Equipment degradation analysis method based on parameter residual error

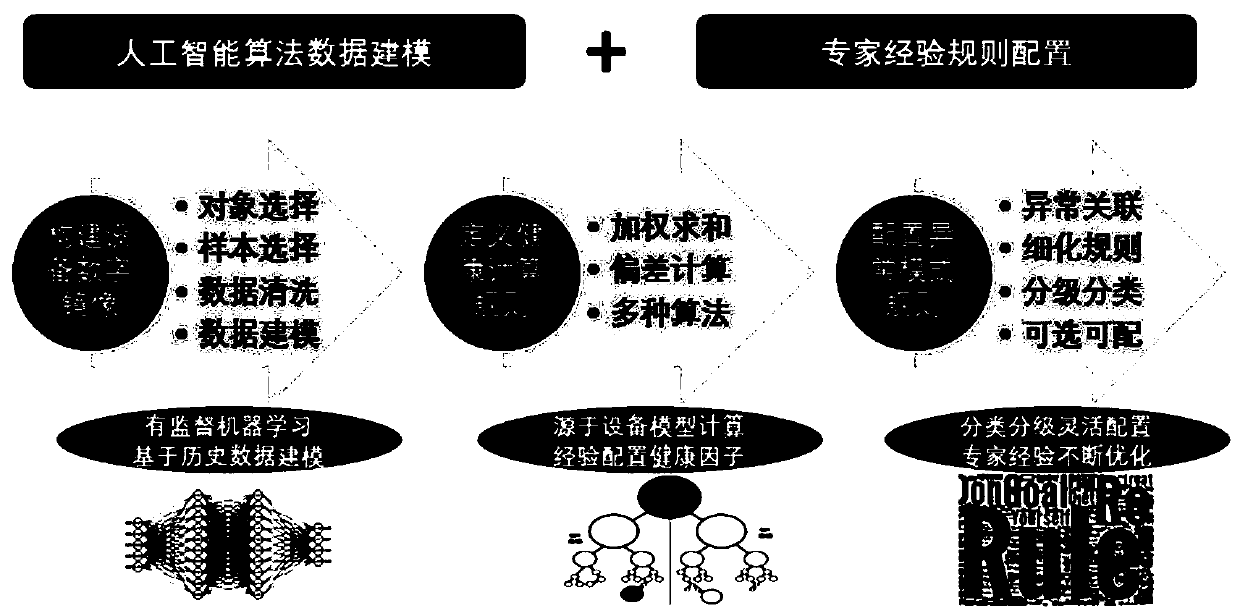

An analysis method and parameter technology, applied in the field of equipment deterioration analysis based on parameter residuals, can solve problems such as failure to identify equipment failure early on deterioration, and achieve the effects of reducing maintenance costs, improving economic benefits, and improving availability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

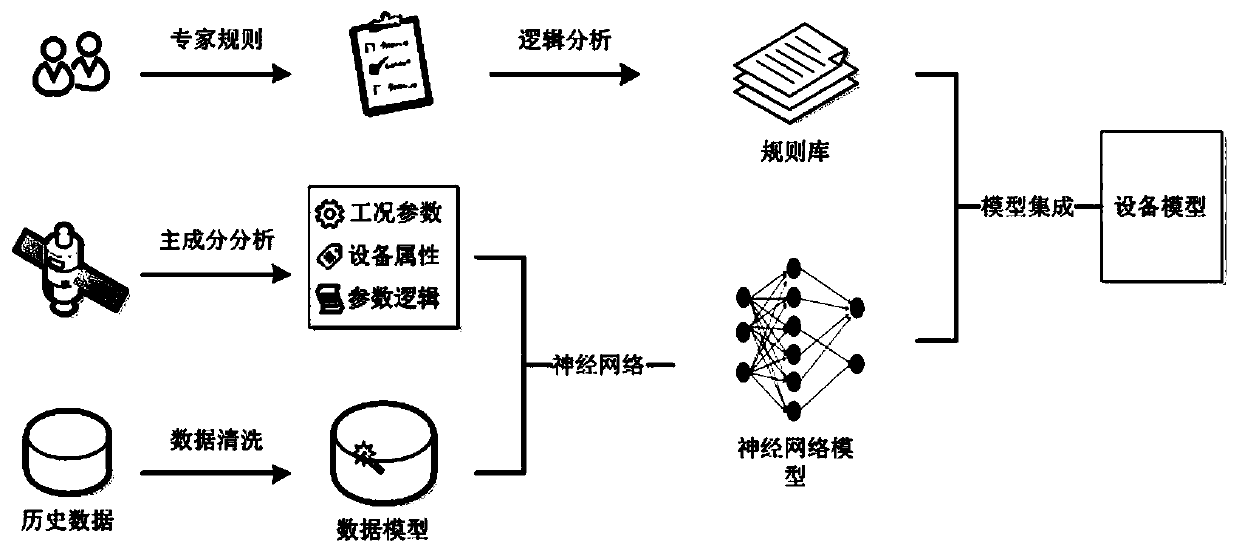

Method used

Image

Examples

Embodiment Construction

[0055] Embodiments of the present invention will be further described in detail below in conjunction with the accompanying drawings.

[0056] This embodiment takes a power plant induced draft fan as an example.

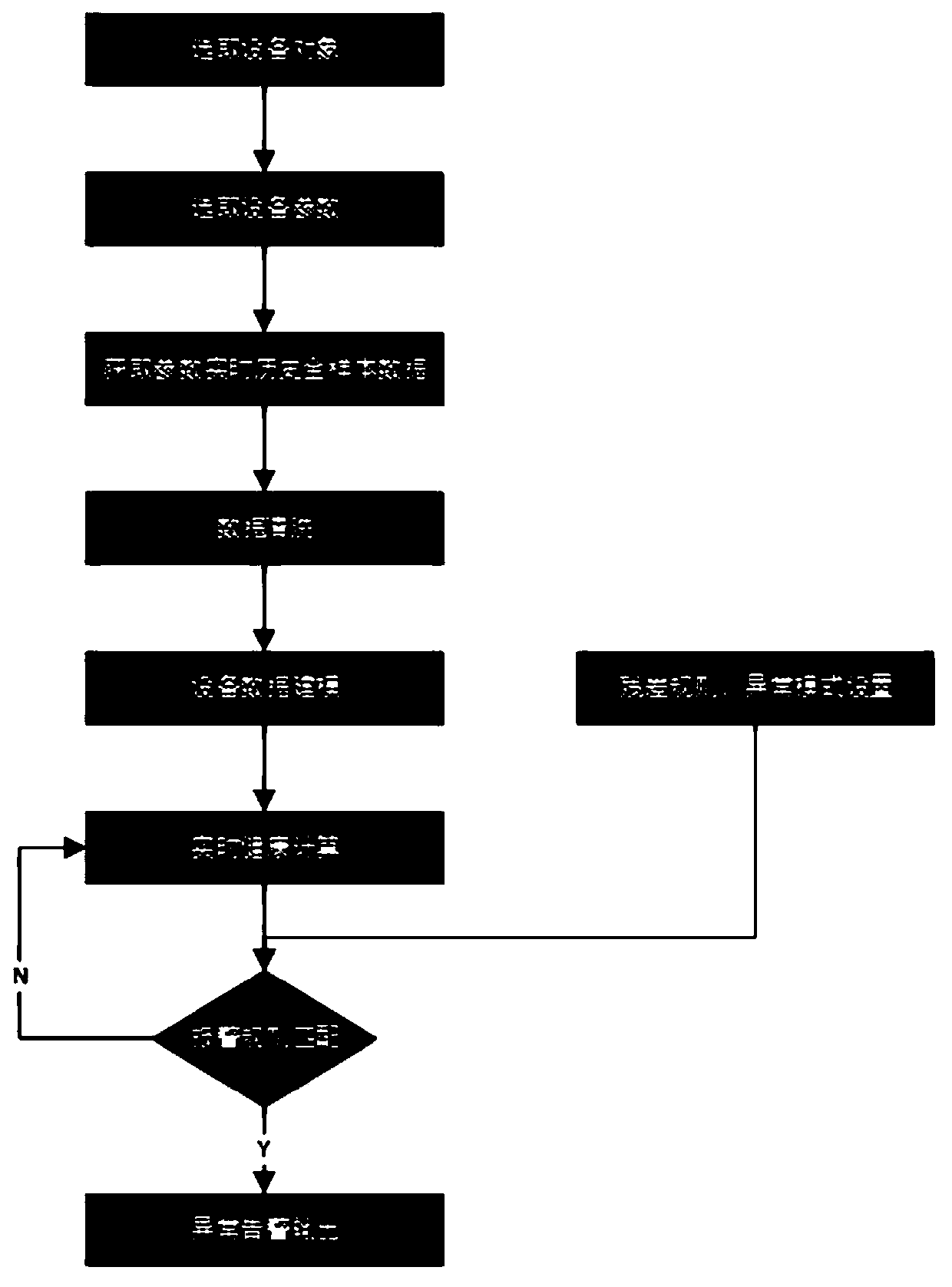

[0057] Such as Figure 1-4 As shown, a method for analyzing equipment degradation based on parameter residuals of the present invention includes the following steps:

[0058] 1. Measuring point selection

[0059] The list of original measurement points is as follows:

[0060]

[0061]

[0062] 2. Data cleaning strategy

[0063] (1) Remove duplicate data

[0064] A measure of similarity calculated from the contents of two numeric fields. The range is 0-1, the closer to 1, the greater the similarity.

[0065] S(s1,s2)=|s1-s2| / (max(s1,s2))

[0066] Set the threshold. When the similarity is greater than the threshold, it will be identified as a duplicate value, and then the duplicate data will be eliminated according to the actual situation.

[0067] (2) Rem...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com