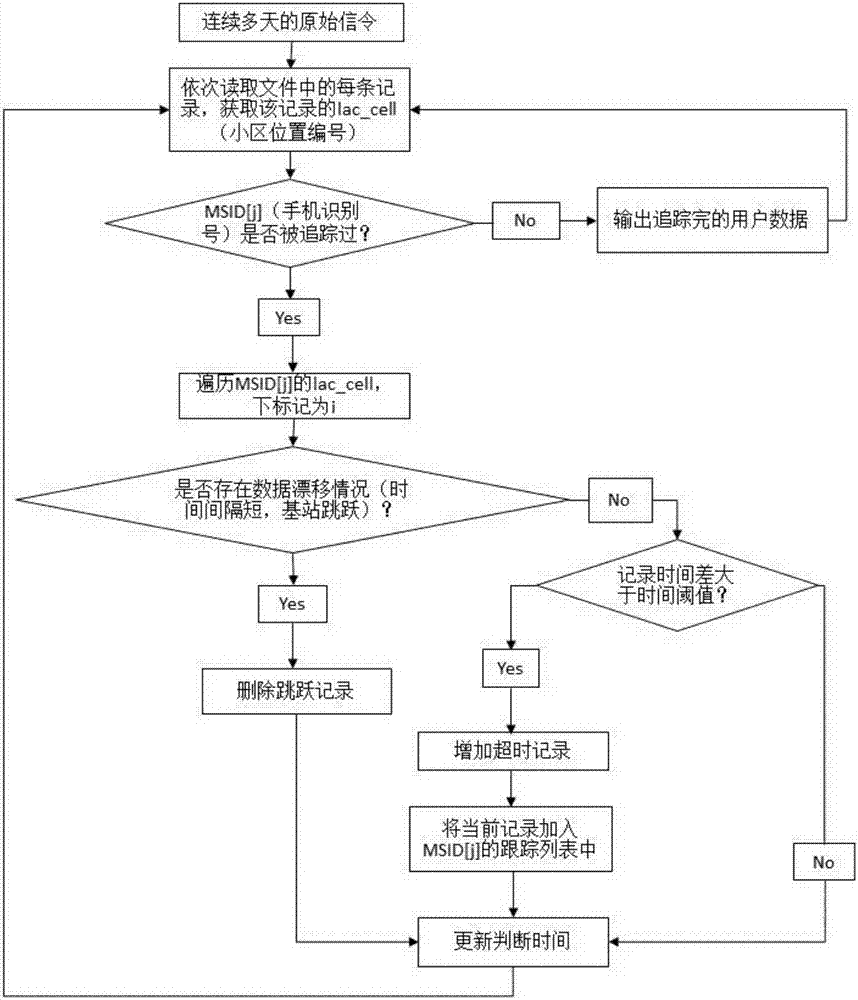

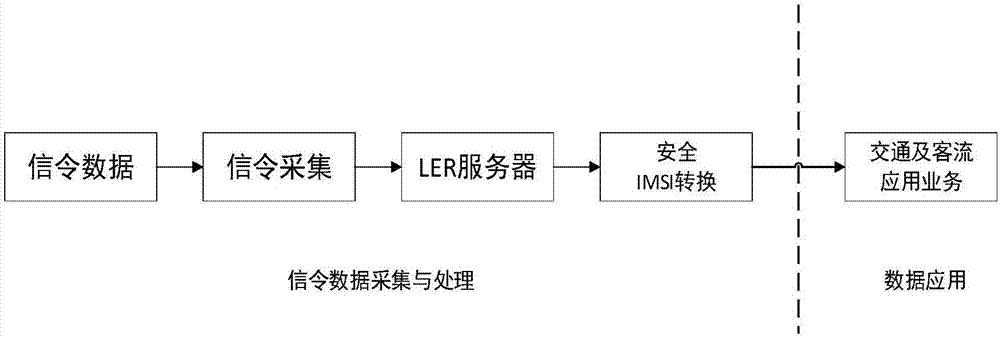

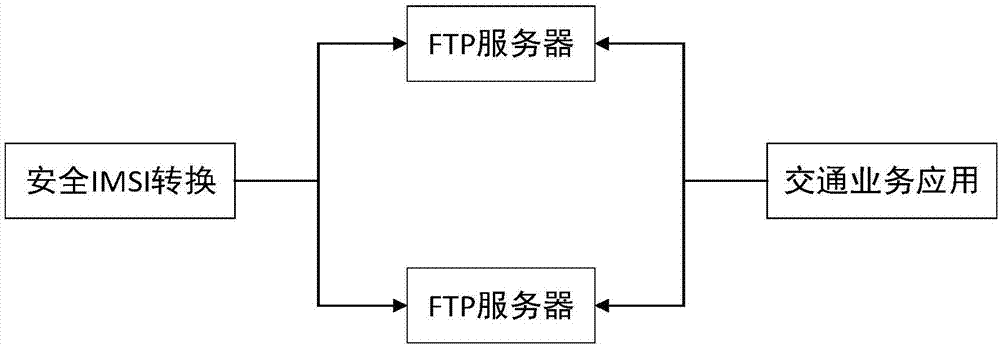

Fusion data-based resident trip OD distribution extraction method

ActiveCN107958031AEvenly distributed tripsOvercoming the defect of uneven samplingData processing applicationsSpecial data processing applicationsDistribution matrixTrip distribution

The invention discloses a fusion data-based resident trip OD distribution extraction method, and the method is realized through fusing mobile phone signalling data and traditional resident investigation data. The method comprises the following steps of: setting a related threshold value through resident trip feature information obtained through traditional resident investigation data on the basisof acquiring and preprocessing original mobile phone signalling data, and converting trip track information in the mobile phone signalling data into a preliminary trip OD distribution matrix; and obtaining a final resident trip OD distribution condition through gross sample expansion. According to the method, the targets of full-sample sampling and sample distribution uniformity are realized underthe condition that resident trip distribution grosses re highly consistent with real trip features, obtained resident trip distribution results are greatly enhanced when being compared with traditional methods, and important theoretical basis and support are provided for the construction of urban traffic facilities and the construction of transit systems.

Owner:SHANGHAI URBAN CONSTR DESIGN RES INST GRP CO LTD

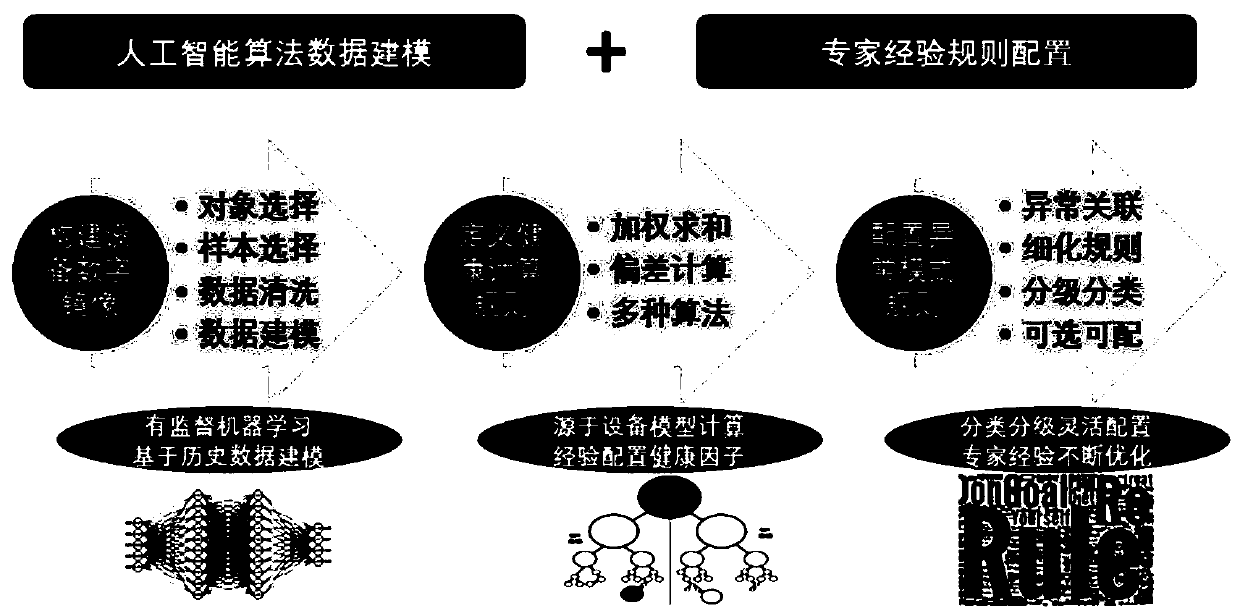

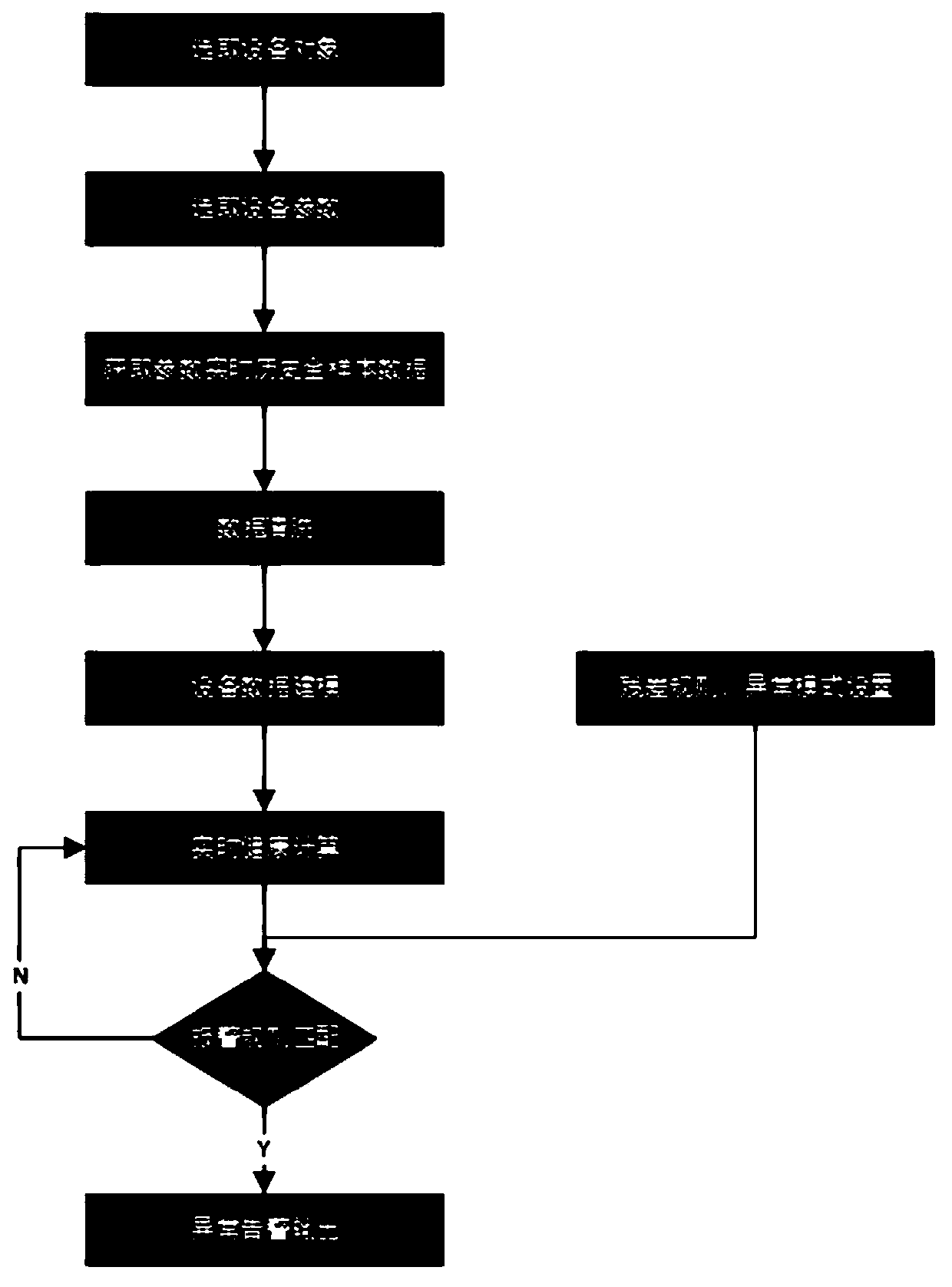

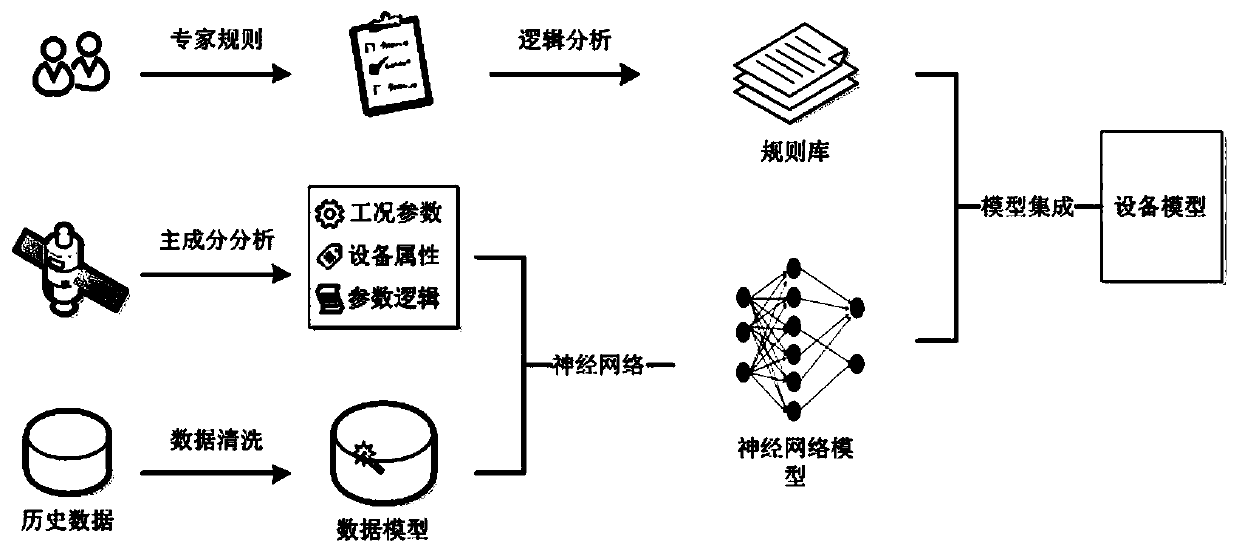

Equipment degradation analysis method based on parameter residual error

InactiveCN110097209AImprove forecast accuracyImprove usabilityForecastingNeural architecturesNetwork modelCorrelation analysis

The invention discloses an equipment degradation analysis method based on a parameter residual error, and the method comprises the steps of building a neural network model through an improved convolutional neural network algorithm and a large amount of historical data, training an equipment model, and simulating the operation of the equipment; model prediction; and expert rule matching. Through the online comparative analysis of the model calculation value and the real-time monitoring value of the parameters, the residual prediction of the parameters is realized, and the degradation analysis and the fault prediction of the equipment are realized in combination with correlation analysis. According to the method, based on the big data, the improved convolutional neural network algorithm andthe expert rules, in combination with an equipment degradation analysis method, the model prediction accuracy can be improved to 99% or above after learning and perfecting the all-working-condition full-sample data, the prediction alarm time can be brought forward 10-15 days earlier than the fault occurrence time, the gateway moves forwards, the precious time is gained for equipment maintenance, the equipment availability is improved, the safety risk caused by equipment faults is reduced, the maintenance cost is reduced, the non-stop is reduced, and the overall economic benefit is improved.

Owner:朗坤智慧科技股份有限公司

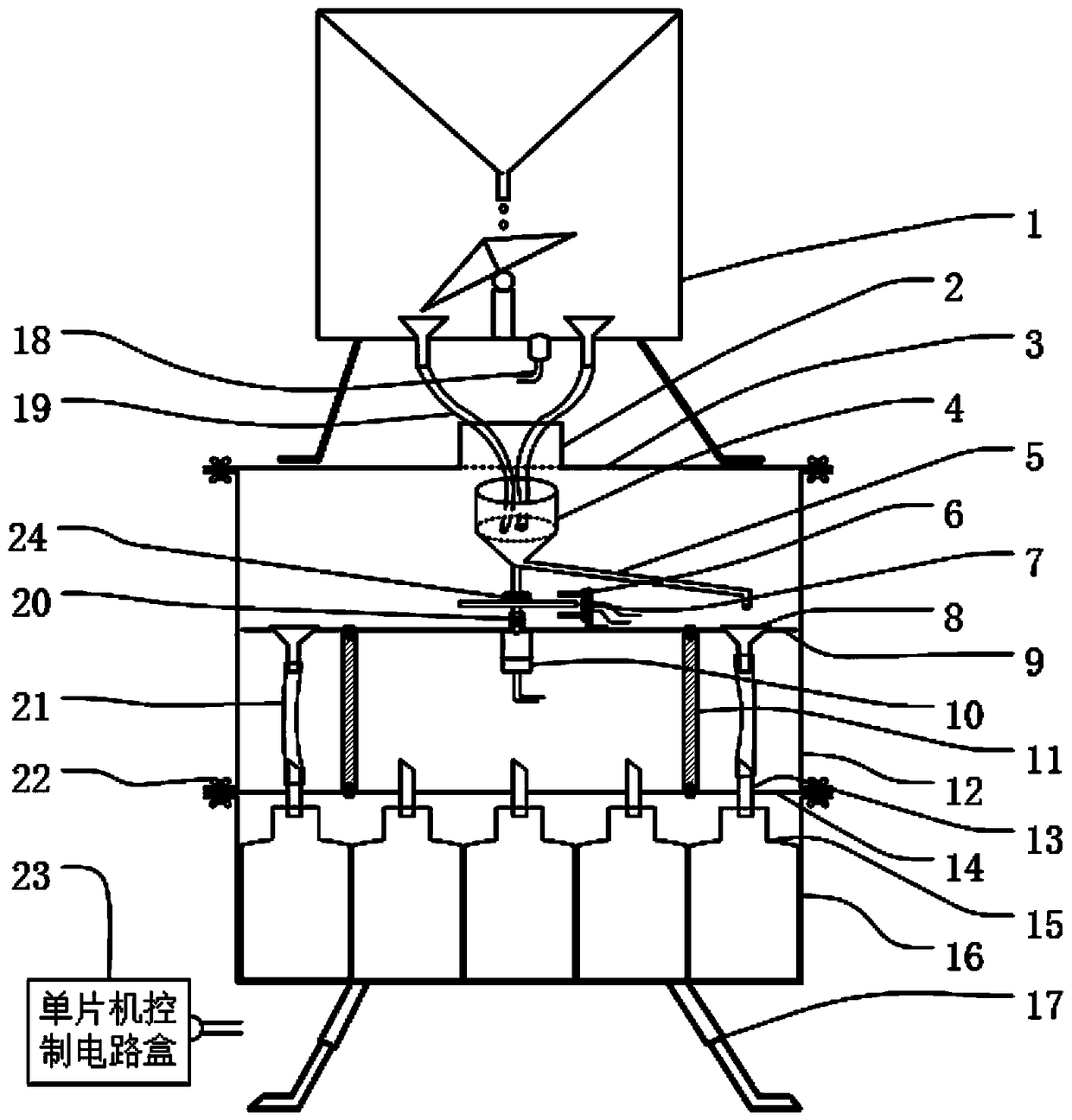

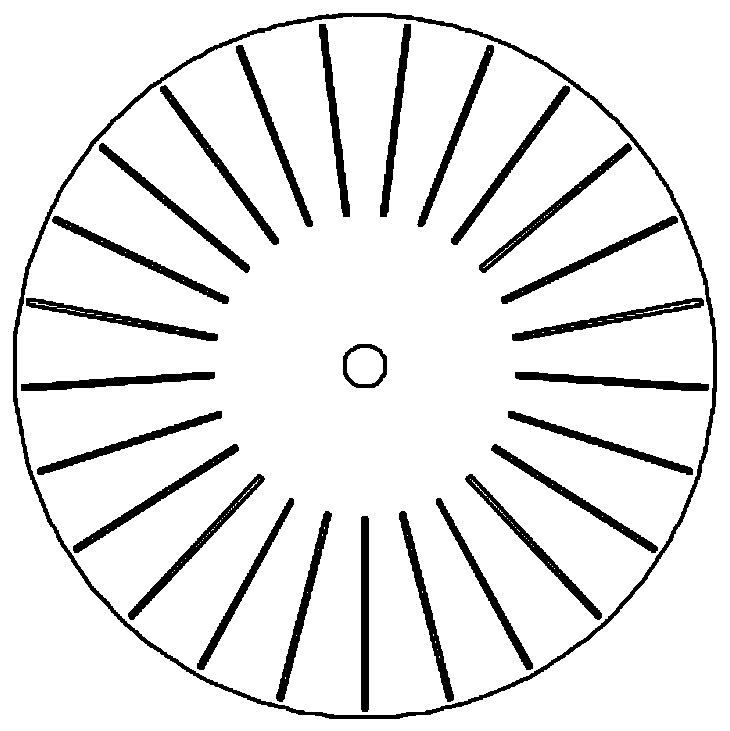

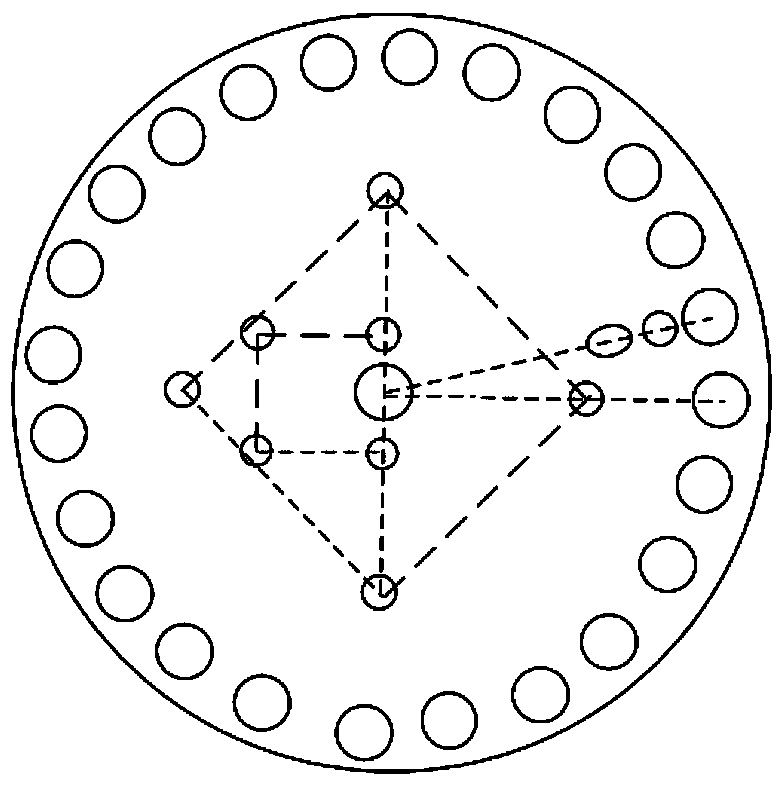

Intelligent rain sampling device suitable for various field environments

PendingCN108387405AMatrix placement implementationImprove space utilizationRainfall/precipitation gaugesWithdrawing sample devicesMicrocontrollerEngineering

The invention belongs to the technical field of environmental monitoring, and relates to a rain sampling device, in particular to an intelligent rain sampling device suitable for various field environments. The device comprises three parts, i.e., a tipping bucket rain sensor, an intermediate box body and a sample box which are assembled in a separated way; the tipping bucket rain sensor is arranged on a top cover of the intermediate box body; the intermediate box body is internally provided with a funnel disc on which small funnels are evenly distributed along the circumference of the funnel disc; a motor is fixed in the center of the funnel disc; a water sample temporary storage device and a positioning plate are installed on a motor shaft; a water supply guide pipe extending to the upperpart of the small funnels is arranged on the water sample temporary storage device; the positioning plate is provided with light-transmitting seams which correspond to the small funnels and are evenly distributed; photosensitive pair transistors are arranged at the light-transmitting seams; the sample box arranged under the intermediate box body is rectangular, and the size of the sample box is the superimposed size of a full sample bottle; the tipping bucket rain sensor, the motor and the photosensitive pair transistors are connected with a single chip microcomputer interface. The device ishigh in sampling accuracy, low in power consumption, high in space utilization rate, small in volume, very suitable for long-time intelligent work in the field environments, and convenient to move.

Owner:YUNNAN UNIV

Forming machine process quality parameter tracking system and tracking method thereof

ActiveCN105867326AReal-timeImplement feedbackComputer controlSimulator controlProcess qualityRelational database

The invention relates to a forming machine process quality parameter tracking system and a tracking method thereof. The forming machine process quality parameter tracking system is composed of a forming machine electric control system, a process parameter acquiring device, an application server, a real-time historical database, a relationship database, a field operation terminal and a PROFINET network. According to the forming machine process quality parameter tracking system and the tracking method, the process quality parameter of the equipment in production process is acquired in real time. According to the process quality standard of a filter rod, through an analysis model and full-sample statistics technology based on big data, real-time monitoring and feedback for change condition, adjustment condition and abnormal condition of the process quality parameter in the filter prod production process are realized. Furthermore, through the forming method of the invention, by means of process quality parameter real-time data which are stored into a real-time historical database according to a time stamp, any change of the process quality parameter can be wholly tracked, thereby truly realizing an original tracking and analyzing system based on the production process.

Owner:CHINA TOBACCO ZHEJIANG IND

Method and system for meeting end conditions in a motion control system

ActiveUS20090105883A1Programme-controlled manipulatorSampled-variable control systemsControl systemPath generation

One embodiment of a system and method for meeting end conditions of a path plan utilizing a path generator that continuously generates commands for a path plan while tracking the total time expired in the path plan. The path generator computes the time remaining in the path plan and substitutes the remaining time for the length of the final sample period in the path plan when the length of the remaining time is less than the length of a full sample period.

Owner:INTELLIGENT PLATFORMS LLC

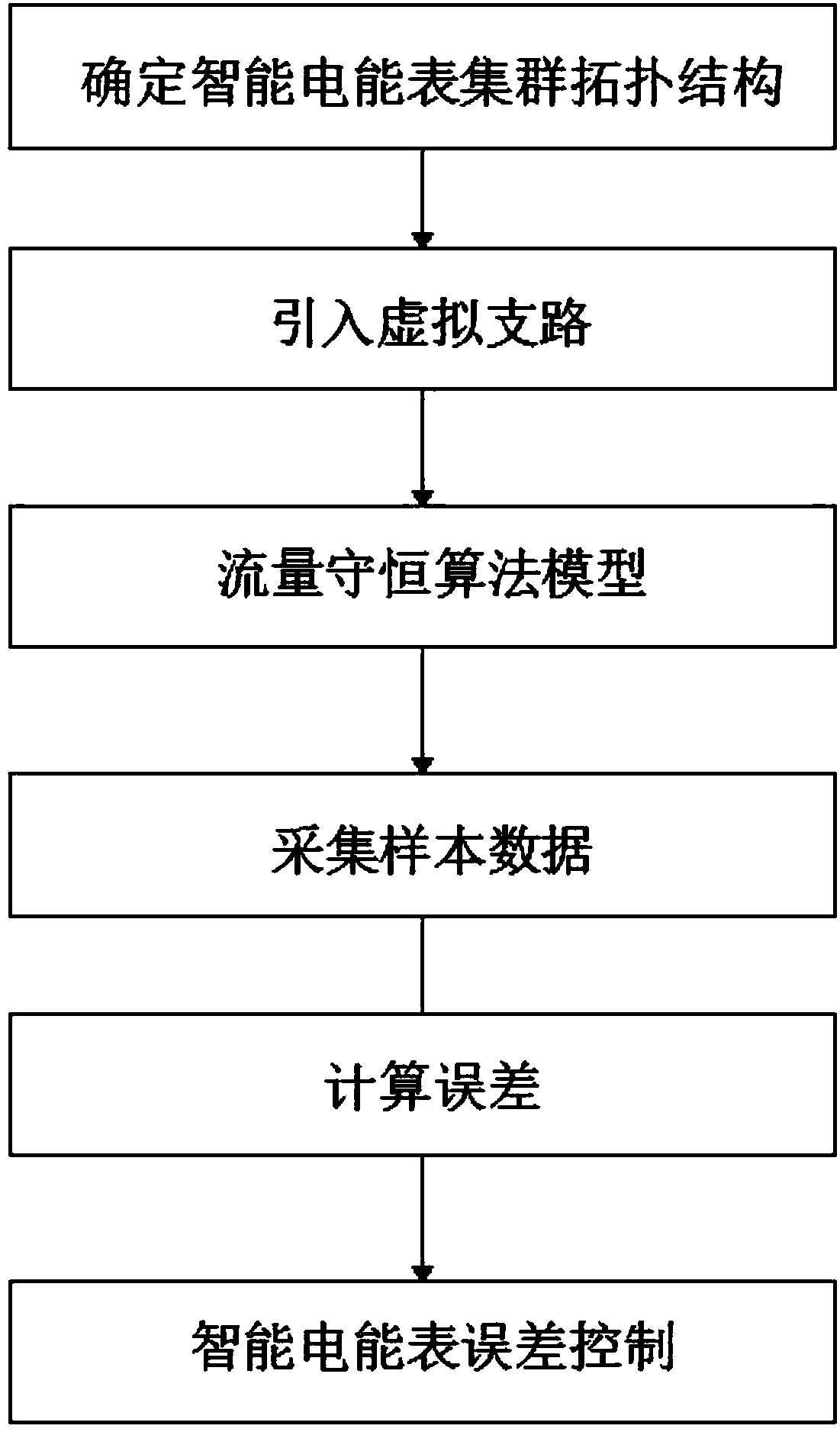

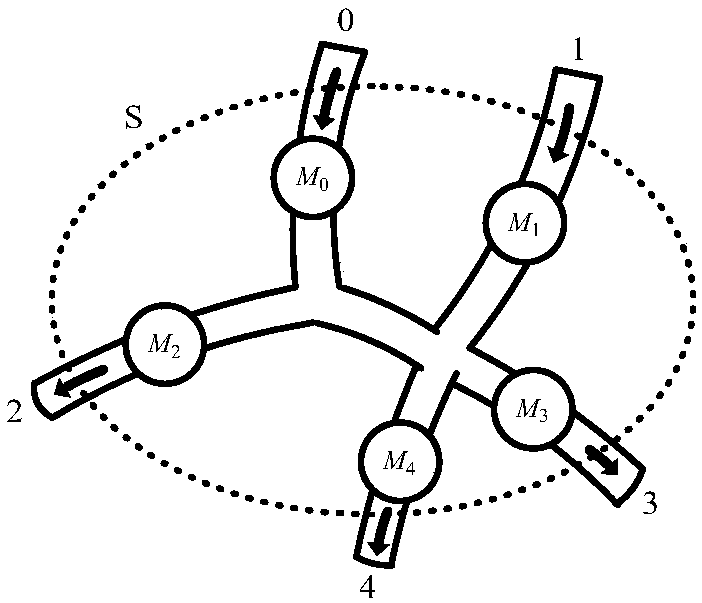

Error control method for online operating smart electric energy meters based on full sample data thinking

InactiveCN107561481ARealize remote detectionDoes not change meter structureElectrical measurementsPower userTechnology research

The invention relates to an error control method for online operating smart electric energy meters based on full sample data thinking. The method comprises the following steps: (1) installing a smartelectric energy meter cluster to form a tree topological structure; (2) introducing a virtual branch to correct a smart electric energy meter cluster topological model; (3) eliciting a flow conservation algorithm model; (4) acquiring the sample data of all smart electric energy meters; (5) substituting all the sample data into the flow conservation algorithm model to calculate the errors of all the smart electric energy meters; and (6) realizing precise control according to the error results of all the smart electric energy meters. The method applies the full sample data thinking to the 480 millions online operating smart electric energy meters of the state grid corporation, excavates massive electric energy data of a power user electric information acquiring system, measures the error data of all electric energy meters, uses whole data instead of a random sample, requires no external standard equipment, carries out smart electric energy meter remote calibration technology research, and enable power supplier and consumers to be able to understand the accuracy of energy metering devices in real time.

Owner:TIANJIN ELECTRIC POWER TECH DEV CO LTD

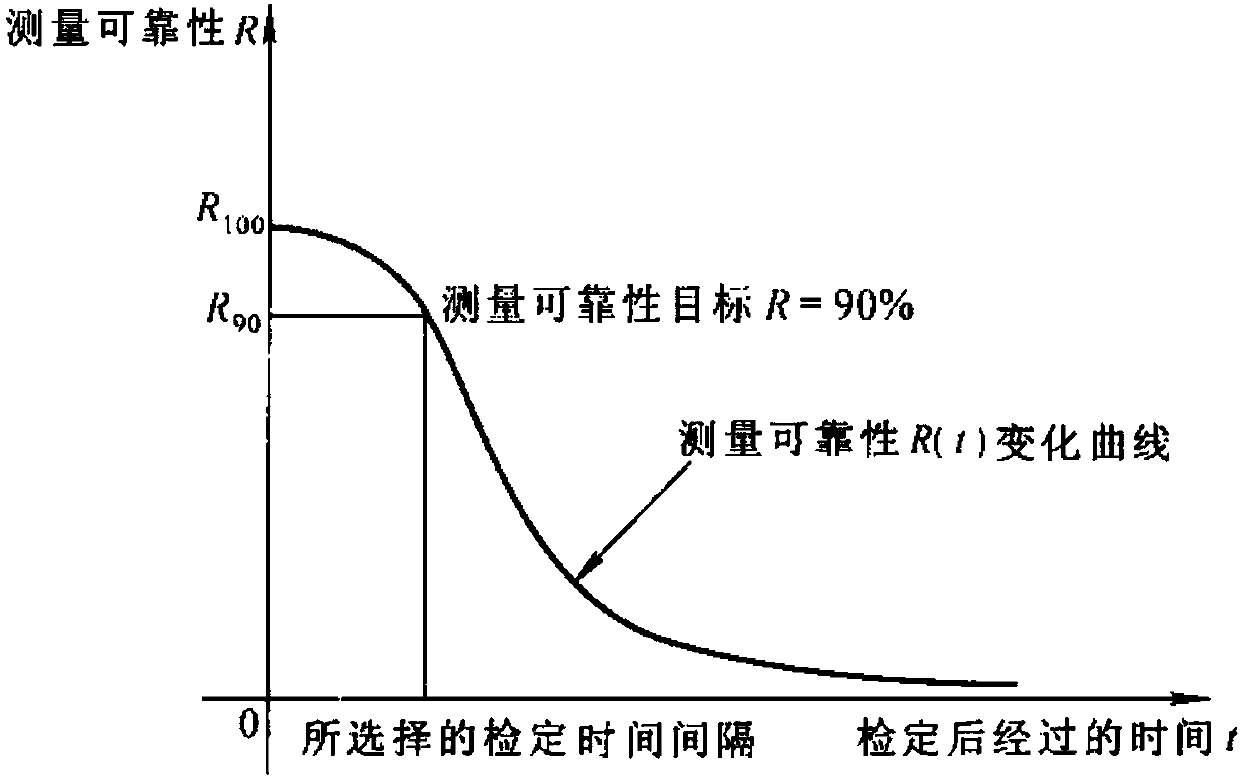

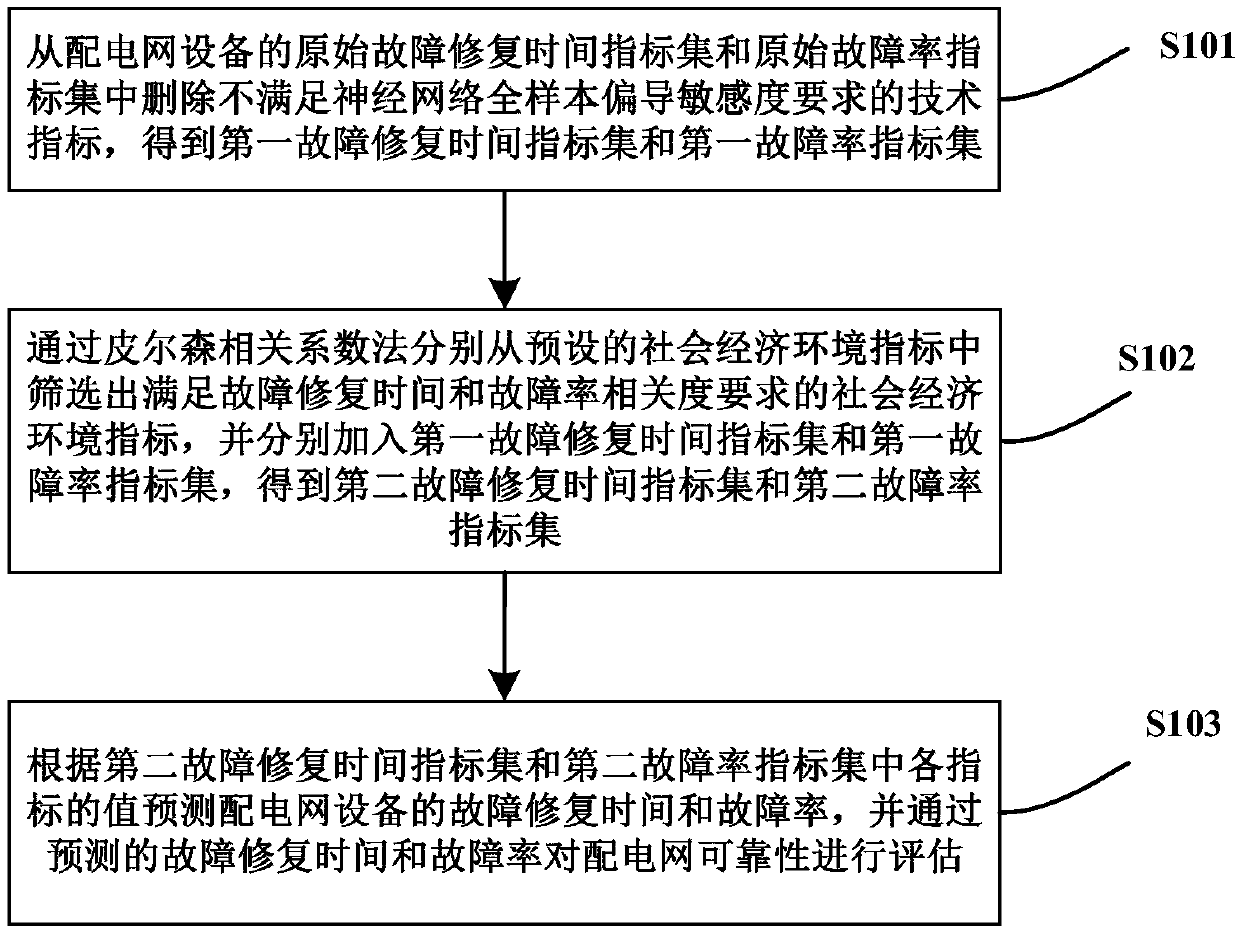

Method and device for evaluating reliability of power distribution network

PendingCN108665181AReduce complexityImprove reliabilityResourcesInformation technology support systemCorrelation coefficientFull sample

The invention provides a method and device for evaluating the reliability of a power distribution network. Firstly, a first fault recovery time index set and a first fault rate index set are obtained,then a second fault recovery time index set and a second fault rate index set are obtained, lastly, fault recovery time and fault rate of power distribution network equipment are predicted, and the reliability of the power distribution network is evaluated. The method and device for evaluating the reliability of the power distribution network have the advantages that technical indexes not satisfying the requirements of full sample partial derivative sensitivity of a neural network are deleted, thereby reducing the complexity of prediction model indexes, socioeconomic environment indexes satisfying the fault recovery time and fault rate relevance requirement are screened from preset socioeconomic environment indexes respectively through a Pearson correlation coefficient method, so that thecredibility of an evaluation result of the reliability of the power distribution network is improved, the accuracy of the evaluation result of the reliability of the power distribution network is ensured, and the method and device evaluating the reliability of the power distribution network are more line with the actual situation and business requirements.

Owner:CHINA ELECTRIC POWER RES INST +2

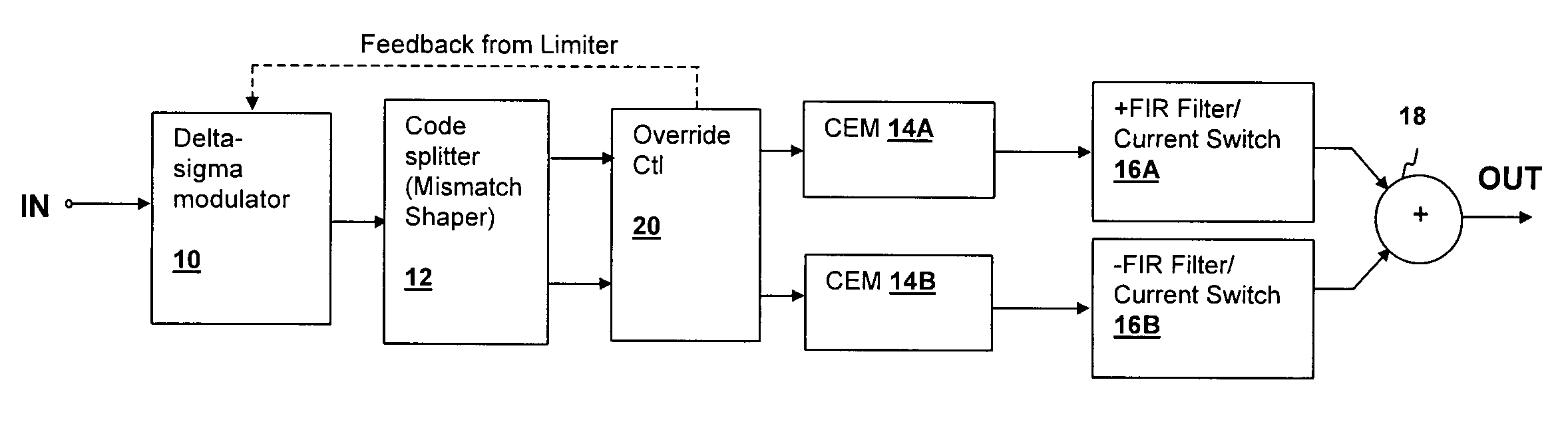

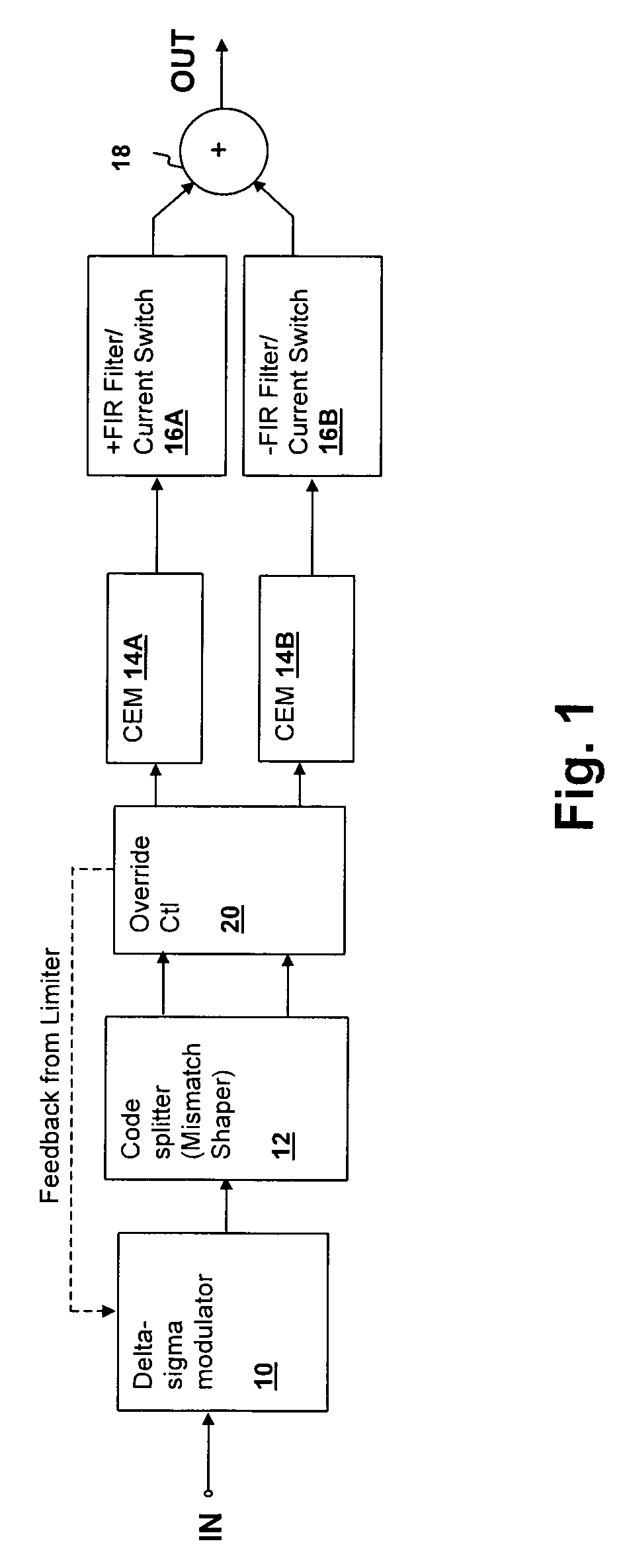

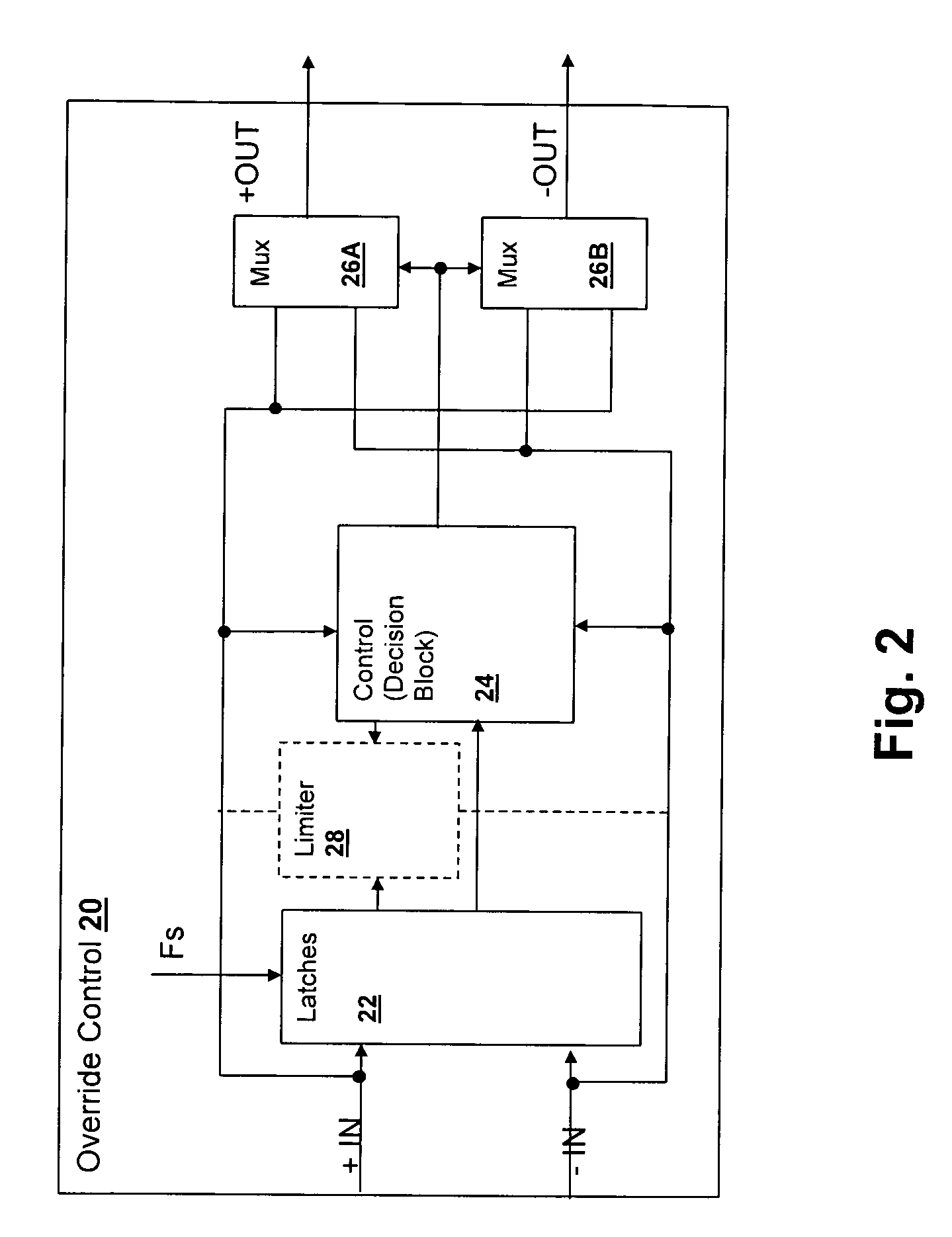

Constant edge-rate ternary output consecutive-edge modulator (CEM) method and apparatus

ActiveUS7327295B1Wide range of controlElectric signal transmission systemsDigital data processing detailsNoise shapingControl circuit

A constant edge-rate ternary output consecutive-edge modulator (CEM) method and apparatus provides improved dynamic range in a noise-shaped CEM ternary pulse generator. A noise shaper shapes an input signal that is supplied to a pair of CEMs through a mismatch shaper or other code splitter that assigns unequal pulse width portions (the extra count in odd counts) between the pair of CEMs. The range of pulse width out of the CEMs can then be allowed to extend to the full sample period for one or possibly both of the CEMs in a given cycle. A control circuit overrides the mismatch shaper's assignment of the unequal pulse width portions when a previous pulse period yielded no transition from a given CEM, so that the given CEM is guaranteed to have a transition in the current pulse period.

Owner:CIRRUS LOGIC INC

On-line cigarette technology quality analysis and traceability system

The present invention relates to an on-line cigarette technology quality analysis and traceability system. The on-line cigarette technology quality analysis and traceability system is composed of a volume package production equipment electric control system, a technology quality parameter acquisition device, a steel seal detection and acquisition device, an OPC server, a real-time historical database server, a relation database server, an accessory bar code acquisition device and system, an application server, an on-site operation terminal, a case quality traceability code pasting system, a whole-tray RFID writing device, an automatic stereo warehouse control system, an automatic stereo warehouse and a PROFINET Ethernet. The on-line cigarette technology quality analysis and traceability system of the present invention analyzes the real-timely acquired technology quality parameters according to a cigarette technology quality standard and by a big data-based analysis model and a full-sample statistics technology to realize the real-time monitoring and feedback of the change and adjustment situations of the technology quality parameters and the abnormal situations during a cigarette production process, and utilizes the technology quality parameter real-time data stored in a real-time historical database according to the timestamps to realize the historical reproduction of the cigarette production process.

Owner:CHINA TOBACCO ZHEJIANG IND

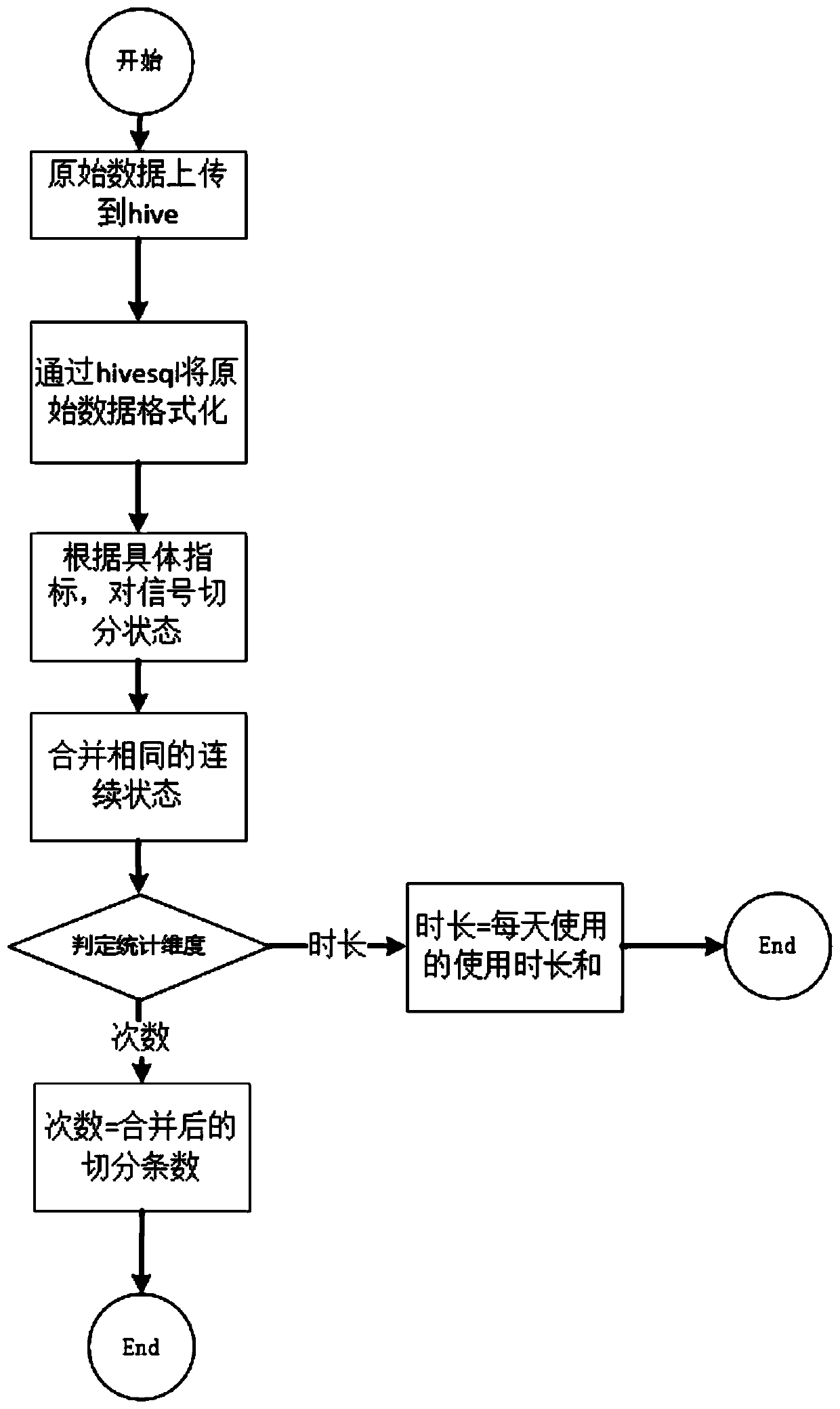

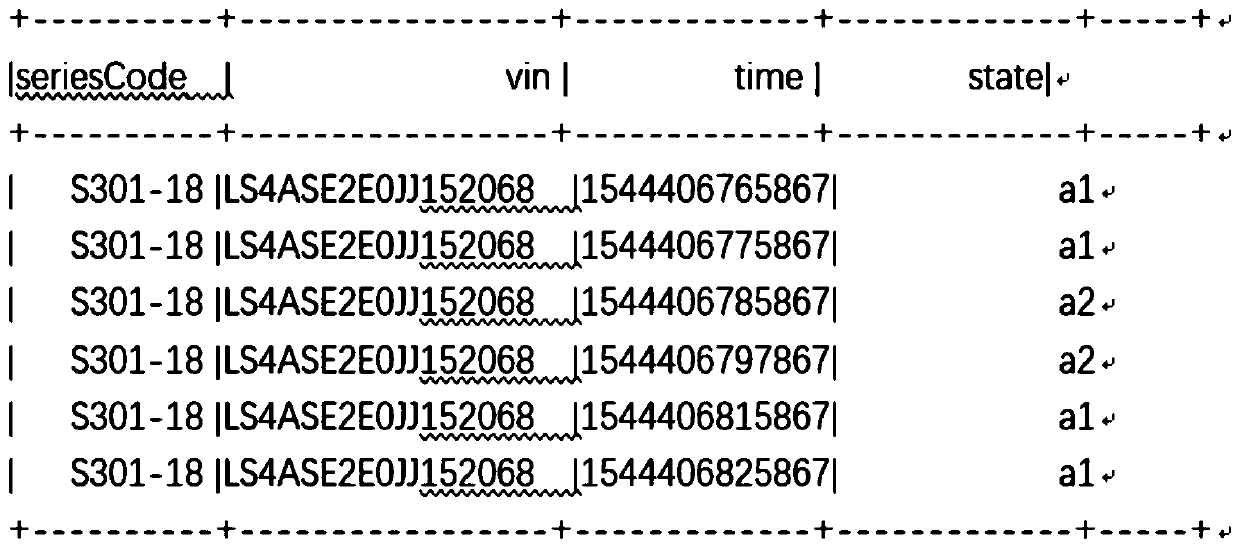

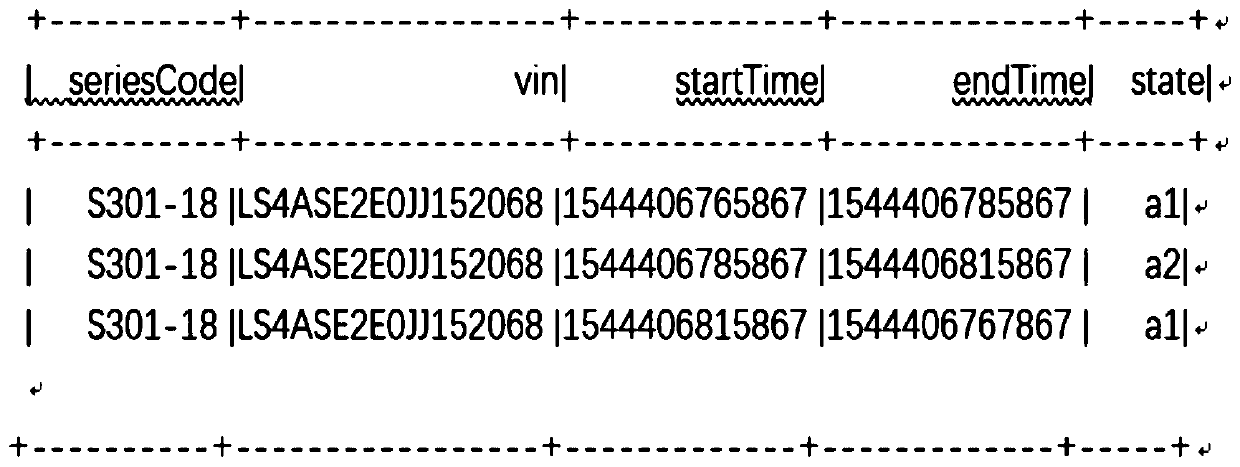

Vehicle function activeness analysis method and system

ActiveCN110517084AMeet needsGuaranteed real-timeRegistering/indicating working of vehiclesMarket data gatheringOriginal dataData operations

The invention aims to provide a vehicle function activeness analysis method and system. The method comprises the steps of original data acquisition, data processing, data analysis and data visualization. Existing data acquisition hardware is utilized, under the condition that cost and manpower are not increased, a terminal monitors CAN bus data, vehicle function signals are uploaded, a backgroundreceives and stores data, the use frequency and duration of vehicle functions are obtained through data operation, and therefore the function activeness is obtained. The method has data real-time performance and full sample size, can reflect the function activity condition of an actual user, forms multi-dimensional analysis, and meets the requirements of products and operators.

Owner:CHONGQING CHANGAN AUTOMOBILE CO LTD

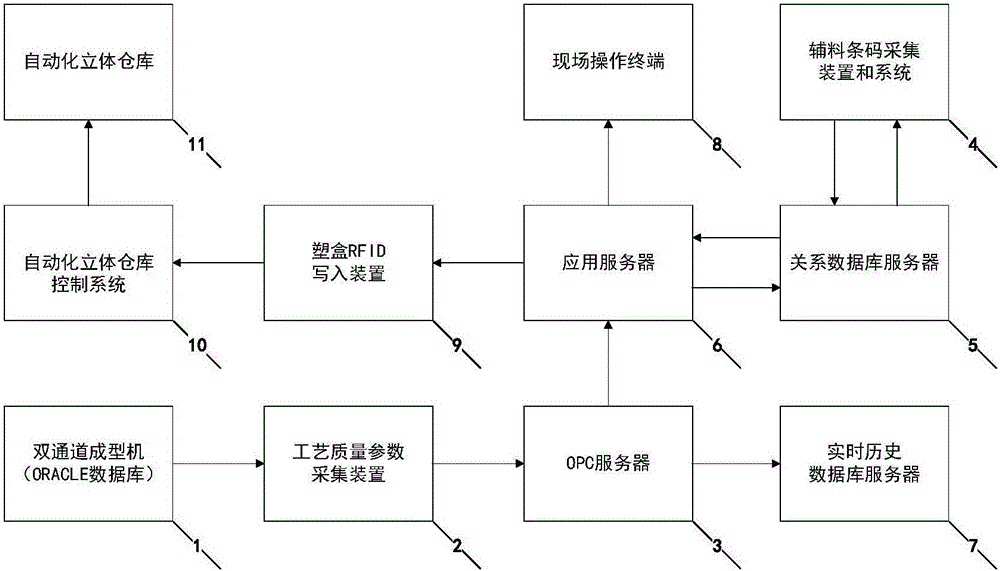

Two-channel filter rod moulding technology quality analyzing and tracing system

ActiveCN105843191AReduce complexityTotal factory controlProgramme total factory controlRelational databaseOracle database

The invention relates to a two-channel filter rod moulding technology quality analyzing and tracing system. The system comprises an Oracle database for forming two channels, a technology quality parameter acquiring apparatus, an OPC server, an accessory material bar code acquiring apparatus and system, a relationship database server, an application server, a real time historical data server, an on-site operation terminal, a plastic box RFID write-in device, an automatic upright warehouse control system, an automatic stereoscopic warehouse, and a PROFINET. According to the invention, it is possible to monitor and give feed back in real time the change, the adjustment and anomaly in technology quality parameters during the manufacturing of a filter rod to prevent another quality anomaly by acquiring the technology quality parameters of each channel through the technology quality parameter acquiring apparatus, on the basis of the technology quality standard, and with the analyzing models and full sample statistical technologies based on big data analysis. When quality anomaly is spotted, the system sends a leave order to the automatic stereoscopic warehouse control system, which makes manual tracing less complicated considerably.

Owner:CHINA TOBACCO ZHEJIANG IND

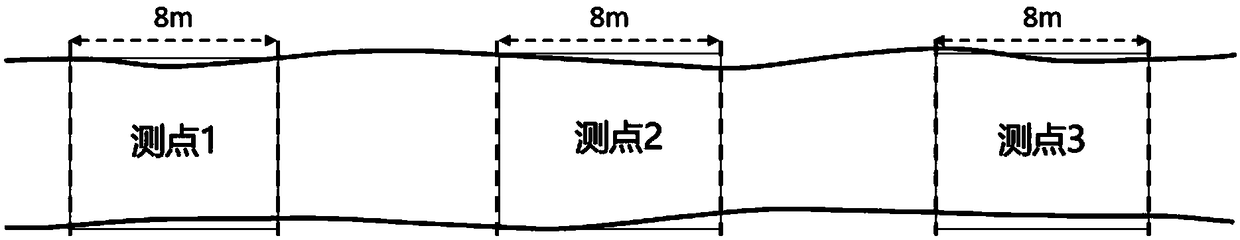

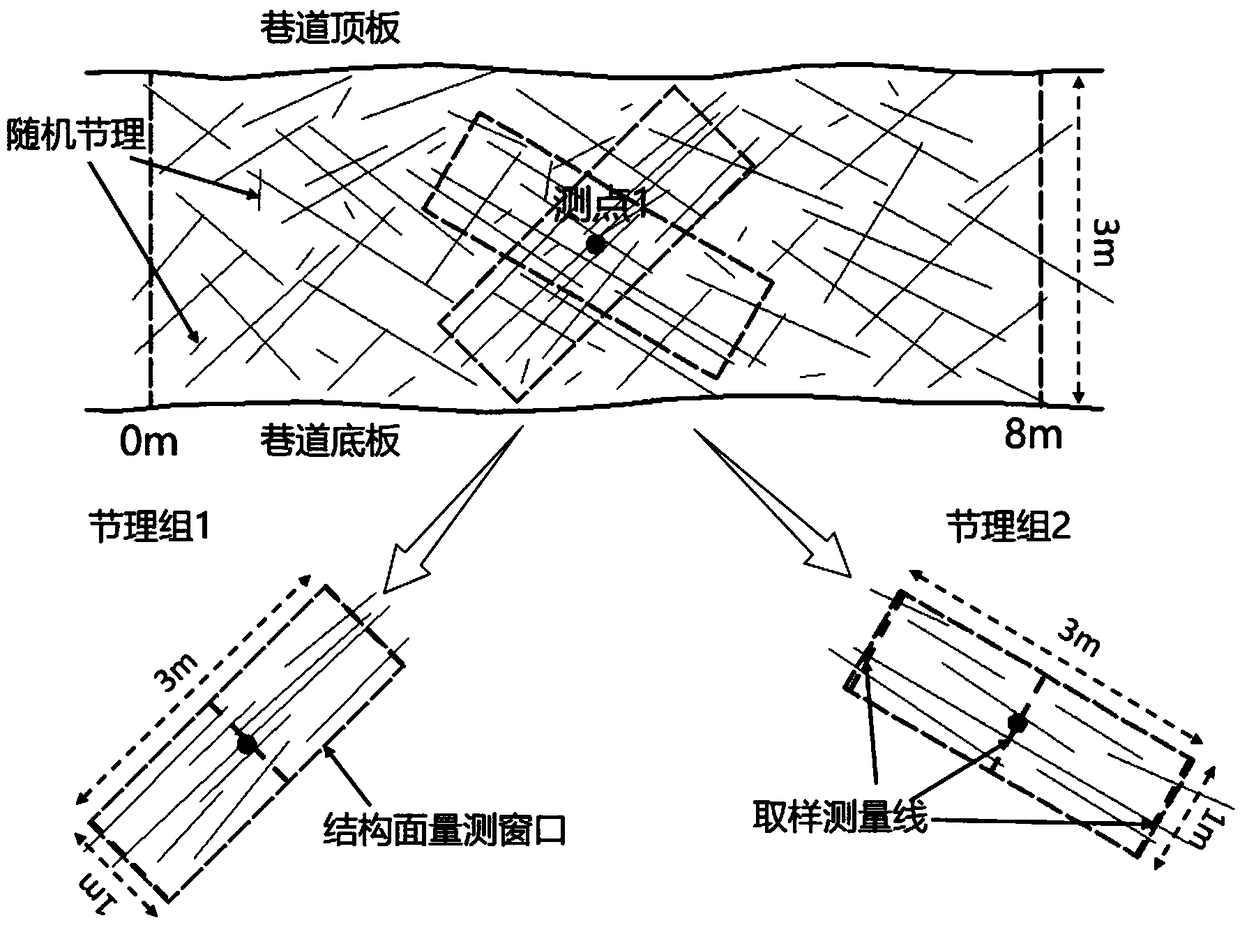

Rapid measurement and analysis method for rock mass structural features of underground engineering

InactiveCN109374047AAccurate and fast measurementFast and accurate analysisSurveying instrumentsCompassesInvestigation methodsAnalysis working

The invention relates to a rapid measurement and analysis method for rock mass structural features of underground engineering. The method comprises the following steps that: step one, a survey area isdetermined based on a survey purpose and the area is divided into a plurality of sub areas by using a large geological structure like a fault as a boundary; step two, a plurality of measuring pointsare divided in the survey area, wherein the measuring points are arranged in the survey area at intervals; step three, according to occurrence characteristics of the joints in the range of the measuring points, dominant joint groups are divided and joint measurement windows are arranged by using the center points of the measuring points as centers based on the trend occurrence characteristics of the dominant joint groups; and step four, the measurement and analysis of the tendency, the inclination angle, the average joint spacing and the average trace length of the joint are carried out basedon the joint measurement windows. Therefore, defects of large field work load, many needed measurement field indexes, and statistic analysis work delay due to the joint information full-sample measurement and statistics of the traditional surveying method are overcome; and the rapid and accurate measurement and analysis of rock mass structure surface of underground space are realized.

Owner:NORTHEASTERN UNIV

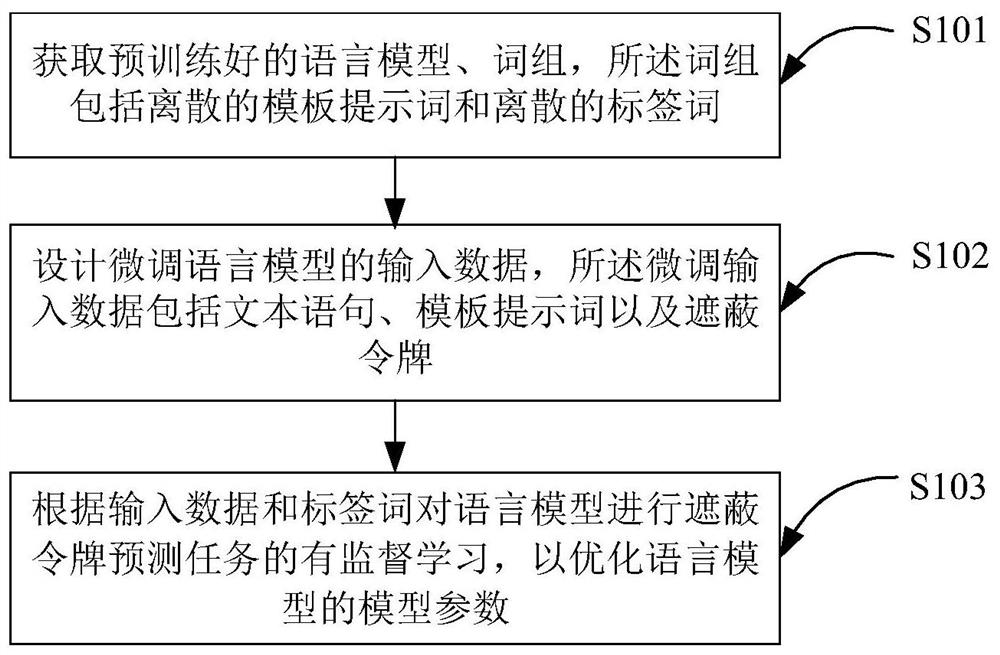

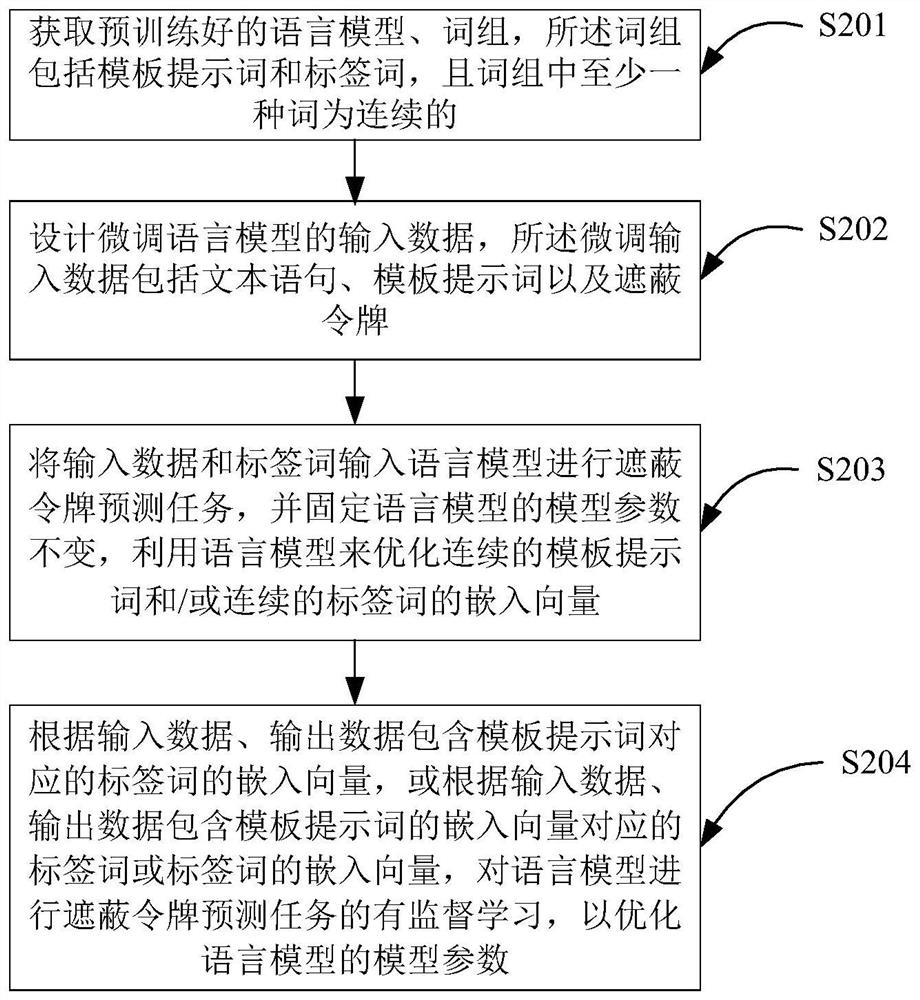

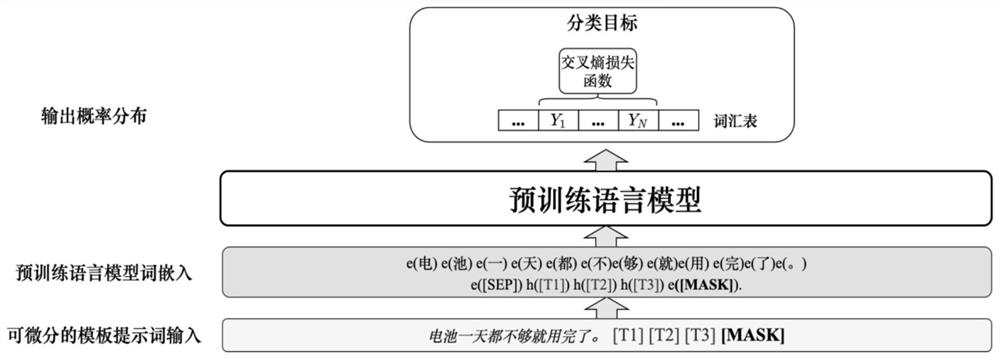

Fine tuning method and device for a language model, computing equipment and storage medium

PendingCN113468877AReduce computing costReduce computational overheadNatural language data processingMachine learningData packAlgorithm

The invention discloses a fine tuning method and device for a language model, computing equipment and a storage medium, and the method comprises the steps: obtaining a pre-trained language model and phrases, wherein the phrases comprise discrete template cue words and discrete tag words; designing input data of a fine tuning language model, wherein the fine tuning input data comprises a text statement, a template cue word and a shielding token; and performing supervised learning of a shielding token prediction task on the language model according to the input data and the tag words to optimize model parameters of the language model. The difference between the pre-trained language model and the fine-tuned language model is bridged, so the fine-tuned language model is better in performance on a downstream shielding token prediction task; under the condition of full samples, compared with a traditional fine adjustment method, the method is better in effect, under the condition of few samples, the effect of the method is improved more remarkably, the calculation cost of a large number of parameters can be reduced, and the calculation overhead of calculation equipment is reduced.

Owner:ZHEJIANG UNIV

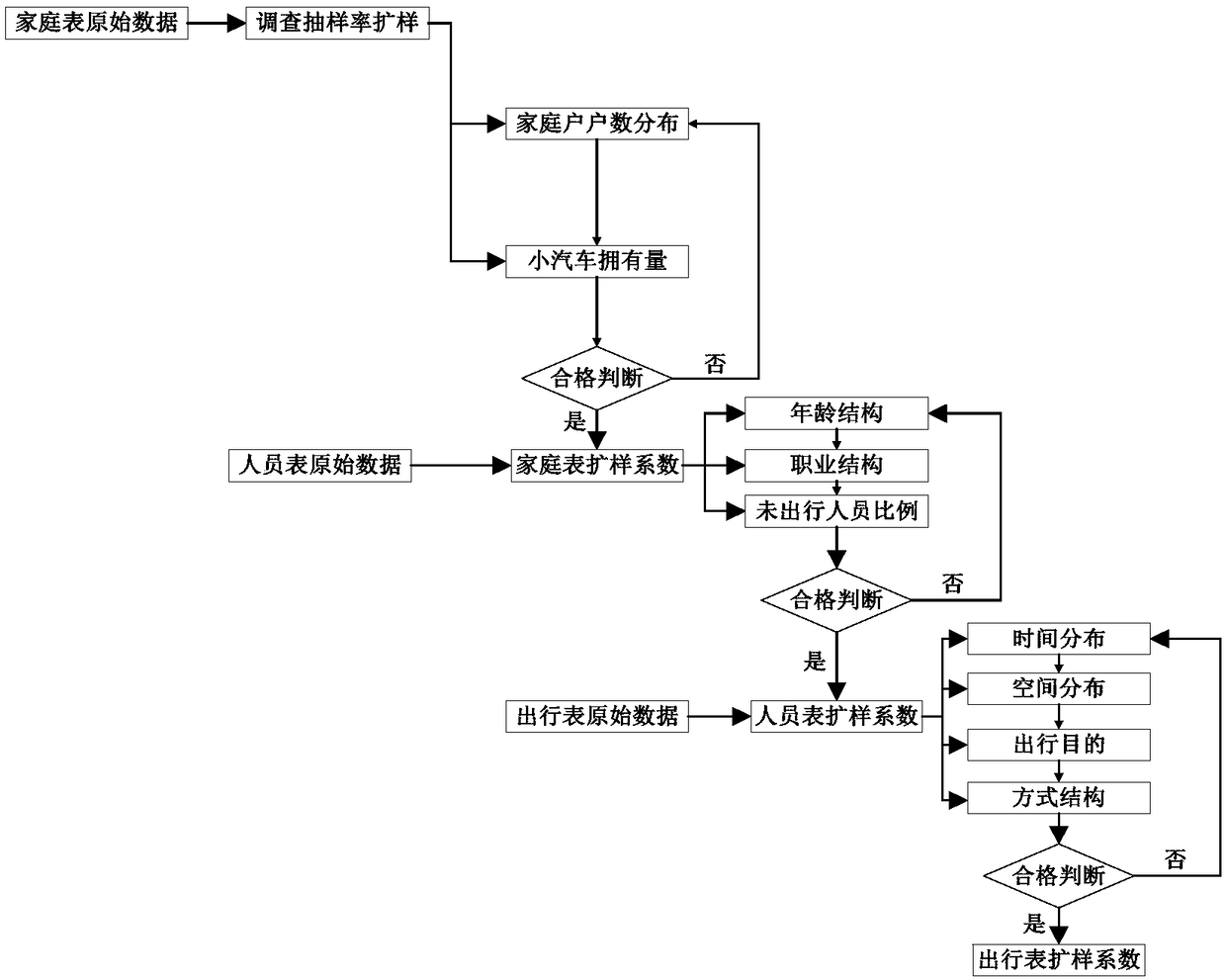

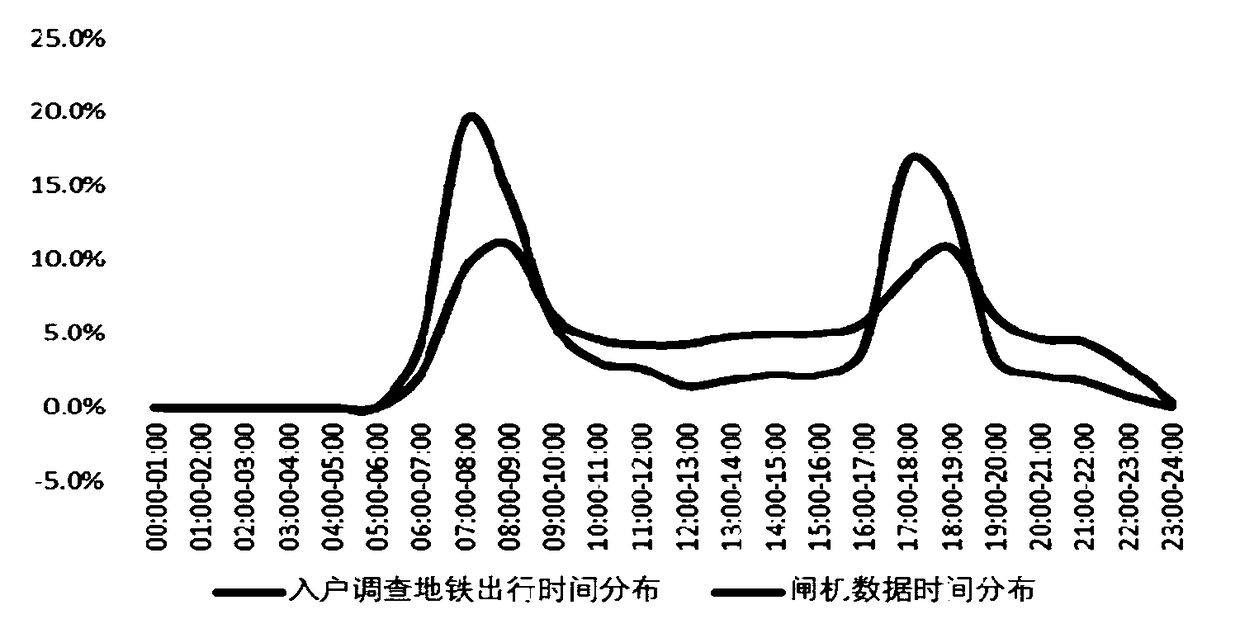

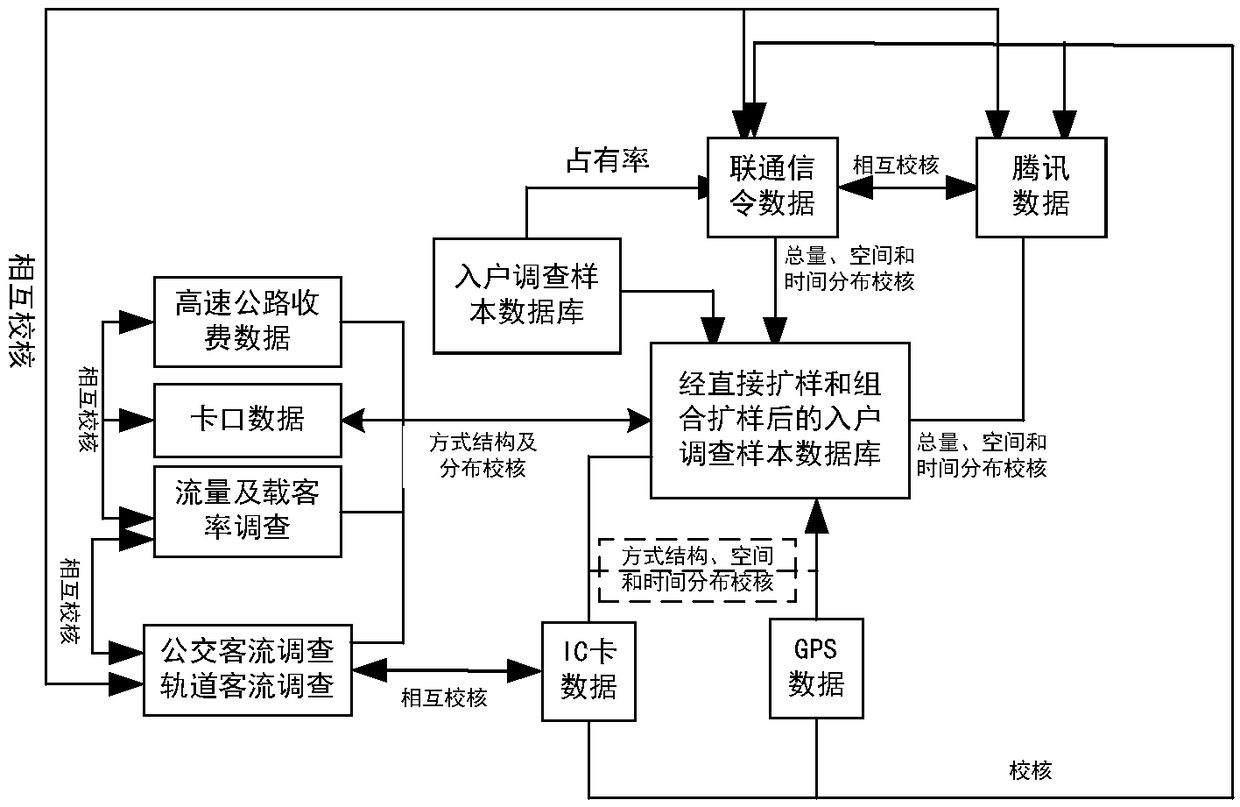

Resident travel survey comprehensive sample expanding and checking method based on combination of big data and traditional method

InactiveCN108629972ARestoring travel characteristicsConducive to mining silent travelDetection of traffic movementSpecial data processing applicationsTravel surveyFull sample

The invention provides a resident travel survey comprehensive sample expanding and checking method based on the combination of big data and a traditional method. The method comprises the following steps: step 1, carrying out overall preliminary checking work by utilizing multi-source big data; step 2, carrying out the classified checking operation: carrying out the classified checking operation onpreliminarily corrected travel features according to two types of travel features, namely commuting travel and non-commuting travel; step 3, re-correcting the overall constraint: re-correcting the overall constraint of travel data after being subjected to the classified checking operation. According to the invention, based on the large-sample or quasi-full-sample characteristics of multi-source big data, the silent travel can be conveniently excavated, so that most real resident travel characteristics are restored. In addition, the real-time performance and the accuracy of big data are utilized, so that the comprehensive sample expansion of a resident travel survey is more accurate and more timely.

Owner:广州市交通规划研究院

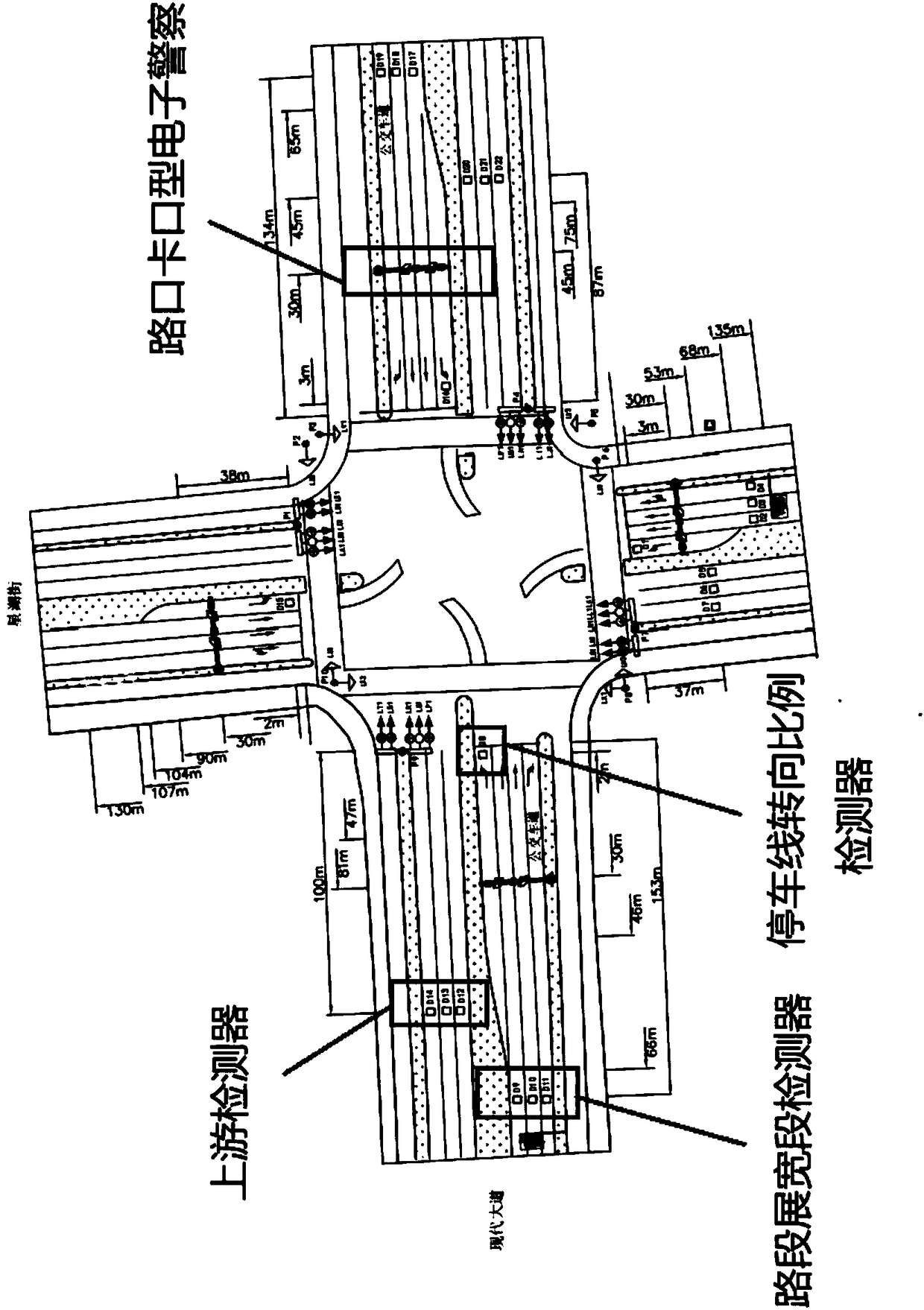

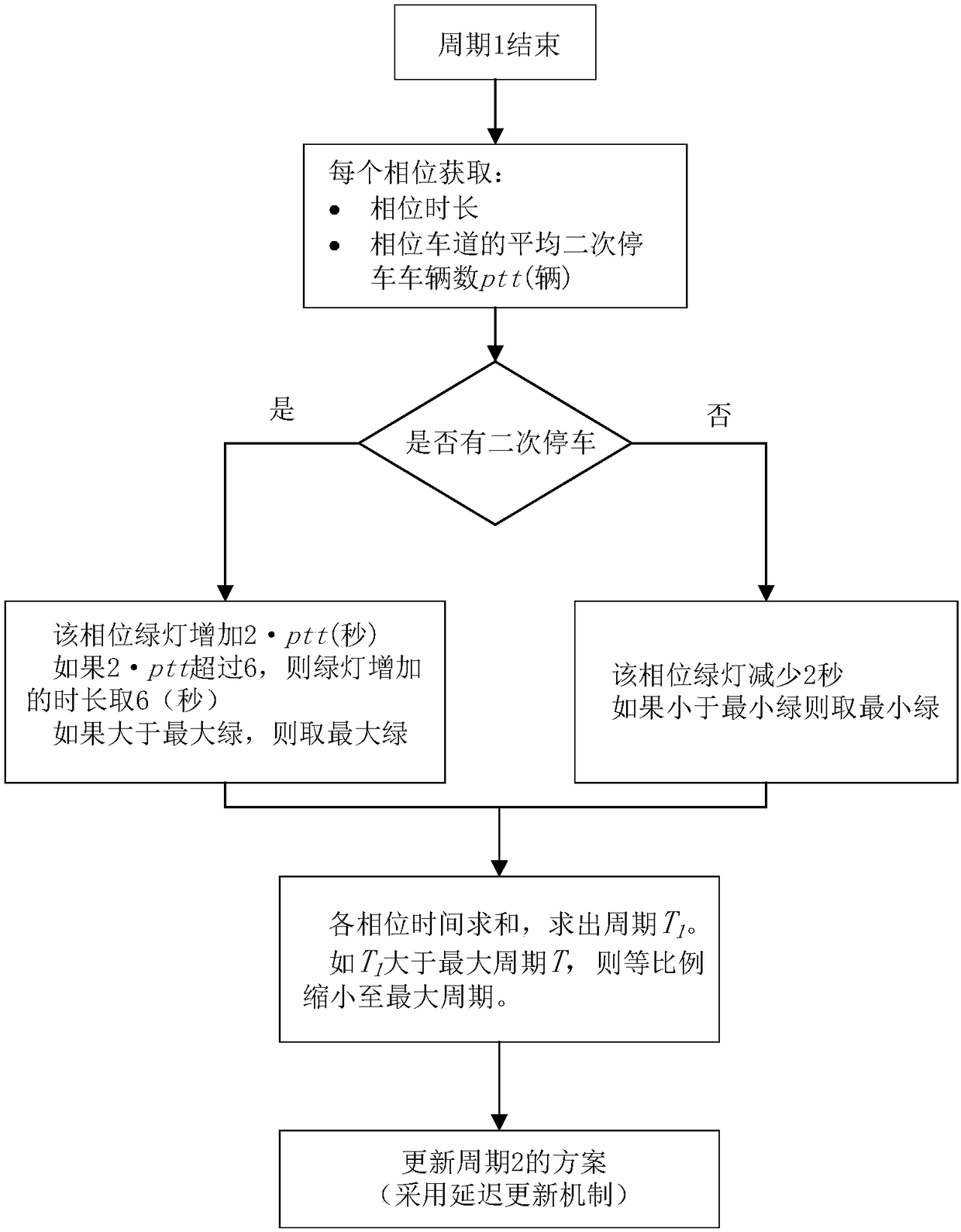

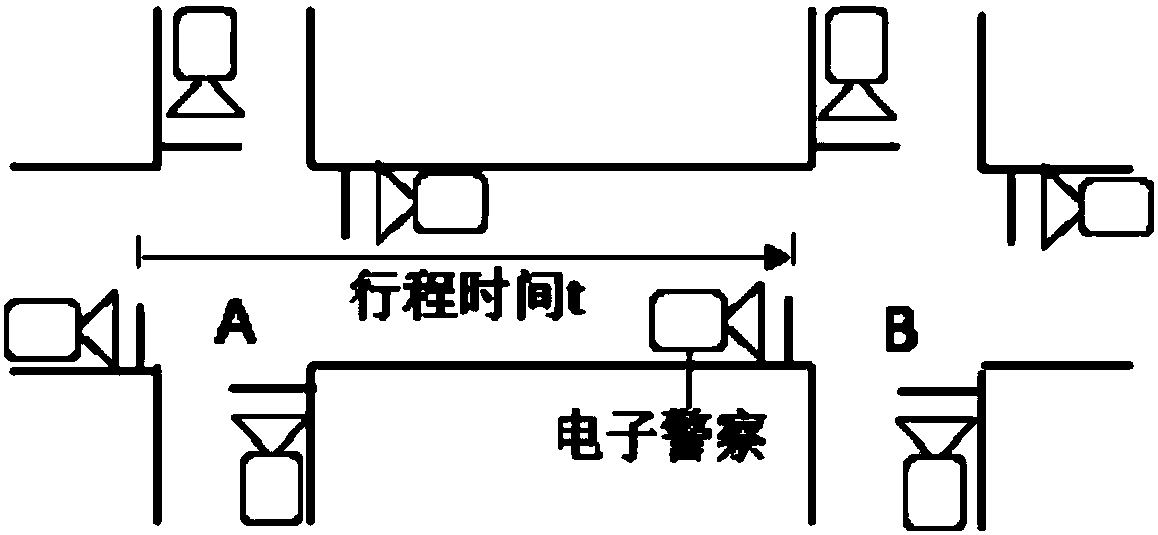

Single-intersection traffic signal control method based on secondary parking

InactiveCN108288394AIncrease profitImprove operational efficiencyControlling traffic signalsTraffic signalEqualization

The invention provides a single-intersection traffic signal control method based on secondary parking and a system thereof. According to the method and the system, electronic police license plate identification data at the intersection are utilized for acquiring full-sample vehicle delay information and performing secondary parking determining, and a timing solution in a next period is adjusted according to the secondary parking condition of each phase, thereby improving intersection utilization rate. According to the method and the system, secondary queuing is used as an optimizing index; andcompared with a traditional method, the method of the invention can realize consideration of a plurality of control targets such as saturation equalization, near saturation control and queuing restriction, thereby realizing relatively high benefit in a non-peak period and a peak period. The method of the invention can effectively improve intersection operation efficiency and reduces traffic jams.

Owner:SHANGHAI INST OF TECH

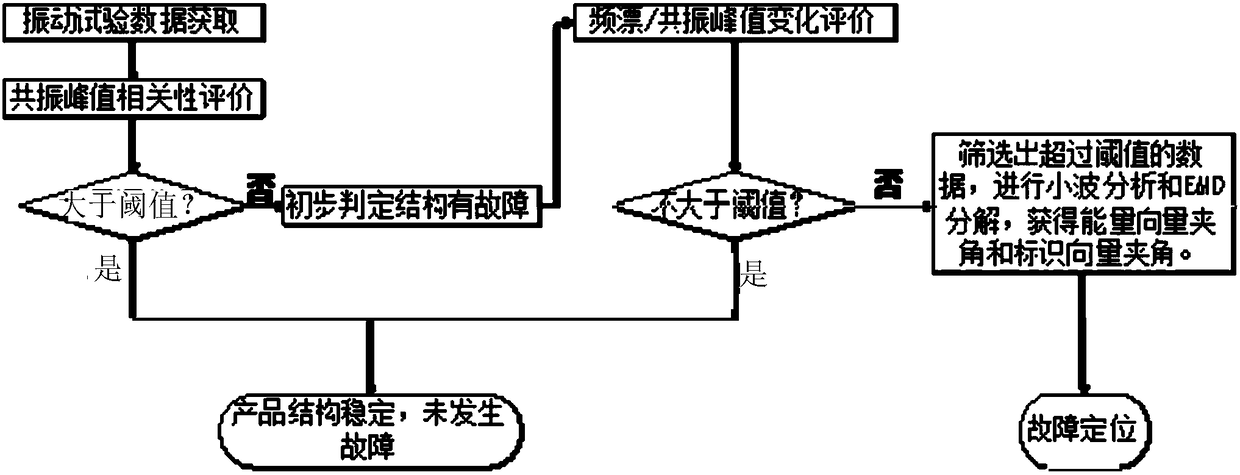

Fault locating method for spacecraft structure based on statistical analysis of vibration test data

InactiveCN108573075AAchieving identifiabilityAchieve positioningGeometric CADSustainable transportationTime–frequency analysisComputer science

The invention discloses a fault locating method for a spacecraft structure based on statistical analysis of vibration test data. On the basis of statistical analysis of a frequency-domain data full sample of test data, a set of data most possibly containing a fault area is screened out, targeted time-frequency analysis is conducted on the data, characteristic data of the vibration test data is extracted, whether or not the spacecraft structure breaks down is judged, and fault locating is achieved. By means of the fault locating method for the spacecraft structure based on the statistical analysis of the vibration test data, a structural fault can be quickly and efficiently identified and located during a ground test of a spacecraft, and the dynamic test level of the spacecraft is increased.

Owner:BEIJING INST OF SPACECRAFT ENVIRONMENT ENG

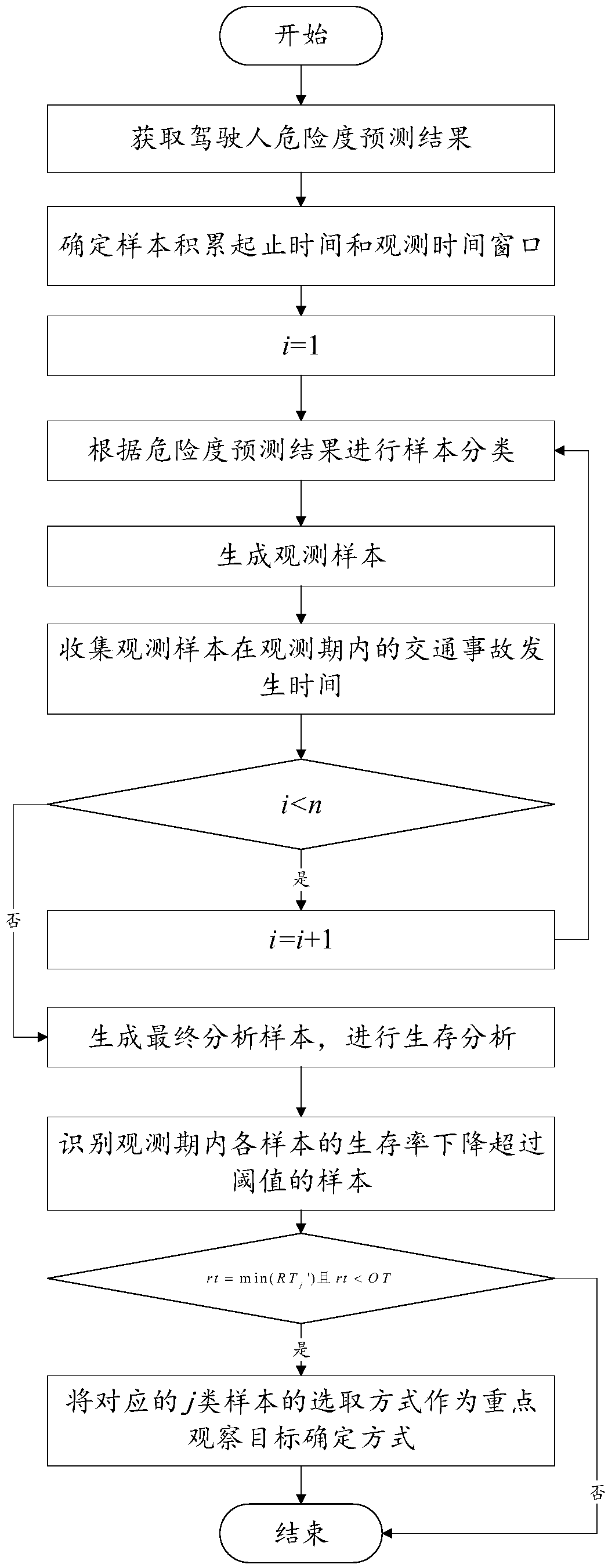

Traffic high-risk personnel key monitoring object identification method and intelligent decision system

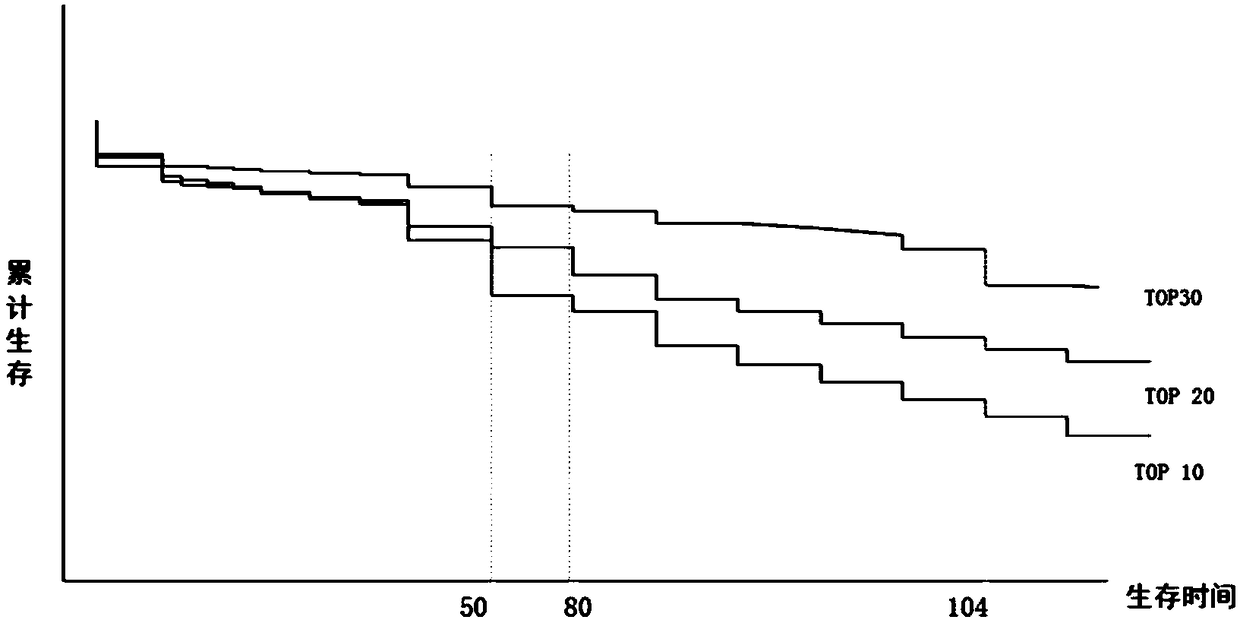

ActiveCN109285344AImprove targetingImprove work efficiencyDetection of traffic movementCumulative Survival RateObservation time

The invention provides a traffic high-risk personnel key monitoring object identification method and intelligent decision system. The risk degree of traffic participants is predicted; the start and end time of the sample accumulation stage and the time window length of the observation period are determined; full sample classification is performed on the obtained risk degree prediction result within the interval and observation samples are generated; the traffic accident occurrence time of the observation samples in the corresponding observation period is collected; and the final analysis samples are generated for survival analysis to identify the minimum analysis sample value of which the cumulative survival rate decline value exceeds the threshold value, and the corresponding sample selection method is used as the key observation target determination method of the traffic high-risk personnel within the continuous observation time limit or the process is ended. The key focus target object is identified from the traffic high-risk personnel group through the data analysis means so as to provide data support and decision support for the implementation of traffic safety pre-control measures such as targeted traffic participant behavior tracking, traffic safety source management and the like.

Owner:JIANGSU ZHITONG TRANSPORTATION TECH

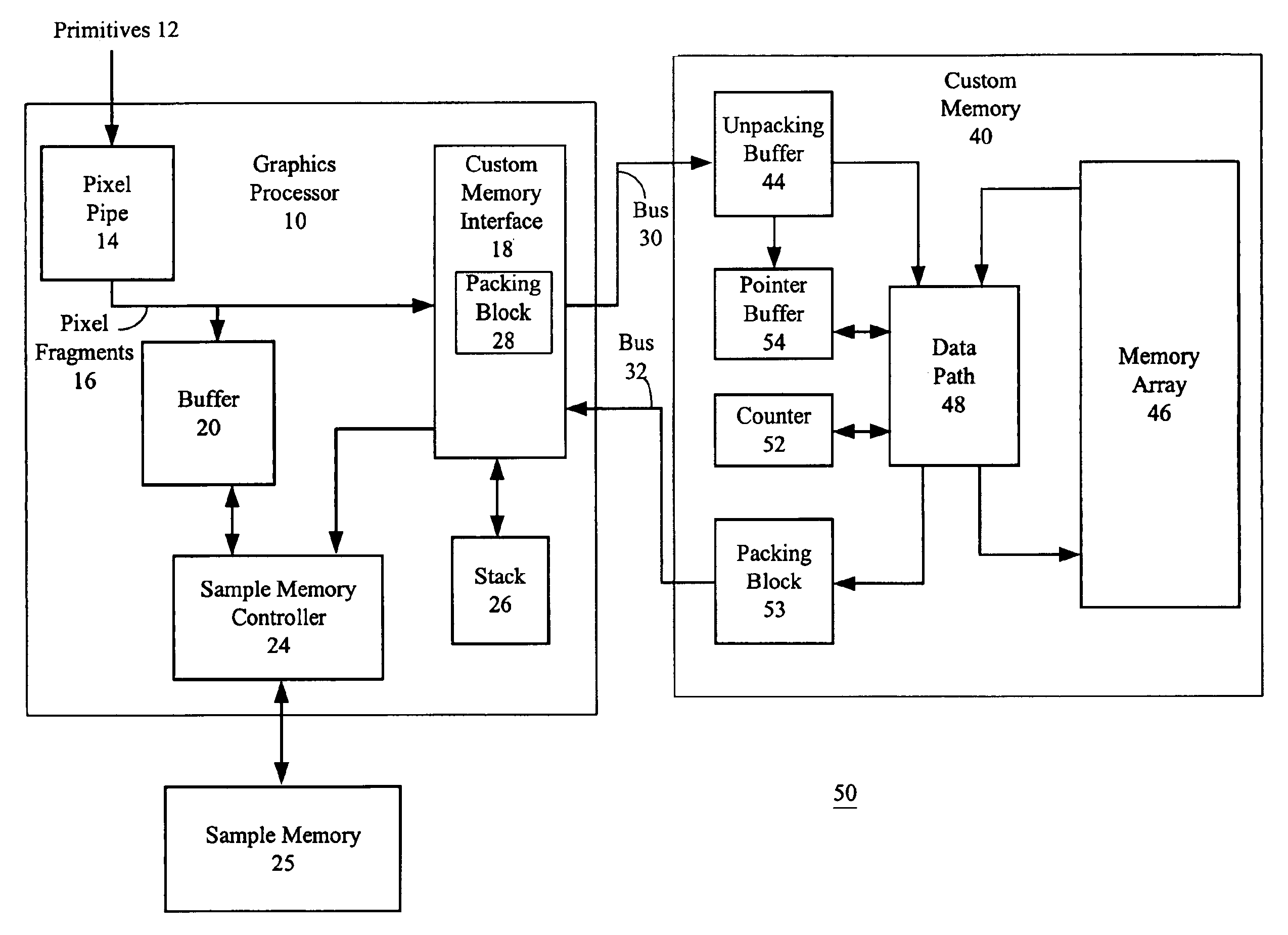

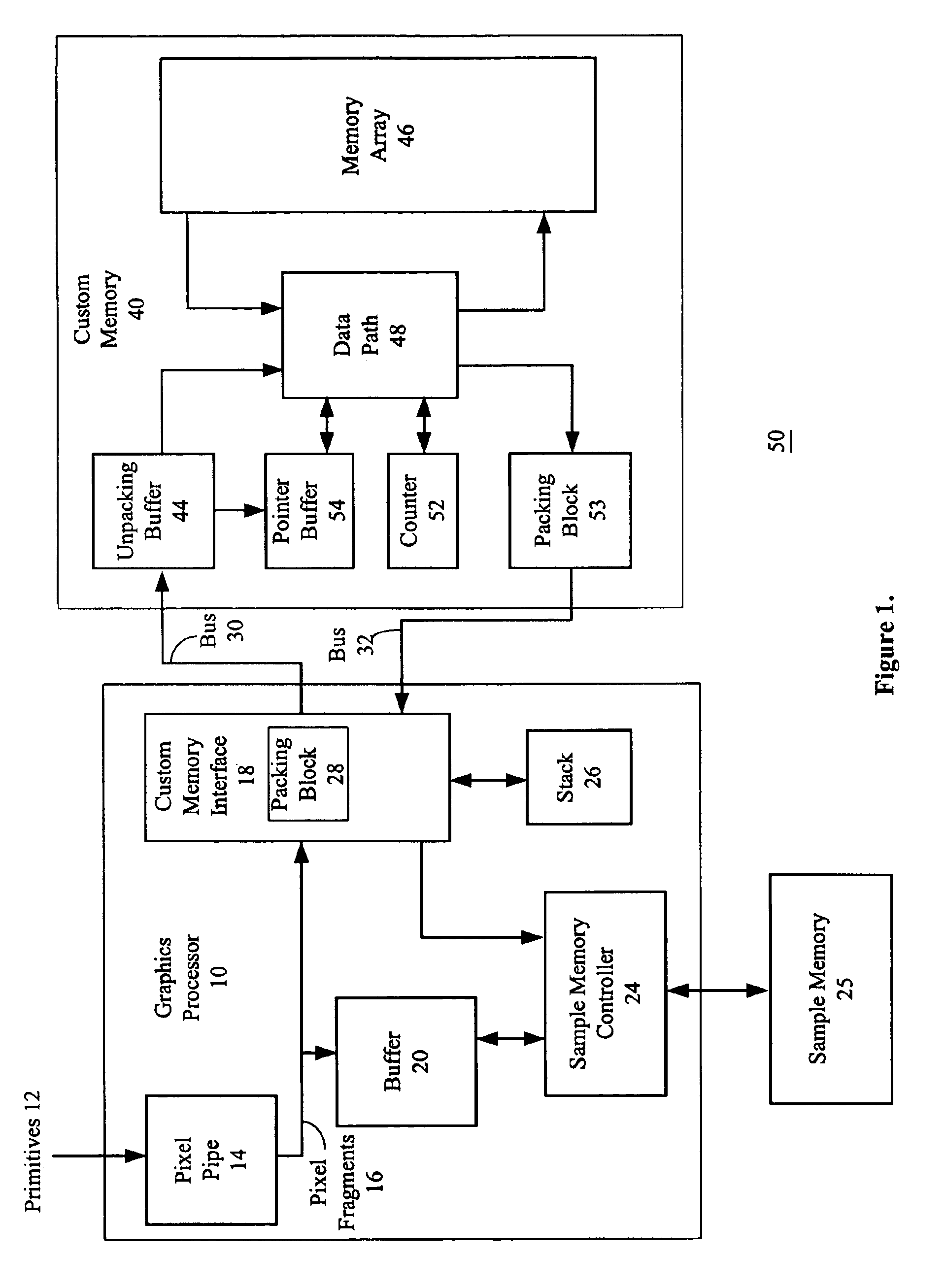

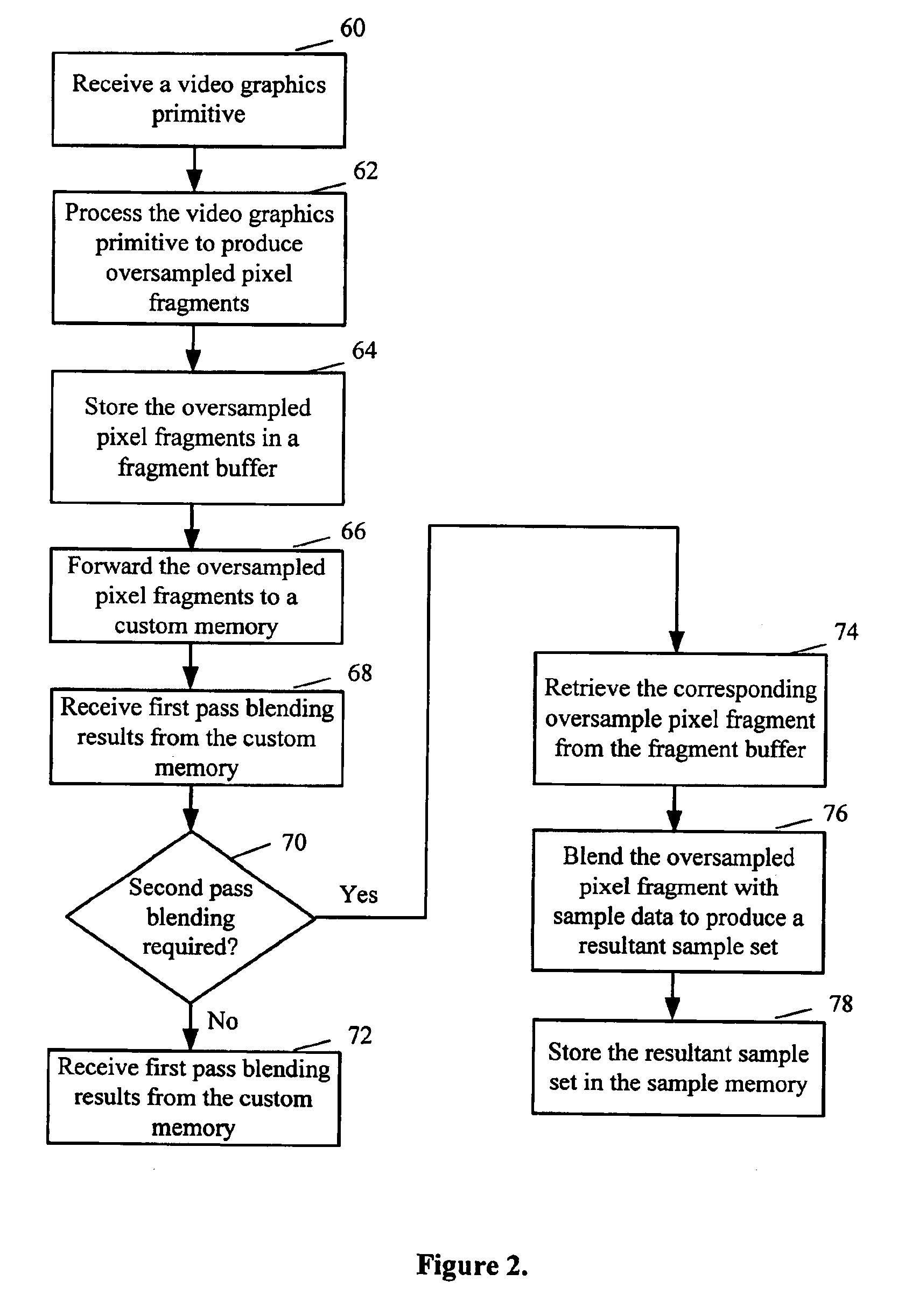

Video graphics system that includes custom memory and supports anti-aliasing and method therefor

A method and apparatus for supporting anti-aliasing oversampling in a video graphics system that utilizes a custom memory for storage of the frame buffer is presented. The custom memory includes a memory array that stores the frame buffer as well as a data path that performs at least a portion of the blending operations associated with pixel fragments generated by a graphics processor. The fragments produced by a graphics processor are oversampled fragments such that each fragment may include a plurality of samples. If the sample set for a particular pixel location can be compressed, the compressed sample set is stored within the frame buffer of the custom memory circuit. However, if such compression is not possible, pointer information is stored within the frame buffer on the custom memory, and a sample memory controller included on the graphics processor maintains a complete sample set for the pixel location within a sample memory. When the sample memory controller maintains a complete sample set for a pixel location, the frame buffer stores a pointer corresponding to the location of the sample set.

Owner:ATI TECH INC

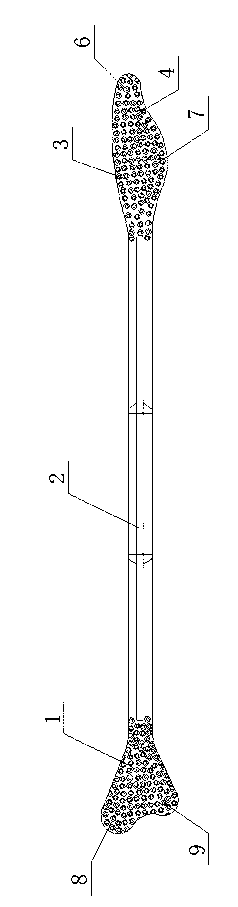

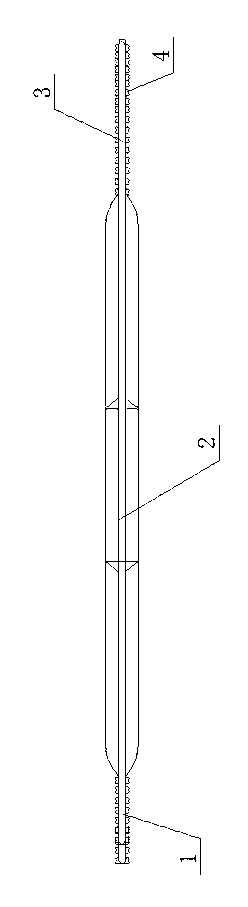

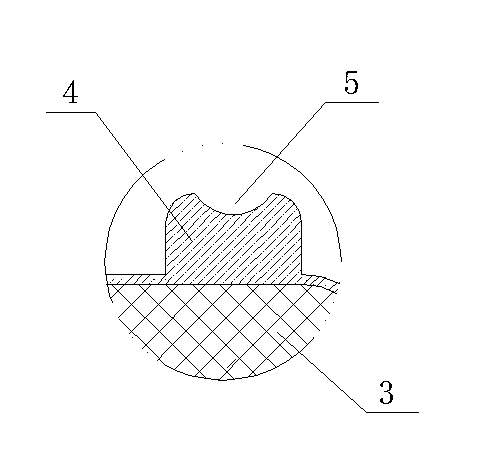

Cervical sampling curette

The invention provides a cervical sampling curette which comprises a handle. A first sampling doctor blade and a second sampling doctor blade are respectively arranged at both ends of the handle. The outer surface of the first sampling doctor blade and the outer surface of the second sampling doctor blade are respectively filled with soft columnar silica gel protrusions in an injection molding mode. A groove is disposed at the end of each soft columnar silica gel protrusion. The diameter of each soft columnar silica gel protrusion is 0.5-5mm, and the height of each soft columnar silica gel protrusion is 1-8mm. Due to the fact that the soft columnar silica gel protrusions are covered on the first sampling doctor blade and the second sampling doctor blade, cells are easy to scrape and store and the cervix uteri cannot be injured during the sampling process. In addition, the first sampling doctor blade and the second sampling doctor blade conform to the ergonomic structure in shape and can closely match with the cervix uteri. When the cervical sampling curette is used, a medical worker can select the first sampling doctor blade or the second sampling doctor blade as needed. The cervical sampling curette is reasonable in design, simple in structure and convenient to use, cannot scratch the cervix uteri, is not prone to brittle failure and safe in use, and helps the medical worker to obtain full samples.

Owner:JIANGSU SUYUN MEDICAL MATERIALS

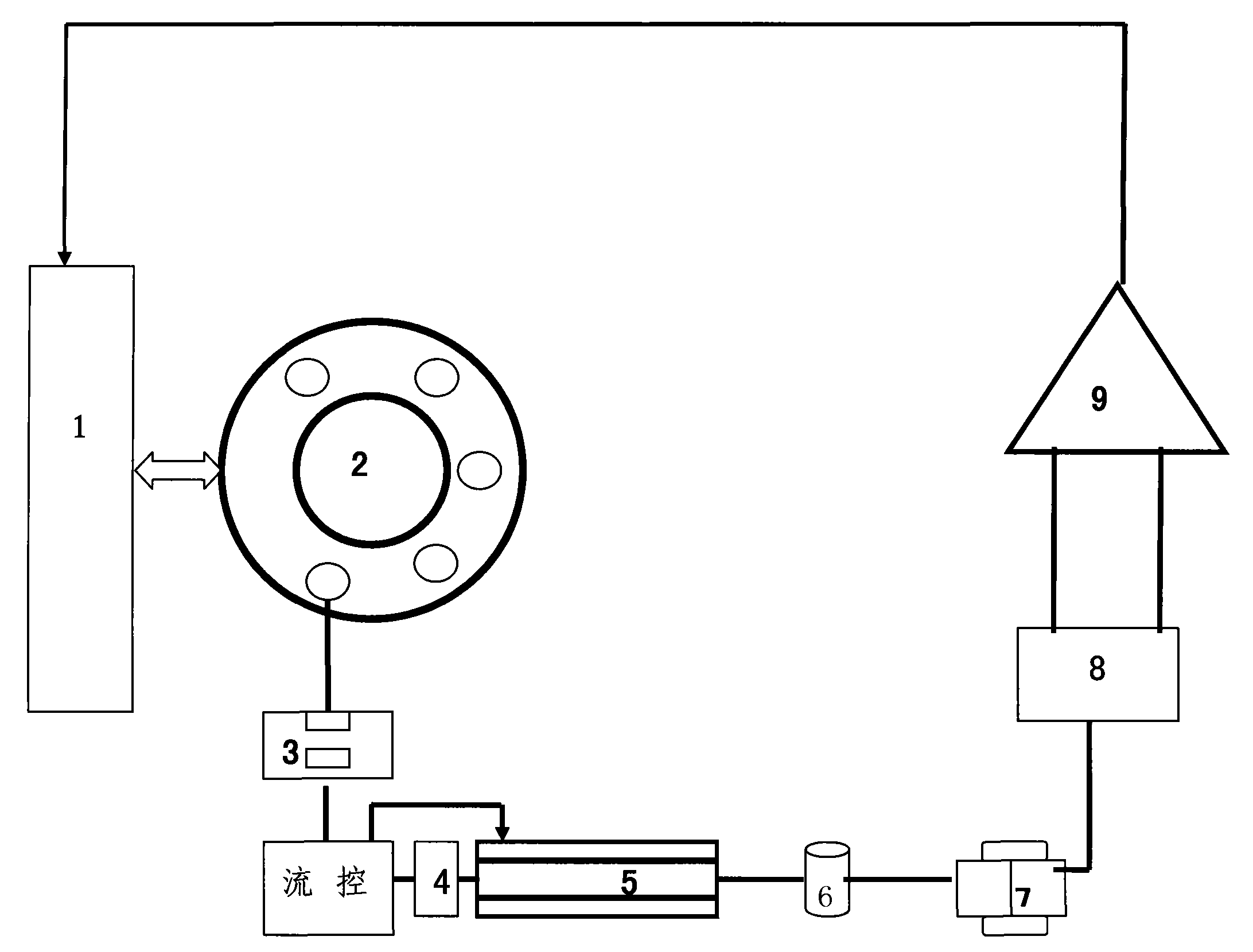

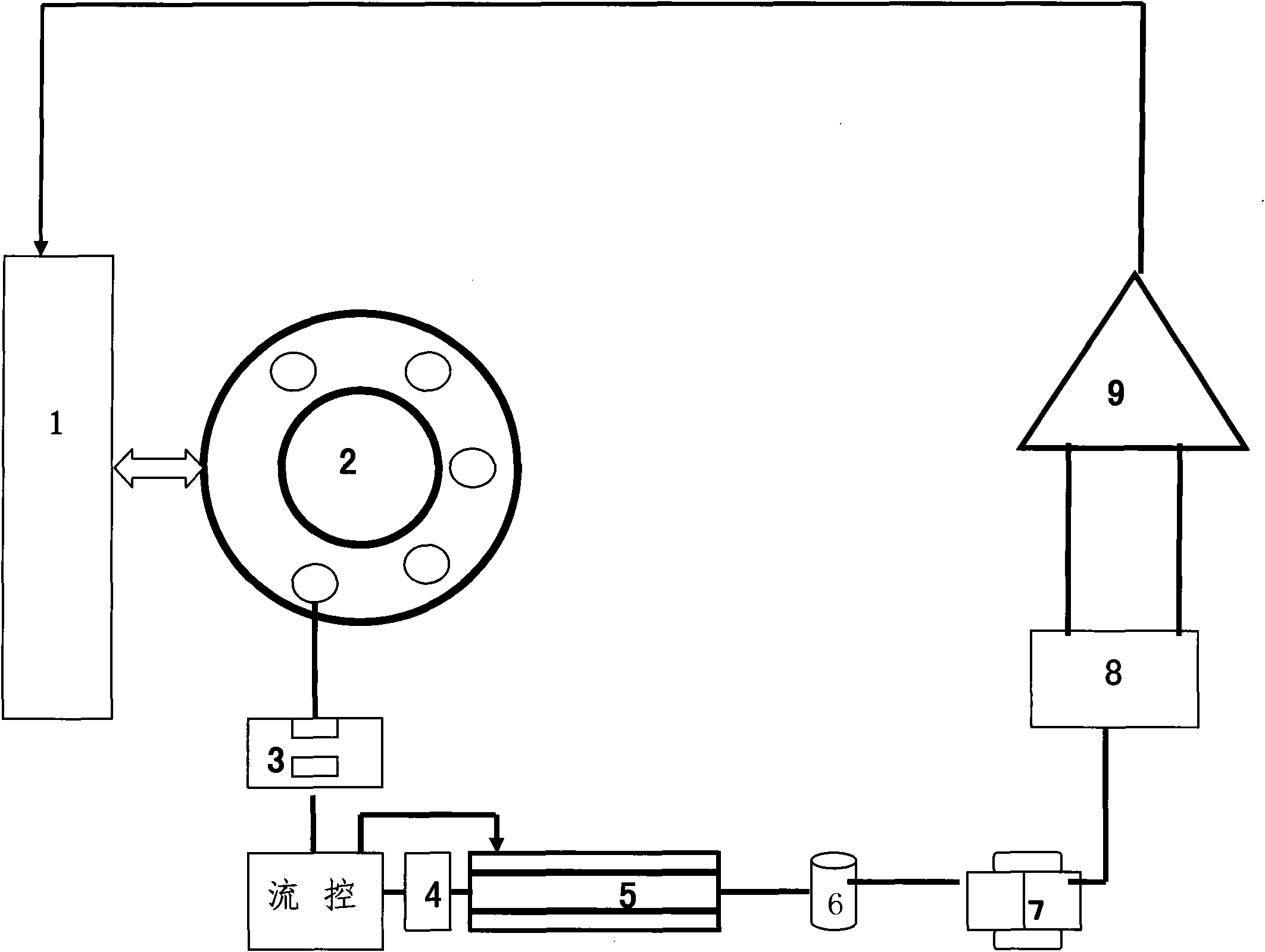

Total organic halogen detector

InactiveCN101813705AWide detection rangeAccurate detectionChemical analysis using titrationMaterial electrochemical variablesWater qualityEngineering

The invention discloses a total organic halogen detector to overcome the defects in the prior art. The total organic halogen detector comprises a sample pre-treatment and automatic sample handling system, a high-temperature combustion cracking device and a detector, wherein the high-temperature combustion cracking device is provided with a double-segment automatic temperature-control heating combustion furnace; and a cascaded drying water treatment system is connected in series between the high-temperature combustion cracking device and the detector. The total organic halogen detector has a further improvement that the cascaded drying water treatment system is formed by connecting a sulphuric acid drying tube and a membrane drying device in series. The total organic halogen detector has the advantages that: the full sample range of the total organic halogen in water samples, solid samples and liquid samples containing a great mount of grains and suspended matters can be detected at low cost; the test sensitivity is high; and the accuracy is high.

Owner:戚玉军 +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com