On-line cigarette technology quality analysis and traceability system

A quality analysis and traceability system technology, which is applied in the field of online cigarette process quality analysis and traceability system, can solve the problems of analysis result error, data misrecording, monitoring and improvement, etc., and achieve the effect of historical reproduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

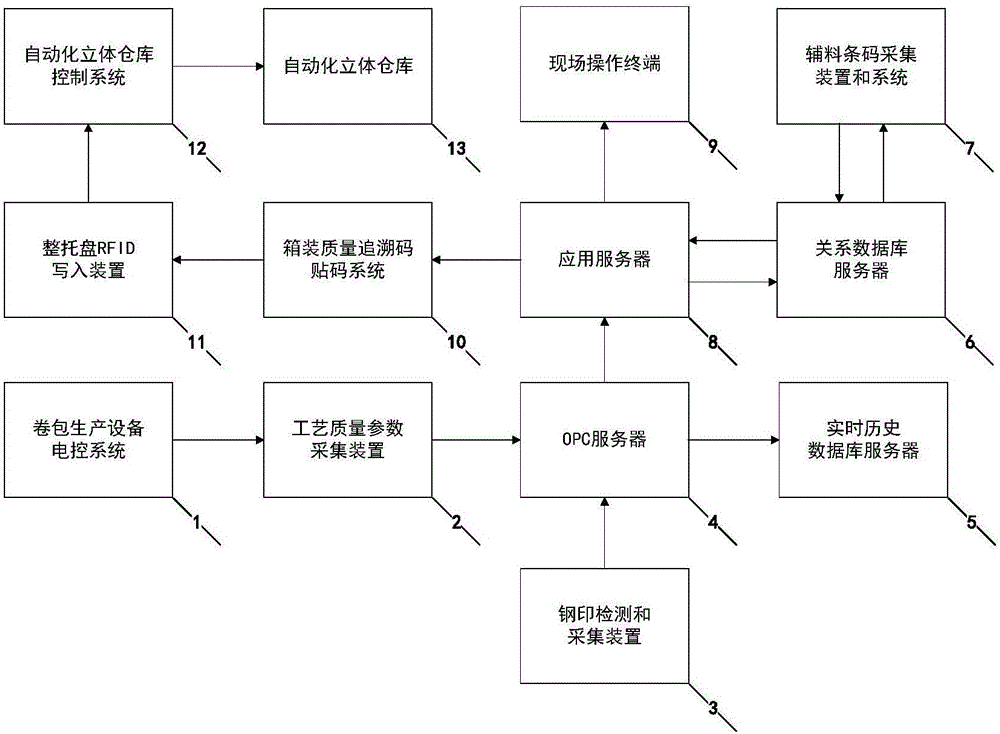

[0020] Such as figure 1 As shown, an online cigarette process quality analysis and traceability system includes an electronic control system 1 for packaging production equipment, a process quality parameter acquisition device 2, a stamp detection and acquisition device 3, an OPC server 4, a real-time historical database server 5, and a relational database Server 6, auxiliary material barcode collection device and system 7, application server 8, on-site operation terminal 9, box quality traceability code labeling system 10, whole pallet RFID writing device 11, automated three-dimensional warehouse control system 12, automated three-dimensional warehouse 13, PROFINET network.

[0021] The process quality parameter acquisition device 2 sends instructions to the electronic control system 1 of the roll production equipment to collect the process quality parameters of the equipment. When the process quality parameter acquisition device 2 receives the process quality parameters, it ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com