Efficient energy-saving stable type steel slag pyrolyzer

A high-efficiency energy-saving, cracking furnace technology, applied in the direction of improving energy efficiency, furnace, furnace charge, etc., can solve the problems of unsatisfactory treatment effect, simple structure, etc., and achieve the effects of efficient recovery, improved production efficiency, and extended life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0047] In this embodiment, 200m 3 , a steel slag cracking furnace with a daily processing capacity of 900 tons / furnace is taken as an example to explain the technical solution of the present invention in detail, but this embodiment does not limit the present invention in any form.

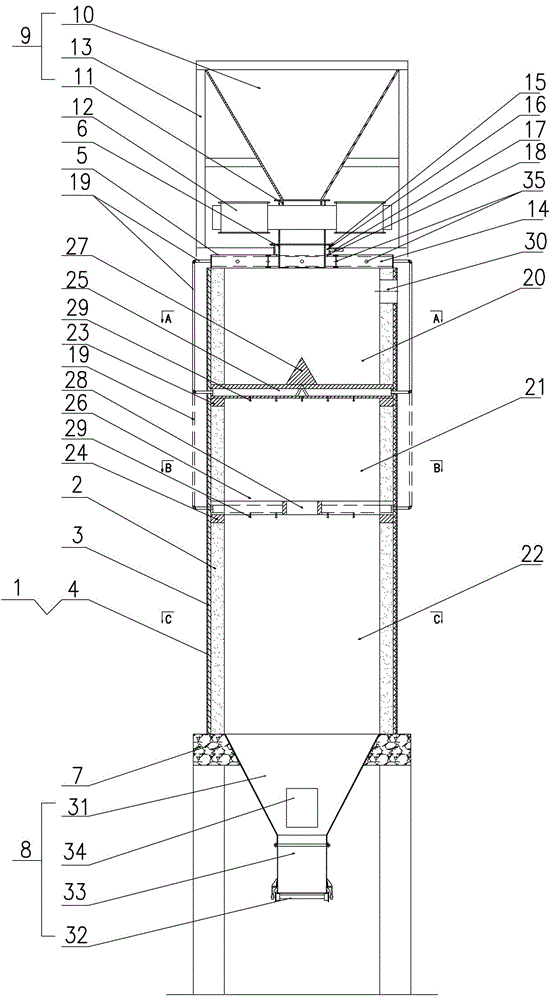

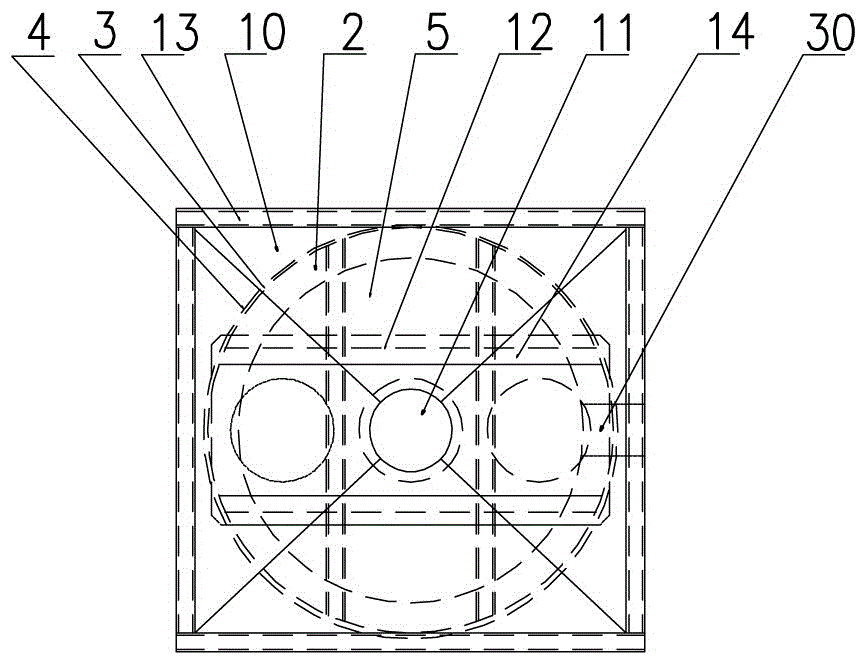

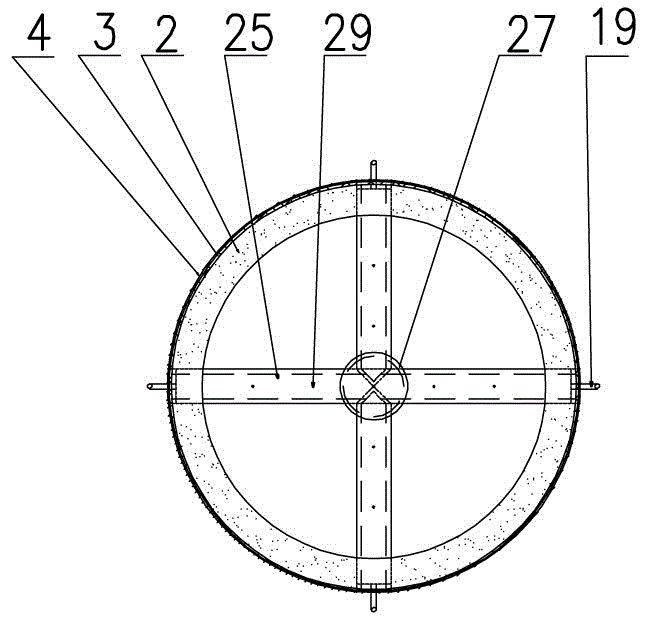

[0048] see Figure 1~5 , the technical scheme of the present invention is: a kind of high-efficiency energy-saving stable steel slag cracking furnace, has furnace body 1, and furnace body 1 is provided with working lining 2, heat insulation layer 3 and furnace shell 4 successively from inside to outside, and the top of furnace body 1 A furnace cover 5 is installed, and the center of the furnace cover 5 is provided with a feed pipe 6, and the bottom of the furnace body 1 is provided with a furnace body support platform 7, and a furnace bottom discharge device 8 is installed below the furnace body support platform 7, especially:

[0049] A. A furnace top charging device 9 is also installed above the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com