Forming machine process quality parameter tracking system and tracking method thereof

A technology of quality parameters and process parameters, applied in general control systems, control/regulation systems, computer control, etc., can solve problems such as data misrecording, low data availability, monitoring and upgrading, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

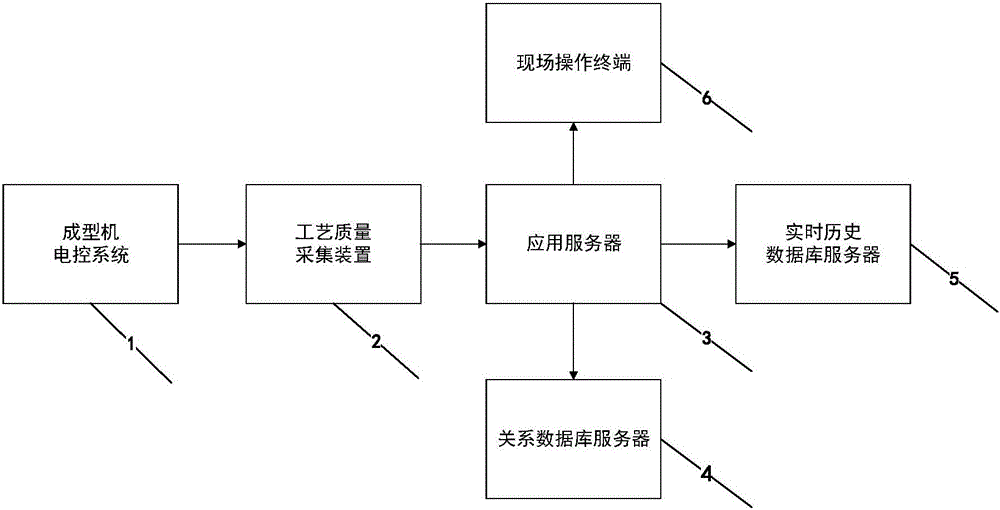

[0020] like figure 1 Shown is a molding machine process quality parameter tracking system, which consists of a molding machine control system 1, a process parameter acquisition device 2, an application server 3, a real-time historical database 5, a relational database 4, an on-site operation terminal 6 and a PROFINET network;

[0021] The process parameter acquisition device 2 is connected with the equipment electronic control system of the molding machine, and sends a data request instruction to the electronic control system of the molding machine equipment in real time through PROFINET Ethernet and according to the data interface interactive protocol, and receives the response from the electronic control system of the molding machine equipment. data, so as to realize the automatic collection of process quality parameters;

[0022] The application server 3 is used to connect with the process quality parameter collection device. When the process quality parameter collection de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com